Abstract

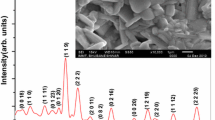

In this article, the structural, dielectric and electrical properties of Bi and Li co-substituted (Ba, Sr) site in Ba0.50Sr0.50TiO3 ceramics are presented. Four different compositions of Ba0.50Sr0.50TiO3, (Ba0.50Sr0.50)0.98(Bi, Li)0.02TiO3, (Ba0.50Sr0.50)0.96(Bi, Li)0.04TiO3, and (Ba0.50Sr0.50)0.92(Bi, Li)0.08TiO3 were synthesized using solid-state reaction with microwave heating of starting materials. Phase detection for all samples has been examined by XRD along with Rietveld refinement analyses, and the results show the formation of single phase without observation of any secondary phase. However, a decrease in crystallite size, lattice parameters, and unit cell volume has been observed with the increase of Bi and Li concentration. A Dense microstructure with different grains sizes and shapes has been obtained by scanning electron microscopy. Impedance spectroscopy in the temperature range of 30–300 °C and frequency range of 60 Hz–1 MHz has been used to study the dielectric properties. The result shows that the Bi and Li co-substituted Ba0.5Sr0.5TiO3 ceramics exhibit very interesting features, such as enhanced dielectric constant with low loss which make it suitable for microwave tunable devices applications. An electric impedance analysis was carried out at different temperatures namely (400, 450, 500, and 550 °C). A single semicircular arc with single relaxation process has been observed in all studied samples which suggest that the grains contribute to the total resistance in these materials. The activation energy was obtained from the impedance analysis using Arrhenius plot of grain conductivity.

Similar content being viewed by others

References

A.K. Tagantsev, V.O. Sherman, K.F. Astaev, J. Venkatesh, N. Setter, J. Electroceram. 11, 5–66 (2003)

E.A. Nenasheva, A.D. Kanareykin, N.F. Kartenko, A.I. Dedyk, S.F. Karmanenko, J. Electroceram. 13, 235–238 (2004)

M.W. Cole, C. Hubbard, E. Ngo, M. Ervin, M. Wood, R.G. Geyer, J. Appl. Phys. 92, 475–483 (2002)

B. Su, T.W. Button, J. Appl. Phys. 95, 1382–1385 (2004)

J. Pundareekam Goud, S. Ramakanth, A. Joseph, K. Sandeep, G. Lakshminarayana Rao, K.C. James Raju, Thin Solid Films 626,126–130 (2017)

K. Sandeep, J. Pundareekam Goud, K.C. James Raju, Appl. Phys. Lett. 111, 012901 (2017)

W.J. Kim, W. Chang, S.B. Qadri, J.M. Pond, S.W. Kirchoefer, D.B. Chrisey, J.S. Horwitz, Appl. Phys. Lett. 76, 1185–1187 (2000)

G. Subramanyam, M.W. Cole, N.X. Sun, J. Appl. Phys. 114, 191301 (2013)

L.C. Sengupta, S. Sengupta, Mater. Res. Innov. 2, 278–282 (1999)

J.W. Wang, C. Xu, B. Shen, J.W. Zhai, J. Mater. Sci. 24, 3309–3314 (2013)

S.B. Herner, F.A. Selmi, V.V. Varadan, V.K. Varadan, Mater. Lett. 15, 317–324 (1993)

T. Hu, T.J. Price, D.M. Iddles, A. Uusimaki, H. Jantumen, J. Eur. Ceram. Soc. 25, 2531–2535 (2005)

S. Garcia, R. Font, J. Portelles, R.J. Quinones, J. Heiras, J.M. Siqueiros, J. Electroceram. 6, 101–108 (2001)

K.T. Kim, C. Kim, Thin Solid Films 472, 26–30 (2004)

J.K. Kim, S.S. Kim, W.J. Kim, T.G. Ha, I.S. Kim, J.S. Song, R. Guo, A.S. Bhalla, Mater. Lett. 60, 2322–2325 (2006)

C.S. Liang, J.M. Wu, J. Cryst. Growth 274, 173–177 (2005)

S.G. Lee, D.S. Kang, Mater. Lett. 57, 1629–1634 (2003)

