Abstract

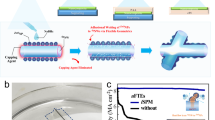

All-solution-processed multilayer ZnO/Ag NWs/ZnO/PVP/PVA composite is introduced as a transparent conductive film (TCF) for optoelectronic applications. Unlike conventional film formation methods that impose high investment expenses, scalable spray coating is applied over the layers using a hand-made spray apparatus. The resulting TCF exhibits high transmittance (T, 86% at 550 nm) and low sheet resistance (Rs, 6 Ω/sq), which is comparable to the sputtered counterparts. The bending test demonstrates the flexibility of the multilayer TCF with no noticeable increase in Rs, even after 1500 bending iterations. Moreover, chemical stability test (exposure to a corrosive agent) and adhesion examination confirm the capability of the fabricated TCF. Furthermore, the electrode is also thermally stable in heat up to 280 °C and is resistant against oxidation, as Rs remains almost unchanged after keeping the electrode in normal atmospheric condition for 200 days. The all-solution-processed electrode demonstrates desirable performance as a transparent electrode and potential to be applied in different optoelectronic and photovoltaic devices.

Similar content being viewed by others

References

J.M. Kim, S. Kim, D.H. Shin, S.W. Seo, H.S. Lee, J.H. Kim, C.W. Jang, S.S. Kang, S. Choi, G.Y. Kwak, K.J. Kim, H. Lee, H. Lee, Si-quantum-dot heterojunction solar cells with 16.2% efficiency achieved by employing doped-graphene transparent conductive electrodes. Nano Energy 43, 124–129 (2018)

T. Mochizuki, Y. Takigami, T. Kondo, H. Okuzaki, Fabrication of flexible transparent electrodes using PEDOT:PSS and application to resistive touch screen panels. J. Appl. Polym. Sci. 135(10), 45972 (2018)

W. Xu, M. Zhang, J. Peng, C. Dai, Chen, Light-extraction enhancement of GaN-based 395 nm flip-chip light-emitting diodes by an Al-doped ITO transparent conductive electrode. Opt. Lett. 43(11), 2684–2687 (2018)

A. Awad, M. Raaif, Optical and electrical performance of transparent conductive TiO2/Cu/TiO2 multilayers prepared by magnetron sputtering. J. Mater. Sci.: Mater. Electron. 29, 2815–2824 (2018)

S. Pang, Y. Hernandez, X. Feng, K. Müllen, Graphene as transparent electrode material for organic electronics. Adv. Mater. 23(25), 2779–2795 (2011)

H. Sun, S. Zhao, W. Chen, J. Lin, Z. Wang, Y. Lin, G. Li, C. Liu, H. Wang, W. Jiang, H. Tao, S. Liu, N. Wang, Y. Cui, W. Ding, B. Han, The resistance temperature stability of ITO film strain gauge: detailed investigate the influence mechanism of (100) preferred orientation of ITO film. J. Mater. Sci: Mater. Electron. 30, 1600–1608 (2019)

X.Y. Zeng, Q.K. Zhang, R.M. Yu, C.Z. Lu, A new transparent conductor: silver nanowire film buried at the surface of a transparent polymer. Adv. Mater. 22(40), 4484–4488 (2010)

B. Yoo, Y. Kim, C.J. Han, M.S. Oh, J.W. Kim, Recyclable patterning of silver nanowire percolated network for fabrication of flexible transparent electrode. Appl. Surf. Sci. 429, 151–157 (2018)

D.Y. Choi, Y.S. Oh, D. Han, S. Yoo, H.J. Sung, S.S. Kim, Highly conductive, bendable, embedded ag nanoparticle wire arrays via convective self-assembly: Hybridization into ag nanowire transparent conductors. Adv. Funct. Mater. 25(25), 3888–3898 (2015)

H. Bae, Y. Kim, X. Lee, J. Xu, Y. Park, J. Zheng, T. Balakrishnan, H.R. Lei, Y.I. Kim, Y. Song, K.S. Kim, B. Kim, J. Özyilmaz, B.H. Ahn, S. Hong, Iijima, Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nature nanotech. 5, 574–578 (2010)

