Abstract

The modification in the Cu2Se thermoelectric system by electron beam irradiation has been carried out in this work. Samples were prepared using the solid-state reaction technique. The prepared samples were irradiated with various energy dosages viz. 50, 100, and 150 kGy. XRD studies reveal that the synthesized samples crystallized in a monoclinic structure. The micro-hardness of the samples decreased with an increase in irradiation dosage. The sample irradiated at 100 kGy dose exhibits the lowest electrical resistivity, moderate Seebeck coefficient, and highest power factor.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The demand for various energy sources is skyrocketing since last few decades. The available energy sources like fossil fuels are heading towards extinction and causing environmental pollution. An increase in energy demand has pushed researchers around the globe to search for alternative renewable energy resources [1]. Along with the development of renewable sustainable energy sources, the utilization of waste energy is yet another alternative which has attracted enough attention among researchers across the world [2, 3]. A huge amount of waste heat is sent back into the environment; utilization of this can possibly contribute to the partial energy requirements of the world. Thermoelectric materials (TE) are good candidates that utilize the waste heat from industries, automobiles, etc. and convert into useful electrical energy. The efficiency of a TE material is given by a dimensionless quantity, called figure of merit denoted by ZT, which is expressed as [4],

where S is the Seebeck coefficient, σ is electrical conductivity, T is the absolute temperature, and κ (= κe + κL) corresponds to total thermal conductivity which is the sum of electronic (κe) and lattice (κL) contributions. An optimized ZT demands a high electrical conductivity and a low value of thermal conductivity. However, optimizing ZT has been a challenging task as thermal conductivity and electrical conductivity are directly proportional to each other; whereas for a good TE material it should have a reverse relationship.

The state-of-the-art materials like Bi2T3 and Si based materials like SiGe alloys have been extensively used for various applications at near room and high temperatures respectively. However, for the last few decades, copper-based compounds have been the most popular TE materials at mid temperature [5, 6] as they are eco-friendly, more abundant, economically affordable, and less toxic. Various copper-based materials like Cu2SnSe3, Cu2Se, CuInTe, CuInSe, BiCuOSe, etc. are found to exhibit promising TE features [7,8,9].

Several attempts have been done to enhance the performance of these Cu-based thermoelectric materials, which include doping, composites and different sintering methods. Y.M. Zhou et al. fabricated the composites of SnTe and CuInTe and obtained an enhanced thermoelectric efficiency [10]. K. Shyam Prasad et al. synthesized Sb doped Cu2SnSe3 and obtained enhanced TE performance for the doped samples [11]. Yaochun Liu et.al synthesized nano composites of BiCuOSe and Cu2Se and achieved enhanced ZT [12].

Yet another way to tailor the performance of TE materials is irradiation using high-energy electron beam. The effect of electron beam irradiation has been primarily studied in TE materials in the form of thin films. Hyun Jung Kim et al. have grown Si1-xGex alloys on sapphire substrate and studied the influence of electron beam irradiation on defect-engineered Si1-xGex alloys. The aforementioned work suggests that growing the Si1-xGex films at high temperatures enhances the crystallinity and the defects engineered through electron beam irradiation enhances the TE properties. An increase in the Seebeck coefficient has been observed for the irradiated films due to enhanced dislocation density and decreased relaxation time [13]. Masayuki Takashiri et al. have grown Bismuth selenium telluride thin films and investigated the effect of electron beam irradiation on the grown thin films. An enhancement in the crystallinity of the irradiated samples has been observed. In addition to this, improved TE properties like Seebeck coefficient, electrical conductivity and power factor have been achieved along with enhanced mobility [14]. Shohei Kudo et al. have fabricated nano-crystalline Bismuth Telluride thin films and studied the effect of electron beam irradiation. The enhancement in the power factor as well as ZT has been observed for electron beam irradiated samples [15]. Nishant Chaudhary et al. synthesized and studied the effect of electron beam irradiation on the TE properties of PEDOT: PSS (Poly (3, 4 ethylenedioxytheophene)) films. The study demonstrates improved TE properties for the electron beam irradiated samples [16]. Inseon Oh et al. fabricated glassy carbon thin films and studied the effect of electron beam irradiation. Enhancement in the electrical conductivity, Seebeck coefficient, and power factor has been observed [17].