A. Beitollahi, S.A. Mortazavi, J. Mater. Sci.:Mater. Electron 14(3), 129–134 (2003)

S.F. Wang, O.D. Gordon, J. Am. Ceram. Soc. 82(10), 2677–2682 (1999)

X.Y. Huang, J. Li, C.H. Gao, Z.G. Chen, J. Chin. Ceram. Soc. 33(3), 402–406 (2005)

X.Y. Huang, Z.G. Chen, J. Li, C.H. Gao, J. Synth. Cryst. 35(3), 623–626C634 (2006) (in Chinese)

X.Y. Huang, C.H. Gao, M.Q. Pan, H. Guan, X.T. Zhu, Chin. J. Sci. Instrum. 26(11), 1127–1129 (2005) (in Chinese)

X.Y. Huang, B. Niu, X.X. Jiang, K.H. Shi, J. Jiangsu Univ. Sci. Technol. (Nat. Sci.) 22(1), 66–70 (2001) (in Chinese)

X.Y. Huang, C.H. Gao, Chin. J. Sci. Instrum. 24(1), 45–48 (2003) (in Chinese)

M.S. Alkathy, K.C. James Raju, J Mater Sci: Mater Electron. 27, 8957–8965 (2016)

M.S. AlKathy, R. Gayam, K.C. James Raju, Ceram. Int. 42, 15432–15441 (2016)

J. Zhang, L. Ji, X. Jia, J. Wang, J. Zhai, Y. Zhou, J. Am. Ceram. Soc. 98(1), 97–103 (2015)

A.S. Attar, E.S. Sichani, S. Sharaf, J. Mater. Res. Technol. 6(2), 108–115 (2017)

P. Bindu, S. Thomas, J. Theor. Appl. Phys. 8, 123–134 (2014)

Y.I. Yuzyuk, Phys. Solid State 54, 1026 (2012)

S.Y. Wang, B.L. Cheng, C. Wang, S.Y. Dai, K.J. Jin, Y.L. Zhou, H.B. Lu, Z.H. Chen, G.Z. Yang, J. Appl. Phys. 99, 013504 (2006)

R. Naik, et.al, Phys. Rev. B 61, 11367 (2000)

L.Z. Cao, et.al, J. Phys. D 39, 2819 (2006)

R.L. Fullman, Trans. AIME 197, 447–452 (1953)

M.S. Alkathy, K.K. Bokinala, K.C. James Raju, J. Mater. Sci.: Mater. Electron. 27, 3175–3181 (2016)

M.N. Rahman, Ceramic Processing and Sintering (Marcel Dekker, Inc., New York, 1995)

A. von Hippel, Dielectrics and Waves (Artech House, Boston, 1995)

A. von Hippel, Rev. Mod. Phys. 22, 221–245 (1950)

L. Davis, L.G. Rubin, J. Appl. Phys. 24, 1194–1197 (1953)

H. Abrams, Metallography 4(1), 59–78 (1971)

B.K. Bammannavar, L.R. Naik, B.K. Chougule, J. Appl. Phys 104, 064123 (2008)

M.S. Alkathy, R. Gayam, K.C. James Raju, J. Mater. Sci.: Mater. Electron. 28, 1684–1694 (2017)

A. Tkach, O. Okhay, P.M. Vilarinho, A.L. Kholkin, J. Phys. Condens. Matter 20, 415224 (2008)

S. Selvasekarapandian, M. Vijaykumar, Mater. Chem. Phys. 80, 29 (2003)

P.K. Patel, J. Rani, N. Adhlakha, H. Singh, K.L. Yadav, J. Phys. Chem. Solids 74, 545–549 (2013)

Acknowledgements

Authors acknowledge the facilities provided by UGC, DST, and DRDO at University of Hyderabad. We thank Mr. Binoy, School of Physics, University of Hyderabad for helping in Electrical measurement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pundareekam Goud, J., Alkathy, M.S. & James Raju, K.C. Structural, dielectric and impedance study of Bi and Li co-substituted Ba0.50Sr0.50TiO3 ceramics for tunable microwave devices applications. J Mater Sci: Mater Electron 29, 3611–3620 (2018). https://doi.org/10.1007/s10854-017-8291-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8291-6