Abstract

In this work we present the influence of in situ deposited non-continous SiN layer and the chemical precursors III/V mole ratio change during GaN buffer growth for AlGaN/GaN/Si(111) heterostructures with low temperature AlN interlayer on their crystalline quality and electrical mobility of two dimensional electron gas (2DEG). We show, that application of SiN layer resulted in a decrease of (0002) full width at half maximum of diffraction peak below 400 arcsec and build-in stress in 2 µm thick heterostructures below 200 MPa without any relaxation visible on the surface. In optimized AlGaN/GaN heterostructures, by altering V/III mole ratio during growth of GaN subbuffer, the maximum 2DEG mobility of 2057 cm2 V−1 s−1, measured by impedance spectroscopy method, was obtained.

Similar content being viewed by others

1 Introduction

AIII-N heterostructure based devices are of great interest in power and high frequency electronics due to their exceptional properties, primarily high breakdown field, high electron saturation velocity and high electron mobility of two dimensional electron gas in AlGaN/GaN heterostructures. Numerous publications devoted to growth and construction of high power p–n [1] or Schottky [2] diodes and high electron mobility transistors [3], as well commercially available devices grown on sapphire and silicon carbide clearly indicate that nitride based devices are serious alternative to the ones, i.e. silicon triacs, IGBTs, MOSFETs, SiC diodes, typically used in many areas of high power and high frequency electronics. In order to exploit the full potential of nitrides, in this context, devices with vertical current conduction need to be extensively investigated. In that respect, growth of high quality material on conducted substrates, that provide low resistive contact to nitrides heterostructure, is essential and in practice will be one of the fundamental factors that determines the devices parameters. The most widely used substrate for GaN-based power devices is SiC, that is characterized by very high thermal conductivity and good crystallographic match to nitrides [4, 5]. However, the high cost and limited availability of large diameter SiC substrates, effectively narrow down the use of high power GaN devices to dedicated, highly performed and expensive applications. In order to enable mass production and increase the widespread availability of affordable GaN-based vertical power diodes and transistors, it is necessary to step up research in the area of AIII-N growth on Si substrates. Silicon, with it’s proofed reputation in semiconductor industry, is the ideal candidate for high volume and low cost GaN devices.

GaN growth on large area silicon substrates is still challenging due to fundamental limitations imposed by thermal and lattice mismatch of GaN and Si, and chemical incompatibility of both material systems. Direct growth of GaN on Si by metalorganic vapor phase epitaxy (MOVPE) resulted in parasitic reactions between substrate and growth precursors (typically NH3 and TMGa) and crystallization of low quality strained layers with high defect density. Different approaches were proposed in order to minimize the occurrence of parasitic surface nitridation and melt-back etching of Si during MOVPE process [6,7,8] as well as strain incorporation in heteroepitaxial AIII-N structures [9, 10].

One of the known method of stress engineering in nitride-based heteroepitaxial structrures is the apllication of thin, several nanometers thick, low temperature (LT) AlN interlayers, which serves as a relaxation spacer between strained GaN layers [11, 12]. This method has been proved as a effective way of reducing tensile strain in thick (above 2 µm) GaN layers. In addition, the application of thin noncontinous SiN layer can enhance the three dimensional growth mode of GaN layer, which suppress formation of threading dislocation in the early sages of GaN crystallization [13,14,15,16]. Unfortunatelly, LT-AlN interlayers as well as SiN nanomask have significant impact on the surface morphology of deposited GaN, due to prolonged coalescence of epitaxial layer and delayed transition from the 3D to 2D growth mode. This problem can be partially solved by optimization of growth condition, i.e. V/III mole ratio during GaN growth. In this research we investigate the influence of growth process parameters, mainly V/III mole ratio of Ga and N precursors, during growth of GaN buffer layer on the structural and electrical properties of AlGaN/GaN/Si HEMT-type heterostructures grown by MOVPE technique with the use of in situ deposited SiN and LT-AlN interlayers.

