Abstract

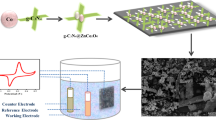

Zn-ion hybrid capacitors (ZIHCs) have been deemed a promising candidate for energy storage equipment to overcome the primary drawback of supercapacitors—low energy density. Herein, inspired by the laminated structure of chitin fibrils, molten salt strategy is proposed to engineer functional carbon as cathode material for ZIHCs, for the first time. Orthogonal design was adopted to ascertain the optimum synthetic conditions for the chitin-derived NaCl-templated and NaNO3-activated carbons (CNNs). The resultant C2NN1-800-1-5 possesses high surface area of 1256 m2 g−1 and rich surface heteroatom content of 11.3 at%, as well as numerous thin intertwined nanofibre bundles. Associated with the synergy of surface capacitive reaction and diffusion battery behavior, the Zn//ZnSO4 (aq, 2 M)//C2NN1-800-1-5 ZIHC can be conducted in a relatively broad potential window ranging from 0 to 1.8 V and manifests remarkable energy density of 133.4 Wh kg−1 at 180 W kg−1. Moreover, charge/discharge cycling further revealed that this device can retain 100% of its initial capacity, together with almost 100% coulombic efficiency after 10,000 cycles at 6 A g−1. The study emphasizes the green synthesis of heteroatom-doped hierarchical porous carbon cathode material, notably facilitating the rapidly increasing popularity of Zn-ion hybrid energy storage devices.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

L. Ling, Y. Bai, Z. Wang et al., ACS Appl. Mater. Interfaces. 10, 5560 (2018). https://doi.org/10.1021/acsami.7b17659

H. Li, J. Chen, B. Yang et al., Electrochim. Acta 299, 163 (2019). https://doi.org/10.1016/j.electacta.2018.12.172

S. Wu, Y. Chen, T. Jiao et al., Adv. Energy Mater. 9, 1902915 (2019). https://doi.org/10.1002/aenm.201902915

K. Zhu, T. Wu, K. Huang, ACS Nano 13, 14447 (2019). https://doi.org/10.1021/acsnano.9b08039

P. Jezowski, O. Crosnier, E. Deunf, P. Poizot, F. Beguin, T. Brousse, Nat. Mater. 17, 167 (2018). https://doi.org/10.1038/nmat5029

D.D. Li, C. Ye, X.Z. Chen, S.Q. Wang, H.H. Wang, J. Power Sources 382, 116 (2018). https://doi.org/10.1016/j.jpowsour.2018.02.036

Y. Zheng, W. Zhao, D. Jia et al., Chem. Eng. J. 387, 124161 (2020). https://doi.org/10.1016/j.cej.2020.124161

J. Wang, Y. Huang, X. Han, Z. Li, S. Zhang, M. Zong, Appl. Surf. Sci. 579, 152247 (2022). https://doi.org/10.1016/j.apsusc.2021.152247

F. Wei, H. Zhang, J. Wang, J. Zhuang, Y. Lv, J. Alloys Compd. 907, 164536 (2022). https://doi.org/10.1016/j.jallcom.2022.164536

Y. Li, P. Lu, P. Shang et al., J. Energy Chem. 56, 404 (2021). https://doi.org/10.1016/j.jechem.2020.08.005

L. Han, X. Zhang, J. Li et al., J. Colloid Interface Sci. 599, 556 (2021). https://doi.org/10.1016/j.jcis.2021.04.114

J. Li, J. Zhang, L. Yu et al., Energy Storage Mater. 42, 705 (2021). https://doi.org/10.1016/j.ensm.2021.08.018

F. Wei, Y. Wei, J. Wang, M. Han, Y. Lv, Chem. Eng. J. 450, 137919 (2022). https://doi.org/10.1016/j.cej.2022.137919

P. Dubey, V. Shrivastav, P.H. Maheshwari, S. Sundriyal, Carbon 170, 1 (2020). https://doi.org/10.1016/j.carbon.2020.07.056

B. van Veenhuyzen, S. Tichapondwa, C. Hörstmann, E. Chirwa, H.G. Brink, J. Hazard. Mater. 416, 125943 (2021). https://doi.org/10.1016/j.jhazmat.2021.125943

