Abstract

Principally novel crosslinking nonlinear optical and optoelectronics system based on Diels–Alder reaction was designed. The copolymer of methyl methacrylate and anthracen-9-ylmethyl methacrylate (PMMA-AMA) was used as a host polymer; chromophore ETO was used as guest chromophore; chromophore ETO and N,N-(methylenediphenyl)bismaleimide were used as crosslinker. The thermodynamic property of crosslinking system studied by differential scanning calorimeter (DSC) showed us that the glass transition temperature was about 65 °C and the crosslinking temperature was varied between 80 and 120 °C The crosslinking reactive speed and effectiveness were studied by ultraviolet absorption and infrared absorption spectroscopy with spectral resoluiotn 1 cm−1. These results have indicated that the cross linking process could be finished at 110 °C for 20 min. Surprisingly, such EO polymer showed us a large EO coefficient of about 96.3 pm/V at wavelength 1 µm and excellent long term stability about 85% with respect to its initial value and can be kept after 250 h of heating at 80 °C.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Comparing with the traditional inorganic crystals and semiconductor nonlinear optical (NLO) materials, organic electro-optic (EO) polymers exhibit substantial advantages in the following aspects: fast response time, easy processing, low dielectric constant and ultra-large EO coefficients [1–5]. So, researchers have paid more and more attentions to organic EO materials in the past decades. And a large amount of novel organic EO materials with excellent EO activity has been emerged [6–10]. Else, the development of novel EO devices including organic EO modulator, optical switch, terahertz detectors and so on is also very fast. Lots of prototype devices based on this kind of materials have been designed and prepared in the area of scientific research [11–15]. Unfortunately, seldom of these devices prepared by organic EO polymers have been used in commercial areas, due to the poor long term stability of organic EO polymers, which can determine the production process and service life.

So, the improvement of long term stability has become the most urgent problem to be solved. Crosslinking process is considered as one of the most effective way for solving the long term stability of organic EO polymers [16–20]. But suitable crosslinking reaction is hard to be found, due to the following requirements: (1) the crosslink temperatures should match the poling process and the thermal stability of chromophores; (2) the crosslink reaction should occur in a mild condition ensuring the chromophores in a low failure rate; (3) the EO polymer should have a high cross-linking degree. Diels–Alder reaction is an optimal choice for this reason. Some crosslinkable EO polymers have been just reported using Diels–Alder reaction as the crosslinking process [21–23]. However, most of the chromophores just have one or none reactive group. In this manuscript, two anthracene groups are introduced to the NLO chromophore. Such chromophore with double anthracene groups can be used as both the functional molecule and crosslinker.

2 Experimental procedure

2.1 Materials and instruments

All the chemicals were purchased from Aldrich or Beijing Lanyi Chemical co. ltd, which were used as received unless otherwise specified. All the organic solvents were distilled before use. 1H NMR and 13C NMR spectra were determined by Varian Gemini 300 400 MHz NMR spectrometer using tetramethylsilane as internal reference. FT-IR spectra were recorded on BIO-RAD FTS-165 spectrometer. MS spectra were obtained on MALDI-TOF Matrix Assisted Laser Desorption/Ionization of Flight on BIFLEX BrukerInc. spectrometer. UV–Vis spectra were performed on Hitachi U2001 photo spectrometer. Thermal properties were determined by differential scanning calorimeter Q20, TA co under the protection of nitrogen.

2.2 Synthesis of chromophore ETO

Chromophore 1 (0.95 g, 1.0 mmol) was dissolved in 20 mL of THF. Aqueous solution of HCl (10 mL, 1 N) was added and the mixture was stirred at ambient temperature for 2 h. Then, the solvent was removed and the crude product was purified by flashchromatography over silica gel using 20% ethyl acetate in hexane as eluent affording chromophore 1-OH (0.79 g, 1.82 mmol). The yield was about 90%. 1H NMR (400 MHz, CD3COCD3),δ : 8.53 (d, J = 15.2 Hz, 1H), 7.78 (d, J = 8.0 Hz, 2H), 7.12 (d, J = 15. 6 Hz, 1H), 7.00 (d, J = 8.4 Hz, 2H), 6.44 (s, 1H), 6.42 (s, 2H), 5. 26 (s, 2H), 3.87 (t, J = 4.8 Hz, 4H), 3.86 (d, J = 5.2 Hz, 4H), 3.80 (t, J = 5.2 Hz, 4H) 1.64–1.68 (m, 2H), 1.28–1.49 (m, 16H), 0.87–0.90 (m, 12H). IR (KBr)ν: 3364, 2933, 2222, 1734, 1539, 1396, 1280, 1180 cm−1. MS (MALDI-TOF) m/z: 744 (M + Na+) calc. for C43H55N5O5: 721.42.