The layer scheme of investigated heterostructures is presented in Fig. 1. Silicon substrate is protected against Ga and Si inter diffusion by high temperature (HT) AlN nucleation layer that is covered by in situ deposited noncontinuous layer of SiN that promotes required 3D growth mode of subsequent GaN buffer. LT-AlN act as a relaxing layer which introduce compressive stress in tensile strained heterostructure. The influence of SiN nanomask and the growth conditions of GaN buffer on the stress state in epitaxial structure was studied. Moreover, the results of electrical characterization of AlGaN/GaN heterostructures, grown on the optimized buffer layers, and the comparison of their parametes with the properties of AlGaN/GaN heterostructures deposited on sapphire was performed.

2 Experimental details

Experimental work was divided in two parts. First, the influence of SiN nanomask on the built-in stress in AlGaN/GaN/Si heterostructures was investigated, second, the optimization of growth conditions (mole ratio of V/III group precursors), in order to enhance crystalline quality and electrical properties, was conducted. All samples were grown on 2 inch, 340 nm thick Si(111) substrates in AIXTRON CCS reactor, using trimethylgallium (TMGa), trimethylaluminium (TMAl), ammonia (NH3) and sillane (SiH4) chemical reagents as a source of gallium, aluminum, nitrogen and silicon atoms respectively. Total gas flow in the reactor during growth procedure was kept constant at 16 sl/min. Initial thermal cleaning of Si substrates, as well as subsequent growth stages were performed in H2 atmosphere. In order to prevent formation of parasitic SiN on the Si surface, prior to AlN deposition, the TMAl preflow (20 s, 8.6 µmol/min) without NH3 was applied. After that, using the same conditions (100 mbar, 1060 °C), NH3 (67 mmol/min) was introduced and 150 nm thick AlN layer was grown. In the case of samples with SiN nanomask, HT-AlN was in situ covered by the non-continuous SiN layer by switching from TMAl to SiH4 (0.11 µmol/min) for 100 s. Subsequently, high temperature (Al,Ga)N layers were deposited at 1045 °C and 100 mbar with constant NH3 (129 mmol/min) flow, whereas low temperature AlN layers at 650 °C with TMAl flow equaled to 9.4 µmol/min. In the first attempt, the impact of non-continous SiN subnanometer layer on the properties of subsequently grown AlGaN/GaN heterostructure was checked. The detailed layers structure scheme and growth parameters of the samples with and without SiN is shown in Table 1 (sample A and B). Application of this layer significantly reduce the built in stress in AlGaN/GaN heterostructure and enhance its crystalline quality (detailed results will be presented later in this manuscript). It led to following investigation of heterostructures containing SiN nanomask. Certain disadvantage of this approach is the increase of the surface defect density—so called micropits [17], however, by altering of NH3 and TMGa mole ratio during the growth of GaN buffer, this issue can be effectively solved. High V/III ratios tend to enhance the lateral growth thus suppress formation of these defects on the SiN/GaN interface and in result their reveal on the samples surface. However, in this work, the focus is placed on the influence of V/III growth ratio on the mobility of 2DEG what is an indirect measure of material quality. The layer structure schemes and growth parameters of investigated samples are presented in Table 1 (samples B–E). Different V/III growth ratios were obtained by altering TMGa flow, keeping NH3 flow constant. V/III mole ratios of 600, 1200, 3000 and 5000 correspond to TMGa flow of 217, 109, 43.5 and 21.7 µmol/min respectivelly at NH3 flow of 129 mmol/min.

3 Results and discussion

3.1 Influence of SiN nanomask

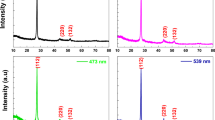

Investigated heterostructures, with and without SiN nanomask (samples A and B), were characterized by SEM, AFM, room temperature PL and XRD. The FWHM values of GaN related PL peak decreased from 97 to 76 meV after SiN introduction in epitaxial structure, which indicates the improvement of material quality. XRD measurements also confirmed increase of GaN crystalline quality, the (0002) and (01-15) diffraction peaks FWHM decreased from 778.39 to 386.64 arcsec and from 700.88 to 362.56 arcsec respectively for sample with SiN layer (Fig. 2). Furthermore, built in stress in heterostructures, determined on the basis of GaN unit cell deformation measured by XRD, was much smaller in the sampe with SiN − 161 versus 872 MPa. Structural characterization was supplemented by the microscopic observations of investigated samples. SEM and AFM surface pictures of the heterostructures with and without SiN nanomask are shown in Fig. 3. Surface of the sample with SiN is much smoother, the RMS value equals to 1.3 nm, compared to the value of 5.8 nm measured for the sample grown without SiN. However, occurrence of hexagoanl micropits on the surface is observed in the case of sample with SiN. The mechanism of bending and recombination of threading dislocations (TDs) and reduction of tensile stress in GaN layers grown on SiN interlayer were widely described in literature [18,19,20,21]. Further information and analysis of micropits like defect formation mechanism in heterostructures grown on silicon with and without SiN interlayer can be found in authors previous publication [13].

