Abstract

Sn-Ag-Cu-based solder alloys are extensively employed in electronic packaging applications, thus necessitating in-depth reliability studies in various environmental conditions. This study investigated the microstructural evolution characteristics of gamma-irradiated 96.5Sn3.0Ag0.5Cu (SAC305) solder joints under varied gamma doses. The findings in this study involved the primary phase beta Sn (β-Sn) and near eutectic phase distributions, intermetallic compound (IMC) layer thickness, and micro-crack occurrences. Therefore, notable phase formation changes in the β-Sn and near eutectic phase distributions occurred following the microstructure changes in the gamma-irradiated solder alloy. Although the SAC305 solder matrix did not demonstrate any new structural phases, the higher radiation exposures increased the β-Sn and Ag3Sn peak intensities. Furthermore, the microstructure analysis presented a higher near eutectic phase percentage upon initial gamma radiation exposure from 5 to 15 Gy, gradually decreasing from 20 to 50 Gy. The IMC layer thickness was also positively correlated with the gamma doses, while the micro-cracks near the IMC layer-solder bulk interface were evident. Consequently, the microstructural evolution varied under different gamma radiation levels, demonstrating a profound correlation to the mechanical properties of the SAC305 solder joints.

Similar content being viewed by others

Data availability

The authors confirmed that this manuscript has no associated data.

References

K. Nanda et al., Fundamental characteristics and application of radiation. GSC Adv. Res. Rev. (2021). https://doi.org/10.30574/gscarr.2021.7.1.0043

A. Karmakar, J. Wang, J. Prinzie, V. De Smedt, P. Leroux, A review of semiconductor based ionising radiation sensors used in harsh radiation environments and their applications. Radiation 1(3), 194–217 (2021). https://doi.org/10.3390/radiation1030018

S.P. Foo, W. Yusmawati, W. Yusoff, A. Jalar, Dimensional and structural stability of gamma irradiated stacked die quad flat no leads (QFN) (Kestabilan Dimensi Dan Struktur Dai Bertingkat Tanpa Kaki (QFN) Tersinar Gamma). Sains. Malays. 43(6), 827–832 (2014)

H. Wang, J. Ma, Y. Yang, M. Gong, Q. Wang, A review of system-in-package technologies: application and reliability of advanced packaging. Micromachines 14(6), 1149 (2023)

R. Berger, R. Schwerz, M. Röllig, H. Heuer, Influence analysis of joint attributes on the fatigue progress of SnAgCu solder joints under thermomechanical loading. Microelectron. Reliab. (2023). https://doi.org/10.1016/j.microrel.2022.114870

N. Ismail et al., A systematic literature review: the effects of surface roughness on the wettability and formation of intermetallic compound layers in lead-free solder joints. J. Manuf. Process. (2022). https://doi.org/10.1016/j.jmapro.2022.08.045

L.M. Lee, A.A. Mohamad, Interfacial reaction of Sn–Ag–Cu lead-free solder alloy on Cu: A review. Adv. Mater. Sci. Eng. (2013). https://doi.org/10.1155/2013/123697

S. Zhang, H. Zhao, H. Xu, X. Fu, Accelerative reliability tests for Sn3.0Ag0.5Cu solder joints under thermal cycling coupling with current stressing. Microelectron. Reliab. (2021). https://doi.org/10.1016/j.microrel.2021.114094

P.H. Yannakopoulos, A.P. Skountzos, M. Vesely, Influence of ionizing radiation in electronic and optoelectronic properties of III-V semiconductor compounds. Microelectron. J. 39(5), 732–736 (2008). https://doi.org/10.1016/j.mejo.2007.12.025

J. Wang, S. Xue, Z. Lv, L. Wang, H. Liu, L. Wen, Effect of gamma-ray irradiation on microstructure and mechanical property of Sn63Pb37 solder joints. J. Mater. Sci.: Mater. Electron. 29(24), 20726–20733 (2018). https://doi.org/10.1007/s10854-018-0213-8

J. Wang, S. Xue, Z. Lv, L. Wen, S. Liu, Microstructure and performance evolution of SnPbSb solder joint under γ-ray irradiation and thermal cycling. J. Materi. Sci.: Mater. Electron. 30(5), 4990–4999 (2019). https://doi.org/10.1007/s10854-019-00795-2