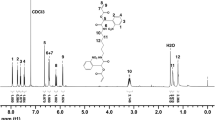

Compound 1-OH (0.36 g, 0.5 mmol) and anthracen-9-ylmethoxy-4-oxobutanoic acid (0.31 g, 1.0 mmol) were dissolved in 50 mL CH2Cl2. DMAP (0.12 g, 1.0 mmol) and DCC (0.21 g, 1.0 mmol) were added to the mother solution. The reaction solution was stirred at room temperature for 5 h under argon. Then, the result solution was poured into 100 mL water and extract with CH2Cl2. The resulting compound was purified by silica gel column chromatography (VEA:Vchloroform = 1:5) to give blue solid. Yield: 60%. 1H NMR (400 MHz, CDCl3): 8.47 (s, 2H), 8.45 (d, J = 16.0 Hz, 1H), 8.30 (d, J = 9.2 Hz, 4H), 8.00 (d, J = 8.4 Hz, 4H), 7.56 (t, J = 8.4 Hz, 4H), 7.47 (t, J = 7.24 Hz, 4H), 7.40 (d, J = 8.8 Hz, 2H), 7.03 (d, J = 15.2 Hz, 1H), 6.48 (d, J = 8.8 Hz, 2H), 6.39 (s, 1H), 6.29 (s, 2H), 6.16 (s, 4H), 5.23 (s, 2H), 4.02 (t, J = 6.0 Hz, 4H), 3.81 (d, J = 6.0 Hz, 4H), 3.30 (t, J = 5.6 Hz, 4H), 2.61 (t, J = 8.4 Hz, 4H), 2.56 (t, J = 6.4 Hz, 4H), 1.67–1.70 (m, 2H), 1.31–1.49 (m, 16H), 0.87–0.90 (m, 12H). IR (KBr),ν: 3327, 2928, 2220, 1734, 1533, 1178, 733 cm−1. MS (MALDI-TOF) m/z: 1324 (M + Na+), calc. for C80H82N5O11: 1302.55.

2.3 Synthesis of polymer PMMA-AMA

Methyl methacrylate(4 g, 40 mmol) and anthracen-9-ylmethyl methacrylate (2.76 g, 10 mmol) was dissolved in 50 ml 1,4-dioxacyclohexane. When all of the solid was dissolved, 2,2′-azobis(2,4-dimethyl)valeronitrile (0.05 g) was added to the solution. Nitrogen was introduced to the mixture for 0.5 h. Then the temperature was raised to 70 °C. And the temperature was kept for 8 h under the nitrogen atmosphere. The solution was slowly dropped into 500 mL ether and the white solid was precipitated. The solid was collected by filtration and washed for three times by methanol. Affording PMMA-AMA 6.12 g, yield: 90%. 1H NMR (400 MHz, CDCl3): 1H NMR (400 MHz, CDCl3): 8.76 (s, 1H), 8.10 (s, 4H), 7.68 (m, 4H), 4.68 (s, 24H), 3.59 (s, 12H), 2.15 (s, 10H), 1.68–1.83 (s, 15H).

2.4 Preparation of polymer EO films

Chromophore ETO (0.015 g, 0.02 mmol) and PMMA-AMA (0.125 g) were dissolved in 1.0 ml 1,1-dichloroethane. After the solution was stirred for 12 h, N, N-(methylenediphenyl)bismaleimide (0.02 g, 0.05 mmol) was added. When all of the solids were dissolved, the solution was filtered by filter with the aperture of 0.22 μm. The filtrate was spin coated on ITO glass with the rotating speed of about 500–600 r/min. The film was dried in vacuum oven at 40 °C for 24 h, affording us the EO films with the thickness of about 2–5 μm with accuracy up to 0.1 µm.