H.Z. Geng, K.K. Kim, K.P. So, Y.S. Lee, Y. Chang, Y.H. Lee, Effect of acid treatment on carbon nanotube-based flexible transparent conducting films. J. Am. Chem. Soc. 129(25), 7758–7759 (2007)

Y.H. Kim, C. Sachse, M.L. Machala, C. May, L. Müller-Meskamp, K. Leo, Highly conductive PEDOT:PSS electrode with optimized solvent and thermal post-treatment for ITO-free organic solar cells. Adv. Funct. Mater. 21(6), 1076–1081 (2011)

L. Li, T. Zhang, Y. Liu, C. Zhu, Flexible conductor fabrication via silver nanowire deposition on a polydopamine-modified pre-strained substrate. J. Mater. Sci: Mater. Electron. 27, 3193–3201 (2016)

M.M. Byranvand, F. Tajabadi, S. Mardi, N. Taghavinia, A.A. Zarandi, A. Dabirian, Controlled electrophoretic deposition of electrochemically exfoliated graphene sheets on Ag nanowires network. Micro Nano Lett. 14(4), 389–393 (2019)

J.H. Chang, K.M. Chiang, H.W. Kang, W.J. Chi, J.H. Chang, C. Wub, H.W. Lin, A solution-processed molybdenum oxide treated silver nanowire network: a highly conductive transparent conducting electrode with superior mechanical and hole injection properties. Nanoscale 7, 4572–4579 (2015)

Q. Sun, S.J. Lee, H. Kang, Y. Gim, H.S. Parkb, J.H. Cho, Positively-charged reduced graphene oxide as an adhesion promoter for preparing a highly-stable silver nanowire film. Nanoscale 7, 6798–6804 (2015)

S. Zhu, Y. Gao, B. Hu, J. Li, J. Su, Z. Fan, J. Zhou, Transferable self-welding silver nanowire network as high performance transparent flexible electrode. Nanotechnology 24(33), 335202 (2013)

K. Zilberberg, F. Gasse, R. Pagui, A. Polywka, A. Behrendt, S. Trost, R. Heiderhoff, P. Görrn, T. Riedl, Highly robust indium-free transparent conductive electrodes based on composites of silver nanowires and conductive metal oxides. Adv. Funct. Mater. 24(12), 1671–1678 (2014)

G. Ricciardulli, S. Yang, G.A.H. Wetzelaer, X. Feng, P.W.M. Blom, Hybrid silver nanowire and graphene-based solution-processed transparent electrode for organic optoelectronics. Adv. Funct. Mater. 28(14), 1706010 (2018)

J. Liu, M. Xu, J. Li, T. Zhang, X. Chu, F. Jin, Y. Zhai, K. Shi, D. Lu, Solution synthesis of Al:ZnO-AgNWs-Al:ZnO flexible transparent conductive film. J. Mater. Sci: Mater. Electron. 31, 4178–4183 (2020)

W. Gaynor, G.F. Burkhard, M.D. McGehee, P. Peumans, Smooth nanowire/polymer composite transparent electrodes. Adv. Mater. 23(26), 2905–2910 (2011)

S. De, T.M. Higgins, P.E. Lyons, E.M. Doherty, P.N. Nirmalraj, W.J. Balu, J.J. Boland, J.N. Coleman, Silver nanowire networks as flexible, transparent, conducting films: extremely high dc to optical conductivity ratios. ACS Nano 3(7), 1767–1774 (2009)

V. Balaprakash, P. Gowrisankar, S. Sudha, R. Rajkumar, Aluminum doped ZnO transparent conducting thin films prepared by sol-gel dip coating technique for solar cells and optoelectronic applications. Mater. Technol. 33(6), 414–420 (2018)

J. Rezek, P. Novák, J. Houška, A.D. Pajdarová, T. Kozák, High-rate reactive high-power impulse magnetron sputtering of transparent conductive Al-doped ZnO thin films prepared at ambient temperature. Thin Solid Films 679, 35–41 (2019)

M.J. Jiamprasertboo, S.C. Powell, R. Dixon, A.M. Quesada-Cabrera, Y. Alotaibi, A. Lu, S. Zhuang, T. Sathasivam, I.P. Siritanon, C.J. Parkin, Carmalt, photocatalytic and electrically conductive transparent Cl-doped ZnO thin films via aerosol-assisted chemical vapour deposition. J. Mater. Chem. A 6, 12682–12692 (2018)