Most of these studies have been performed on thin films. Keeping this in mind, we were motivated to study the effect of electron beam irradiation on bulk materials. In the present work, we have synthesized the Cu2Se compound using conventional solid-state reaction and irradiated it with an electron beam for various energy dosages. The results on the effect of electron beam irradiation on structural, electrical transport properties of Cu2Se system are presented in this work. To the best of our knowledge, this is the first report on modifying the TE properties of Cu2Se by employing electron beam irradiation and we could achieve improved thermoelectric power factor. We are demonstrating in the present work that electron beam irradiation is an effective technique to enhance the power factor.

2 Experimental details

The Cu2Se bulk polycrystalline samples were prepared by employing the conventional solid-state reaction method. The starting materials Cu (99.7%, Loba Chemie) and Se (99.999%, Alfa aesar) in powder form were taken in stoichiometric ratio and were ground using a mortar pestle. The obtained powders were compressed into rectangular pellets with a pressure of 5 MPa using a hydraulic press and sealed in quartz tube under a high vacuum (10−6 mBar). The sealed quartz tube was kept in a furnace at 873 K for 72 h, and then the furnace was cooled naturally to room temperature. For better homogeneity, sintering was repeated twice. Samples from the same batch were exposed to electron beam of energy 8 MeV with a fluence of 1014 cm−2 by the help of a Linear accelerator (LINAC) and irradiated with dosage of 50, 100 and 150 kGy. The stopping power, continuous slow down approximation range, radiation yield and density effect of the pristine compound have been estimated with ESTAR software. The powder X-ray diffraction (XRD) studies were carried out using Rigaku Miniflex 600 X-ray diffractometer to estimate the various crystallographic parameters pristine and irradiated samples. Surface morphology was examined with scanning electron microscope (Oxford instruments employed with Zeiss optics EVO MA-18). The hardness was measured using a Vickers Micro-hardness Tester (MMTX7 Matsuzawa CO. LTD.) Density of the samples was measured using the Archimedes principle with CONTECH CAS – 234 density measurement system and the results show that the prepared samples exhibit density in the range 88 – 92% of the theoretical density. Hall measurements were performed using HMS 5500 (Ecopia) essentially to estimate the carrier concentration and carrier mobility. To carry out the Hall measurements, samples were cut in square shape and contacts were made at four corners with Indium-Tin alloy soldering. The sample was loaded into the system and four contacts were connected to gold plated electrodes. A constant current about 20 mA was supplied and voltages across the contacts were measured with and without the application of magnetic field. The instrument is connected to a PC and data acquisition was performed with the help of a software. Resistivity and thermopower were simultaneously measured using LSR—3 (Linseis) system. To carry out these measurements a rectangular sample was loaded into the system and direct contacts were made to the electrodes. The values of resistivity and thermopower have been measured with a step size of 30 K. Entire measurement has been carried out in high pure (99.999%) Helium environment.

3 Results and discussions

3.1 Phase formation and microstructure

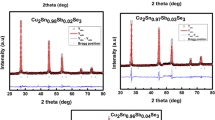

X-ray diffraction study of all the synthesized samples was carried out in the 2θ range 20–80°. The diffraction patterns matches well with the monoclinic structure of the C1m1 space group in the standard ICDD data [3] which confirms the proper phase formation in the samples. To derive the crystallographic information, Rietveld analysis was done on the XRD profile using Fullprof suite. The Rietveld refined plots of XRD patterns are shown in Fig. 1. Various crystallographic parameters have been estimated and are depicted in Table 1. Crystallite size and strain were calculated using Scherrer formula, Williamson Hall (WH) method and the size-strain plot method respectively given by the following equations [18].

where K = 0.9 is the Scherrer constant for the spherical geometry of the crystallites, d represents the inter-planar distance of (hkl) planes, λ = 1.5406 Å is the wavelength of the X-ray source, β is the Full Width at Half Maxima (FWHM) of the diffraction peaks, and \(\in\) represents the strain induced. Figure 2 shows the linear fit for WH and SS plot methods. The estimated values of crystallite size and strain are listed in Table 2. The crystallites sizes of the prepared compounds lie in the range 20–100 nm. A slight variation in the intensity of the peak around 25° is observed which signifies the creation of defects [19].