2.5 Poling of the EO films

The EO films were poled at a temperature of 75 °C under an electric field voltage of 10.5 kV for 15 min, at the first stage. And most of the chromophores were aligned in this stage. The polymer EO films were pre-polymerized at 80 °C for 5 min and the temperature were raised to 110 °C at the heating rate of about 5 °C/min, at the second stage. At the third stage, the EO films were kept at 110 °C for 20 min. Then, the temperature was reduced to room temperature and the electric field was removed.

3 Results and discussion

3.1 Structures of the EO polymer and the preparation of EO films

The structure of the EO polymer is shown in Scheme 1. The synthesis process of this polymer can divide into the following steps: (1) the synthesis of NLO chromophore ETO, which is a complex process and will be described in the following part; (2) the synthesis of polymer PMMA-AMA, which is a normal free radical polymerization, excepting the large steric effect of anthracene; (3) NLO chromophore ETO, polymer PMMA-AMA and N, N-(methylenediphenyl)bismaleimide were dissolved in 1,1-dichloroethane with a appropriate ratio; (4) the solution was filtered and spin coated on ITO glass with thickness about 2–5 μm; (5) the EO films were poling and cross linking under direct current field and special temperatures. In the whole process, the poling process and cross linking process are combined into one step. And such process is the critical process. Thermodynamics of this process is studied in details using differential scanning calorimeter technologies and the result is discussed in the following part.

3.2 Synthesis of chromophore ETO

The structure and synthesized process of chromophore ETO is shown in Scheme 2. In our past article, the synthesis of chromophore 1 has been reported [24]. In this article, chromophore 1 is used as a starting material. After two chemical reaction, chromophore ETO can be prepared. In the first step, chromophore 1 ishydrolysized affording us chromophore 1-OH with two hydroxyl groups, which were the reactive active group in the following step. In the second step, chromophore 1-OH reacted with anthracen-9-ylmethoxy-4-oxobutanoicacid under the dehydrating agent of 4-dimethylaminopyridine (DMAP) and dicyclohexylcarbodiimide (DCC) affording us chromophore ETO.The esterification reaction used in this process is very successful, due to the high yield and mild reactive conditions.

3.3 Crosslinking and poling process of the EO polymer

The crosslinking process of the EO polymer is firstly studied by differential scanning calorimeter (DSC). The results are shown in Fig. 1. The sample is scanned for two times from low temperature to high temperature. At the first time, there is a strong heat absorption peak from 80 to 140 °C, which is attributed to the crosslink reaction process. Else, there is a small step at 65 °C, which is not very obvious comparing with the strong heat absorption peak. But this small step is very important, because it tells us the glass transition temperature of this complex system before the cross linking process. At the second time, such a heat absorption peak disappears, which indicates that the crosslinking process had been finished in the first scanning process. Else, there is no melting point and glass transition temperature found in the second scanning process. Such a result indicates that the crosslinking degree is very high. Such a high crosslinking degree can confirm the long term stability of this EO polymer effectively.

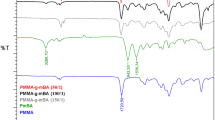

The crossling reaction speed was also studied by infrared spectroscopy. The results are shown in Fig. 2. The infrared absorption peaks between 800–1000 cm−1 are attributed to the C–H out-of-plane bending vibration of the carbon carbon double bond including the carbon carbon double bond of maleimide, anthracene and other conjugated groups. Obviously, before the poling process, the absorption peaks between 800–1000 cm−1 are very strong; after poling at 110 °C for 20 min, the absorption peak between 800–1000 cm−1 is reduced significantly; the difference of the absorption peak between 800–1000 cm−1 is not very obvious between poling for 20 and 30 min at 110 °C. Such a result indicates that the crosslinking process has been almost finished under the poling process at 110 °C for 20 min.

