Abstract

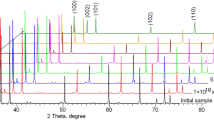

The work is devoted to the study of the effect of helium ion irradiation on the properties of ceramics based on Li2TiO3, which have great potential as a breeding blanket in the design of thermonuclear reactors. The choice of the type of ions and irradiation doses of 1–5 × 1017 ion/cm2 is due to the possibility of modeling the processes of defect formation as a result of the accumulation of helium in the structure of the surface layer of ceramics during their operation. As research methods, scanning electron microscopy, X-ray diffraction, and X-ray photoelectron spectroscopy were used and the dielectric properties were studied by impedance spectroscopy. It was found that at irradiation doses of 1–3 × 1017 ion/cm2, these ceramics have high radiation resistance to structural changes, while increasing the radiation dose above 5 × 1017 ion/cm2 leads to significant changes in the properties of ceramics, which are caused by partial degradation of the surface layer of ceramics in the process exposure. As a result of measuring the strength characteristics, it was determined that the greatest decrease in the hardness of the surface layer occurs at an irradiation dose of 5 × 1017 ion/cm2. In the course of studying the dielectric characteristics, it was found that the main changes are associated with a decrease in the dielectric constant, as well as an insignificant shift of the maximum towards high temperatures, which is due to an increase in the concentration of defects in the structure of ceramics arising during irradiation.

Similar content being viewed by others

References

M. Salavati-Niasari, Synthesis and characterization of host (nanodimensional pores of zeolite-Y)–guest [unsaturated 16-membered octaaza–macrocycle manganese (II), cobalt (II), nickel (II), copper (II), and zinc (II) complexes] nanocomposite materials. Chem. Lett. 34(10), 1444–1445 (2005)

F. Mohandes, F. Davar, M. Salavati-Niasari, Magnesium oxide nanocrystals via thermal decomposition of magnesium oxalate. J. Phys. Chem. Solids 71(12), 1623–1628 (2010)

M. Salavati-Niasari, M.R. Loghman-Estarki, F. Davar, Controllable synthesis of nanocrystalline CdS with different morphologies by hydrothermal process in the presence of thioglycolic acid. Chem. Eng. J. 145(2), 346–350 (2008)

M. Salavati-Niasari, D. Ghanbari, M.R. Loghman-Estarki, Star-shaped PbS nanocrystals prepared by hydrothermal process in the presence of thioglycolic acid. Polyhedron 35(1), 149–153 (2012)

S. Mortazavi-Derazkola, S. Zinatloo-Ajabshir, M. Salavati-Niasari, Novel simple solvent-less preparation, characterization and degradation of the cationic dye over holmium oxide ceramic nanostructures. Ceram. Int. 41(8), 9593–9601 (2015)

T. Gladkikh et al., Changes in optical and structural properties of AlN after irradiation with C2+ ions of 40 keV. Vacuum 161, 103–110 (2019)

F. Davar, M. Salavati-Niasari, Synthesis and characterization of spinel-type zinc aluminate nanoparticles by a modified sol–gel method using new precursor. J. Alloys Compd. 509(5), 2487–2492 (2011)

P. Mehdizadeh et al., Green synthesis using cherry and orange juice and characterization of TbFeO3 ceramic nanostructures and their application as photocatalysts under UV light for removal of organic dyes in water. J. Clean. Prod. 252, 119765 (2020)

M. Salavati-Niasari, A. Sobhani, F. Davar, Synthesis of star-shaped PbS nanocrystals using single-source precursor. J. Alloys Compd. 507(1), 77–83 (2010)

Y. Orooji et al., Gd2ZnMnO6/ZnO nanocomposites: green sol–gel auto-combustion synthesis, characterization and photocatalytic degradation of different dye pollutants in water. J. Alloys Compd. 835, 155240 (2020)

M. Salavati-Niasari, Ship-in-a-bottle synthesis, characterization and catalytic oxidation of styrene by host (nanopores of zeolite-Y)/guest ([bis (2-hydroxyanil) acetylacetonato manganese (III)]) nanocomposite materials (HGNM). Microporous Mesoporous Mater. 95(1-3), 248–256 (2006)

