Abstract

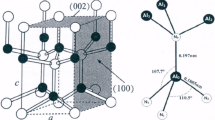

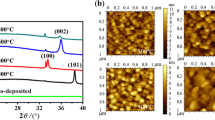

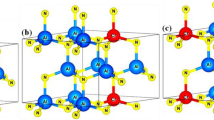

Aluminium nitride-based MEMS resonators are one of the interesting recent research topics for its tremendous potential in a wide variety of applications. This paper focuses on the detrimental effect of residual stress on the AlN-based MEMS resonator design for acoustic applications. The residual stress in the sputtered c-axis (< 001 >) preferred oriented AlN layers on Si (111) substrates are studied as a function of layer thickness. The films exhibited compressive residual stresses at different thickness values: − 1050 MPa (700 nm), − 500 MPa (900 nm), and − 230 MPa (1200 nm) with ± 25 MPa accuracy. A mushroom-shaped AlN-based piezoelectric MEMS resonator structure has been designed for the different AlN layer thicknesses. The effect of the residual stresses on the mode shapes, resonant frequencies, and quality factor (Q) of the resonator structures are studied. The resonant frequency of the structures are altered from 235 kHz, 280 kHz, and 344 kHz to 65 kHz, 75 kHz and 371 kHz due to the residual stress of − 1050 MPa (thickness: 700 nm), − 500 MPa (thickness: 900 nm) and − 230 MPa (thickness: 1200 nm), respectively. At no residual stress, the quality factors of the resonator structures are 248, 227, 241 corresponding to the 700 nm, 900 nm, and 1200-nm-thick AlN layers, respectively. The presence of the residual stress reduced the Q values from 248 (thickness: 700 nm), 227 (thickness: 900 nm), 241 (thickness: 1200 nm) to 28, 53, and 261, respectively.

Similar content being viewed by others

Data availability

The data that support the findings of this study will be available on request from the corresponding author.

References

M.Y. Chao, A. Ali, S. Ghosh, J. Lee, An aluminum nitride on silicon resonant MEMS accelerometer operating in ambient pressure, in IEEE 19th International Conference on Solid-State Sensors, Actuators, Microsystems (TRANSDUCERS) (2017), p. 607

Y.Q. Fu, J.K. Luo, N.T. Nguyen, A.J. Walton, A.J. Flewitt, X.T. Zu, Y. Li, G. McHale, A. Matthews, E. Iborra, H. Du, W.I. Milne, Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 89, 31 (2017)

N. Jaber, A. Ramini, Q. Hennawi, M.I. Younis, Wideband MEMS resonator using multifrequency excitation. Sens. Actuator A 242, 140 (2016)

H. Lei, Q. Wen, F. Yu, D. Li, AlN film based piezoelectric large-aperture MEMS scanning micromirror integrated with angle sensors. J. Micromech. Microeng. 28, 115012 (2018)

X. Li, Y. Huang, Y. Du, Z. Li, F. Bao, J. Bao, Study of a 10 MHz MEMS oscillator with a TPoS resonator. Sens. Actuator A 258, 59 (2017)

H.P. Loebl, M. Klee, O. Wunnicke, R. Kiewitt, R. Dekker, E.V. Pelt, Piezoelectric AlN and PZT films for micro-electronic applications. IEEE Ultrason. Symp. 2, 1031 (1999)

M. Marzencki, Y. Ammar, S. Basrour, Integrated power harvesting system including a MEMS generator and a power management circuit. Sens. Actuators A 145–146, 363 (2008)

Y. Parmar, N. Gupta, V. Gond, S.S. Lamba, S.R.K. Vanjari, S. Dutta, K.K. Jain, D.K. Bhattacharya, Microsyst. Technol. 26(3), 701 (2020)

G. Pfusterschmied, J. Toledo, M. Kucera, W. Steindl, S. Zemann, V.R. Díez, M. Schneider, A. Bittner, J.L.S. Rojas, U. Schmid, Potential of piezoelectric MEMS resonators for grape must fermentation monitoring. Micromachines 8, 200 (2017)

G. Pfusterschmied, F. Patocka, C. Weinmann, M. Schneider, D. Platz, U. Schmid, Responsivity and sensitivity of piezoelectric MEMS resonators athigher order modes in liquids. Sens. Actuator A 295, 84 (2019)

S. Dutta, S.M. Imran, R. Pal, R.K. Bhan, Diffusion induced residual stress in comb-type microaccelerometer structure. J. Mater. Sci. 25(9), 3828 (2014)

S. Dutta, A. Panchal, M. Kumar, R. Pal, R.K. Bhan, Effect of residual stress on modal patterns of MEMS vibratory gyroscope. AIP Conf. Proc. 1724, 020103 (2016)

S. Dutta, P. Saxena, A. Panchal, R. Pal, K.K. Jain, D.K. Bhattacharya, Effect of vacuum packaging on bandwidth of push–pull type capacitive accelerometer structure. Microsyst. Technol. 24, 4855 (2018)