The energy loss of electron beam, as it penetrates deep inside the sample due to various scattering phenomena, was estimated by calculating total mass stopping power which gives average energy loss per unit path length of the compound, and it is a combination of electronic and radiative mass stopping power. Electronic and radiative mass stopping power provide stopping power due to Coulomb interaction and collisions with atom and atomic electrons. Continuous slow down approximation range (CSDA) is a close approximation to average path length of the electron before slowing down to rest, which is evaluated by ESTAR software and is given in Table 3. Radiation yield quantifies the fraction of primary electrons that converted to bremsstrahlung. Density effect which is a correction term to electronic stopping power due to polarization effect has been estimated using ESTAR software [20] and listed in Table 3.

SEM micrographs of the fractured surface of the synthesized samples were taken to observe the grain growth, which is shown in Fig. 3. The sample irradiated with 0 and 50 kGy exhibit a large number of small pores whereas the sample irradiated at 100 kGy shows a comparatively reduced number of pores. The sample irradiated with 150 kGy shows the absence of the pores and exhibits well-connected grains, therefore, exhibiting superior TE properties. The pristine and irradiated samples have grain size in the range 1–20 µm.

3.2 Vicker’s microhardness

Vicker’s micro-hardness of pristine and irradiated samples of Cu2Se (at 0, 50, 100, and 150 kGy) was measured using a diamond indenter with a load of 100 g force and a dwell time of 10 s. Micro-hardness is an essential quantity as it provides stability to a device. Although the samples were prepared by employing the solid-state reaction method, they exhibit micro-hardness comparable with those prepared by spark plasma sintering [21]. The pure sample shows the highest hardness of around 0.50 GPa which is comparable with the available reports [21]. Micro-hardness of the prepared samples decreased with an increase in the irradiation dose, which might be due to the degradation of the surface. Figure 4 shows the variation of micro-hardness as function of irradiation dose.

3.3 Electrical resistivity

Electrical resistivity measurement of the prepared samples has been carried out in the temperature range 300–623 K. The temperature-dependent resistivity plot is shown in Fig. 5. All the samples show a linear increase in resistivity with the increase in temperature, indicating the highly degenerate semiconducting behavior. All the samples possess resistivity in the range 2–10 μΩm. The pristine and irradiated samples exhibit a transition in the resistivity curve at around 350 K which is due to the change in the crystal structure from room temperature monoclinic to high-temperature cubic [21, 22]. The irradiation of the electron beam on the Cu2Se samples effectively influences the resistivity. The sample which is irradiated at 50 kGy exhibits a large increase in resistivity which might be due to the increased distortion in the crystal structure as the unit shell has shrunk. The sample irradiated at 100 kGy exhibits the lowest resistivity at room temperature which is due to the enhanced mobility as confirmed by Hall measurements. The high-energy electron beam breaks the bonding arrangement at the surface and a certain distance below the surface due to repeated striking of the electron beam which causes the formation of short-range disorders [13]. The estimated carrier concentration and Hall mobility are listed in Table 4.

3.4 Seebeck coefficient

Seebeck coefficient measurement of pure and irradiated samples has been carried out in the temperature range 300–623 K. The temperature dependency of the Seebeck coefficient is shown in Fig. 6. Seebeck coefficient of all the samples increases with increase in temperature which is indicates a behavior of highly degenerate materials as reflected in resistivity. All the samples possess positive values of the Seebeck coefficient which suggests that holes are the majority charge carriers [23, 24]. The variation in temperature dependent Seebeck coefficient follows the same trend as that of the resistivity indicating that the Seebeck coefficient is dependent on carrier concentration. The sample irradiated at 100 kGy exhibits the lowest Seebeck coefficient at room temperature due to enhanced mobility.

