Abstract

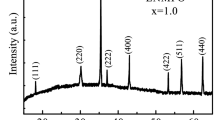

In the present study, the effect of the composites made up of magnetostrictive Co0.9Ni0.1Fe2O4 (CNFO) and colossal magnetoresistive La0.67Sr0.33MnO3 (LSMO) ferrites with the ferroelectric solid solution of 0.5Ba0.7Ca0.3TiO3-0.5BaZr0.2Ti0.8O3 (0.5BCT-0.5BZT) on the multiferroic properties are studied comparatively. Here, the magnetodielectric (MD) composite of 0.5(CNFO)-0.5(0.5BCT-0.5BZT) and 0.175(LSMO)-0.825(0.5BCT-0.5BZT) investigated comparatively using various characterization techniques. The simple and low-cost hydroxide co-precipitation method was used for the synthesis of individual constituents of the ferroelectric 0.5BCT-0.5BZT and ferromagnetic CNFO and LSMO. Structural studies of composites verified the existence of ferrite and ferroelectric phases. The microstructure displays the LSMO and CNFO particles arranged in close proximity over the BCT-BZT ferroelectric phase. The dielectric constant and tangent loss (Quality factor) variation of the composites were investigated for 100 Hz to 1 MHz frequency from room temperature to higher temperatures upto 500 °C. The magnetic hysteresis plot can be used to study how the composite saturation magnetization increases with an increase in ferrite content. Magnetocapacitance measurements up to 1 Tesla magnetic field gives 7% and 2.5% MD coefficients for the both composite materials.

Similar content being viewed by others

Data availability

Data sets generated during the current study are available from the corresponding author on reasonable request.

References

R. Ramesh, N.A. Spaldin, Nat. Mater. 6, 21–29 (2007). https://doi.org/10.1038/nmat1805

C.W. Nan, M.I. Bichurin, S. Dong, D. Viehland, G. Shrinivasan, J. Appl. Phys. 103, 1–36 (2008). https://doi.org/10.1063/1.2836410

G. Lawes, A.P. Ramirez, C.M. Varma, M.A. Subramanian, Phys. Rev. Lett. 91, 257208 (2003). https://doi.org/10.1103/PhysRevLett.91.257208

W. Eerenstein, N.D. Mathur, J.F. Scott, Nature 442, 759–765 (2006). https://doi.org/10.1038/nature05023

K.F. Wang, J.-M. Liu, Z.F. Ren, Adv. Phys. 58, 321–448 (2009). https://doi.org/10.1080/00018730902920554

Y. Tokura, S. Seki, Adv. Mater. 22, 1554–1565 (2010). https://doi.org/10.1002/adma.200901961

T. Kimura, T. Goto, H. Shintani, K. Ishizaka, T. Arima, Y. Tokura, Nature 426, 55–58 (2003). https://doi.org/10.1038/nature02018

N. Mufti, A.A. Nugroho, G.R. Blake, T.T.M. Palstra, J. Phys. Condens. Matter. 22, 075902 (2010). https://doi.org/10.1088/0953-8984/22/7/075902

F. Zhu, J. Qiu, H. Ji, K. Zhu, K. Wen, J. Mater. Sci. Mater. Electron. 26, 2897–2904 (2015). https://doi.org/10.1007/s10854-015-2775-z

J. Rodel, W. Jo, K.T.P. Seifert, E. Anton, T. Granzow, J. Am. Ceram. Soc. 1177, 1153–1177 (2009). https://doi.org/10.1111/j.1551-2916.2009.03061.x

J.P. Praveen, T. Karthik, A.R. James, E. Chandrakala, S. Asthana, D. Das, J. Eur. Ceram. Soc. 35, 1785–1798 (2014). https://doi.org/10.1016/j.jeurceramsoc.2014.12.010

T.R. Shrout, S.J. Zhang, J. Electroceramics 19, 111–124 (2007). https://doi.org/10.1007/s10832-007-9047-0

X. Wang, H. Yamada, C.N. Xu, Appl. Phys. Lett. 86, 022905 (2005). https://doi.org/10.1063/1.1850598

W. Liu, X. Ren, Phys. Rev. Lett. 103, 257602 (2009). https://doi.org/10.1103/PhysRevLett.103.257602

S.S. Kumbhar, M.A. Mahadik, V.S. Mohite, Y.M. Hunge, K.Y. Rajpure, C.H. Bhosale, Mater. Res. Bull. 67, 47–54 (2015). https://doi.org/10.1016/j.materresbull.2015.02.056

