Abstract

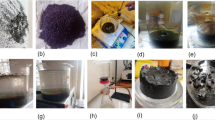

We demonstrate an efficient and non-explosive method for synthesizing graphene and reduced graphene oxide (rGO). To enable the use of both materials in broad electronic applications, a large-scale production method with controllable electrical properties must be needed. In the current state of graphene oxide preparation, Hummers method is the most widely used. In this method, NaNO3 produces toxic gases during the reaction, and hence, this method is not recommended for the large-scale production. Here, we adopted the liquid-phase exfoliation and Improved Hummers method to produce graphene and GO since it eliminates the use of NaNO3 and its toxicity. We introduced a pre-cooling procedure to reduce the explosive nature of the extremely exothermic reactions. This method yields more oxidized graphene compared to Hummers’ method. We experimentally compared the structural, electrical, and thermal transport properties of both the materials. Characterization techniques such as X-ray diffraction, FTIR, and optical microscopy reveal the high quality of graphene and rGO. Here, we also report the results on the conversion of rGO from n-type to p-type. It was found that graphene behaves as p-type material, whereas rGO behaves as an n-type up to an annealing temperature of 350 °C, while after 600 °C, it is converted to a p-type material. These results demonstrate that thermal annealing treatment drastically varies the carrier properties of rGO, allowing it to be used in various applications, including flexible thermoelectrics. A high-yield production of graphene and rGO could be beneficial from this improved synthesis.

Similar content being viewed by others

Data availibility

The authors confirm that the data and findings of this study are available in the article. Raw data that support the results of this study are available from the corresponding authors, upon reasonable request.

References

R. Hoffmann, A.A. Kabanov, A.A. Golov, D.M. Proserpio, Angew. Chem. Int. 55, 10962–10976 (2016)

V. Singh, D. Joung, L. Zhai, S. Das, S.I. Khondaker, S. Seal, Prog. Mater. Sci. 56, 1178–1271 (2011)

J.B. Wang, Z. Ren, Y. Hou, X.L. Yan, P.Z. Liu, H. Zhang et al., New Carbon Mater. 35, 193–208 (2020)

Ö. Güler, S.H. Güler, V. Selen, M.G. Albayrak, E. Evin, Fullerenes Nanotubes Carbon Nanostruct. 24, 123–127 (2016)

A. Amiri, M. Naraghi, G. Ahmadi, M. Soleymaniha, M. Shanbedi, FlatChem 8, 40–71 (2018)

V. Chabot, B. Kim, B. Sloper, C. Tzoganakis, A. Yu, Sci. Rep. 3, 1378 (2013)

C. Cozic, L. Picton, M.-R. Garda, F. Marlhoux, D. Le Cerf, Food Hydrocolloids 23, 1930–1934 (2009)

X. Xiang, Y. Zhu, C. Gao, H. Du, C. Guo, Carbon Lett. 32, 557–566 (2022)

C. Qiu, L. Jiang, Y. Gao, L. Sheng, Mater. Des. 230, 111952 (2023)

W.S. Hummers, R.E. Offeman, J. Am. Chem. Soc. 80, 1339–1339 (1958)

V.B. Mbayachi, E. Ndayiragije, T. Sammani, S. Taj, E.R. Mbuta, Results Chem. 3, 100163 (2021)

H. Yu, B. Zhang, C. Bulin, R. Li, R. Xing, Sci. Rep. 6, 36143 (2016)

L. Peng, Z. Xu, Z. Liu, Y. Wei, H. Sun, Z. Li et al., Nat. Commun. 6, 5716 (2015)

Z. Sofer, J. Luxa, O. Jankovský, D. Sedmidubský, T. Bystroň, M. Pumera, Angew. Chem. Int. Ed. 55, 11965–11969 (2016)

Z. Benzait, P. Chen, L. Trabzon, Nanoscale Adv. 3, 223–230 (2021)

D.C. Marcano, D.V. Kosynkin, J.M. Berlin, A. Sinitskii, Z. Sun, A. Slesarev et al., ACS Nano 4, 4806–4814 (2010)

