Abstract

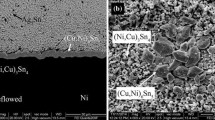

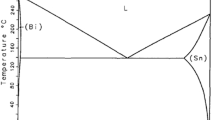

This study investigated the interfacial reactions of Co with molten In and eutectic In–48at.%Sn solders at different temperatures. For the In/Co reactions at 350 °C, the intermetallic compound (IMC) of CoIn3 was formed with a uniform and dense structure. It exhibited a unique linear growth with aging time, suggesting that the CoIn3 formation was reaction-controlled. In the eutectic In–Sn/Co reactions at 350 °C, the formed Co(Sn,In)2 phase also displayed a linear growth and its growth rate (~ 5 μm/h) was higher than that of the In/Co reactions (~ 2 μm/h). Moreover, in these two interfacial systems, both the CoIn3 and Co(Sn,In)2 IMCs revealed the so-called cruciform pattern, which is the important feature of the reaction-controlled linear growth. It was the first time to find the special linear growths in the Co/In and In–48at.%Sn/Co reactions. The reactions were carried out at lower temperatures and the microstructures of the reaction phases had a significant change. In the In/Co reactions at 250 °C, the CoIn3 showed a microstructure of isolated particulates and a significant grain coarsening occurred due to the Ostwald ripening. At 180 °C, the CoIn3 grains was unstable at the interface and drastically spalled into the molten In. A similar phenomenon and the microstructural evolutions were also observed in the eutectic In–Sn/Co reactions. It was attributed to the fact that the diffusion and dissolution of the formed phase became dominant at lower reaction temperatures. Based on the detailed results, the correlated reaction mechanism was discussed in detail.

Similar content being viewed by others

Data availability

The datasets generated during the current study are available from the corresponding author on reasonable request.

References

N. Jiang, L. Zhang, Z.-Q. Liu, L. Sun, W.-M. Long, P. He, M.-Y. Xiong, M. Zhao, Reliability issues of lead-free solder joints in electronic devices. Sci. Technol. Adv. Mater. 20, 876–901 (2019)

W. Liu, S. Bai, Thermoelectric interface materials: a perspective to the challenge of thermoelectric power generation module. J. Materiomics 5, 321–336 (2019)

C.E. Ho, S.Y. Yang, C.R. Kao, Interfacial reactions issues for lead-free electronic solders. J. Mater. Sci.: Mater. Electron. 18, 155–174 (2007)

M.-Y. Xiong, L. Zhang, Interface reaction and intermetallic compound growth behavior of Sn-Ag-Cu lead-free solder joints on different substrates in electronic packaging. J. Mater. Sci. 54, 1741–1768 (2019)

T. Laurila, V. Vuorinen, J.K. Kivilahti, Interfacial reactions between lead-free solders and common base materials. Mater. Sci. Eng. R 49, 1–60 (2005)

Y. Liu, K.N. Yu, Low melting point solders based on Sn, Bi, and In elements. Mater. Today Adv. 8, 100115 (2020)

C.Y. Huang, S.W. Chen, Interfacial reactions in In-Sn/Ni couples and phase equilibria of the In-Sn-Ni system. J. Electron. Mater. 31, 152–160 (2002)

R. Tian, C. Hang, Y. Tian, L. Zhao, Growth behavior of intermetallic compounds and early formation of cracks in Sn-3Ag-0.5Cu solder joints under extreme temperature thermal shock. Mater. Sci. Eng. A 709, 125–133 (2018)

C.-H. Wang, S.-W. Chen, Sn-0.7wt%Cu/Ni interfacial reactions at 250°C. Acta Mater. 54, 247–253 (2006)

C. Key Chung, Y.J. Chen, W.M. Chen, C.R. Kao, Origin and evolution of voids in electroless Ni during solder reaction. Acta Mater. 60, 4586–4593 (2012)

E. Kaloyeros, Y. Pan, J. Goff, B. Arkles, Review—cobalt thin films: trends in processing technologies and emerging applications. ECS J. Solid State Sci. Technol. 8, 119–152 (2019)

C.-H. Wang, H.-C. Hsieh, H.Y. Lee, A.T. Wu, Co-P diffusion barrier for p-Bi2Te3 thermoelectric material. J. Electron. Mater. 48, 53–57 (2019)

H.-C. Hsieh, C.-H. Wang, W.-C. Lin, S. Chakroborty, T.-H. Lee, H.-S. Chu, A.T. Wu, Electroless Co-P diffusion barrier for n-PbTe thermoelectric material. J. Alloys Compd. 728, 1023–1029 (2017)

C.-H. Wang, C.-Y. Kuo, Y.-B. Guo, Effects of minor Cu, Ni and Ag additions on the reactions between Sn-based solders and Co substrate. JOM 71, 3023–3030 (2019)

C.-H. Wang, K.T. Li, Strong effects of minor Ga addition on liquid-state Sn-Ga/Co interfacial reactions. J. Alloys Compd. 649, 1197–1204 (2015)

C.-H. Wang, C.-C. Wen, C.-Y. Lin, Solid-state interfacial reactions of Sn and Sn–Ag–Cu solders with an electroless Co(P) layer deposited on a Cu substrate. J. Alloys Compd. 662, 475–483 (2016)

N. Lu, D. Yang, L. Li, Interfacial reaction between Sn-Ag-Cu solder and Co-P films with various microstructures. Acta Mater. 71, 4581–4590 (2013)

