Abstract

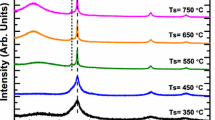

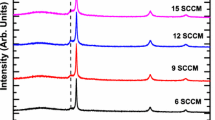

We perform pulsed DC sputtering of aluminium nitride (002) thin films on top of cubic silicon carbide-on-silicon (100) substrates at different substrate temperatures and deposition powers. The films are characterized using the following parameters: FWHM of diffraction peak, FWHM of the rocking curve, residual stress, thickness, deposition rate, grain size, and surface roughness. The overall quality of the films improve at escalated temperature and power. However, they have hillocks on the surface, which is caused by high amount of tensile stress.

Similar content being viewed by others

References

J. Ruffner, P. Clem, B. Tuttle, D. Dimos, D. Gonzales, Effect of substrate composition on the piezoelectric response of reactively sputtered AlN thin films. Thin Solid Films 354(1–2), 256–261 (1999)

A. Claudel et al., Aluminum nitride homoepitaxial growth on polar and non-polar AlN PVT substrates by high temperature CVD (HTCVD). Physica Status Solidi (c) 8(7–8), 2019–2021 (2011)

D. Isarakorn et al., Epitaxial piezoelectric MEMS on silicon. J. Micromech. Microeng. 20(5), 055008 (2010)

V. Cimalla, J. Pezoldt, O. Ambacher, Group III nitride and SiC based MEMS and NEMS: materials properties, technology and applications. J. Phys. D Appl. Phys. 40(20), 6386 (2007)

C. Zuo, N. Sinha, J. Van der Spiegel, G. Piazza, Multifrequency pierce oscillators based on piezoelectric AlN contour-mode MEMS technology. J. Microelectromech. Syst. 19(3), 570–580 (2010)

S. Trolier-McKinstry, P. Muralt, Thin film piezoelectrics for MEMS. J. Electroceram. 12(1–2), 7–17 (2004)

X. Jiang, K. Kim, S. Zhang, J. Johnson, G. Salazar, High-temperature piezoelectric sensing. Sensors 14(1), 144–169 (2013)

K.-H. Chiu, J.-H. Chen, H.-R. Chen, R.-S. Huang, Deposition and characterization of reactive magnetron sputtered aluminum nitride thin films for film bulk acoustic wave resonator. Thin Solid Films 515(11), 4819–4825 (2007)

X.-P. Kuang et al., Effect of deposition temperature on the microstructure and surface morphology of c-axis oriented AlN films deposited on sapphire substrate by RF reactive magnetron sputtering. Superlattices Microstruct. 52(5), 931–940 (2012)

G. Iriarte, J. Rodriguez, F. Calle, Synthesis of c-axis oriented AlN thin films on different substrates: a review. Mater. Res. Bull. 45(9), 1039–1045 (2010)

A. Iqbal, F. Mohd-Yasin, Reactive sputtering of aluminum nitride (002) thin films for piezoelectric applications: a review. Sensors 18(6), 1797 (2018)

M. Benetti et al., Growth and characterization of piezoelectric AlN thin films for diamond-based surface acoustic wave devices. Thin Solid Films 497(1), 304–308 (2006)

K. Kusaka, D. Taniguchi, T. Hanabusa, K. Tominaga, Effect of input power on crystal orientation and residual stress in AlN film deposited by dc sputtering. Vacuum 59(2), 806–813 (2000)

Z. Vashaei et al., Influence of sputtering parameters on the crystallinity and crystal orientation of AlN layers deposited by RF sputtering using the AlN target. J. Crystal Growth 311(3), 459–462 (2009)

H. Jin et al., Influence of substrate temperature on structural properties and deposition rate of AlN thin film deposited by reactive magnetron sputtering. J. Electron. Mater. 41(7), 1948–1954 (2012)

W.-J. Liu, S.-J. Wu, C.-M. Chen, Y.-C. Lai, C.-H. Chuang, Microstructural evolution and formation of highly c-axis-oriented aluminum nitride films by reactively magnetron sputtering deposition. J. Cryst. Growth 276(3), 525–533 (2005)