I. Sengupta, S. Chakraborty, M. Talukdar, S.K. Pal, S. Chakraborty, J. Mater. Res. 33, 4113–4122 (2018)

S. Pei, H.-M. Cheng, Carbon 50, 3210–3228 (2012)

S. Dungani, D. Anadkat, A. Pandya, A.V. Sanchela, Flex. Print. Electron. 9, 015008 (2024)

A.V. Sanchela, M. Wei, H.J. Cho, H. Ohta, Small 15, 1805394 (2019)

D. Anadkat, C. Badampudi, A. Gor, A.V. Sanchela, J. Alloys Compd. 958, 170350 (2023)

V. Uvarov, Popov, Mater. Charact. 85, 111–123 (2013)

C. Su, M. Acik, K. Takai, J. Lu, S.J. Hao, Y. Zheng et al., Nat. Commun. 3, 1298 (2012)

B.C. Smith, Spectroscopy 37, 17–19 (2022)

N.D.K. Tu, J. Choi, C.R. Park, H. Kim, Chem. Mater. 27, 7362–7369 (2015)

B. Lesiak, G. Trykowski, J. Tóth, S. Biniak, L. Kövér, N. Rangam et al., J. Mater. Sci. 56, 3738–3754 (2021)

T. Islam, Md.M. Hasan, S. Sarker, A.J.S. Ahammad, ACS Omega 8, 14013–14024 (2023)

A.C. Ferrari, J. Robertson, Phys. Rev. B 61, 14095–14107 (2000)

S. Claramunt, A. Varea, D. Lopez-Diaz, M.M. Velázquez, A. Cornet, A. Cirera, J. Phys. Chem. C 119, 10123–10129 (2015)

S. Vollebregt, R. Ishihara, F.D. Tichelaar, Y. Hou, C.I.M. Beenakker, Carbon 50, 3542–3554 (2012)

P. Das, S. Ibrahim, K. Chakraborty, S. Ghosh, T. Pal, Sci. Rep. 14, 294 (2024)

J. Tauc, R. Grigorovici, A. Vancu, Physica Status Solidi (b) 15, 627–637 (1966)

Y. Jin, Y. Zheng, S.G. Podkolzin, W.J. Lee, Mater. Chem. C 8, 4885–4894 (2020)

H. Huang, Z. Li, J. She, W. Wang, J. Appl. Phys. 111, 054317 (2012)

W.-D. Yang, Y.-J. Lin, J. Electr. Eng. 70, 101–106 (2019)

M. Karakoti, R. Jangra, S. Pandey, P.S. Dhapola, S. Dhali, S. Mahendia et al., High Perform. Polym. 32, 175–182 (2020)

F. Farivar, P. Lay Yap, R.U. Karunagaran, D. Losic, C 7, 41 (2021)

J.-H. Kim, S.-H. Kim, B.-J. Kim, H.-M. Lee, Nanomaterials 13, 262 (2023)

Acknowledgements

This research was supported by financial support from the Department of Physics, School of Energy Technology, Pandit Deendayal Energy University (R&D/SRP-2022-025)). We thank to Solar Research and Development Centre, Pandit Deendayal Energy University for structural and optical measurements. Further, we extend our thanks to department of Materials Engineering, Indian Institute of Technology, Gandhinagar for TGA measurement.

Author information

Authors and Affiliations

Contributions

Conceptualization: A.V.S.; Sample preparation and measurements: D.A. A.P., A.J., and S.D.; Original draft preparation: D.A. and S.D.; Data analysis and Methodology: A.V.S, D.A., A.J., S.D., and A.P.; Writing – review & editing: A.V.S., D.A.; Supervision: A.V.S.

Corresponding authors

Ethics declarations

Conflict of interset

There are no conflicts of interset to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Anadkat, D., Pandya, A., Jaiswal, A. et al. Experimental comparison between graphene and reduced graphene oxide along with significant conversion of rGO from n-to p-type. J Mater Sci: Mater Electron 35, 821 (2024). https://doi.org/10.1007/s10854-024-12591-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12591-8