M. Arefpour, M.A. Kashi, F.K. Barzoki, M. Noormohammadi, A. Ramazani, Electrodeposited metal nanowires as transparent conductive electrodes: their release conditions, electrical conductivity, optical transparency and chemical stability. Mater. Des. 157, 326–336 (2018)

P. Zhang, I. Wyman, J. Hu, S. Lin, Z. Zhong, Y. Tu, Z. Huang, Y. Wei, Silver nanowires: synthesis technologies, growth mechanism and multifunctional applications. Mater. Sci. Eng. B 223, 1–23 (2017)

Y. Zhang, J. Wang, P. Yang, Convenient synthesis of Ag nanowires with tunable length and morphology. Mater. Res. Bull. 48(2), 461–468 (2013)

A. Zarandi, A. Khosravi, M. Dehghani, N. Taghavinia, The role of mixed reaction promoters in polyol synthesis of high aspect ratio Ag nanowires for transparent conducting electrodes. J. Electron. Mater. (2020). https://doi.org/10.1007/s11664-020-08206-7

M. Wang, Y. Lian, X. Wang, PPV/PVA/ZnO nanocomposite prepared by complex precursor method and its photovoltaic application. Curr. Appl. Phys. 9, 189–194 (2009)

S.I. White, P.M. Vora, J.M. Kikkawa, K.I. Winey, Resistive switching in bulk silver nanowire-polystyrene composites. Adv. Funct. Mater. 21(2), 233–240 (2011)

M. Amjadi, A. Pichitpajongkit, S. Lee, S. Ryu, I. Park, Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite. ACS Nano 8(5), 5154–5163 (2014)

J. Hwang, Y. Shim, S. Yoon, S.H. Lee, S. Park, Influence of polyvinylpyrrolidone (PVP) capping layer on silver nanowire networks: theoretical and experimental studies. RSC Adv. 6, 30972–30977 (2016)

R. Al-Gaashani, S. Radiman, A.R. Daud, N. Tabet, Y. Al-Douri, XPS and optical studies of different morphologies of ZnO nanostructures prepared by microwave methods. Ceram. Int. 39(3), 2283–2292 (2013)

B. Han, K. Pei, Y. Huang, X. Zhang, Q. Rong, Q. Lin, Y. Guo, T. Sun, Ch Guo, D. Carnahan, M. Giersig, Y. Wang, J. Gao, Z. Ren, K. Kempa, Uniform self-forming metallic network as a high-performance transparent conductive electrode. Adv. Mater. 26(6), 873–877 (2014)

E.J. Lee, Y.H. Kim, D.K. Hwang, W.K. Choi, J.Y. Kim, Synthesis and optoelectronic characteristics of 20 nm diameter silver nanowires for highly transparent electrode films. RSC Adv. 6, 11702–11710 (2016)

Z. Yu, Q. Zhang, L. Li, Q. Chen, X. Niu, J. Liu, Q. Pei, Highly flexible silver nanowire electrodes for shape-memory polymer light-emitting diodes. Adv. Mater. 23(5), 664–668 (2011)

G.Y. Margulis, M.G. Christoforo, D. Lam, Z.M. Beiley, A.R. Bowring, C.D. Bailie, A. Salleo, M.D. McGehee, Spray deposition of silver nanowire electrodes for semitransparent solid-state dye-sensitized solar cells. Adv. Energy Mater. 3(12), 1657–1663 (2013)

D.S. Ghosh, T.L. Chen, V. Mkhitaryan, V. Pruneri, Ultrathin transparent conductive polyimide foil embedding silver nanowires. ACS Appl. Mater. Interface 6(23), 20943–20948 (2014)

L. Hu, H.S. Kim, J.Y. Lee, P. Peumans, Y. Cui, Scalable coating and properties of transparent, flexible, silver nanowire electrodes. ACS Nano 4(5), 2955–2963 (2010)

T. Akter, W.S. Kim, Reversibly stretchable transparent conductive coatings of spray-deposited silver nanowires. ACS App. Mater. Interface 4(4), 1855–1859 (2012)

