Abstract

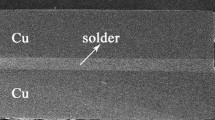

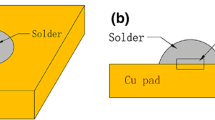

The properties of the intermetallic compounds (IMCs) formed at the interface between the solder and the Under Bump Metallization (UBM) are crucial for the reliability of solder joints. Cobalt (Co) is a potential candidate for UBM since it can act as a diffusion barrier and hence can improve the performance of tin-based solder joints. Growth kinetics, mechanism of formation, and properties of IMC in the copper-tin-cobalt (Cu–Sn–Co) system that is encountered with Co UBM are presented in this paper. Cu–Sn–Co systems were prepared by electrodeposition of Cu, Sn and Co multilayers on Cu substrates followed by reflow at 250 °C for varying durations (1–30 min). Microscopic observation revealed the formation of defect-free (Co,Cu)Sn3, crack-containing (Cu,Co)6Sn5 and thin irregular Cu3Sn IMCs after 1 min reflow. As reflow duration increased, (Co,Cu)Sn3 and Cu3Sn grew at the expense of (Cu, Co)6Sn5. The consumption of the entire Sn layer after 1 min and the calculated effective interdiffusion coefficient of (Co,Cu)Sn3 suggested that the growth of (Co,Cu)Sn3 after 1 min is controlled by solid-state diffusion of Sn. The average Young’s Modulus values of (Co,Cu)Sn3, (Cu,Co)6Sn5 and Cu3Sn are 99.5 ± 3.2 GPa, 110.8 ± 7.3 GPa and 109.4 ± 0.3 GPa, respectively, while the nanohardness values are 4.15 ± 0.34 GPa, 6.74 ± 0.62 GPa and 4.96 ± 1.09 GPa, respectively. Increasing the reflow duration in the Cu–Sn–Co system is expected to improve the performance of the solder joint, through the replacement of the crack-containing (Cu,Co)6Sn5 by the defect-free (Co,Cu)Sn3.

Similar content being viewed by others

References

W.W. Lee, L.T. Nguyen, G.S. Selvaduray, Microelectron. Reliab. 40, 2 (2000)

K.J. Puttlitz, K.A. Stalter, Handbook of Lead-Free Solder Technology for Microelectronic Assemblies (Marcel Dekker Inc, New York, 2004), pp. 1–12

R. Labie, W. Ruythooren, J.V. Humbeeck, Intermetallics 15, 3 (2007)

G. Vakanas, O. Minho, B. Dimcic, K. Vanstreels, B. Vandecasteele, I.D. Preter, J. Derakhshandeh, K. Rebibis, M. Kajihara, I.D. Wolf, Microelectron. Eng. (2015). https://doi.org/10.1016/j.mee.2015.04.116

N. Odashima, M.O.M. Kajihara, J. Electron. Mater. 49, 2 (2020)

D. Kim, S. Nagao, C.T. Chen, N. Wakasugi, Y. Yamamoto, A. Suetake, T. Takemasa, T. Sugahara, K. Suganuma, IEEE Trans. Power Electron. 36, 5 (2021)

P. Zhang, S.B. Xue, J.H. Wang, Mater. Des. 192, 108726 (2020)

H. Vafaeenezhad, S.H. Seyedein, M.R. Aboutalebi, A.R. Eivani, O. Nikan, Eng. Failure Anal. 120, 87–95 (2021)

C.-H. Wang, C.-Y. Kuo, J. Mater. Sci. 46, 8 (2011)

Y. Goh, Y.S. Goh, E.L. Lee, M.T. Ong, A.S.M.A. Haseeb, J. Mater. Sci. 29, 7 (2018)

C.-C. Chen, Y.-T. Chan, Intermetallics 18, 4 (2010)

S.-W. Chen, Y.-K. Chen, H.-J. Wu, Y.-C. Huang, C.-M. Chen, J. Electron. Mater. 39, 11 (2010)

G. Humpston, J. Mater. Sci. 21, 6 (2010)

P. Limaye, B. Vandevelde, R. Labie, D. Vandepitte, B. Verlinden, IEEE Trans. Adv. Packag. 31, 1 (2008)

L. Magagnin, V. Sirtori, S. Seregni, A. Origo, P.L. Cavallotti, Electrochim. Acta 50, 23 (2005)

C.-H. Wang, S.-W. Chen, J. Mater. Res. 22, 12 (2007)

C.-H. Wang, S.-W. Chen, Intermetallics 16, 4 (2008)

C.-H. Wang, C.-Y. Kuo, S.-E. Huang, P.-Y. Li, Intermetallics 32, 57 (2013)

C.-H. Wang, C.-Y. Kuo, J. Electron. Mater. 39, 8 (2010)

V.A. Baheti, S.N. Appl, Science 1, 2 (2019)

