Abstract

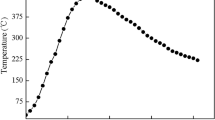

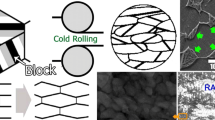

The growth mechanism of Cu6Sn5 intermetallic compound (IMC) at Sn/Cu interface reflowed under 250 °C, 275 °C, and 300 °C for a duration of 60 s and undergoing highly pressurized air action (HP), water cooling (WC), air cooling (AC) or furnace cooling (FC) in the aftermath has been outlined. In addition, synchrotron radiation imaging technique has been utilized to in situ observe interfacial Cu6Sn5 grains growth. It has been revealed that the morphologies of Cu6Sn5 grains under HP and AC are both scallop-like, whereas the samples processed with HP and FC bear plane structure and prismatic morphologies. These revelations indicate the secondary growth of Cu6Sn5 grains during the cooling stage as the significant determinant of the final IMC morphology. Thus, continuous growth on the rough surface (M1), spiral dislocation growth (M2), and 2D nucleation and growth (M3), have been proposed to explain the observed morphologies of interfacial Cu6Sn5 grains. M1 has been recognized as the principal mechanism responsible for IMC morphology undergoing water cooling, whereas combination of M1 and M2 decide the morphological feature of interface resulting from air cooling. Finally, all of the three mechanisms (M1, M2 and M3) account for the IMC morphology corresponding to furnace cooling. As all of these three growth mechanisms are affected by the degree of supercooling (ΔT), it is inferred that the ΔT can influence the secondary nucleation of IMC at the cooling stage. With the fact that the homogeneous nucleation occurs at larger ΔT, and the relative favorability for heterogeneous nucleation at smaller ΔT; the growth mechanisms can be mapped with the degree of undercooling. Consequently, the IMC growth mechanisms proposed and their association with ΔT, can be used to obtain an appropriate thickness and morphology of IMC to improve the reliability of solder joints.

Similar content being viewed by others

References

F. Sun, Z. Yin, J. Mater. Sci.: Mater. Electron. 30, 18878–18884 (2019)

O.Y. Liashenko, F. Hodaj, J. Mater. Sci.: Mater. Electron. 30, 1838–1849 (2019)

Z. Zhu, H. Ma, S. Shang, H. Ma, Y. Wang, X. Li, J. Mater. Sci.: Mater. Electron. 30, 15964–15971 (2019)

K. Chen, D. Wang, H. Ling, A. Hu, M. Li, W. Zhang, L. Cao, J. Mater. Sci.: Mater. Electron. 29, 19484–19490 (2018)

H.M. Kim, K.N. Tu, Phys. Rev. B 53(23), 16027–16034 (1996)

Y.G. Lee, J.G. Duh, J. Mater. Sci. 33, 5569–5572 (1998)

K.H. Prakash, T. Sritharan, Acta Mater. 49, 2481–2489 (2001)

Y.M. Leong, A.S.M.A. Haseeb, H. Nishikawa, O. Mokhtari, J. Mater. Sci.: Mater. Electron. 30, 11914–11922 (2019)

K. Zeng, K.N. Tu, Mater. Sci. Eng. R 38, 55–105 (2002)

J.M. Song, J.J. Lin, C.F. Huang, H.Y. Chuang, Mater. Sci. Eng. A 466, 9–17 (2007)

M. Yang, M. Li, L. Wang, Y. Fu, J. Kim, J. Electron. Mater. 40, 176–188 (2001)

H.T. Lee, H.M. Chen, H.M. Jiao, T.L. Liao, Mater. Sci. Eng. A 358, 134–141 (2003)

A. Kumar Gain, L. Zhang, Materialia 3, 64–73 (2018)

D. Zhao, K. Zhang, N. Ma, S. Li, C. Yin, F. Huo, Materials 13, 831 (2020)

T.T.D. Afolabi, M.A.A. Hanim, M. Norkhairunnisa, H.M. Yusoff, M.T. Suraya, J. Alloys Compd. 649, 368–374 (2015)

X. Hu, T. Xu, L.M. Keer, Y. Li, X. Jiang, Mater. Sci. Eng. A 673, 167–177 (2016)

Y. Tang, S.M. Luo, K.Q. Wang, G.Y. Li, J. Alloys Compd. 684, 299–309 (2016)

H.L.J. Pang, K.H. Tan, X.Q. Shi, Z.P. Wang, Mater. Sci. Eng. A 307, 42–50 (2001)