3.4 Second order nonlinear optical features of the EO polymers

The UV–Vis spectra of the EO polymer films before poling and after poling are shown in Fig. 3. After the poling process, the maximum absorption peak for the EO film prepared by the EO polymer greatly decreases, which is used to characterize the poling efficiency by formula (4):

where ϕ is the poling parameter, A is the maximum absorption after poling and A 0 is the maximum absorption before poling process.

The ϕ value is about 15.1%. According to the lectures, such a ϕ value is not very large [25]. This means that not all of the chromophore molecules are aligned in the poling process. Such a result is attributed to the fast crosslinking process. The crosslinking process can be finished in about 20 min; in such a short time, the chromophore molecules couldn’t be oriented sufficiently. So, there is still a large space for optimization of this kind of EO polymer system.

Else, the crosslinking process could also be determined by the UV–Vis spectra of the poling process. As shown in Fig. 3, before the poling process, there are three strong absorption peaks at 352, 369 and 389 nm, which are the characteristic absorption peaks of anthracene. After the poling process, these strong absorption peaks disappeared with accuracy up to 3%. Such a result indicates that the crosslinking process is sufficient. The EO efficient of poled film is determined by a simple reflection technique initially proposed by Teng and Man [26]. The r 33 value is calculated via the following equation:

Here, r 33 is the EO coefficient of the poled polymer, λ is the probing optical wavelength, θ is the incident angle, I c is the output beam intensity, I m is the amplitude of the modulation, V m is the modulating voltage, and n is the refractive index of the polymer films. The EO coefficient usually depends on the concentration of chromophore. The highest r 33 value for this EO polymer system is about 96.3 pm/V with the chromophore loading density of 24%. Comparing with the EO coefficients of chromophore 1 doped in guest–host system, the EO coefficient exhibited in this system was improved for about 50% [24]. Such a large improvement was attributed to large isolated groups (anthracen-9-ylmethoxy-4-oxobutanoic acid), which could reduce the intermolecular dipole interaction effectively and improve the poling efficiency.

3.5 Long term stability of the crosslinking system

The long-term stability of the EO activity is an important factor for device fabrication. In later fabrication, the poled EO polymer must resist temperatures up to 80 °C to complete the micro-nano-processing, such as: photo-etching, plating, etching, dicing treatment and so on. Most of these processes should withstand a certain temperature. To investigate the long-term NLO stability of the poled polymers, a normalized EO coefficient [r33 (t)/r33 (t0)] was measured as a function of time at 80 °C.

Figure 4 shows that a fast decay was observed in the first 50 h for the EO film. This was due to the recovery of bond angles and bond lengths in the oriented chromophores. Next, the r 33 value remained nearly constant in the remaining time. The initial r33 value held 85% of its initial value after 250 h of heating at 80 °C.Comparing with the EO materials based on guest-host system reported before, such long term stability is improved greatly [24].

3.6 Theoretical calculation of chromophore ETO

We have performed also quantum chemical calculations of the ground state dipole moments and nonlinear optical susceptibilities of ETO chromophore molecule using Gaussian W09 package [27, 28] at the DFT level [29, 30] in order to analyze the origin of the enhanced effects. Initial geometries of molecule was estimated by AM1 method and obtained model was subsequently optimized using DFT and B3LYP functional supplemented with the standard 6-31G(d,p) basis set [31, 32]. Shape of HOMO and LUMO (Fig. 5), ground state dipole moments and average hyperpolarizabilities were calculated applying DFT B3LYP/ 6-31G (d, p) method. The calculated ground state dipole moment value is equal to 16.8767D and average hyperpolarizability—about 2.1031 × 10−29 esu. This is in agreement with principal role of ground state dipole moments [33].

Finally it should be added that the background surrounding the organic chromophore may also differently influence on the output susceptibilities [34–36].