3.2 Influence of III/V ratio

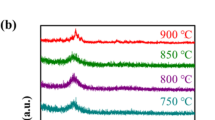

Surface AFM scans of samples B–E grown with different V/III mole ratio are presented in Fig. 4. It is clearly visible, that in ammonia rich atmosphere the density of hexagonal micropits is smaller. This can be partially attributed to the fact, that high V/III conditions result in enhanced lateral growth of GaN, that can suppress the formation of surface defects. XRD measurements of investigated samples showed strong correlation between growth conditions and crystalline quality. The relationship between V/III mole ratio and (0002) GaN FWHM peak is presented in Fig. 5. For reference, on the same graph the values of 2DEG mobility, measured by impedance spectroscopy [22] method, were indicated. In this case the crystal quality improvement are not reflected in the increase of electron mobility. The highest mobility (2057 cm2 V−1 s−1) was observed in the sample grown with V/III = 1200. Unfortunately, the impedance spectroscopy measurements were impossible for sample grown in Ga rich conditions (V/III = 600) due to high surface deterioration by shallow micropits.

In order to enhance electrical properties (to decrease the 2DEG surface resistance), the heterostructure (sample F) with Si dopants and higher Al content in AlGaN barrier was deposited using the same buffer grown scheme as sample B (III/V = 1200). CV and impedance spectroscopy measurements indicated very low sheet resistance of \(392\,\Omega /\text {sq}\) for this sample. For reference, on the graph presented in Fig. 6, the comparison of sheet charge concentration and electron mobility of 2DEG of different heterostructures grown on sapphire and silicon with SiN interlayer, using different buffer thicknesses and V/III mole ratios during GaN growth, are shown. This proves usefulness of presented method in MOVPE deposition of high quality AlGaN/GaN heterostructures with thick GaN buffers on Si(111) without cracking.

4 Conclusions

The undertaken experimental studies have proved the usefulness of in situ grown non-continous sub-nanometer SiN layer in stress reduction and material quality improvement of AlGaN/GaN heterostructures deposited on Si(111) substrates. The fabricated sample with SiN nanomask exhibited good structural properties, with GaN (0002) diffraction peak FWHM equals to 362 arcsec and calculated basal plane stress lower than 200 MPa. Structural characterization of investigated samples confirmed the influence of V/III mole ratio, during growth of GaN buffer, on the crystalline quality of AlGaN/GaN heterostructures. Higher V/III mole ratios enabled growth the better quality material with smoother surface. Furthermore, the NH3 to TMGa molar ratio has noticeable impact on the electrical parameters of 2DEG of AlGaN/GaN heterostructures. However, higher mobility was obtained for lower V/III mole ratios, what is not expected and may indicate another important factors, other than crystalline quality, that influence the scattering mechanism of 2DEG in these type of structures. Electrically optimized AlGaN/GaN heterostructures deposited on silicon showed similar performance to those grown on sapphire substrates. This indicates the suitability of discussed growth method in fabrication of AlGaN/GaN/Si heterostructures for lateral and vertical HEMTs.

References

I.C. Kizilyalli, A.P. Edwards, O. Aktas, T. Prunty, D. Bour, Vertical power p-n diodes based on bulk GaN. IEEE Trans. Electron Devices 62(2), 414–422 (2015). https://doi.org/10.1109/TED.2014.2360861. (ISSN 0018-9383)

R.P. Tompkins, J.R. Smith, K.W. Kirchner, K.A. Jones, J.H. Leach, K. Udwary, E. Preble, P. Suvarna, J.M. Leathersich, F. Shahedipour-Sandvik, GaN power schottky diodes with drift layers grown on four substrates. J. Electron. Mater. 43(4), 850–856 (2014). https://doi.org/10.1007/s11664-014-3021-9. (ISSN 03615235)

