Abstract

The electrical and thermal conductivity of the sample containing 97% by volume of the Ti3AlC2 MAX phase and 3% volume TiC was experimentally studied in the temperature range 15–300 K. The temperature dependence of the electrical resistance is approximated by a relation that takes into account the scattering of electrons by phonons and defects. The temperature dependence of the thermal conductivity shows a maximum at about 75 K. In the region of elastic scattering of electrons, the phonon and electron heat transfer are separated. With increasing temperature, the fraction of phonon heat transfer decreases from ∼90% at low temperatures to ∼40% near room temperature.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Synthesizing and studying new functional materials that can be employed in multiple technological applications [1,2,3,4,5] is a key direction of solid state physics. One of the most promising classes of such compounds are the so-called MAX phases [1,2,3] (with the general formula Mn+1AXn, where M is the transition material, A is the element of the III- or IV-subgroup of the periodic system, and X is carbon or nitrogen). Strong M–X bonds, weaker M–A bonds associated with the nanolayered nature of the structure provide a unique combination of metal and ceramic properties for these substances [6]. The layered perovskite-like unit cell leads to the nanolaminated structure of the MAX-phase based materials which in turn gives the possibility of grains local deformation in the zone of stress concentration without their macroscopic destruction. These compounds have a unique combination of metallic and ceramic properties, such as high hardness, high refractive index, elasticity, good thermal and electrical conductivity. The latter is crucial for the successful application of these materials in modern micro- and nanoelectronics, switching devices, and energy [7,8,9]. For example, recent studies have examined the application of MAX phases in nuclear applications [7] and the use of the 2D MXenes (synthesized from the MAX phases) for electromagnetic interference shielding [8].

The study of the mechanisms of electrical and heat transfer in these compounds is a tool for testing the adequacy of the corresponding theoretical models and facilitates the determination of empirical ways of improving their technological characteristics. In the present study we have investigated the thermal and electrical conductivity of the Ti3AlC2 MAX phase in the temperature range of 15–300 K.

2 Experimental methods and techniques

2.1 Sample preparation

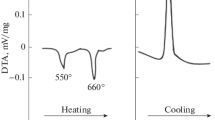

The sample of the MAX phase Ti3AlC2 were fabricated using Spark Plasma Sintering (SPS) technology by sintering the initial powder in a hot pressing plant, while simultaneously passing a current of the order of several kA along the pressing axis through the graphite mold and the powder itself, which resulted both, the heating and the cleaning of the surface of the powder particles, due to microdischarges on their surface.

Figure 1 shows a diffraction pattern from the investigated sample—pressing temperature T = 1350 °С, pressure P = 30 MPa, holding time 30 min. In Table 1 we report the data characterizing the material. The predominant phase is Ti3AlC2 (volume fraction ≈97%); whereas the volume fraction of TiC is ≈3%. The lattice parameters are close to [10].

2.2 Measurements

The electrical resistivity of the sample was measured using the standard four-probe technique. The thermal conductivity was measured by the uniaxial stationary heat flow method. The temperature drop along the sample was measured with a copper-constantan thermocouple. The electrical contacts in the electrical resistivity measurements and the heat contacts in the thermal conductivity measurements were located in the same positions.

3 Results and discussion

The experimental results for the electrical resistivity of the investigated sample in the interval 15–320 K are shown in Fig. 2. Notably, the resistivity values obtained are characteristic for alloys with defects, as evidenced by the ratio RRR = ρ(300 K)/ρ(4.2 K) ≈ 1.9.

In the temperature range investigated, the electric resistance of the sample is due to the scattering of charge carriers by phonons and defects:

where ρ0 is the residual resistivity, caused by scattering of charge carriers by defects. The scattering of charge carriers by phonons, \(\rho _{{ph}}^{{}}(T)\), can be approximated with a high degree of accuracy by the formula [14]:

where θ is the Debye temperature; С3 is a fitting coefficient.