4 Conclusions

The Diels–Alder reaction among N,N-(methylenediphenyl)bismaleimide, PMMA-AMA and nonlinear optical chromophore was used as a novel crosslinking system for improving the long term stability of organic EO materials. The thermodynamic property of this crosslinking system was firstly studied by differential scanning calorimeter. The results showed that the glass transition temperature for the titled system was about 65 °C and the crosslinking temperature was between 80 °C and 120 °C. Moreover, after the crosslinking process, the EO polymer could form a network structure. On the other way, the cross linking process was also monitored by ultraviolet absorption and infrared absorption spectroscopy. These results indicated that the cross linking process could be finished at 110 °C for 20 min. Surprising, such EO polymer showed us a large EO coefficient of about 96.3 pm/V. And the long term stability was also very good. 85% of its initial value can be kept after 250 h of heating at 80 °C.

References

J. Liu, W. Gao, I. Kityk, X. Liu, Z. Zhen, Dyes Pigm. 122, 74–84 (2015)

S.H. Jang, J. Luo, N.M. Tucker, A. Leclercq, E. Zojer, M.A. Halleret et al., Chem. Mater. 18, 2982–2988 (2006)

S. Benight, D. Bale, B. Olbricht, L. Dalton, J. Mater. Chem. 19, 7466–7475 (2009)

Y.Y. Siao, S.M. Shau, W.H. Tsai, Y.C. Chen, T.H. Wu, J.J. Lin et al., Polym. Chem. 4, 2747–2759 (2013)

S. Farsadpour, L. Ghoochany, C. Kaiser, G. Von Freymann, Dyes Pigm. 127, 73–77 (2016)

Y. Shi, A.J.-T. Lou, G.S. He, A. Baev, M.T. Swihart, N. Paras et al., J. Am. Chem. Soc. 137, 12521–12538 (2015)

J. Liu, Y. Yang, X. Liu, Zhen, Mater. Lett. 142, 87–89 (2015)

F. Bures, D. Cvejn, K. Melanova, L. Benes, J. Svoboda, V. Zimaet et al., J. Mater. Chem. C 4, 468–478 (2016)

W. Wu, R. Xiao, W. Xiang, Z. Wang, Z. Li, J. Phys. Chem. C 119, 14281–14287 (2015)

Z. Shi, S. Hau, J. Luo, T.D. Kim, N.M. Tucker, J.W. Ka et al., Adv. Funct. Mater. 17, 2557–2563 (2007)

J. Liu et al., RSC Adv. 5, 15784 (2015)

V. Katopodis, P. Groumas, Z. Zhang, R. Dinu, E. Miller, A. Konczykowska et al., Opt. Commun. 362, 13–21 (2016)

F. Qiu, H. Sato, A.M. Spring, D. Maeda, M. Ozawa, K. Odoi et al., Appl. Phys. Lett. 107, 123302 (2015)

Y. Enami, Y. Jouane, J. Luo, A. Jen, Opt. Express 22, 30191–30199 (2014)

Y. Jouane, Y. Chang, D. Zhang, J. Luo, A. Jen, Y. Enami, Opt. Express 22, 27725–27732 (2014)

W. Gao, W. Hou, Z. Zhen, X. Liu, J. Liu, A. Fedorchuk, P. Czaja, Opt. Mater. 57, 63–70 (2016)

J. Liu, P. Si, X. Liu, Z. Zhen, Opt. Mater. 47, 256–262 (2015)

A. Priimagi, K. Ogawa, M. Virkki, J. Mamiya, M. Kauranen, A. Shishido, Adv. Mater. 24, 6410–6415 (2012)

Y. Mori, K. Nakaya, X. Piao, K. Yamamoto, A. Otomo, S. Yokoyama, J. Polym. Sci. Part. A 50, 1254–1260 (2012)

H. Yang, R. Tang, W. Wu, W. Liu, Q. Guo, Y. Liu, S. Xu, S. Cao, Polym. Chem. 7, 4016–4024 (2016)

M. Arseneault, C. Wafer, J. Morin, Molecules 20, 9263–9294 (2015)

S. Bae, H. Kim, H. Min, D. Kim, T. Kim, J. Nanosci. Nanotechnol. 12, 730–736 (2012)

Z. Shi, J. Luo, S. Huang, Y. Cheng, T. Kim, B. Polishak, X. Zhou, Y. Tian, S. Jang, D. Knorr, R. Overney, T. Younkin, A. Jen, Macromolecules 42, 2438–2445 (2009)