X. Huang, Z. Liu, Q. Li, F.C. Lee, Evaluation and application of 600 V GaN HEMT in cascode structure. IEEE Trans. Power Electron. 29(5), 2453–2461 (2014). https://doi.org/10.1109/TPEL.2013.2276127. (ISSN 08858993)

J. Millan, P. Godignon, X. Perpina, A. Perez-Tomas, J. Rebollo, A survey of wide bandgap power semiconductor devices. IEEE Trans. Power Electron. 29(5), 2155–2163 (2014). https://doi.org/10.1109/TPEL.2013.2268900. (ISSN 08858993)

R.S. Pengelly, S.M. Wood, J.W. Milligan, S.T. Sheppard, W.L. Pribble, A review of GaN on SiC high electron-mobility power transistors and MMICs. IEEE Trans. Microw. Theory Tech. 60(6 PART 2), 1764–1783 (2012). https://doi.org/10.1109/TMTT.2012.2187535. (ISSN 00189480)

H. Ishikawa, G.Y. Zhao, N. Nakada, T. Egawa, T. Soga, T. Jimbo, M. Umeno, High-quality GaN on Si substrate using AlGaN/AlN intermediate layer. Phys. Status Solidi A 176(1), 599–603 (1999). https://doi.org/10.1002/(SICI)1521-396X(199911)176:1<599::AID-PSSA599>3.0.CO;2-F. (ISSN 00318965)

A. Able, W. Wegscheider, K. Engl, J. Zweck, Growth of crack-free GaN on Si(1 1 1) with graded AlGaN buffer layers. J. Cryst. Growth 276(3–4), 415–418 (2005). https://doi.org/10.1016/j.jcrysgro.2004.12.003. (ISSN 00220248)

M. Khoury, O. Tottereau, G. Feuillet, P. Vennéguès, J. Zúñiga-Pérez, Evolution and prevention of meltback etching: case study of semipolar GaN growth on patterned silicon substrates. J. Appl. Phys. 122(10), 105108 (2017). https://doi.org/10.1063/1.5001914. (ISSN 10897550)

A. Watanabe, J.J. Freedsman, R. Oda, T. Ito, T. Egawa, Characterization of InAlN/GaN high-electron-mobility transistors grown on Si substrate using graded layer and strain-layer superlattice. Appl. Phys. Express 7(4), 041002 (2014). https://doi.org/10.7567/APEX.7.041002. (ISSN 18820786)

M. Wośko, B. Paszkiewicz, T. Szymański, R. Paszkiewicz, Optimization of AlGaN/GaN/Si(111) buffer growth conditions for nitride based HEMTs on silicon substrates. J. Cryst. Growth 414, 248–253 (2015). https://doi.org/10.1016/j.jcrysgro.2014.10.048. (ISSN 00220248)

A. Dadgar, J. Bläsing, A. Diez, A. Alam, M. Heuken, A. Krost, Metalorganic chemical vapor phase epitaxy of crack-free GaN on Si (111) exceeding 1 µm in thickness. Jpn. J. Appl. Phys. 39(Part 2, No. 11B), L1183–L1185 (2000). https://doi.org/10.1143/JJAP.39.L1183. (ISSN 00214922)

A. Krost, A. Dadgar, GaN-based devices on Si. Phys. Stat. Solidi A 194(2 SPEC.), 361–375 (2002). https://doi.org/10.1002/1521-396X(200212)194:2<361::AID-PSSA361>3.0.CO;2-R. (ISSN 00318965)

T. Szymański, M. Wośko, B. Paszkiewicz, J. Serafińczuk, M. Drzik, R. Paszkiewicz, Stress control by micropits density variation in strained AlGaN/GaN/SiN/AlN/Si(111) heterostructures. Cryst. Res. Technol. 51(3), 225–230 (2016). https://doi.org/10.1002/crat.201500276. (ISSN 15214079)

A. Dadgar, R. Clos, G. Strassburger, F. Schulze, P. Veit, T. Hempel, J. Bläsing, A. Krtschil, I. Daumiller, M. Kunze, A. Kaluza, A. Modlich, M. Kamp, A. Diez, J. Christen, A. Krost, in Advances in Solid State Physics, ed. by B. Kramer. Strains and stresses in GaN heteroepitaxy—sources and control (Springer, Berlin, 2004), pp. 313–326. https://doi.org/10.1007/978-3-540-39970-4-24