R. Mayappan, I. Yahya, N.A.A. Ghani, H.A. Hamid, J. Mater. Sci.: Mater. Electron. 25, 2913–2922 (2014)

M. Schafer, R.A. Fournelle, J. Liang, J. Electron. Mater. 27, 1167–1176 (1998)

B.F. Guo, H.T. Ma, C.R. Jiang, Y.P. Wang, A. Kunwar, N. Zhao, M.L. Huang, J. Mater. Sci.: Mater. Electron. 28, 5398–5406 (2017)

F.C. Frank, Farad. Soc. Discuss. 5, 48–54 (1949)

N.F. Mott, Nature 165, 295–297 (1950)

A.R. Verma, Nature 167, 939 (1951)

I.M. Dawson, Nature 167, 476 (1951)

K.A. Jackson, J. Cryst. Growth 5, 13–18 (1969)

D.E. Temkin, Crystallization Process (Consultants Bureau, New York, 1966), p. 15

J.W. Cahn, Acta Met. 8, 554–562 (1960)

P. Harman, Crystal Growth: An Introduction (North-Holland Publishing Company, Amsterdam, 1973), p. 10

B.F. Guo, A. Kunwar, C. Jiang, N. Zhao, J. Sun, J. Chen, Y. Wang, M. Huang, H. Ma, J. Mater. Sci.: Mater. Electron. 29, 589–601 (2018)

L. Qu, N. Zhao, H.J. Zhao, M.L. Huang, H.T. Ma, Scr. Mater. 72–73, 43–46 (2014)

M. Yang, M. Li, C. Wang, Intermetallic 25, 86–94 (2012)

Z.H. Zhang, H.J. Cao, H.F. Yang, M.Y. Li, Y.X. Yu, J. Electron. Mater. 45, 5985–5986 (2016)

M. Yang, Y. Cao, S. Joo, H.T. Chen, X. Ma, M.Y. Li, J. Alloys. Compd. 582, 688–695 (2014)

M.L. Huang, T. Loeher, A. Ostmann, H. Reichl, Appl. Phys. Lett. 86, 181908 (2005)

A.M. Gusak, K.N. Tu, Phys. Rev. B 66(11), 115403 (2002)

Z.E. Liu, Materials Science Foundation, 3rd edn. (Northwestern Polytechnical University Press, Xi’an, 2007), pp. 92–93

M. Yang, M.Y. Li, L. Wang, Y.G. Fu, J. Kim, L. Weng, Mater. Lett. 65, 1506–1509 (2011)

M. Mueller, I. Panchenko, S. Wiese, K. Wolter, IEEE Trans. Compd. Pack. Manuf. Technol. 10(1), 18–29 (2020)

J.W. Xian, S.A. Belyakov, M. Ollivier, K. Nogita, H. Yasuda, C.M. Gourlay, Acta Mater. 126, 540–551 (2017)

J.W. Mullin, Crystallization (Butterworth-Heinemann, Oxford, 2001), pp. 124–130

R.A. Laudise, The Growth of Single Crystals (Prentice Hall, Englewood Cliffs, 1970), pp. 349–350

J.C. Brice, J. Cryst. Growth 6, 205 (1970)

P. Zou, H.J. Kang, F. Cao, Y.N. Fu, T.Q. Xiao, T.M. Wang, J. Mater. Sci: Mater. Electron. 25, 4538 (2014)

M.S. Park, S.L. Gibbons, R. Arroyave, J. Electron. Mater. 43, 2510 (2014)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51871040), Department of Education Science and Technology Research Youth Project of Jiangxi Provincial (Grant Nos. GJJ201631 and GJJ180860), Student Innovation and Entrepreneurship Training Program of Yichun University (Grant Nos. 202010417079) and BL13W1 beam line of The Shanghai Synchrotron Radiation Facility (SSRF), China.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, B., Ma, H., Kunwar, A. et al. Effect of the degree of supercooling on growth mechanism of Cu6Sn5 in pure Sn/Cu solder joint. J Mater Sci: Mater Electron 32, 7528–7540 (2021). https://doi.org/10.1007/s10854-021-05467-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05467-8