S. Joshi, M. Kumar, Ceram. int. 42(16), 18154–18165 (2016). https://doi.org/10.1016/j.ceramint.2016.08.130

P. Pan, J. Tao, F. Ma, N. Zhang, J. Magn. Magn. Mater. 453, 91–95 (2018). https://doi.org/10.1016/j.jmmm.2017.12.107

C. Lavado, M.S. Alkathy, J.A. Eiras, M.G. Stachiotti, Appl. Phy. A-Mater. 129, 147 (2023). https://doi.org/10.1007/s00339-023-06445-z

R.C. Kambale, P.A. Shaikh, K.Y. Rajpure, P.B. Joshi, Y.D. Kolekar, Integr. Ferroelectr. 121(1), 1–12 (2010). https://doi.org/10.1080/10584587.2010.491765

M.M. Sutar, A.N. Tarale, S.R. Jigajeni, S.B. Kulkarni, P.B. Joshi, Appl. Nanosci. 2, 311–317 (2012). https://doi.org/10.1007/s13204-012-0119-3

M. Cesaria, A.P. Caricato, G. Maruccio, M. Martino, J. Phys. Conf. Ser. 292, 12003 (2011). https://doi.org/10.1088/1742-6596/292/1/012003

C. Martínez-Boubeta, Z. Konstantinovic, L. Balcells, S. Estrade, J. Arbiol, A. Cebollada, B. Martinez, Cryst. Growth Des. 10, 1017–1020 (2010). https://doi.org/10.1021/cg900866g

Z. Shui, D. Xianlin, Y. Genshui, J. Zhu, X. Tang, Solid State Commun. 151(14), 982–984 (2011). https://doi.org/10.1016/j.ssc.2011.05.005

A.B. Kakade, S.K. Deshpande, S.B. Kulkarni, Eng. Sci. 18, 168–176 (2021). https://doi.org/10.30919/es8d485

A.B. Kakade, S.M. Mane, J.C. Shin, S.B. Kulkarni, Ceram. int. 48(19), 29403–29413 (2022). https://doi.org/10.1016/j.ceramint.2022.06.080

S.M. Mane, P.M. Tirmali, S.L. Kadam, A.N. Tarale, C.B. Kolekar, S.B. Kulkarni, J. Chin. Advn. Mater. Soc. 4, 269–284 (2016). https://doi.org/10.1080/22243682.2016.1214924

V.S. Puli, D.K. Pradhan, D.B. Chrisey, M. Tomozawa, G.L. Sharma, J.F. Scott, R.S. Katiyar, J. Mater. Sci. 48(5), 2151–2157 (2013). https://doi.org/10.1007/s10853-012-6990-1

A. Kumar, P. Sharma, D. Varshney, Ceram. Int. 40(8), 12855–12860 (2014). https://doi.org/10.1016/j.ceramint.2014.04.140

K. Maaz, W. Khalid, A. Mumtaz, S.K. Hasanain, J. Liu, J.L. Duan, Physica E 41(4), 593–599 (2009). https://doi.org/10.1016/j.physe.2008.10.009

J. Rani, K.L. Yadav, S. Prakash, Mater. Chem. Phys. 147(3), 1183–1190 (2014). https://doi.org/10.1016/j.matchemphys.2014.07.002

S.M. Bobade, D.D. Gulwade, A.R. Kulkarni, P. Gopalan, J. Appl. Phys. 97, 074105 (2005). https://doi.org/10.1063/1.1879074

J.Y. Zhai, N. Cai, L. Liu, Y.H. Lin, C.W. Nan, Mater. Sci. Eng. B 99(1), 329–331 (2003). https://doi.org/10.1016/S0921-5107(02)00565-2

A. Ghosh, K. Dey, M. Chakraborty, S. Majumdar, S. Giri, Lett. J. Explor. Front. Phys. 107(4), 47012 (2014). https://doi.org/10.1209/0295-5075/107/47012

M.D. Rather, R. Samad, B. Want, J. Alloy. Comp. 755, 89–99 (2018). https://doi.org/10.1016/j.jallcom.2018.04.289

S.R. Jigajeni, A.N. Tarale, D.J. Salunkhe, S.B. Kulkarni, P.B. Joshi, Appl. Nanosci. 2(3), 275–283 (2012). https://doi.org/10.1007/s13204-012-0104-x

Acknowledgements

Authors are thankful to UGC-DAE CSR for financial support through grant (CRS-M-283).

Funding

This work was funded by UGC-DAE Consortium for Scientific Research,University Grants Commission, CRS-M-283, Abhishek Kakade.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by all the authors partially. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kakade, A., Kamat, R. & Kulkarni, S. Multiferroic properties of composites made up of ferromagnetic Co0.9Ni0.1Fe2O4 and La0.67Sr0.33MnO3 with ferroelectric 0.5Ba0.7Ca0.3TiO3-0.5BaZr0.2Ti0.8O3. J Mater Sci: Mater Electron 35, 905 (2024). https://doi.org/10.1007/s10854-024-12682-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12682-6