Estimation of Lorenz number is essential to understand the degeneracy of materials. For highly degenerate semiconductor materials, the various electronic scattering mechanisms and temperature can change the Lorenz number significantly from the degenerate value of 2.44 × 10−8 WΩK−2. Recently, Kim et al. [25] proposed an equation to evaluate the Lorenz number from the Seebeck coefficient (S) measurements. According to Kim et al., the Lorenz number (L) can be approximated up to 5% accuracy of the single parabolic band model with the following equation,

The values of temperature-dependent Lorenz numbers have been estimated using Eq. 5. One can observe that the estimated values of the Lorenz number fall within the degenerate limit. The temperature dependent Lorenz number are shown in Fig. 7.

In low mobility materials like chalcogenides, weighted mobility provides more accurate information than Hall mobility. Temperature-dependent weighted mobility of the prepared materials is calculated assuming SPB–APS (Single Parabolic Band with Acoustic phonon scattering) with experimentally measured Seebeck coefficient and electrical resistivity values. According to Snyder et al. [26], weighted mobility is given by,

where h is Planck’s constant, kB is Boltzmann constant, ρ is electrical resistivity, e is a charge on the electron, and T is the absolute temperature.

The weighted mobility of the prepared compounds is found to decrease with increase in temperature. The sample, which was irradiated at 100 kGy, exhibited the highest weighted mobility. Figure 8 shows the variation of the weighted mobility with temperature.

3.5 Power factor (PF)

The temperature-dependent power factor in the temperature range 300–623 K of the synthesized samples is shown in Fig. 9. The sample irradiated at 100 kGy exhibits highest PF of 726 µWm−1 K−2 at 620 K as it shows the low resistivity and moderately enhanced Seebeck coefficient. The power factor is an essential parameter that represents the whole electrical transport in the system, [27] and here the highest obtained PF is over 30% higher than that of the pristine Cu2Se.

4 Conclusions

Polycrystalline bulk Cu2Se samples have been synthesized with solid-state reaction technique. XRD diffraction studies revealed that synthesized samples are crystallized in monoclinic structure. Prepared samples exhibit the density in the range 88 – 92%. The resistivity of the all the samples has increased with increase in temperature which indicates the highly degenerate behavior of the samples. Positive values of the Seebeck coefficient indicates that the majority charge carriers are holes. The sample irradiated at 150 kGy exhibited the highest PF of 726 µWm−1 K−2 at 620 K which is over 30% higher than that of the pristine Cu2Se. In summary electron beam irradiation is found to be efficient technique to tune the transport properties of Cu2Se material.

Data availability

Data will be made available on reasonable request.

References

G.J. Snyder, E.S. Toberer, Nat. Mater. 7, 105 (2008)

D. Rowe, C. Bhandari, CRC Handbook of thermoelectrics (CRC Press, 1995)

S. Mangavati, A. Pal, A. Rao, Z.-Z. Jiang, Y.-K. Kuo, J. Phys. Chem. Solids 160, 110301 (2022)

H. Lee, Thermoelectrics: design and materials (John Wiley & Sons Ltd, Chichester, 2016)

B. Madavali, H.S. Kim, S.J. Hong, J. Electron. Mater. 43, 2390 (2014)

Y. Li, G. Wang, M. Akbari-Saatlu, M. Procek, H.H. Radamson, Front. Mater. 8, 1 (2021)

P. Qiu, X. Shi, L. Chen, Energy Storage Mater. 3, 85 (2016)

V. Kucek, C. Drasar, J. Navratil, T. Plechacek, L. Benes, J. Phys. Chem. Solids 83, 18 (2015)

J. Yao, N.J. Takas, M.L. Schliefert, D.S. Paprocki, P.E.R. Blanchard, H. Gou, A. Mar, C.L. Exstrom, S.A. Darveau, P.F.P. Poudeu, J.A. Aitken, Phys. Rev. B Condens. Matter Mater. Phys. 84, 1 (2011)

Y.M. Zhou, H.J. Wu, Y.L. Pei, C. Chang, Y. Xiao, X. Zhang, S.K. Gong, J.Q. He, L.D. Zhao, Acta Mater. 125, 542 (2017)

K.S. Prasad, A. Rao, N.S. Chauhan, R. Bhardwaj, A. Vishwakarma, K. Tyagi, Appl. Phys. A Mater. Sci. Process. 124, 98 (2018)