K. Moon, J.I. Kim, H. Lee, K. Hur, W.C. Kim, H. Lee, 2D graphene oxide nanosheets as an adhesive over-coating layer for flexible transparent conductive electrodes. Sci Rep 3, 1112 (2013)

C. Mayousse, C. Celle, A. Fraczkiewicza, J.P. Simonato, Stability of silver nanowire based electrodes under environmental and electrical stresses. Nanoscale 7, 2107–2115 (2015)

S. Nam, M. Song, D.H. Kim, B. Cho, H.M. Lee, J.D. Kwon, S.G. Park, K.S. Nam, Y. Jeong, S.H. Kwon, Y.C. Park, S. Ho, J.W. Kang, S. Jo, C.S. Kim, Ultrasmooth, extremely deformable and shape recoverable Ag nanowire embedded transparent electrode. Sci Rep 4, 4788 (2014)

H. Hagendorfer, K. Lienau, S. Nishiwaki, C.M. Fella, L. Kranz, A.R. Uhl, D. Jaeger, L. Luo, C. Gretener, S. Buecheler, Y.E. Romanyuk, A.N. Tiwari, Highly transparent and conductive ZnO: Al thin films from a low temperature aqueous solution approach. Adv. Mater. 26(4), 632–636 (2014)

P.C. Hsu, H. Wu, T.J. Carney, M.T. McDowell, Y. Yang, E.C. Garnett, M. Li, L. Hu, Y. Cui, Passivation coating on electrospun copper nanofibers for stable transparent electrodes. ACS Nano 6(6), 5150–5156 (2012)

F.S.F. Morgenstern, D. Kabra, S. Massip, T.J.K. Brenner, P.E. Lyons, J.N. Coleman, R.H. Friend, Ag-nanowire films coated with ZnO nanoparticles as a transparent electrode for solar cells. Appl. Phys. Lett. 99, 183307 (2011)

B.E. Hardin, W. Gaynor, I.K. Ding, S.B. Rim, P. Peumans, M.D. McGehee, Laminating solution-processed silver nanowire mesh electrodes onto solid-state dye-sensitized solar cells. Org. Electron. 12(6), 875–879 (2011)

Y. Kim, J.H. Jeon, M.K. Kwon, Indium tin oxide-free transparent conductive electrode for GaN-based ultraviolet light-emitting diodes. ACS App. Mater. Interface 7(15), 7945–7950 (2015)

M.Y. Lin, W.C. Tu, T.J. Chen, W.F. Xu, L.J. Hsiao, W. Budiawan, S.L. Chen, C.W. Chu, P.K. Wei, Fabrication of flexible indium tin oxide-free polymer solar cells with silver nanowire transparent electrode. Jpn. Jn Appl. Phys. 57, 03DD01 (2018)

M.A. Kasry, G.J. Kuroda, G.S. Martyna, A. Tulevski, A. Bol, Chemical doping of large-area stacked graphene films for use as transparent, Conducting Electrodes. ACS Nano 4(7), 3839–3844 (2010)

J. Jeon, U. Yoon, C. Kim, R. Lee, A. Xiang, J. Shawky, J. Xi, H.M. Byeon, M. Lee, S. Choi, Y. Maruyama, Matsuo, high-performance solution-processed double-walled carbon nanotube transparent electrode for perovskite solar cells. Adv. Energy Mater. 9(27), 1901204 (2019)

T.M. Higgins, J.N. Coleman, Avoiding resistance limitations in high-performance transparent supercapacitor electrodes based on large-area, high-conductivity PEDOT:PSS films. ACS Appl. Mater. Interfaces 7(30), 16495–16506 (2015)

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

AAZ: Conceptualization, methodology, formal analysis, investigation, writing—original draft, and visualization. AK: validation, resources, and supervision. MD: conceptualization, methodology, and writing—review and editing. NT: validation, resources, writing—review and editing, supervision, and project administration.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Availability of data and material

Authors are ready to make the data available to editors and reviewers if requested.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amiri Zarandi, A., Khosravi, A., Dehghani, M. et al. All-spray multilayer transparent electrode based on Ag nanowires: improved adhesion and thermal/chemical stability. J Mater Sci: Mater Electron 31, 14078–14087 (2020). https://doi.org/10.1007/s10854-020-03962-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03962-y