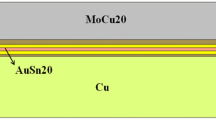

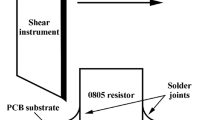

L. Wen, S. Xue, L. Wang, H. Liu, J. Wu, Microstructural evolution and shear performance of AuSn20 solder joint under gamma-ray irradiation and thermal cycling. J. Mater. Sci.: Mater. Electron. 31(9), 7200–7210 (2020). https://doi.org/10.1007/s10854-020-03292-z

N.F.N.M. Lehan et al., EDS analysis on effect of low dosage gamma radiation and micromechanical properties of SnAg3Cu0.5 solder. J. Mater. Sci. Mater. Electron. 33(7), 4225–4236 (2022). https://doi.org/10.1007/s10854-021-07617-4

W.Y. Wan Yusoff et al., Micromechanical response of SAC305 solder alloy under gamma radiation via nanoindentation approach. Solder. Surface Mount Technol. 35(1), 51–58 (2023). https://doi.org/10.1108/SSMT-09-2021-0060

Q. Guan et al., Effect of gamma irradiation on microstructural evolution and mechanical properties of Sn3Ag0.5Cu solder joints. J. Mater. Res. Technol. 24, 6022–6033 (2023). https://doi.org/10.1016/j.jmrt.2023.04.148

H. Xin et al., Effect of Au ion irradiation on the surface morphology, microstructure and mechanical properties of AlNbTiZr medium-entropy alloy coatings with various Al content for ATF. Surf. Coat. Technol. (2022). https://doi.org/10.1016/j.surfcoat.2022.128157

A.M. Mostafa, E.A. Mwafy, Effect of dual-beam laser radiation for synthetic SnO2/Au nanoalloy for antibacterial activity. J. Mol. Struct. (2020). https://doi.org/10.1016/j.molstruc.2020.128913

A. Ali, Y.W. Chiang, R.M. Santos, X-Ray Diffraction Techniques for Mineral Characterization: A Review for Engineers of the Fundamentals, Applications, and Research Directions. Minerals (2022). https://doi.org/10.3390/min12020205

S.M.K. Saha et al., Structural, morphological, and optical properties of CuO thin films treated by gamma ray. Int. Conf. Comput. Commun. Chem. Mater. Electron. Eng. (2018). https://doi.org/10.1109/IC4ME2.2018.8465649

S. Li, Y. Liu, H. Zhang, H. Cai, F. Sun, G. Zhang, Microstructure and hardness of SAC305 and SAC305-0.3Ni solder on Cu, high temperature treated Cu, and graphene-coated Cu substrates. Results Phys. (2018). https://doi.org/10.1016/j.rinp.2018.10.005

W. Paulus et al., The relationship between XRD peak intensity and mechanical properties of irradiated lead-free solder. Mater. Sci. Forum (2017). https://doi.org/10.4028/www.scientific.net/MSF.888.423

D.A. Shnawah, M.F.M. Sabri, I.A. Badruddin, S.B.M. Said, T. Ariga, F.X. Che, Effect of ag content and the minor alloying element fe on the mechanical properties and microstructural stability of Sn–Ag–Cu solder alloy under high-temperature annealing. J. Electron. Mater. (2013). https://doi.org/10.1007/s11664-012-2343-8

M. Sona, K.N. Prabhu, Review on microstructure evolution in Sn–Ag–Cu solders and its effect on mechanical integrity of solder joints. J. Mater. Sci.: Mater. Electron. (2013). https://doi.org/10.1007/s10854-013-1240-0

N.F.N.M. Lehan et al., Influence of gamma radiation on eutectic phase area and hardness properties of SAC305 solder SOLDE. J. Teknol. 84(6–2), 113–118 (2022). https://doi.org/10.11113/jurnalteknologi.v84.19358

W. Schule, Enhancement of diffusion due to irradiation. Z. fur Naturforschung - Sect. J. Phys. Sci. (1965). https://doi.org/10.1515/zna-1965-0405

L. Qi, J. Huang, X. Zhao, H. Zhang, Effect of thermal-shearing cycling on Ag3Sn microstructural coarsening in SnAgCu solder. J. Alloys Compd. 469, 1–2 (2009). https://doi.org/10.1016/j.jallcom.2008.01.108