Y. Liu, Y. Zhou, J. Lan, C. Zeng, Y. Zheng, B. Zhan, B. Zhang, Y. Lin, C.W. Nan, J. Alloys Compd. 662, 320 (2016)

H.J. Kim, H. Bin Bae, Y. Park, S.H. Choi, RSC Adv. 2, 12670 (2012)

M. Takashiri, K. Kurita, H. Hagino, S. Tanaka, K. Miyazaki, J. Appl. Phys. 118, 0 (2015)

S. Kudo, S. Tanaka, K. Miyazaki, Y. Nishi, M. Takashiri, Mater. Trans. 58, 513 (2017)

N. Chaudhary, A. Singh, D.K. Aswal, M. Bharti, A. Sharma, A.R. Tillu, M. Roy, B.P. Singh, J. Bahadur, V. Putta, A.K. Debnath, Polymer (Guildf). 202, 122645 (2020)

I. Oh, J. Jo, J. Park, J. Lee, H. Shin, J.W. Yoo, Curr. Appl. Phys. 16, 1511 (2016)

T. Tatarchuk, M. Bououdina, W. Macyk, O. Shyichuk, N. Paliychuk, I. Yaremiy, B. Al-Najar, M. Pacia, Nanoscale Res. Lett. 12, 141 (2017)

M. Takashiri, K. Imai, M. Uyama, H. Hagino, S. Tanaka, K. Miyazaki, Y. Nishi, J. Alloys Compd. 612, 98 (2014)

M. J. Berger, Atomic and Molecular Data for Radiotherapy and Radiation Research Final Report of a Co-Ordinated Research Programme (IAEA, Austria, 1995).

K. Tyagi, B. Gahtori, S. Bathula, M. Jayasimhadri, S. Sharma, N.K. Singh, D. Haranath, A.K. Srivastava, A. Dhar, Solid State Commun. 207, 21 (2015)

Y. Bin Zhu, B.P. Zhang, Y. Liu, Phys. Chem. Chem. Phys. 19, 27664 (2017)

C. Raju, M. Falmbigl, P. Rogl, X. Yan, E. Bauer, J. Horky, M. Zehetbauer, R. Chandra Mallik, AIP Adv. 3, 032106 (2013)

S.K. Prasad, A. Rao, B. Gahtori, S. Bathula, A. Dhar, C.C. Chang, Y.K. Kuo, Phys. B Condens. Matter 520, 7 (2017)

H.S. Kim, Z.M. Gibbs, Y. Tang, H. Wang, G.J. Snyder, APL Mater. 3, 1 (2015)

G.J. Snyder, A.H. Snyder, M. Wood, R. Gurunathan, B.H. Snyder, C. Niu, Adv. Mater. 32, 1 (2020)

W. Liu, H.S. Kim, Q. Jie, Z. Ren, Scr. Mater. 111, 3 (2016)

Acknowledgements

One of the authors (AR) acknowledge the DST—FIST grant (SR/FIST/ PS-1/2017/8) and Council of Scientific and Industrial Research Grant (sanction no: 03(1409)/17/E MR-II) for the financial support required for this work. The author (SM) acknowledges MAHE for providing financial support to this work.

Funding

Open access funding provided by Manipal Academy of Higher Education, Manipal. This study was supported by the DST–FIST Grant (SR/FIST/ PS-1/2017/8) and Council of Scientific and Industrial Research Grant (Sanction No: 03(1409)/17/E MR-II) to Ashok Rao.

Author information

Authors and Affiliations

Contributions

SM—Sample synthesis, characterization, writing original draft, Conceptualization; GK—Review and editing; AR—Supervision, reviewing, and manuscript editing; VCP—Irradiation of the samples; VPV—Irradiation of the samples; JD—Irradiation of the samples.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This work does not involve any human participants and animals. There are no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mangavati, S., Gurukrishna, K., Rao, A. et al. Enhancement of thermoelectric power factor in Cu2Se superionic conductor via high energy electron beam irradiation. J Mater Sci: Mater Electron 34, 87 (2023). https://doi.org/10.1007/s10854-022-09494-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-022-09494-x