The minimum error of approximation after (1, 2), Δρ/ρ ≈ 0.5%, was achieved at the parameters’ values, shown in Table 2. In the same table, we compare the parameters of a similar fit for the data [11, 12] for Ti3AlC2, [13] for TiC and our data for Ti.

From Fig. 2 and Table 2 it is shown that ρ0 for Ti3AlC2 and TiC is much larger than for Ti. Because the residual resistivity ρ0 is caused by scattering of charge carriers by defects, it is deduced that the MAX-phase and titanium carbide contain significantly more defects than metallic Ti. Therefore, at low temperatures, where the main role is played by the scattering of charge carriers by defects, ρTi < ρTi3AlC2. At sufficiently high temperatures ρTi > ρTi3AlC2 due to more intensive scattering of charge carriers by phonons (C3Ti > C3Ti3AlC2).

The values of the Debye temperature for Ti3AlC2 decrease with increasing ρ0. The fact is that the comparatively high values of θ are due to significant anisotropy of Ti3AlC2 [12], but the defects make the phonon spectrum more isotropic, thereby reducing θ. The fitting coefficient C3 for Ti3AlC2 is very weakly dependent on the concentration of defects.

The temperature dependence of the thermal conductivity of the sample shows a maximum at Т m ≈ 85 K (refer to Fig. 3). We note that the maximum of thermal conductivity exists both in the case of heat transfer by charge carriers and in the case of heat transfer by phonons if the structure of the sample is quite perfect. Defects shift both maxima to the right and reduce their heights. However, in our case the higher maximum (refer to Fig. 3, curve 2) is located to the right of the lower maximum. This indicates the presence of two mechanisms of heat transfer—by charge carriers and by phonons, comparable in efficiency. The evolution of the total maximum is due to the fact that the defects have different effects on each of the maxima.

Temperature dependences of thermal conductivity, λ(T), of Ti3AlC2: 1—our data, 2—[12]. The points are for the experiment, the lines are drawn “to the eye”

In the region of charge carriers’ elastic scattering is performed the Wiedemann–Franz law [15]:

here, λе is the thermal conductivity, which characterizes the transfer of heat by charge carriers; L 0 = 2.45 × 10−8 W Ω K−2 is the Sommerfeld value of the Lorentz number.

The elastic scattering conditions are satisfied at low temperatures (T≪θ), where the elastic scattering of charge carriers by defects predominates. Here ρ(Т) ≈ ρ0, λ е = L0T/ρ0. At T ≈ 15 K this gives λ е ≈ 1 W m−1 K−1. Comparing this value with the experimental value of low-temperature thermal conductivity (≈ 10 W m−1 K−1) shows that at low temperatures the 90% of the heat is transferred by phonons.

The elastic scattering conditions are satisfied too at sufficiently high temperatures (T > θ), where the elastic scattering of charge carriers by phonons predominates. Here ρ(Т) ≈ ρ0(1 + αТ) and λ е = L0T/ρ(Т) ≈ const. The λ е value estimated from relation (3) is λ е ≈ 10 W m−1 K−1 for T = 300 K, which is about 60% of the experimental value of thermal conductivity at this temperature, that is, phonons part is about 40% of the transferred heat. A specific role in this may be played by specific mechanisms of quasiparticle scattering [16,17,18,19,20,21], due to the presence of structural and kinematic anisotropy in the system.

Thus, the fraction of phonon heat transfer in the MAX phase Ti3AlC2 decreases by increasing temperature, since the charge carriers thermal conductivity at high temperatures is constant, and the phonon thermal conductivity decreases as 1/T.

4 Conclusions

The electrical and thermal conductivity studies of the MAX phase Ti3AlC2 sample showed that the investigated MAX phase contains a large number of defects, which leads to a large value of the residual resistance and reduces the Debye temperature, probably due to isotropization. Heat in the sample is transferred both by phonons and charge carriers, with phonon thermal conductivity predominating at low temperatures, but decreases with increasing temperature.