F.-Y. Ouyang, G.-L. Hong, Y.-R. Hsu, S.-Y. Mao, W.-J. Liu, Microelectron. Reliab. 97, 16–23 (2019)

T.T. Kyaw, P. Tunthawiroon, K. Kanlayasiri, K. Yamanaka, A. Chiba, Intermetallics 125, 106875 (2020)

L. Hou, N. Moelans, J. Derakhshandeh, I. De Wolf, E. Beyne, Sci. Rep. 9, 1 (2019)

C.-H. Wang, C.-Y. Lin, J. Electron. Mater. 48, 7 (2019)

H.-C. Pan, T.-E. Hsieh, J. Electrochem. Soc. 158, 11 (2011)

T. Gupta, Copper Interconnect Technology (Springer, New York, 2010), pp. 16–50

X. Hu, Y. Qiu, X. Jiang, Y. Li, J. Mater. Sci. 29, 18 (2018)

K.N. Tu, Microelectron. Reliab. 51, 3 (2011)

J. Ke, Y. Gao, C. Kao, Y. Wang, Acta Mater. 113, 245–258 (2016)

C. Ho, R. Tsai, Y. Lin, C. Kao, J. Electron. Mater. 31, 6 (2002)

H.-S. Chun, J.-W. Yoon, S.-B. Jung, J. Alloys Compd. 439, 1–2 (2007)

K. Chan, Z. Zhong, K. Ong, Soldering Surf. Mount Technol. 15, 2 (2003)

Y.-K. Chen, C.-M. Hsu, S.-W. Chen, C.-M. Chen, Y.-C. Huang, Metall. Mater. Trans. A 43, 10 (2012)

C. Du, X. Wang, S. Tian, J. Mater. Sci. 29, 1 (2018)

A.S.M.A. Haseeb, T.S. Leng, Intermetallics 19, 5 (2011)

F. Gao, F. Cheng, H. Nishikawa, T. Takemoto, Mater. Lett. 62, 15 (2008)

C.-H. Wang, C.-Y. Kuo, Y.-B. Guo, JOM 71, 9 (2019)

P.Y. Chia, A.S.M.A. Haseeb, J. Mater. Sci. 26, 1 (2015)

Y. Goh, A.S.M.A. Haseeb, M.F.M. Sabri, Soldering Surf. Mount Technol. 25, 2 (2013)

H.-T. Lee, M.-H. Chen, H.-M. Jao, T.-L. Liao, Mater. Sci. Eng. A 358, 1–2 (2003)

S. Tian, J. Zhou, F. Xue, R. Cao, F. Wang, J. Mater. Sci. 29, 19 (2018)

Z. Mei, A.J. Sunwoo, J.W. Morris, Metall. Trans. A 23, 3 (1992)

R.A. Gagliano, M.E. Fine, J. Electron. Mater. 32, 12 (2003)

A. Paul, C. Ghosh, W. Boettinger, Metall. Mater. Trans. A 42, 4 (2011)

W. Zhu, J. Wang, H. Liu, Z. Jin, W. Gong, Mater. Sci. Eng. A 456, 1–2 (2007)

P. Shang, Z. Liu, X. Pang, D. Li, J. Shang, Acta Mater. 57, 16 (2009)

J. Gong, C. Liu, P.P. Conway, V.V. Silberschmidt, Scr. Mater. 60, 5 (2009)

E.L. Lee, Y. Goh, A.S.M.A. Haseeb, J. Mater. Sci. 31, 6 (2020)

S. Kumar, C. Handwerker, M. Dayananda, J. Phase Equilib. Diffus. 32, 309–319 (2011)

C.-H. Wang, C.-Y. Kuo, Mater. Chem. Phys. 130, 1 (2011)

M.S. Park, R. Arróyave, J. Electron. Mater. 39, 4900–4910 (2010)

C.S. Tan, R.J. Gutmann, L.R. Reif, Wafer Level 3-D ICs Process Technology (Springer, New York, 2009).

T. Laurila, V. Vuorinen, J.K. Kivilahti, Mater. Sci. Eng. R 49, 1 (2005)

G.-Y. Jang, J.-W. Lee, J.-G. Duh, J. Electron. Mater. 33, 10 (2004)

P.-F. Yang, Y.-S. Lai, S.-R. Jian, J. Chen, R.-S. Chen, Mater. Sci. Eng. A 485, 1–2 (2008)

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

All authors contributed to the conceptualization and design of this study. Methodology was designed by PYC and YG. Preparation of materials, data collection and formal analysis were performed by YSG. The study was supervised by ASMAH. The first draft of the manuscript was written by YSG and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

This work declares no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Goh, Y.S., Goh, Y., Chia, P.Y. et al. Formation and nanomechanical properties of intermetallic compounds in electrodeposited Cu–Sn–Co multilayers. J Mater Sci: Mater Electron 32, 9490–9499 (2021). https://doi.org/10.1007/s10854-021-05612-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05612-3