Y. Kado, Y. Soneda, Microporous Mesoporous Mater. 287, 101 (2019). https://doi.org/10.1016/j.micromeso.2019.04.067

A. Szczurek, G. Amaral-Labat, V. Fierro, A. Pizzi, A. Celzard, Microporous Mesoporous Mater. 196, 8 (2014). https://doi.org/10.1016/j.micromeso.2014.04.051

J. Ding, P. Wang, S. Ji, H. Wang, V. Linkov, R. Wang, Electrochim. Acta 296, 653 (2019). https://doi.org/10.1016/j.electacta.2018.11.105

X. Liu, M. Antonietti, Carbon 69, 460 (2014). https://doi.org/10.1016/j.carbon.2013.12.049

J. Wang, B. Ding, X. Hao et al., Carbon 102, 255 (2016). https://doi.org/10.1016/j.carbon.2016.02.047

H. Chen, L. Liu, F. Chen, Y. Fan, Q. Yong, Carbohydr. Polym. 283, 119138 (2022). https://doi.org/10.1016/j.carbpol.2022.119138

Y. Lu, Z. Li, Z. Bai et al., Nano Energy 66, 104132 (2019). https://doi.org/10.1016/j.nanoen.2019.104132

A. Sanchez-Sanchez, M.T. Izquierdo, G. Medjahdi, J. Ghanbaja, A. Celzard, V. Fierro, Microporous Mesoporous Mater. 270, 127 (2018). https://doi.org/10.1016/j.micromeso.2018.05.017

V. Khomenko, E. Raymundo-Piñero, F. Béguin, J. Power Sources 153, 183 (2006). https://doi.org/10.1016/j.jpowsour.2005.03.210

C. Xiang, M. Li, M. Zhi, A. Manivannan, N. Wu, J. Power Sources 226, 65 (2013). https://doi.org/10.1016/j.jpowsour.2012.10.064

Q. Yan, C. Shuai, L. Ying et al., Carbohydr Polym 133, 163 (2015)

S. Li, K. Han, J. Li, M. Li, C. Lu, Microporous Mesoporous Mater. 243, 291 (2017). https://doi.org/10.1016/j.micromeso.2017.02.052

W. Tian, H. Hu, Y. Wang et al., ACS Nano 12, 1990 (2018). https://doi.org/10.1021/acsnano.7b09175

L. Yang, X. Li, S. He et al., J. Mater. Chem. A 4, 10842 (2016). https://doi.org/10.1039/C6TA03083A

L. Dong, X. Ma, Y. Li et al., Energy Storage Mater. 13, 96 (2018). https://doi.org/10.1016/j.ensm.2018.01.003

S. Zeng, X. Shi, D. Zheng et al., Mater. Res. Bull. 135, 111134 (2021). https://doi.org/10.1016/j.materresbull.2020.111134

S. Chen, L. Ma, K. Zhang, M. Kamruzzaman, C. Zhi, J.A. Zapien, J. Mater. Chem. A 7, 7784 (2019). https://doi.org/10.1039/C9TA00733D

H. Chen, Y. Zheng, X. Zhu et al., Mater. Res. Bull. 139, 111281 (2021). https://doi.org/10.1016/j.materresbull.2021.111281

J. Yin, W.L. Zhang, W.X. Wang, N.A. Alhebshi, N. Salah, H.N. Alshareef, Adv. Energy Mater. (2020). https://doi.org/10.1002/aenm.202001705

H. Liu, H. Chen, K. Shi et al., Ind. Crops Prod. 187, 115519 (2022). https://doi.org/10.1016/j.indcrop.2022.115519

Y. Liu, H. Tan, Z. Tan, X. Cheng, Appl. Surf. Sci. 608, 155215 (2023). https://doi.org/10.1016/j.apsusc.2022.155215

Funding

This work is supported by the National Natural Science Foundation of China (Project No. 21406044) and the Zhejiang Province Public Welfare Technology Application Research Project (Grant No. LGF19B060007).

Author information

Authors and Affiliations

Contributions

HY: Investigation, discussion, writing—draft preparation. XC: Experiment, data analyzing. JZ: Conceptualization, supervision, writing—reviewing and editing. HW: Sample characterization.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors. In this manuscript, we did not collect any samples of human and animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yu, H., Chen, X., Zhou, J. et al. Boosting energy density for Zn-ion hybrid capacitors by engineering chitin-derived carbon in molten salt. J Mater Sci: Mater Electron 34, 675 (2023). https://doi.org/10.1007/s10854-023-09959-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-09959-7