N. Gupta, S. Dutta, A. Panchal, I. Yadav, S. Kumar, Y. Parmar, S.R.K. Vanjari, K.K. Jain, D.K. Bhattacharya, Design and fabrication of SOI technology-based MEMS differential capacitive accelerometer structure. J. Mater. Sci. 30(16), 15705 (2019)

N. Gupta, A. Pandey, S.R.K. Vanjari, S. Dutta, Influence of residual stress on performance of AlN thin film based piezoelectric MEMS accelerometer structure. Microsyst. Technol. 25, 3959–3967 (2019). https://doi.org/10.1007/s00542-019-04334-1

B. Kim, R.H. Olsson, K.E. Wojciechowski, AlN microresonator-based filters with multiple bandwidths at low intermediate frequencies. J. Microelectromech. Syst. 22, 949–961 (2013)

A.L. Gesing, F.D.P. Alves, S. Paul, J.A. Cordioli, On the design of a MEMS piezoelectric accelerometer coupled to the middle ear as an implantable sensor for hearing devices. Sci. Rep. 8, 3920 (2018)

M. Mehrpouya, H.C. Bidsorkhi, MEMS applications of NiTi based shape memory alloys: a review. Micro Nanosyst. 8(2), 79 (2016)

U. Sharma, M. Kumar, R. Sharma, T. Saha, K.K. Jain, S. Dutta, E.K. Sharma, Fabrication process induced changes in scattering parameters of meander type RFMEMS shunt switch. Microsyst. Technol. 23(12), 5561 (2017)

U. Sharma, S. Dutta, E.K. Sharma, Improved broadband (75–110 GHz) radio frequency characteristics of MEMS shunt switches on quartz substrate. Microsyst. Technol. 25(3), 977 (2019)

H.C. Nathanson, W.E. Newell, R.A. Wickstrom, J.R. Davis, The resonant gate transistor. IEEE Trans. ED 14(3), 117 (1967)

N. Alcheikh, S.A. Tella, M.I. Younis, An investigation into the mechanical behavior of multi-input and multi-output MEMS resonators. Sens. Actuators A 280, 309 (2018)

F.H. Bao, J.F. Bao, J.E.Y. Lee, L.L. Bao, M.A. Khana, X. Zhoua, Q.D. Wu, T. Zhanga, X.S. Zhang, Quality factor improvement of piezoelectric MEMS resonator by the conjunction of frame structure and phononic crystals. Sens. Actuators A 297, 111541 (2019)

F.H. Bao, Q.D. Wu, X. Zhou, T. Wua, X.Y. Li, J.F. Bao, High-Q multi-frequency ring-shaped piezoelectric MEMS resonators. Microelectronics 98, 104733 (2020)

S. Ilyas, M.I. Younis, Resonator-based M/NEMS logic devices: review of recent advances. Sens. Actuators A 302, 111821 (2020)

R.H. Olsson, K.E. Wojciechowski, M.S. Baker, M.R. Tuck, J.G. Fleming, Post-CMOS-compatible aluminum nitride resonant MEMS accelerometers. IEEE MEMS 18(3), 671 (2009)

N. Sepulveda, D. Aslam, J.P. Sullivan, Polycrystalline diamond MEMS resonator technology for sensor applications. Diam. Relat. Mater. 15, 398 (2006)

J. Toledo, V.R. Díez, M. Bertke, H.S. Wasisto, E. Peiner, J.L.S. Rojas, Piezoelectric MEMS resonators for cigarette particle detection. Micromachines 10, 145 (2019)

C. Zhao, M.H. Montaseri, G.S. Wood, S.H. Pu, A.A. Seshiad, M. Krafte, A review on coupled MEMS resonators for sensing applications utilizing mode localization. Sens. Actuators A 249, 93 (2016)

S.C. Ur, E.S. Kim, S.H. Yi, The Effects of residual stresses in the composite diaphragm on the performance of piezoelectric microspeakers. Electron Mater. Lett. 9, 119 (2013)

J.C. Yu, C.B. Lan, System modeling of microaccelerometer using piezoelectric thin films. Sens. Actuators A 88, 178 (2001)

H.G. Yu, L. Zou, K. Deng, R. Wolf, S. Tadigadapa, S.T. McKinstry, Lead zirconate titanate MEMS accelerometer using interdigitated electrodes. Sens. Actuators A 107, 26 (2003)

E. Iborra, J. Olivares, M. Clement, L. Vergara, A.S. Hervas, J. Sangrador, Piezoelectric properties and residual stress of sputtered AlN thin films for MEMS applications. Sens. Actuators A 115, 501 (2004)

J. Yang, M. Zhang, Y. He, Y. Su, G. Han, C. Si, J. Ning, F. Yang, X. Wang, A resonant z-axis aluminum nitride thin-film piezoelectric MEMS accelerometer. Micromachines 10, 589 (2019)