T. Wágner et al., The study of photo-and thermally-induced diffusion and dissolution of Ag in As30S70 amorphous films and its reaction products. J. Non-Cryst. Solids 299, 1028–1032 (2002)

A.J. Sisi et al., Systematic activation of potassium peroxydisulfate with ZIF-8 via sono-assisted catalytic process: mechanism and ecotoxicological analysis. J. Mol. Liq. 308, 113018 (2020)

M. Salavati-Niasari, Nanoscale microreactor-encapsulation of 18-membered decaaza macrocycle nickel (II) complexes. Inorg. Chem. Commun. 8(2), 174–177 (2005)

M. Ghasemi et al., In-situ electro-generation and activation of hydrogen peroxide using a CuFeNLDH-CNTs modified graphite cathode for degradation of cefazolin. J. Environ. Manag. 267, 110629 (2020)

M. Sabet, M. Salavati-Niasari, O. Amiri, Using different chemical methods for deposition of CdS on TiO2 surface and investigation of their influences on the dye-sensitized solar cell performance. Electrochim. Acta 117, 504–520 (2014)

N. Hossain et al., Structural and physical properties of NbO2 and Nb2O5 thin films prepared by magnetron sputtering. J. Mater. Sci.: Mater. Electron. 30(10), 9822–9835 (2019)

Y. Orooji et al., Facile fabrication of silver iodide/graphitic carbon nitride nanocomposites by notable photo-catalytic performance through sunlight and antimicrobial activity. J. Hazard. Mater. 389, 122079 (2020)

E. Esmaeili et al., Modified single-phase hematite nanoparticles via a facile approach for large-scale synthesis. Chem. Eng. J. 170(1), 278–285 (2011)

Y. Orooji et al., Co-reinforcing of mullite-TiN-CNT composites with ZrB2 and TiB2 compounds. Ceram. Int. 45(16), 20844–20854 (2019)

D.A.H. Hanaor et al., Solution based synthesis of mixed-phase materials in the Li2TiO3–Li4SiO4 system. J. Nucl. Mater. 456, 151–161 (2015)

M. Xiang et al., Preparation of Li2TiO3–Li4SiO4 core–shell ceramic pebbles with enhanced crush load by graphite bed process. J. Nucl. Mater. 466, 477–483 (2015)

T. Hoshino et al., Development of advanced tritium breeding material with added lithium for ITER-TBM. J. Nucl. Mater. 417(1–3), 684–687 (2011)

H. Kashimura et al., Mass loss of Li2TiO3 pebbles and Li4SiO4 pebbles. Fusion Eng. Des. 88(9-10), 2202–2205 (2013)

J. Han et al., Fabrication of a Li4SiO4–Pb tritium breeding material. Fusion Eng. Des. 89(12), 3046–3053 (2014)

W. Zhang et al., Fabrication of Li2TiO3 pebbles with small grain size via hydrothermal and improved dry-rolling methods. J. Nucl. Mater. 464, 389–393 (2015)

V. Correcher, M. Gonzalez, Preliminary results on the relationship between luminescence and crystalline structure of lithium metatitanate. Nucl. Instrum. Methods Phys. Res. B 326, 86–89 (2014)

E. Carella, T. Hernández, The effect of γ-radiation in Li4SiO4 ceramic breeder blankets. Fusion Eng. Des. 90, 73–78 (2015)

S.T. Murphy, Tritium solubility in Li2TiO3 from first-principles simulations. J. Phys. Chem. C 118(51), 29525–29532 (2014)

Y. Zeng et al., Fast fabrication of high quality Li2TiO3–Li4SiO4 biphasic ceramic pebbles by microwave sintering: in comparison with conventional sintering. Ceram. Int. 45(15), 19022–19026 (2019)

H. Guo et al., Low-cost fabrication of Li2TiO3 tritium breeding ceramic pebbles via low-temperature solid-state precursor method. Ceram. Int. 45(14), 17114–17119 (2019)