Y. Tian, N. Ren, Z. Zhao, F. Wu, S.K. Sitaraman, Ag3Sn compounds coarsening behaviors in micro-joints. Materials (2018). https://doi.org/10.3390/ma11122509

G. Zeng, S. Xue, L. Zhang, L. Gao, W. Dai, J. Luo, A review on the interfacial intermetallic compounds between Sn–Ag–Cu based solders and substrates. J. Mater. Sci.: Mater. Electron. (2010). https://doi.org/10.1007/s10854-010-0086-y

M. Xiong, L. Zhang, Interface reaction and intermetallic compound growth behavior of Sn–Ag–Cu lead-free solder joints on different substrates in electronic packaging. J. Mater. Sci. (2019). https://doi.org/10.1007/s10853-018-2907-y

H. Ma, J.C. Suhling, A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. (2009). https://doi.org/10.1007/s10853-008-3125-9

J.S. George, An overview of radiation effects in electronics. AIP Conf. Proc. (2019). https://doi.org/10.1063/1.5127719

M. Said, N.M. Sharif, M.F.M. Nazeri, S. Kheawhom, A.A. Mohamad, Comparison of intermetallic compound growth and tensile behavior of Sn-3.0Ag-0.5Cu/Cu solder joints by conventional and microwave hybrid heating. J. Mater. Res. Technol. (2022). https://doi.org/10.1016/j.jmrt.2022.01.085

Q. Guan et al., Research progress on the solder joint reliability of electronics using in deep space exploration. Chin. J. Mech. Eng. (English Edition) (2023). https://doi.org/10.1186/s10033-023-00834-4

X. Xiao, Fundamental mechanisms for irradiation-hardening and embrittlement: a review. Metals (2019). https://doi.org/10.3390/met9101132

S. Wang, Y. Yao, X. Long, Critical review of size effects on microstructure and mechanical properties of solder joints for electronic packaging. Appl. Sci. (Switzerland) (2019). https://doi.org/10.3390/app9020227

X. Li, R. Sun, Y. Wang, A review of typical thermal fatigue failure models for solder joints of electronic components. IOP Conf. Ser.: Mater. Sci. Eng. (2017). https://doi.org/10.1088/1757-899X/242/1/012103

M.Z. Yahaya, A.A. Mohamad, Hardness testing of lead-free solders: A review. Solder. Surface. Mount. Technol. (2017). https://doi.org/10.1108/SSMT-01-2017-0002

L. Yang, X. Shi, S. Quan, Evolution of microstructure and effects on crack formation of Sn3.0Ag0.5Cu/Cu solder joints under accelerated thermal cycling. Mater. Res. Express (2019). https://doi.org/10.1088/2053-1591/ab1334

W.Y.W. Yusoff, R. Ismail, A. Jalar, N.K. Othman, I. Abdul Rahman, Microstructural evolution and micromechanical properties of gamma-irradiated au ball bonds. Mater. Charact. 93, 129–135 (2014). https://doi.org/10.1016/j.matchar.2014.03.024

A. Ray, Radiation effects and hardening of electronic components and systems: an overview. Indian J. Phys. (2023). https://doi.org/10.1007/s12648-023-02644-9

Acknowledgements

This research was fully supported by the Tabung Amanah PPPI grant (UPNM/2023/GPPP/SG/1). The authors thank Universiti Pertahanan Nasional Malaysia (UPNM) for funding this study.

Funding

This research was fully supported by the Tabung Amanah PPPI grant (UPNM/2023/GPPP/SG/1).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study of conception, design, and visualization. NI, WYWY, NFN, and WP: performed material preparation, data collection, and analysis. NI: wrote the first draft of the manuscript, and all authors commented on previous versions. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships, which could have influenced the work reported in this paper. The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ismail, N., Yusoff, W.Y.W., Lehan, N.F.N.M. et al. Microstructural evolution of 96.5Sn-3.0Ag-0.5Cu (SAC305) solder joints induced by variation doses of gamma-irradiation. J Mater Sci: Mater Electron 35, 18 (2024). https://doi.org/10.1007/s10854-023-11749-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11749-0