Abstract

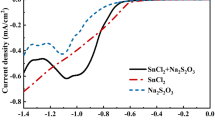

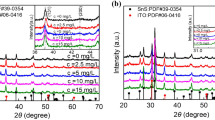

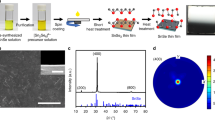

SnS is considered being a promising thermoelectric material because it has the same crystal structure as that of SnSe which has excellent thermoelectric properties. However, the low electronic transmission properties confine its performances. The difficult preparation and poor mechanism property of SnS single crystal also confined its commercial application. In this paper, we successfully doped aluminum into the SnS films by a simple one-step co-deposition method. We obtained compact aluminum-doped SnS films with orthogonal crystal structure, which was caused by the properly controlled composition. The carrier concentration of the aluminum-doped SnS films was successful increased by the increase in Al content. The resistivity was further decreased by the additives in the electrolytes because the additives changed the texture orientation and texture coefficient, which caused the change of carrier mobility. When CTAB was added into the electrolytes, the strong (200) texture formed in the aluminum-doped film which caused a relatively large carrier mobility. The combination of the large carrier mobility and concentration determined the resistivity as small as 91.82 Ω·cm. The results proved that aluminum doping can effectively increase the carrier concentration of SnS films, and the simultaneous carrier mobility decrease can be compensated by additives. The aluminum doping and additive application pave an effective way to promote the electric transition properties of SnS films which is profitable for its thermoelectric characters. And the simplicity of the co-deposition method of aluminum doping and texture adjustment exhibits a potential of commercial application.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

B. Qin, D. Wang, X. Liu, Y. Qin, J.F. Dong, J. Luo, J.W. Li, W. Liu, G. Tan, X. Tang, J.F. Li, J. He, L.D. Zhao, Science 373, 556 (2021)

L. Su, D. Wang, S. Wang, B. Qin, Y. Wang, Y. Qin, Y. Jin, C. Chang, L.D. Zhao, Science 375, 1385 (2022)

L.D. Zhao, S.H. Lo, Y. Zhang, H. Sun, G. Tan, C. Uher, C. Wolverton, V.P. Dravid, M.G. Kanatzidis, Nature 508, 373 (2014)

L.D. Zhao, G. Tan, S. Hao, J. He, Y. Pei, H. Chi, H. Wang, S. Gong, H. Xu, V.P. Dravid, C. Uher, G.J. Snyder, C. Wolverton, M.G. Kanatzidis, Science 351, 141 (2016)

Y. Xiao, L.D. Zhao, Science 367, 1196 (2020)

Y. Xiao, C. Chang, Y. Pei, D. Wu, K. Peng, X. Zhou, S. Gong, J. He, Y. Zhang, Z. Zeng, L.D. Zhao, Phys. Rev. B 94, 125203 (2016)

C. Chang, D. Wang, D. He, W. He, F. Zhu, G. Wang, J. He, L.D. Zhao, Adv. Energy Mater. 9, 1901334 (2019)

B. Qin, D. Wang, W. He, Y. Zhang, H. Wu, S.J. Pennycook, L.D. Zhao, J. Am. Chem. Soc. 141, 1141 (2019)

C. Chang, M. Wu, D. He, Y. Pei, C.F. Wu, X. Wu, H. Yu, F. Zhu, K. Wang, Y. Chen, L. Huang, J.F. Li, J. He, L.D. Zhao, Science 360, 778 (2018)

T. Gotoh, Phys. Status Solidi A. 213, 1869 (2016)

R. Guo, X. Wang, Y. Kuang, B. Huang, Phys. Rev. B 92, 1 (2015)

T.M. Tritt, Science 283, 804 (1999)

J. Yang, L. Xi, W. Qiu, L. Wu, X. Shi, L. Chen, J. Yang, W. Zhang, C. Uher, D.J. Singh, NPJ. Comput. Mater. 2, 1 (2016)

B.Z. Sun, Z. Ma, C. He, K. Wu, RSC Adv. 5, 56382 (2015)

Q. Tan, C.F. Wu, W. Sun, J.F. Li, RSC Adv. 6, 43985 (2016)

H.S. Kim, Z.M. Gibbs, Y. Tang, H. Wang, G.J. Snyder, APL Mater. 3, 041506 (2015)

N.K. Singh, S. Bathula, B. Gahtori, K. Tyagi, D. Haranath, A. Dhar, J. Alloys Comp. 668, 152 (2016)

E.K. Chere, Q. Zhang, K. Dahal, F. Cao, J. Mao, Z. Ren, J. Mater. Chem. A. 4, 1848 (2016)