G.F. Iriarte, F. Engelmark, M. Ottosson, I. Katardjiev, Influence of deposition parameters on the stress of magnetron sputter-deposited AlN thin films on Si (100) substrates. J. Mater. Res. 18(02), 423–432 (2003)

H. Zhong et al., Residual stress of AlN films RF sputter deposited on Si (111) substrate. J. Mater. Sci.: Mater. Electron. 23(12), 2216–2220 (2012)

C.-M. Lin, W.-C. Lien, V.V. Felmetsger, M.A. Hopcroft, D.G. Senesky, A.P. Pisano, AlN thin films grown on epitaxial 3C–SiC (100) for piezoelectric resonant devices. Appl. Phys. Lett. 97(14), 141907 (2010)

A. Iqbal, K. Chaik, G. Walker, A. Iacopi, F. Mohd-Yasin, S. Dimitrijev, RF sputtering of polycrystalline (100), (002), and (101) oriented AlN on an epitaxial 3C-SiC (100) on Si (100) substrate. J. Vac. Sci. Technol. B 32(6), 06F401 (2014)

A. Iqbal, G. Walker, A. Iacopi, F. Mohd-Yasin, Controlled sputtering of AlN (002) and (101) crystal orientations on epitaxial 3C-SiC-on-Si (100) substrate. J. Cryst. Growth 440, 76–80 (2016)

L. Wang et al., Growth of 3C–SiC on 150-mm Si (100) substrates by alternating supply epitaxy at 1000 C. Thin Solid Films 519(19), 6443–6446 (2011)

A. Iqbal, G. Walker, L. Hold, A. Fernandes, A. Iacopi, F. Mohd-Yasin, DC sputtering of highly c-axis AlN films on top of 3C-SiC (111)-on-Si (111) substrates under various N2 concentrations. J. Vacuum Sci. Technol. B Nanotechnol. Microelectron. 35(6), 06GH01 (2017)

A. Iqbal et al., The sputtering of AlN films on top of on-and off-axis 3C-SiC (111)/Si (111) substrates at various substrate temperatures. J. Mater. Sci.: Mater. Electron. 29(3), 2434–2446 (2018)

S. Khan et al., Texture of the nano-crystalline AlN thin films and the growth conditions in DC magnetron sputtering. Prog. Nat. Sci.: Mater. Int. 25(4), 282–290 (2015)

E. Chason, A kinetic analysis of residual stress evolution in polycrystalline thin films. Thin Solid Films 526, 1–14 (2012)

Z. Fang, Z. Yan, Y. Tan, X. Liu, Y. Wang, Influence of post-annealing treatment on the structure properties of ZnO films. Appl. Surf. Sci. 241(3), 303–308 (2005)

S.-H. Lee, K.H. Yoon, D.-S. Cheong, J.-K. Lee, Relationship between residual stress and structural properties of AlN films deposited by rf reactive sputtering. Thin Solid Films 435(1–2), 193–198 (2003)

J.A. Thornton, D. Hoffman, Stress-related effects in thin films. Thin Solid Films 171(1), 5–31 (1989)

F. Liu et al., Visible and infrared emissions from c-axis oriented AlN: Er films grown by magnetron sputtering. J. Appl. Phys. 99(5), 053515 (2006)

G. Ke et al., Highly c-axis oriented AlN film grown by unbalanced magnetron reactive sputtering and its electrical properties. J. Alloys Compd. 646, 446–453 (2015)

Acknowledgments

This work is supported by Queensland Micro- and Nanotechnology Centre (QMNC) and School of Engineering and Built Environment. This work was performed in part at the Queensland node of the Australian National Fabrication Facility, a company established under the National Collaborative Research Infrastructure Strategy to provide nano and microfabrication facilities for Australia’s researchers.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Iqbal, A., Walker, G., Hold, L. et al. Sputtering of aluminium nitride (002) film on cubic silicon carbide on silicon (100) substrate: influences of substrate temperature and deposition power. J Mater Sci: Mater Electron 31, 239–248 (2020). https://doi.org/10.1007/s10854-019-02480-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02480-w