References

M.A. Hadi, R.V. Vovk, A. Chroneos, J. Mater. Sci. Mater. Electron. 27, 11925–11933 (2016)

E.N. Sgourou, Y. Panayiotatos, R.V. Vovk, A. Chroneos, Appl. Sci. 7, 674 (2017)

T.A. Prikhna, A.V. Starostina, I.A. Petrusha, S.A. Ivakhnenko, A.I. Borimskii, Yu.D. Filatov, M.G. Loshak, M.A. Serga, V.N. Tkach, V.Z. Turkevich, V.B. Sverdun, S.A. Klimenko, D.V. Turkevich, S.N. Dub, T.V. Basyuk, M.V. Karpets, V.E. Moshchil’, A.V. Kozyrev, G.D. Il’nitskaya, V.V. Kovylyaev, D. Lizkendorf. T. Cabiosh, P. Chartier, J. Superhard Mater. 36, 9–17 (2014)

M. Dahlqvist, B. Alling, J. Rosén., Phys. Rev. B 81, 220102 (2010). R)

M.A. Hadi, M. Roknuzzaman, A. Chroneos, S.H. Naqib, A.K.M.A. Islam, R.V. Vovk, K. Ostrikov, Comp. Mater. Sci. 137, 318 (2017)

M. Barsoum, Prog. Solid St. Chem. 28, 201–228 (2000)

D. Horlait, S.C. Middleburgh, A. Chroneos, W.E. Lee, Sci. Rep. 6, 18829 (2016)

F. Shahzad, M. Alhabeb, C.B. Hatter, B. Anasori, S.M. Hong, C.M. Koo, Y. Gogotsi, Science 353, 1137–1140 (2016)

Y. Tong, M. He, Y. Zhou, X. Zhong, L. Fan, T. Huang, Q. Liao, Y. Wang, Appl. Surf. Sci. 434, 28–293 (2018)

Z.M. Sun, Inter. Mater. Rev. 56, 143–166 (2011)

M.W. Barsoum, MAX Phases, Properties of Machinable Ternary Carbides and Nitrides. First Edition (Wiley, Hoboken, 2013) р. 421

X.H. Wang, Y.C. Zhou, Acta Mater. 50, 3141 (2002)

S.N. L’vov, V.F. Nemchenko, T.Ya. Kosolapova, G.V. Samsonov, Dokl. АS USSR 157, 408–411 (1964)

L. Colquitt, J. Appl. Phys. 36, 2454 (1965)

R. Berman, Thermal Conduction of Solids (Clarendon Press, Oxford, 1976)

O.V. Dobrovolskiy, V.V. Sosedkin, R. Sachser, V.A. Shklovskij, R.V. Vovk, M. Huth, J. Supercond. Nov. Magn. 30, 735–741 (2017)

P.G. Curran, V.V. Khotkevych, S.J. Bending, A.S. Gibbs, S.L. Lee, A.P. Mackenzie, Phys. Rev. B 84, 104507 (2011)

A.L. Solovyov, L.V. Omelchenko, V.B. Stepanov, R.V. Vovk, H.-U. Habermeier, P. Przyslupski, K. Rogacki, Phys. Rev. B 94, 224505 (2016)

V.M. Apalkov, M.E. Portnoi, Phys. Rev. B 65, 125310 (2002)

O.V. Dobrovolskiy, M. Huth, V.A. Shklovskij, R.V. Vovk, Sci. Rep. 7, 13740 (2017)

I.N. Adamenko, K.E. Nemchenko, V.I. Tsyganok, A.I. Chervanev. Low Temp. Phys. 20, 498 (1994)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Vovk, R.V., Khadzhai, G.Y., Prikhna, T.A. et al. Charge and heat transfer of the Ti3AlC2 MAX phase. J Mater Sci: Mater Electron 29, 11478–11481 (2018). https://doi.org/10.1007/s10854-018-9242-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9242-6