D.M. Unuchak, K. Bente, V.A. Ivanov, V.F. Gremenok, Cryst. Res. Technol. 45, 1113 (2010)

W. He, D. Wang, H. Wu, Y. Xiao, Y. Zhang, D. He, Y. Feng, Y.J. Hao, J.F. Dong, R. Chetty, L. Hao, D. Chen, J. Qin, Q. Yang, X. Li, J.M. Song, Y. Zhu, W. Xu, C. Niu, X. Li, G. Wang, C. Liu, M. Ohta, S.J. Pennycook, J. He, J.F. Li, L.D. Zhao, Science 365, 1418 (2019)

Y. Goto, F. Naito, R. Sato, K. Yoshiyasu, T. Itoh, Y. Kamihara, M. Matoba, Inorg. Chem. 52, 9861 (2013)

V. Steinmann, R.E. Brandt, R. Chakraborty, R. Jaramillo, M. Young, B.K. Ofori-Okai, C. Yang, A. Polizzotti, K.A. Nelson, R.G. Gordon, T. Buonassisi, APL Mater. 4, 026103 (2016)

M.A. Almessiere, A.L. Al-Otaibi, I.B. Assaker, T. Ghrib, R. Chtourou, Mater. Sci. Semicond. Proc. 40, 267 (2015)

Y. Yang, S. Cheng, J. Semico. 29, 2322 (2008)

O. Falkenbach, J. Tinz, A.S. Schulze, E. Mueller, S. Schlecht, Phys. Status Solidi A. 213, 699 (2016)

C. Bera, S. Jacob, I. Opahle, N.S. Gunda, R. Chmielowski, G. Dennler, G.K. Madsen, Phys. Chem. Chem. Phys. 16, 19894 (2014)

S. Bhattacharya, N.S. Gunda, R. Stern, S. Jacobs, R. Chmielowski, G. Dennler, G.K. Madsen, Phys. Chem. Chem. Phys. 17, 9161 (2015)

Y. Kawano, J. Chantana, T. Minemoto, Curr. Appl. Phys. 15, 897 (2015)

J. Sun, Y. Huang, S. Nie, Z. Chen, J. Xu, L. Zhao, W. Zhou, Q. Wang, H. Gong, Mater. Lett. 178, 231 (2016)

H. Zhang, Y. Balaji, A.N. Mehta, M. Heyns, M. Caymax, I. Radu, W. Vandervorst, A. Delabie, J. Mater. Chem. C 6, 6172 (2018)

J. Xia, X.Z. Li, X. Huang, N. Mao, D.D. Zhu, L. Wang, H. Xu, X.M. Meng, Nanoscale 8, 2063 (2016)

M. Patel, A. Ray, RSC Adv. 4, 3934 (2014)

B. Ghosh, R. Roy, S. Chowdhury, P. Banerjee, S. Das, Appl. Surf. Sci. 256, 4328 (2010)

H. Kafashan, F.J. Sheini, R.E. Kahrizsangi, R. Yousefi, J. Alloys Comp. 681, 595 (2016)

A.A. Ramadan, A.A. Abd El-Mongy, A.M. El-Shabiny, A.T. Mater, S.H. Mostafa, E.A. El-Sheheedy, H.M. Hashem, Cryst. Res. Technol. 44, 111 (2009)

H. Kafashan, R.E. Kahrizsangi, F.J. Sheini, R. Yousefi, Phys. Status Solidi A 213, 1302 (2016)

C. Wu, L. Shen, H. Yu, Q. Huang, Y.C. Zhang, Mater. Res. Bull. 46, 1107 (2011)

G. Kaurn, A. Mitra, K.L. Yadav, Prog. Nat. Sci. Mater. 25, 12 (2015)

C.E. Benouis, M. Benhaliliba, Z. Mouffak, A.A. Garcia, A.T. Silver, M.O. Lopez, R.R. Trujillo, Y.S. Ocak, J. Alloys Compd. 603, 213 (2014)

Y. Li, G. Wang, M.A. Saatlu, M. Procek, H.H. Radamson, Frontiers Mater. 8, 611078 (2021)

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 51472020).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation and data collection were performed by YL, and data analysis was performed by ZL and YL. The first draft of the manuscript was written by YL, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that there is no competing interest to disclose that is directly or indirectly related to the work submitted for publication.

Research involving human and animal rights

The authors have no relevant financial or non-financial interests to disclose. This this work involved no human participants and animals and had no informed consent.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Liu, Y., Cao, K. et al. Electrodeposition of low-cost SnS films with increasing carrier concentration and mobility by aluminum doping and texture adjustment. J Mater Sci: Mater Electron 33, 26870–26880 (2022). https://doi.org/10.1007/s10854-022-09352-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-09352-w