Abstract

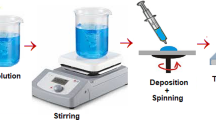

In this work, undoped and Fe-doped ZnO thin films at various concentrations (2, 4 and 6 at.%) were deposited onto glass substrate by using ultrasonic spray pyrolysis in order to investigate the effect of Fe doping on the structural, morphological, optical, electrical and magnetic properties of ZnO thin films. X-ray diffractometer (XRD) results revealed that all deposited thin films have hexagonal wurtzite structure and Fe doping led to decrease in mean crystallite size. Atomic force microscopy images showed that thin films were composed of tightly packed grains. Optical examinations indicated that optical transmittance remarkably decreased with the increase in the amount of Fe concentration in thin films. Additionally, optical band gap of deposited films were determined in the range of 3.26–3.29 eV. It was determined that all deposited thin films have n-type conductivity and electrical resistivity increased up to 253.6 Ωcm as a consequence of Fe doping. Vibrating sample magnetometer measurements showed that all films have ferromagnetic behavior.

Similar content being viewed by others

References

T. Dietl, H. Ohno, F. Matsukura, J. Cibert, D. Ferrand, Science 287, 1019 (2000)

M. Li, J. He, Mater. Lett. 174, 48 (2016)

J. Wang, W. Zhou, P. Wu, Appl. Surf. Sci. 314, 188 (2014)

G. Vijayaprasath, R. Murugan, G. Ravi, T. Mahalingam, Y. Hayakawa, Appl. Surf. Sci. 313, 870 (2014)

L.W. Lai, C.T. Lee, Mater. Chem. Phys. 110, 393 (2008)

L.V. Gritsenko, K.A. Abdullin, M.T. Gabdullin, Z.K. Kalkozova, S.E. Kumekov, Z.O. Mukash, A.Y. Sazonov, E.I. Terukov, J. Cryst. Growth 457, 164 (2017)

B. Santara, K. Imakita, M. Fujii, P.K. Giri, J. Alloy. Compd. 661, 331 (2016)

G.G. Khan, S. Ghosh, K. Mandal, J. Solid State Chem. 186, 278 (2012)

H. Cao, P. Xing, D. Yao, P. Wu, J. Magn. Magn. Mater. 429, 69 (2017)

S.W. Kim, S. Lee, A.N.S. Saqib, Y.H. Lee, M.H. Jung, Curr. Appl. Phys. 17, 181 (2017)

Z. Quan, X. Liu, Y. Qi, Z. Song, S. Qi, G. Zhou, X. Xu, Appl. Surf. Sci. 399, 751 (2017)

A.K. Das, A. Srinivasan, J. Magn. Magn. Mater. 404, 190 (2016)

S. Mal, S. Nori, J. Narayan, J.T. Prater, D.K. Avasthi, Acta Mater. 61, 2763 (2013)

K. Rainey, J. Chess, J. Eixenberger, D.A. Tenne, C.B. Hanna, A. Punnoose, J. Appl. Phys. 115, 17D727 (2014)

S. Ghose, T. Rakshit, R. Ranganathan, D. Jana, RSC Adv. 5, 99766 (2015)

C. Liu, F. Yun, H. Morkoc, J. Mater. Sci.-Mater. Electron. 16, 555 (2005)

K. Sato, H. Katayama-Yoshida, Phys. Status Solidi B 229, 673 (2002)

P.W. Anderson, H. Hasegawa, Phys. Rev. 100, 675 (1955)

S.J. Chen, H.Y. Xu, S.X. Wang, K. Suzuki, Integr. Ferroelectr. 144, 1 (2013)

S.A. Ahmed, Appl. Phys. A 123, 440 (2017)

M. Ashokkumar, S. Muthukumaran, Physica E 69, 354 (2015)

M. Cernea, V. Mihalache, E.C. Secu, R. Trusca, V. Bercu, L. Diamandescu, Superlattice Microstruct. 104, 362 (2017)

A. Goktas, I.H. Mutlu, Y. Yamada, Superlattice Microstruct. 57, 139 (2013)

F. Lmai, R. Moubah, A. El Amiri, Y. Abid, I. Soumahoro, N. Hassanain, S. Colis, G. Schmerber, A. Dinia, H. Lassri, Opt. Mater. 57, 28 (2016)

P. Ariyakkani, L. Suganya, B. Sundaresan, J. Alloy. Compd. 695, 3467 (2017)

T. Srinivasulu, K. Saritha, K.T.R. Reddy, Mod. Electron. Mater. 3, 76 (2017)

A. Kumar, P. Dhiman, M. Singh, Ceram. Int. 42, 7918 (2016)

K. Singh, V. Devi, R. Dhar, D. Mohan, Superlattice Microstruct. 85, 433 (2015)

P.S. Patil, Mater. Chem. Phys. 59, 185 (1999)

M.R. Islam, J. Podder, Cryst. Res. Technol. 44, 286 (2009)

L. Xu, X. Li, J. Cryst. Growth 312, 851 (2010)

A. Goktas, F. Aslan, A. Tumbul, S.H. Gunduz, Ceram. Int. 43, 704 (2017)

V.K. Pecharsky, P.Y. Zavalij, Fundamentals of Powder Diffraction and Structural Characterization of Materials (Springer Science-Business Media Inc., Berlin, 2003), pp. 164–167

