Abstract

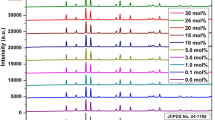

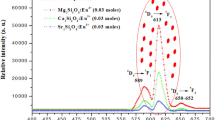

Eu3+-doped SrLa2Al2O7 (0.5–30 mol%) nano-series was well-synthesized through an effective solution combustion (SC) way. A tetragonal prototype with S.G.–I4/mmm (139) & lattice parameters for SrLa2(1−x)Al2O7:xEu3+ (x = 20 mol%) nanosample have been measured and analyzed via Rietveld refinement process. Surface morphology, crystallite size and chemical composition of SrLa2(1−x)Al2O7:xEu3+ (x = 20 mol%) nanopowder are checked through SEM, TEM & EDS analysis. The energy band-gap (Eg = 4.62 eV) is determined for optimum (x = 20 mol%) composition using DR measurements. Further, 396 nm energy excitation provides blue-white-red emissions with intense band at 621 nm, deriving from 5D0‐7F2 transition of Eu3+ ions. The critical separation among dopant centres for x = 20 mol% is found as 8.82 Å, for which dipole-quadrupole (s = 8.04) energy transfer mechanism is determined. Judd–Ofelt (J-O) theory is used to evaluate the intensity parameters Ωλ (λ = 2, 4) = 1.38 × 10–20 & 0.24 × 10–20 cm2 of Eu3+ ions in SrLa2Al2O7 host lattice. The results give CIE color coordinates covering blue to red region (x = 0.2452, y = 0.2380 to x = 0.6376, y = 0.3527) and CCT value range (30,812-1807 K) for warm as well as cool light emission. Finally, the concentration-dependent chromatic behaviour in blue-white-red region reflects the role of Eu3+-activated SrLa2Al2O7 nanophosphor in single-phased as well as RGB-based NUV-WLEDs.

Similar content being viewed by others

References

X. Wang, Z. Zhao, Q. Wu, Y. Li, C. Wang, A. Mao, Y. Wang, Dalton Trans. 44, 11057 (2015)

S. Devi, A. Khatkar, V.B. Taxak, M. Dalal, S. Chahar, J. Dalal, S.P. Khatkar, J. Alloys Compd. 767, 409 (2018)

VP Manjari, CR Krishna, CV Reddy, SM Begum, YP Reddy, RVSSN Ravikumar (2014) J Lumin 145:324

M. RajeshYadav, B. JayaRaja, M. Avinash, C. RamaKrishna, R.V.S.S.N. Ravikumar, J Mater Sci 27, 1318 (2016)

B. Raja, M. Yadav, V. Manjari, B. Babu, C. Krishna, R. Ravikumar, J. Mol. Struc. 1076, 461 (2014)

F. Baur, F. Glocker, T. Jüstel, J. Mater Chem C 3, 20542064 (2015)

A. Chapel, R. Boonsin, G. Chadeyron, D. Boyer, A. Bousquet, R. Mahiou, W. Henrique Cassinelli, C.V. Santilli, S. Therias, New J. Chem 41, 12006 (2017)

H. Xu, L. Wang, D. Qu, Z. Si, J. Shi, RSC Adv. 7, 41282 (2017)

M. Dalal, V.B. Taxak, S. Chahar, J. Dalal, A. Khatkar, S.P. Khatkar, J. Alloy. Compd. 686, 366 (2016)

S. Devi, M. Dalal, J. Dalal, A. Hooda, A. Khatkar, V.B. Taxak, S.P. Khatkar, Ceram. Int. 45, 7397 (2019)

M. Jiao, Y. Jia, W. Lü, W. Lv, Q. Zhao, B. Shao, H. You, J. Mater. Chem. C 2, 90 (2014)

X. Zhang, L. Zhou, Q. Pang, M. Gong, RSC Adv. 5, 54622 (2015)

S. Singh, S.P. Khatkar, V.B. Taxak, J Mater Sci: Mater Electron 24, 4677 (2013)

J. Dalal, M. Dalal, S. Devi, R. Devi, A. Hooda, A. Khatkar, V.B. Taxak, S.P. Khatkar, J. Lumin. 210, 293 (2019)

M. Dalal, V.B. Taxak, J. Dalal, A. Khatkar, S. Chahar, R. Devi, S.P. Khatkar, J. Alloys Compd. 698, 662 (2017)

S. Chahar, R. Devi, M. Dalal, P. Boora, V.B. Taxak, S.P. Khatkar, J. Lumin. 194, 271 (2018)

L. Yi, X.Q. Liu, L. Li, X.M. Chen, Int. J. Appl. Ceram. Technol. 10(S1), E177 (2013)

L. Yi, X.Q. Liu, X.M. Chen, Int. J. Appl. Ceram. Technol. 12(S3), E33 (2015)

I. Zvereva, Y. Smirnov, V. Gusarov, V. Popova, J. Choisnet, Solid State Sci. 5, 343 (2003)

S. Devi, V.B. Taxak, S. Chahar, M. Dalal, J. Dalal, A. Hooda, A. Khatkar, R.K. Malik, S.P. Khatkar, Ceram. Int. 45, 15571 (2019)