H. Wang et al., An innovative process for synthesis of superfine nanostructured Li2TiO3 tritium breeder ceramic pebbles via TBOT hydrolysis–solvothermal method. Ceram. Int. 45(5), 5189–5194 (2019)

S. Gu et al., The effects of irradiation and high temperature on chemical states in Li2TiO3. Int. J. Hydrogen Energy 44(60), 32151–32157 (2019)

E. Carella, M. González, 3He behaviour in Li2TiO3 ceramics for fusion breeding blanket applications. Energy Procedia 41, 26–33 (2013)

E. Carella, M. Gonzalez, R. Gonzalez-Arrabal, D-depth profiling in as-implanted and annealed Li-based breeder blanket ceramics. J. Nucl. Mater. 438(1-3), 193–198 (2013)

E. Carella et al., Nuclear reaction analysis as a tool for the 3He thermal evolution in Li2TiO3 ceramics. Nucl. Instrum. Methods Phys. Res. B 332, 85–89 (2014)

Q. Zhou et al., Release kinetics of tritium generation in neutron irradiated biphasic Li2TiO3–Li4SiO4 ceramic breeder. J. Nucl. Mater. 522, 286–293 (2019)

Y. Chikhray et al., Measurement system for in-pile tritium monitoring from Li2TiO3 ceramics at WWRK reactor. J. Nucl. Mater. 367, 1028–1032 (2007)

J. Wang et al., The influences of deuterium irradiation defects on mechanical properties for ceramic breeder material Li2TiO3. Fusion Eng. Des. 121, 182–187 (2017)

C. Alvani, S. Casadio, Kinetics of tritium release from irradiated Li2TiO3 pebbles in out-of-pile TPD tests. Fusion Eng. Des. 69(1–4), 275–280 (2003)

T. Nakazawa et al., High energy heavy ion induced structural disorder in Li2TiO3. J. Nucl. Mater. 367, 1398–1403 (2007)

M.V. Zdorovets, A.S. Kurlov, A.L. Kozlovskiy, Radiation defects upon irradiation with Kr14+ ions of TaC0. 81 ceramics. Surf. Coat. Technol. 386, 125499 (2020)

S.B. Kislitsin et al., Degradation processes and helium swelling in beryllium oxide. Surf. Coat. Technol. 386, 125498 (2020)

M.V. Zdorovets, A.L. Kozlovskiy, Study of the stability of the structural properties of CeO2 microparticles to helium irradiation. Surf. Coat. Technol. 383, 125286 (2020)

S.J. Zinkle, Microstructure of ion irradiated ceramic insulators. Nucl. Instrum. Methods Phys. Res. B 91(1-4), 234–246 (1994)

S.J. Zinkle, Effect of H and He irradiation on cavity formation and blistering in ceramics. Nucl. Instrum. Methods Phys. Res. B 286, 4–19 (2012)

M. Obradović et al., Effects of helium ion irradiation on bubble formation in AlN/TiN multilayered system. Thin Solid Films 591, 164–168 (2015)

A. Kozlovskiy et al., Influence of He-ion irradiation of ceramic AlN. Vacuum 163, 45–51 (2019)

Q. Hu et al., Aggregation of radiation defects in AIN ceramics under He+ ion irradiation. Radiat. Eff. Defects Solids 152(3), 247–253 (2000)

J.P. Ziegler, M.D. Ziegler, J.P. Biersack, The program stopping and Range of Ion in Matter (SRIM) 2013 Pro. (2018)

D. Nikolopoulos et al., Study of the response of open CR-39 detector to radon and progeny by Monte Carlo simulation with SRIM 2013. International Scientific Conference eRA-8 ISSN-1791-1133-1. 2013

Funding

This study was funded by the Ministry of Education and Science of the Republic of Kazakhstan (Grant BR05235921).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shlimas, D.I., Zdorovets, M.V. & Kozlovskiy, A.L. Synthesis and resistance to helium swelling of Li2TiO3 ceramics. J Mater Sci: Mater Electron 31, 12903–12912 (2020). https://doi.org/10.1007/s10854-020-03843-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-03843-4