J. Liu, L. Qiu, X. Liu, Z. Zhen, J. Optoelectron. Adv. Mater. 11, 1765–1768 (2009)

J. Liu, W. Hou, S. Feng, L. Qiu, X. Liu, Z. Zhen, J. Phys. Org. Chem. 24, 439–444 (2011)

C. Teng, H. Man, Appl. Phys. Lett. 56, 1734–1736 (1990)

M.J. Frisch, G.W. Trucks, H.B. Schlegel, G.E. Scuseria, M.A. Robb, J.R. Cheeseman, G. Scalmani, V. Barone, B. Mennucci, G.A. Petersson, H. Nakatsuji, M. Caricato, X. Li, H.P. Hratchian, A.F. Izmaylov, J. Bloino, G. Zheng, J.L. Sonnenberg, M. Hada, M. Ehara, K. Toyota, R. Fukuda, J. Hasegawa, M. Ishida, T. Nakajima, Y. Honda, O. Kitao, H. Nakai, T. Vreven, J.A. Montgomery Jr., J.E. Peralta, F. Ogliaro, M. Bearpark, J.J. Heyd, E. Brothers, K.N. Kudin, V.N. Staroverov, R. Kobayashi, J. Normand, K. Raghavachari, A. Rendell, J.C. Burant, S.S. Iyengar, J. Tomasi, M. Cossi, N. Rega, J.M. Millam, M. Klene, J.E. Knox, J.B. Cross, V. Bakken, C. Adamo, J. Jaramillo, R. Gomperts, R.E. Stratmann, O. Yazyev, A.J. Austin, R. Cammi, C. Pomelli, J.W. Ochterski, R.L. Martin, K. Morokuma, V.G. Zakrzewski, G.A. Voth, P. Salvador, J.J. Dannenberg, S. Dapprich, A.D. Daniels, Ö Farkas, J.B. Foresman, J.V. Ortiz, J. Cioslowski, D.J. Fox, Gaussian 09, Revision E.01. (Gaussian, Inc, Wallingford, 2009)

Dennington R, Keith T, Millam, J. GaussView, Version 5. (Semichem Inc., Shawnee, 2009)

R.G. Parr, W. Yang, Density-Functional Theory of Atoms and Molecules (Oxford University Press, New York, 1989)

W. Koch, M.C. Holthausen, A Chemist’s Guide to Density Functional Theory (Wiley-VCH, Weinheim, 2000)

A.D. Becke, Phys. Rev. A 38, 3098–3100 (1988)

C. Lee, W. Yang, R.G. Parr, Phys. Rev. B 37, 785–789 (1988)

T. Kolev, B. Koleva, J. Kasperczyk, I. Kityk, S. Tkaczyk, M. Spiteler, A. H. Reshak, W. Kuznik, J. Mater. Sci. Mater. Electron. 20, 1073–1077 (2009)

Ts. Kolev, I.V. Kityk, J. Ebothe, B. Sahraoui, Chem. Phys. Lett. 443, 309–312 (2007)

F. Bures, H. Cermakova, J. Kulhanek, M. Ludwig, W. Kuznik, I.V. Kityk, T. Mikysek, A. Ruzicka, Eur. J. Org. Chem. 2012, 529–538 (2012)

F. Bures, D. Cvejn, K. Melánová, L. Beneš, J. Svoboda, V. Zima, O. Pytela, T. Mikysek, Z. Růžičková, I. V. Kityk, A. Wojciechowski, N. AlZayed, J. Mater. Chem. C 4, 468 (2016)

Acknowledgements

We are grateful to the National Natural Science Foundation of China (No. 51503215) and the Fund of Key Laboratory of Agrifood Safety and Quality, MOA (2016-KF-14) for financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Gao, W., Qin, G., Liu, J. et al. Design and preparation of novel Diels–Alder crosslinking polymer and its application in NLO materials. J Mater Sci: Mater Electron 28, 8480–8486 (2017). https://doi.org/10.1007/s10854-017-6569-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-6569-3