A. Pandey, R. Prakash, S. Dutta, S. Dalal, R. Raman, A.K. Kapoor, D. Kaur, Growth and evaluation of residual stress of AlN films on Si (100) wafers. Mater. Sci. Semicond. Process. 52, 16–23 (2016)

S. Pawar, K. Singh, S. Sharma, A. Pandey, S. Dutta, D. Kaur, Growth assessment and scrutinize dielectric reliability of c-axis oriented insulating AlN thin films in MIM structures for microelectronics applications. Mater. Chem. Phys. 219, 74 (2018)

A. Pandey, R. Prakash, S. Dutta, S. Dalal, A. Kumar, A.K. Kapoor, D. Kaur, Growth and morphological evolution of c-axis oriented AlN films on Si (100) substrates by DC sputtering technique. AIP Conf. Proc. 1953, 100028 (2018)

J.X. Zhang, J.X. Zhang, H. Cheng, Y.Z. Chen, A. Uddin, S. Yuan, S.J. Geng, S. Zhang, Growth of AlN films on Si (100) and Si (111) substrates by reactive magnetron sputtering. Surf. Coat. Technol. 198, 68–73 (2005)

C. Caliendo, P. Imperaton, E. Cianci, Structural, morphological and acoustic properties of AlN thick films sputtered on Si(001) and Si(111) substrates at low temperature. Thin Solid Films 441, 32–37 (2003)

H. Altuntas, C.O. Akgun, I. Donmez, N. Biyikli, Current transport mechanisms in plasma-enhanced atomic layer deposited AlN thin films. J. Appl. Phys. 117, 155101 (2015)

Y. Feng, H. Wei, S. Yang, Z. Chen, L. Wang, S. Kong, G. Zhao, X. Liu, Competitive growth mechanisms of AlN on Si (111) by MOVPE. Sci. Rep. 4, 06416 (2014)

S. Tanaka, R.S. Kern, J. Bentley, R.F. Davis, Defect formation during hetero-epitaxial growth of aluminum nitride thin films on 6h-silicon carbide by gas-source molecular beam epitaxy. Jpn. J. Appl. Phys. 35, 1641 (1996)

K. Antonova, L. Duta, A. Szekeres, G.E. Stan, I.N. Mihailescu, M. Gartner, Influence of laser pulse frequency on the microstructure of aluminum nitride thin films synthesized by pulsed laser deposition. Appl. Surf. Sci. 394, 197 (2017)

R.E. Sah, L. Kirste, M. Baeumler, P. Hiesinger, V. Cimalla, V. Lebedev, H. Baumann, H.E. Zschau, Residual stress stability in fiber textured stoichiometric AlN film grown using rf magnetron sputtering. J. Vac. Sci. Technol. A 28, 394 (2010)

A. Pandey, S. Dutta, R. Prakash, R. Raman, A.K. Kapoor, D. Kaur, Growth and comparison of residual stress of AlN films on silicon (100), (110) and (111) substrates. J. Electron. Mater. 47, 1405–1413 (2018)

Y. Ye, Z. Yi, M. Qin, Q. Huang, DRIE trenches and full-bridges design for sensitivity improvement of MEMS silicon thermal wind sensor, in IEEE 30th IntConf MEMS (2017), p. 985

C.H. Ma, J.H. Huang, H. Chen, Residual stress measurement in textured thin film by grazing-incidence X-ray diffraction. Thin Solid Films 418, 73–78 (2002)

K. Kim, W.R.L. Lambrecht, B. Segall, Elastic constants and related properties of tetrahedrally bonded BN, AlN, GaN, and InN. Phys. Rev. B 53, 16310 (1996)

R. Ruh, A. Zangvil, J. Barlowe, Elastic properties of SiC, AlN, and their solid-solution and particulate composites. Am. Ceram. Soc. Bull. 64, 1368–1373 (1985)

M. Bao, Analysis and Design Principles of MEMS Devices (Elsevier Science Publication, Amsterdam, 2005).

A.W. Leissa, The historical bases of the Rayleigh and Ritz methods. J. Sound Vib. 287(4–5), 961–978 (2005)

Acknowledgements

The authors would like to thank Dr. Seema Vinayak, Director, Solid State Physics Laboratory (DRDO) for her guidance and for the permission to publish this work. We would like to acknowledge Mr. Sandeep Dalal and Mr. Anand Kumar for the XRD and FESEM measurements. Help from other colleagues is also acknowledged.

Funding

There is not any founding for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

I assure that this manuscript has not been submitted elsewhere for publication and all authors have been informed. There is not any conflict of interest regarding this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pandey, A., Dutta, S., Gupta, N. et al. Evaluation of residual stress of c oriented AlN/Si (111) and its impact on mushroom-shaped piezoelectric resonator. J Mater Sci: Mater Electron 32, 13499–13510 (2021). https://doi.org/10.1007/s10854-021-05927-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05927-1