L. Sun, M.-H. Chen, L. Zhang, P. He, L.-S. Xie, Recent progress in SLID bonding in novel 3D-IC technologies. J. Alloys Compd. 818, 152825 (2020)

D.H. Jung, A. Sharma, M. Mayer, J.P. Jung, A review on recent advances in transient liquid phase (TLP) bonding for thermoelectric power module. Rev. Adv. Mater. Sci. 53, 147–160 (2018)

T.-H. Chuang, W.-T. Yeh, C.-H. Chuang, J.-D. Hwang, Improvement of bonding strength of a (Pb,Sn)Te–Cu contact manufactured in a low temperature SLID-bonding process. J. Alloys Compd. 613, 46–54 (2014)

J.F. Li, P.A. Agyakwa, C.M. Johnson, Interfacial reaction in Cu/Sn/Cu system during the transient liquid phase soldering process. Acta Mater. 59, 1198–1211 (2011)

Y.S. Chiu, H.Y. Yu, H.T. Hung, Y.W. Wang, C.R. Kao, Phase formation and microstructure evolution in Cu/In/Cu joints. Microelectron. Reliab. 95, 18–27 (2019)

F. Tian, Z.-Q. Liu, P.-J. Shang, J. Guo, Phase identification on the intermetallic compound formed between eutectic SnIn solder and single crystalline Cu substrate. J. Alloys Compd. 613, 46–54 (2014)

S.-K. Lin, C.-W. Hsu, S.-W. Chen, C.-M. Hsu, Interfacial reactions in Sn-20In-2.8Ag/Cu couples. Mater. Chem. Phys. 142, 268–275 (2013)

I. Panchenko, S. Bickel, J. Meyer, M. Mueller, J.M. Wolf, Characterization of low temperature Cu/In bonding for fine-pitch interconnections in three-dimensional integration. Jpn. J. Appl. Phys. 57, 1–6 (2018)

S.S. Wang, Y.H. Tseng, T.H. Chuang, Intermetallic compounds formed during the interfacial reactions between liquid-Sn-49Sn solder and Ni substrates. J. Electron. Mater. 35, 165–169 (2006)

J.-B. Lee, H.-Y. Hwang, M.-W. Rhee, Reliability investigation of Cu/In TLP bonding. J. Electron. Mater. 44, 435–441 (2015)

L. Yang, Y. Xiong, Y. Zhang, W. Jiang, D. Wei, Microstructure and shear property of In-Sn-xAg solder joints, fabricated by TLP bonding. J. Mater. Sci. Mater. Electron. 30, 18211–18219 (2019)

S.-W. Chen, T.-C. Yang, J.-M. Lin, T.-Y. Huang, Interfacial reactions in the Co/In/Cu and Ni/In/Cu samples. J. Taiwan Inst. Chem. Eng. 97, 356–369 (2019)

H. Okamoto, The Co-In system. Bull. Alloy Phase Diagr. 11, 137–139 (1990)

C.-H. Wang, S.-W. Chen, Sn/Co solid/solid interfacial reactions. Intermetallics 16, 524–530 (2008)

O. Suh, K.N. Tu, G.V. Lutsenko, A.M. Gusak, Size distribution and morphology of Cu6Sn5 scallops in wetting reaction between molten solder and copper. Acta Mater. 56, 1075–1083 (2008)

C.-H. Wang, H.-H. Chen, W.-H. Lai, Effects of minor amounts of Zn on the Sn-Zn/Ni interfacial reactions and phase equilibria of the ternary Sn-Zn-Ni system at 250°C. J. Electron. Mater. 40, 2436–2444 (2011)

W.R. Teo, Y.F. Sun, Spalling behavior of interfacial intermetallic compounds in Pb-free solder joints subjected to temperature cycling loading. Acta Mater. 56, 242–249 (2008)

C.E. Ho, S.P. Yang, P.T. Lee, C.Y. Lee, C.C. Chen, T.T. Kuo, IMC microstructure modification and mechanical reinforcement of Sn-Ag-Cu/Cu microelectronic joints through an advanced surface finish technique. J. Mater. Res. Technol. 11, 1895–1910 (2021)

W.M. Chen, S.C. Yang, M.H. Tsai, C.R. Kao, Uncovering the driving force for massive spalling in the Sn-Cu/Ni system. Scripta Mater. 63, 47–49 (2010)

S.C. Yang, C.E. Ho, C.W. Chang, C.R. Kao, Massive spalling of intermetallic compounds in solder-substrate reactions due to limited supply of the active element. J. Appl. Phys. 101, 084911 (2007)

C.-H. Wang, H.-H. Chen, C.-W. Chiu, Cruciform pattern of Ni5Zn21 formed in interfacial reactions between Ni and Sn–Zn solders. J. Electron. Mater. 43, 1362–1369 (2014)

Acknowledgements

This work was financially supported by Ministry of Science and Technology of Taiwan (MOST 109-2221-E-194-007).

Funding

This work was financially supported by Ministry of Science and Technology, Taiwan [Grant No. MOST 109-2221-E-194-007].

Author information

Authors and Affiliations

Contributions

All authors contributed to the conception and design of this study and data interpretation. Material preparation, data collection and analysis were performed by T-YC. The original draft of the manuscript was written by C-hW.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Ch., Chang, TY. Reaction mechanism for liquid-state interfacial reactions of Co with In and eutectic In–48at.%Sn solders. J Mater Sci: Mater Electron 33, 12321–12333 (2022). https://doi.org/10.1007/s10854-022-08190-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-08190-0