Abstract

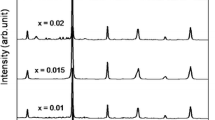

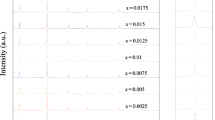

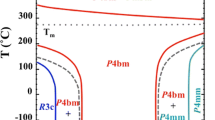

The study highlights the effect of donor (Sr2+) and acceptor (Zr4+) co-doping on phase formation, microstructure, density, ferroelectric, dielectric, piezoelectric, fatigue and aging properties of (Na0.52 K0.48)(Nb0.95 Sb0.05)O3, abbreviated as NKNS, lead free piezoelectric ceramics. The composition (1–x)(NKNS)—xSrZrO3 (where x = 0.0, 0.02, 0.04, 0.06 and 0.08) were synthesized by mixed oxide route. The doping drastically affected the phase formation and the microstructure. The poling studies suggested that the material requires higher poling temperature (120 °C) for optimum properties. At the small concentration of SrZrO3, the dominant effect of acceptor doping induced ‘hybrid’ piezoelectric behavior which improved fatigue, ageing and piezoelectric properties. The mechanical quality factor (Qm) more than doubled (96) and piezoelectric charge co-efficient peaked to 157 × 10 −12 C/N for 2% SrZrO3. The study of Raman spectra ascertained that the doping influenced the nature of B–O bonding. The electrical fatigue behavior in conjunction with ferroelectric studies confirmed that due to complex doping different mechanisms work to stabilize the polarization state which influenced the ageing and fatigue behavior.

Similar content being viewed by others

References

G.H. Heartling, J. Am. Ceram. Soc. 82(4), 797 (1999). doi:10.1111/j.1151-2916.1999.tb01840.x

S.T. Lau, C.H. Cheng, S.H. Choy, D.M. Lin, K.W. Kwok, H.L.W. Chan, J. Appl. Phys. 103, 104105 (2008). doi:10.1063/1.2927252

P. Kumari, R. Rai, S. Sharma, M. Shandilya, A. Tiwari, Adv. Mater. Lett. 6, 453 (2015). doi:10.5185/amlett.2015.4086

Y. Gong, G. Yang, X. Li, L. Gong, L. Li, J. Peng, X. Zheng, J. Mater. Sci. 23, 1910 (2012). doi:10.1007/s10854-012-0879-2

X. Vendrell, J.E. Gorcia, X. Brill, D.A. Ochoa, L. Mestres, G. Dezanneau, J. Eur. Ceram. Soc. 35, 125 (2015). doi:10.1016/j.jeurceramsoc.2014.08.033

J.B. Lim, S. Zhang, J.-H. Jeon, T.R. Shrout, J. Am. Ceram. Soc. (2010). doi:10.1111/j.1551-2916.2009.03528.x

B. Jaffe, W.R. Cook Jr., H. Jaffe, Piezoelectric Ceramics (Academic Press, London and New York, 1971), pp. 150–250

R.A. Eichel, H. Kungl, M.J. Hoffmann, J. Appl. Phys. 95, 8092 (2004). doi:10.1063/1.1728310

R.A. Eichel, P. Erhart, P. Traskelin, K. Albe, H. Kungl, M.J. Hoffmann, Phys. Rev. Lett. 100, 095504 (2008). doi:10.1103/PhysRevLett.100.095504

B. Malic, J. Bernard, J. Holc, D. Jenko, M. Kosec, J. Eur. Ceram. Soc. 25, 2707 (2005). DOI:10.1016/j.jeurceramsoc.2005.03.127

N.M. Hagh, B. Jadidian, E. Ashbahian, A. Safari, IEEE Trans. Ultrason. Ferroelectr. FrEq. Control 55(1), 212 (2008). doi:10.1109/TUFFC.2008.630

B.W. Lee, E.J. Lee, J. Electroceram. 17, 597 (2006). doi:10.1007/s10832-006-8568-2

E. Erdem, R.A. Eichel, H. Kungl, M.J. Hoffmann, A. Ozarowski, J. V. Tol, L.C. Brunel, IEEE Trans. Ultrason. Ferroelectr. FrEq. Control 55(5), 1061 (2008). doi:10.1109/TUFFC.2008.757

B.J. Kennedy, C.J. Howard, B.C. Chakoumakos, Phys. Rev. B 59(6), 4023 (1999). doi:10.1103/PhysRevB.59.4023

A. Ahtee, M. Ahtee, A.M. Glazer, A.W. Hewat, J. Acta Crystallogr. B32, 3243 (1976). doi:10.1107/S0567740876010029

R.D. Shannon, Acta Cryst. A 32, 751 (1976). doi:10.1107/S0567739476001551.

R. Zuo, M. Wang, B. Ma, J. Fu, T. Li, J. Phys. Chem. Solids 70, 750 (2009). doi:10.1016/j.jpcs.2009.03.003

Q. Li, M.H. Zhang, Z.X. Zhu, K. Wang, J.S. Zhou, F.Z. Yao, J.F. Li, J. Mater. Chem. C 5, 549 (2017). doi:10.1039/C6TC04723H

J.L. Jones, B.J. Iverson, K.J. Bowman, J. Am. Ceram. Soc. 90(8), 2297 (2007). doi:10.1111/j.1551-2916.2007.01820.x

Y. Li, J. Yuan, D. Wang, D. Zhang, H. Jin, M. Cao, J. Am. Ceram. Soc. 96(11), 3440 (2013). doi:10.1111/jace.12479

S. Zhang, J.B. Lim, H.J. Lee, T.R. Shrout, IEEE trans. Ultrason. Ferroelectr. FrEq. Control 56(8), 1523 (2009). doi:10.1109/TUFFC.2009.1215

H.E. Mgbemere, R.P. Herber, G.A. Schneider, J. Eur. Ceram. Soc. 29(9), 1729 (2009). doi:10.1016/j.jeurceramsoc.2008.10.012

V.M. Goldschmidt, Naturwissenschaften 21, 477 (1926). DOI:10.1007/BF01507527

Y. Na, J. Abolfazl, Z. Lanling, G. Zhigang, C. Zhenxiang, W. Xiaolin, J. Alloys Compd. 652, 341 (2015). doi:10.1016/j.jallcom.2015.08.222

R.C. Cohen, Nature 358, 136 (1992). doi:10.1038/358136a0

M.M. Shamim, T. Ishidate, K. Ohi, J. Phys. Soc. Jpn. 72(3), 551 (2003). doi:10.1143/JPSJ.72.551

H. Birol, D. Damjanovic, N. Setter, J. Eur. Ceram. Soc. 26, 861 (2006). doi:10.1016/j.jeurceramsoc.2004.11.022

U. Robels, G. Arlt, J. Appl. Phys. 73, 3454 (1993). doi:10.1063/1.352948

K. Carl, K.H. Hardtl, Ferroelectrics 17, 473 (1977). doi:10.1080/00150197808236770

Z. Luo, T. Granzow, J. Glaum, W. Jo, J. Rödel, M. Hoffman, J. Am. Ceram. Soc. 94(11) 3927 (2011). doi:10.1111/j.1551-2916.2011.04605.x

Acknowledgements

The authors express their sincere gratitude to Director, Armament Research and Development Establishment for extending his support for this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rawal, B., Wathore, N.N., Praveenkumar, B. et al. Effect of donor and acceptor co-doping in (Na0.52 K0.48) (Nb0.95 Sb0.05)O3 lead-free piezoceramic. J Mater Sci: Mater Electron 28, 16426–16432 (2017). https://doi.org/10.1007/s10854-017-7553-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7553-7