M. Dalal, V.B. Taxak, X.X.X. Sheetal, D. Kumar, S.P. Khatkar, Mater. Chem. Phys. 149, 713 (2015)

S.T. Aruna, A.S. Mukasyan, Curr. Opin. Solid State Mater. Sci. 12, 44 (2008)

K. Patil, Curr. Opin. Solid State Mater. Sci. 2, 158 (1997)

A.C. Larson, R.B.V. Dreele, Los Alamos National Laboratory Report LAUR 86, 1 (2000)

B.H. Toby, R.B.V. Dreele, J. Appl. Crystallogr. 46, 544 (2013)

B.R. Kumar, B. Hymavathi, J. Asian Ceram. Soc. 5, 94 (2017)

Z. Xia, J. Zhou, Z. Mao, J. Mater. Chem. C 1, 5917 (2013)

A. Hooda, S.P. Khatkar, A. Khatkar, M. Kumar, M. Dalal, V.B. Taxak, J. Mater Sci: Mater Electron 30, 1297 (2018)

F. Davar, A. Hassankhani, M.R.L. Estarki, Ceram. Int. 39, 2933 (2013)

X. Wang, C. Liu, T. Yu, X. Yan, Phys. Chem. Chem. Phys. 16, 13440 (2014)

Y. Liu, G. Liu, J. Wang, X. Dong, W. Yu, New J. Chem. 39, 8282 (2015)

P. Kubelka, J. Opt. Soc. Am. 38, 448 (1948)

J. Chen, Y. Liu, L. Mei, H. Liu, M. Fang, Z. Huang, Sci. Rep. 5, 9673 (2015)

V.B. Pawade, A. Zanwar, R.P. Birmod, S.J. Dhoble, L.F. Koao, J. Mater Sci: Mater Electron (2017). https://doi.org/10.1007/s10854-017-7536-8

B.P. Maheshwary, R.A. Singh, J. Singh, Chem. 39, 4494 (2015)

S. Chahar, M. Dalal, R. Devi, A. Khatkar, P. Boora, V.B. Taxak, S.P. Khatkar, J. Lumin. 199, 442 (2018)

A. Lakshmanan, R.S. Bhaskar, P.C. Thomas, R.S. Kumar, V.S. Kumar, M.T. Jose, Mater. Lett. 64, 1809 (2010)

E. Pavitra, G.S.R. Raju, J.Y. Park, Y.H. Ko, J.S. Yu, J. Alloys Compd. 553, 291 (2013)

P. Niu, X. Liu, Y. Wang, W. Zhao, J. Mater. Sci: Mater. Electron. 29, 124 (2017)

B. Tian, B. Chen, Y. Tian, X. Li, J. Zhang, J. Sun, H. Zhong, L. Cheng, S. Fu, H. Zhong, Y. Wang, X. Zhang, H. Xia, R. Hua, J. Mater. Chem. C 1, 2338 (2013)

G. Blasse, Phys. Lett. A 28, 444 (1968)

D.L. Dexter, J. Chem. Phys. 21, 836 (1953)

Y. Tian, B. Chen, B. Tian, R. Hua, J. Sun, L. Cheng, H. Zhong, X. Li, J. Zhang, Y. Zheng, T. Yu, L. Huang, Q. Meng, J. Alloys Compd. 509, 6096 (2011)

F. Auzel, J. Lumin. 100, 125 (2002)

M.H.V. Werts, R.T.F. Jukes, J.W. Verhoeven, Phys. Chem. Chem. Phys. 4, 1542 (2002)

B.R. Judd, Phys. Rev. 127, 750 (1962)

G.S. Ofelt, J. Chem. Phys. 37, 511 (1962)

C.S. McCamy, Color Res. Appl. 17, 142 (1992)

P. Du, L. Wang, J.S. Yu, J. Alloy. Compd. 673, 426 (2016)

M. Venkataravanappa, H. Nagabhushana, G.P. Darshan, B.D. Prasad, G.R. Vijayakumar, H.B. Premkumar, Udayabhanu. Ultrason. Sonochem. 33, 226 (2016)

Acknowledgements

One of the authors, Sushma Devi gratefully acknowledges the financial support in the form of senior research fellowship (SRF) from University Grant Commission (UGC), New Delhi, India (Award No. 2061410088).

Author information

Authors and Affiliations

Contributions

SD: Conceptualization, Methodology, Software, Writing – original draft. VBT: Software validation, Visualization, Writing – Review & Editing. DS: Formal analysis, Validation, Conceptualization. AH: Methodology, Formal analysis, Software. SPK: Project administration, Supervision.

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they have no conflict of interest.

Ethical approval

All applicable international, national and institutional guidelines for the care are followed.

Data availability

The authors declare that the data that support the findings of this study are available on request from the corresponding author.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

About this article

Cite this article

Devi, S., Taxak, V.B., Sangwan, D. et al. Design of color tunable SrLa2Al2O7:Eu3+ perovskite type nanophosphor for near-ultraviolet excited white LEDs. J Mater Sci: Mater Electron 33, 5983–5996 (2022). https://doi.org/10.1007/s10854-022-07778-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-07778-w