Abstract

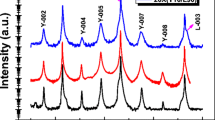

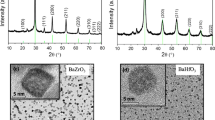

La0.67Sr0.33MnO3 (LSMO) nanoparticles/SrTiO3 (STO) structures were prepared as substrates using RF magnetron sputtering and GdBa2Cu3O7−x [(Gd)BCO] films were deposited on top. A significant improvement in superconductivity is observed under a magnetic field parallel to the GBCO H//c-axis. Due to the wider hysteresis loop, we observe that the Jc value of (Gd)BCO films on LSMO/STO remains at 1.0 × 105 A cm−2 at 77 K and 3 T magnetic field compared to 1.0 × 102 A cm−2 for (Gd)BCO films grown on bare STO. A significant enhancement of Fp and a shift of the [(Fp)max] magnetic field from 0.8 to 1.5 T. LSMO-induced defects and pinned Vortex properties in GdBa2Cu3O7−x matrix were investigated. We find that the formation of threading dislocation defects along the H//c-axis is the source of the improved induced properties in the GdBa2Cu3O7−x matrix.

Similar content being viewed by others

Data availability

Data sharing is not applicable to this article as no datasets were generated or analysed during the current study.

References

M. Guidry, Y. Sun, Cl. Wu, Front. Phys. China 5, 171–175 (2010)

K.A. Müller, A. Shengelaya, Dielectricly. J. Supercond. Nov. Magn. 26, 491–493 (2013)

U. Chatterjee, D. Ai, J. Zhao et al., PNAS 23, 9346–9349 (2011)

M. Mumtaza, L. Ali, Mubasher et al., Cryogenics 105, 103021 (2020)

A. Abrar, M. Khan, J. Low. Temp. Phys. 199, 1268–1298 (2020)

F.-C. Hsu, J.-Y. Luo, K.-W. Yeh et al., Proc. Natl. Acad. Sci. 105, 14262 (2008)

Y. Mizoguchi, Y. Takano, J. Phys. Soc. Jpn. 79, 102001 (2010)

Q. Nouailhetas, A. Koblischka-Veneva, M.R. Koblischka et al., AIP Adv. 11, 015230 (2021)

M.R. Koblischka, Y. Slimani, A. Koblischka-Veneva et al., Materials 13, 5018 (2020)

E. Hannachi, K.A. Mahmoud et al., Materials 3, 1034 (2022)

M.R. Koblischka, A. Koblischka-V eneva, XianLin Zeng et al., Crystals 10, 986 (2020)

G. Blatter, M.V. Feigelman, V.B. Geshkenbein et al., Rev. Mod. Phys. 66(4), 1125–1388 (1994)

T. Petrisor Jr., M.S. Gabor, C. Tiusan et al., J. Appl. Phys. 112, 5 (2012)

S.R. Foltyn, L. Civale, J.L. MacManus-Driscoll et al., Nature Mater. 6, 631–642 (2007)

Y. Slimani, E. Hannachi, M.K. Ben Salem et al., J. Supercond. Nov. Magn. 28, 3001–3010 (2015)

B. Maiorov, S.A. Baily, H. Zhou et al., Nat. Mater. 8, 398–404 (2009)

E. Hannachi, M.A. Almessiere, Y. Slimani et al., J. Alloys Compd. 812, 152150 (2020)

Y. Slimani, E. Hannachi, A. Ekicibil et al., J. Alloys Compd. 781, 664–673 (2019)

Y. Slimania, M.A. Almessiere, E. Hannachi et al., Ceram. Int. 45, 6828–7683 (2019)

M.K. Ben Salem, E. Hannachi, Y. Slimani et al., Ceram. Int. 40, 4953–4962 (2014)

P. Mele, K. Matsumoto, T. Horide et al., Supercond. Sci. Tech. (2008). https://doi.org/10.1088/0953-2048/21/3/032002

D.M. Feldmann, T.G. Holesinger, B. Maiorov et al., Supercond. Sci. Tech. 23, 115016 (2010)

A. Hamrita, Y. Slimani, M.K. Ben Salem et al., Ceram. Int. 40, 1461–1470 (2014)

Y. Slimania, E. Hannachi, F. Ben Azzouz et al., Cryogenics 92, 5–12 (2018)

J.H. Wimbush, R.B. Durrell et al., IEEE T Appl. Supercon. 3, 3148–3151 (2009)

S.C. Wimbush, J.H. Durrell, C.F. Tsai et al., Sci. Technol. 23, 045019 (2010)

A.V. Ushakov, I.V. Karpov, V.G. Demin et al., J. Mater. Sci: Mater. Electron. 30, 15592–15598 (2019)

Xu. Kun, D. Zhou, B. Li et al., PHYSICA C 510, 54–56 (2015)

M. Rekaby, Appl. Phys. A 126, 664 (2020)

A.K. Jha, K. Matsumoto, T. Horide et al., J. Appl. Phys. 122, 093905 (2017)

J. Gutierrez, T. Puig, M. Gibert, C. Moreno et al., Appl. Phys. Lett. 94, 172513 (2009)

A.K. Jha, N. Khare, R. Pinto, J. Appl. Phys. 110, 113920 (2011)

D.H. Tran, W.B.K. Putri, C.H. Wie et al., Thin Solid Films 526, 241–245 (2012)

Z. Xie, Z. Li, H. Lu, Y. Wang et al., J. Mater. Sci: Mater. Electron. 31, 19056–19063 (2020)

F. Touri, A. Sahari, A. Zouaoui et al., Surf. Rev. Lett. 27, 1950114 (2020)

R. Bean, Mod. Phys. 1, 31–39 (1964)

E.M. Gyorgy, R.B. van Dover, K.A. Jackson et al., Appl. Phys. Lett. 55, 283 (1989)

M. Tange, R. Yoshizaki, J. Phys. Soc. Jpn. 78, 024703 (2009)

J.H. Kwon, Y.F. Meng, L.J. Wu et al., Supercond. Sci. Technol. 31, 105006 (2018)

J.C. Nie, Z.Y. Hua, Q.Y. Tu et al., PHYSICA C 460, 1353–1354 (2007)

J. Wang, C.-F. Tsai, Z. Bi et al., IEEE T Appl. Supercon. 3, 3503–3506 (2009)

S.C. Wimbush, J.H. Durrell, C.F. Tsai et al., Supercond. Sci. Technol. 23, 045019 (2010)

M.G. Blamire, R.B. Dinner, S.C. Wimbush et al., Supercond. Sci. Technol. 22, 025017 (2009)

Funding

National Natural Science Foundation of China, Grant No 51502168, Ying Wang, Grant No 11504227, Ying Wang, Science and Technology Innovation Plan Of Shanghai Science and Technology Commission, Grant No 19DZ2271100, Ying Wang

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by TW, WW and YW. The first draft of the manuscript was written by TW and WW and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, T., Wang, W. & Wang, Y. Enhanced flux pinning properties for GdBa2Cu3O7−x films with nanosized La0.67Sr0.33MnO3 inclusions on SrTiO3 substrate by RF magnetic sputtering method. J Mater Sci: Mater Electron 34, 257 (2023). https://doi.org/10.1007/s10854-022-09765-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09765-7