M. Salem, S. Akir, T. Ghrib, K. Daoudi, M. Gaidi, J. Alloy. Compd. 685, 107 (2016)

J.A.R. Márquez, C.M.B. Rodríguez, C.M. Herrera, E.R. Rosas, O.Z. Angel, O.T. Pozos, Int. J. Electrochem. Sci. 6, 4059 (2011)

E. Sarica, V. Bilgin, Surf. Coat. Technol. 286, 1 (2016)

H. Mahdhi, J.L. Gauffier, K. Djessas, Z.B. Ayadi, Opt.-Int. J. Light Electron Opt. 137, 156 (2017)

O. Makuku, F. Mbaiwa, T.S. Sathiaraj, Ceram. Int. 42, 14581 (2016)

U. Chaitra, D. Kekuda, K.M. Rao, Ceram. Int. 43, 7115 (2017)

K.M. Sandeep, S. Bhat, S.M. Dharmaprakash, J. Phys. Chem. Solids 104, 36 (2017)

B.D. Cullity, Elements of X-ray Diffraction (Addison-Wesley Publishing Company Inc., Boston, 1956), pp. 259–263

R. Saleh, N.F. Djaja, Spectrochim. Acta A 130, 581 (2014)

K. Xu, C. Liu, R. Chen, X. Fang, X. Wu, J. Liu, Physica B 502, 155 (2016)

T. Suzuki, H. Chiba, T. Kawashima, K. Washio, Thin Solid Films 605, 53 (2016)

N.A. Ahmed, G. Fortas, H. Hammache, S. Sam, A. Keffous, A. Manseri, L. Guerbous, N. Gabouze, Appl. Surf. Sci. 256, 7442 (2010)

F. Wang, R. Liu, A. Pan, L. Cao, K. Cheng, B. Xue, G. Wang, Q. Meng, J. Li, Q. Li, Y. Wang, T. Wang, B. Zou, Mater. Lett. 61, 2000 (2007)

B.P. Kafle, S. Acharya, S. Thapa, S. Poudel, Ceram. Int. 42, 1133 (2016)

J.I. Pankove, Optical process in semiconductors, (Solid State Physical Electronics Series (Prentice-Hall, New Jersey, 1971)

F. Gao, X.Y. Liu, L.Y. Zheng, M.X. Li, Y.M. Bai, J. Xie, J. Cryst. Growth 371, 126 (2013)

Z.C. Chen, L.J. Zhuge, X.M. Wu, Y.D. Meng, Thin Solid Films 515, 5462 (2007)

C. Wang, Z. Chen, Y. He, L. Li, D. Zhang, Appl. Surf. Sci. 255, 6881 (2009)

S. Kose, F. Atay, V. Bilgin, I. Akyuz, Int. J. Hydrogen Energy 34, 5260 (2009)

D.C. Look, J.W. Hemsky, J.R. Sizelove, Phys. Rev. Lett. 82, 2552 (1999)

S. Alamdari, M.J. Tafreshi, M.S. Ghamsari, Mater. Lett. 197, 94 (2017)

J. Angulo-Rocha, O. Velarde-Escobar, C. Yee-Rendón, G. Atondo-Rubio, R. Millan-Almaraz, E. Camarillo-García, M. Garcia-Hipolito, F. Ramos-Brito, J. Lumin. 185, 306 (2017)

K.L. Chopra, Thin Film Phenomena, (MC Graw Hill, New York, 1969) pp. 84–90

H. Colak, O. Türkoğlu, J. Mater. Sci. Technol. 28, 268 (2012)

W. Cheng, X. Ma, J. Phys. Conf. Ser. 152, 012039 (2009)

G. Srinet, P. Varshney, R. Kumar, V. Sajal, P.K. Kulriya, M. Knobel, S.K. Sharma, Ceram. Int. 39, 6077 (2013)

X. Hou, H. Liu, H. Sun, L. Liu, X. Jia, Mater. Sci. Eng. B 200, 22 (2015)

S. Mal, T.H. Yang, C. Jin, S. Nori, J. Narayan, J.T. Prater, Scr. Mater. 65, 1061 (2011)

S. Majumder, D. Paramanik, A. Gupta, S. Varma, Appl. Surf. Sci. 256, 513 (2009)

J.M.D. Coey, M. Venkatesan, C.B. Fitzgerald, Nat. Mater. 4, 173 (2005)

Y. Tian, Y. Li, M. He, I.A. Putra, H. Peng, B. Yao, S.A. Cheong, T. Wu, Appl. Phys. Lett. 98, 162503 (2011)

R.H. Yu, S. Basu, Y. Zhang, A. Parvizi-Majidi, J.Q. Xiao, J. Appl. Phys. 85, 6655 (1999)

Acknowledgements

This work was supported by the Canakkale Onsekiz Mart University Scientific Research Projects Committee under the Project Number 2010/0198.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bilgin, V., Sarica, E., Demirselcuk, B. et al. Iron doped ZnO thin films deposited by ultrasonic spray pyrolysis: structural, morphological, optical, electrical and magnetic investigations. J Mater Sci: Mater Electron 29, 17542–17551 (2018). https://doi.org/10.1007/s10854-018-9855-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9855-9