Abstract

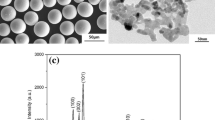

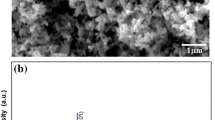

The effect of aging temperature on microstructure and mechanical properties of Sn–9Zn–xZrC (x = 0, 0.06) solder joints was investigated. The results showed that the wettability of Sn–9Zn based alloys was improved by ZrC nanoparticles, the spreading areas of Sn–9Zn–xZrC (x = 0–0.12) were increased firstly then decreased with increasing ZrC content. The spreading area of Sn–9Zn was about 143.64 mm2 and reached maximum about 190.92 mm2 of Sn–9Zn–0.06ZrC. The microstructure of Sn–9Zn–0.06ZrC solder alloy consisted of β-Sn, Sn–Zn eutectic and intermetallic compounds (IMCs), and the microstructure of Sn–9Zn alloy was refined by adding appropriate amounts of ZrC nanoparticles. The interfacial IMCs at the β-Sn boundary in the Sn–9Zn–0.06ZrC solder joint was Cu5Zn8, and partial Cu5Zn8 was transformed to Cu6Sn5 during aging treatment. The IMCs layer thickness was dominated by aging temperature, and ZrC facilitated the IMCs layer growth. The tensile strength of Sn–9Zn based solder joints was enhanced by adding ZrC particles, and then are decreased simultaneously with increasing aging temperature. The fracture surface of Sn–9Zn joints after aging was mainly composed of uniform dimples, and the fracture mechanism of Sn–9Zn based solder joints was ductile fracture.

Similar content being viewed by others

References

J.C. Liu, Z.H. Wang, J.Y. Xie, J.S. Ma, Q.Y. Shi, G. Zhang, K. Suganuma, Corros. Sci. 112, 150 (2016)

S. Liu, S.B. Xue, P. Xue, D.X. Luo, J. Mater. Sci.: Mater. Electron. 26, 4389 (2015)

T. Gancarz, P. Bobrowski, J. Pstruś, S. Pawlak, J. Alloys Compd. 679, 442 (2016)

T. Gancarz, Metall. Mater. Trans. A 47, 1 (2016)

P. Xue, S.B. Xue, Y.F. Shen, F. Long, H. Zhu, J. Mater. Sci.: Mater. Electron. 25, 4219 (2014)

P. Xue, S.B. Xue, Y.F. Shen, H. Zhu, Mater. Des. 60, 1 (2014)

G. Ren, M.N. Collins, Mater. Des. 119, 133 (2017)

M.M. Billah, K.M. Shorowordi, A. Sharif, J. Alloys Compd. 585, 32 (2014)

C.Y. Liu, M.H. Hon, M.C. Wang, Y.R. Chen, K.M. Chang, W.L. Li, J. Alloys Compd. 582, 229 (2014)

A.B. El Basaty, A.M. Deghady, E.A. Eid, Mater. Sci. Eng. A 701, 245 (2017)

W.Q. Xing, X.Y. Yu, H. Li, L. Ma, W. Zuo, P. Dong, W.X. Wang, M. Ding, Mater. Sci. Eng. A 678, 252 (2016)

M. Ding, W. Xing, X. Yu, L. Ma, W. Zuo, Z. Ji, J. Alloys Compd. 739, 481 (2018)

M.L. Huang, F. Zhang, F. Yang, N. Zhao, J. Mater. Sci.: Mater. Electron. 26, 2278 (2015)

T. Gancarz, P. Bobrowski, S. Pawlak, N. Schell, R. Chulist, K. Janik, J. Electron. Mater. 47, 49 (2017)

J.X. Jiang, J.E. Lee, K.S. Kim, J. Alloys Compd. 462, 244 (2008)

K.S. Kim, T. Matsuura, K. Suganuma, J. Electron. Mater. 35, 41 (2006)

G.Q. Wei, J. Mater. Sci.: Mater. Electron. 23, 130 (2012)

T. Gancarz, P. Fima, J. Pstruś, J.Mater. Eng. Perform. 23, 1524 (2014)

T. Luan, W. Guo, S. Yang, Z. Ma, J. He, J. Yan, J. Mater. Process. Technol. 248, 123 (2017)

D.X. Luo, S.B. Xue, S. Liu, J. Mater. Sci.: Mater. Electron. 25, 5195 (2014)

L. Yang, J. Ge, Y. Zhang, J. Dai, Trans. Indian Inst. Met. 70, 2429 (2017)

C.S. Lee, F.S. Shieu, J. Electron. Mater. 35, 1660 (2006)

L. Yang, Y.C. Zhang, J. Dai, Y.F. Jing, J.G. Ge, N. Zhang, Mater. Des. 67, 209 (2015)

C.L. Chuang, L.C. Tsao, J. Mater. Sci.: Mater. Electron. 29, 4096 (2017)

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant Nos. 51375294, 51505010, 51401037).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yang, L., Wei, D., Zhang, Y. et al. Effect of aging temperature on microstructure and mechanical properties of Sn–9Zn–xZrC solder joints. J Mater Sci: Mater Electron 30, 753–759 (2019). https://doi.org/10.1007/s10854-018-0344-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-0344-y