T. Fan, W. Jia, G. Tong, G. Zhai, T. Li, H. Dong, B. Xu, Influence of in-situ deposited SiNx interlayer on crystal quality of GaN epitaxial films. Superlattices Microstruct. 117, 57–64 (2018). https://doi.org/10.1016/j.spmi.2018.03.019. ISSN 07496036

A. Sagar, R.M. Feenstra, C.K. Inoki, T.S. Kuan, Y. Fu, Y.T. Moon, F. Yun, H. Morkoç, Dislocation density reduction in GaN using porous SiN interlayers. Phys. Stat. Solidi A 202(5), 722–726 (2005). https://doi.org/10.1002/pssa.200461486. (ISSN 18626300)

T. Szymański, M. Wośko, M. Wzorek, B. Paszkiewicz, R. Paszkiewicz, Origin of surface defects and influence of an in situ deposited SiN nanomask on the properties of strained AlGaN/GaN heterostructures grown on Si(111) using metal-organic vapour phase epitaxy. CrystEngComm 18(45), 8747–8755 (2016). https://doi.org/10.1039/C6CE01804A. (ISSN 1466-8033)

F. Yun, Y.T. Moon, Y. Fu, K. Zhu, Ü. Ozgür, H. Morkoç, C.K. Inoki, T.S. Kuan, A. Sagar, R.M. Feenstra, Efficacy of single and double SiNx interlayers on defect reduction in GaN overlayers grown by organometallic vapor-phase epitaxy. J. Appl. Phys. 98(12), 123502 (2005). https://doi.org/10.1063/1.2142074. (ISSN 0021-8979)

K.Y. Zang, Y.D. Wang, L.S. Wang, S.Y. Chow, S.J. Chua, Defect reduction by periodic SiNx interlayers in gallium nitride grown on Si (111). J. Appl. Phys. 101(9), 093502 (2007). https://doi.org/10.1063/1.2724793. (ISSN 0021-8979)

M.J. Kappers, R. Datta, R.A. Oliver, F.D.G. Rayment, M.E. Vickers, C.J. Humphreys, Threading dislocation reduction in (0 0 01) GaN thin films using SiNx interlayers. J. Cryst. Growth 300(1), 70–74 (2007). https://doi.org/10.1016/j.jcrysgro.2006.10.205. (ISSN 00220248)

Z. Huang, Y. Zhang, G. Deng, B. Li, S. Cui, H. Liang, Y. Chang, J. Song, B. Zhang, G. Du, Improvements of epitaxial quality and stress state of GaN grown on SiC by in situ SiNx interlayer. J. Mater. Sci.: Mater. Electron. 27(10), 10003–10009 (2016). https://doi.org/10.1007/s10854-016-5071-7. (ISSN 1573482X)

B. Paszkiewicz, M. Wosko, R. Paszkiewicz, M. Tlaczala, Nondestructive method for evaluation of electrical parameters of AlGaN/GaN HEMT heterostructures. Phys. Stat. Solidi C 10(3), 490–493 (2013). https://doi.org/10.1002/pssc.201200709. (ISSN 18626351)

Acknowledgements

This work was co-financed by the National Centre for Research and Development Grants TECHMATSTRATEG No. 1/346922/4/NCBR/2017 and LIDER No. 027/533/L-5/13/NCBR/2014, the National Science Centre Grant No. DEC-2015/19/B/ST7/02494, Wroclaw University of Science and Technology statutory grants and by the Slovak-Polish International Cooperation Program. This work was accomplished thanks to the product indicators and result indicators achieved within the projects co-financed by the European Union within the framework of the European Regional Development Fund, through a grant from the Innovative Economy (POIG.01.01.02-00-008/08-05) and by the National Centre for Research and Development through the Applied Research Program Grant No. 178782.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wośko, M., Szymański, T., Paszkiewicz, B. et al. MOVPE growth conditions optimization for AlGaN/GaN/Si heterostructures with SiN and LT-AlN interlayers designed for HEMT applications. J Mater Sci: Mater Electron 30, 4111–4116 (2019). https://doi.org/10.1007/s10854-019-00702-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-00702-9