Abstract

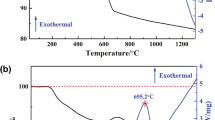

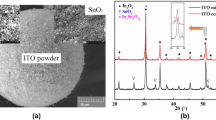

High density indium tin oxide (ITO) ceramic targets with low SnO2 content were prepared successfully by sintering co-precipitationally synthesized powders. The sintering behavior, properties and refining grains of the ITO targets were studied in normal pressure oxygen ambience. Higher sintering temperature promoted sintering densification, resulted in abnormal grain growth and decreased bending strength. By a two-step sintering method, the uniform and fine-grained microstructures were obtained. The sintered density of the ITO targets was further improved. Furthermore, the grain size was reduced, and the bending strength was also enhanced.

Similar content being viewed by others

References

S.I. Kim, S.H. Cho, S.R. Choi, M.C. Oh, J.H. Jang, P.K. Song, Thin Solid Films 517(14), 4061 (2009)

J. Xu, Z. Yang, X. Zhang, H. Wang, H. Xu, J. Mater. Sci. Mater. Electron. 25, 1792 (2014)

T. Minami, Semicond. Sci. Technol. 20, S35 (2005)

G. Goncalves, V. Grasso, P. Barquinha, L. Pereira, E. Elamurugu, M. Brignone, R. Martins, V. Lambertini, E. Fortunato, Plasma Process. Polym. 8, 340 (2011)

E. Fortunato, P. Nunes, A. Marques, D. Costa, H. Aguas, I. Ferreira, M.E.V. Costa, M.H. Godinho, P.L. Almeida, J.P. Borges, R. Martins, Surf. Coat. Technol. 151, 247 (2002)

C.H. Liu, X. Yu, Nanoscale Res. Lett. 6, 75 (2011)

S.J. Wang, Y. Geng, Q. Zheng, J.K. Kim, Carbon 48, 1815 (2010)

S. Parthiban, V. Gokulakrishnan, K. Ramamurthi, E. Elangovan, R. Martins, E. Fortunato, R. Ganesan, Sol. Energy Mater. Sol. Cells 93, 92 (2009)

G.G. Untila, T.N. Kost, A.B. Chebotareva, M.A. Timofeyev, Semiconductors 46(7), 962 (2012)

P.K. Biswas, A. Dea, K. Ortner, S. Korder, Mater. Lett. 58(10), 1540 (2004)

H. Kostlin, R. Jost, W. Lems, Phys. Status Solidi A 29, 87 (1975)

S.F. Tseng, W.T. Hsiao, K.C. Huang, D. Chiang, M.F. Chen, C.P. Chou, Appl. Surf. Sci. 257, 1487 (2010)

J.O. Song, K.K. Kim, H. Kim, H.G. Hong, H. Na, T.Y. Seong, Electrochem. Solid State Lett. 10(9), H270 (2007)

J. Hotovy, J. Hupkes, W. Bottler, E. Marins, L. Spiess, T. Kups, V. Smirnov, I. Hotovy, J. Kovac, Appl. Surf. Sci. 269, 81 (2013)

A.E. Lozano, J.D. Abajo, J.G.D.L. Campa, C. Guillen, J. Herrero, M.T. Gutierrez, J. Appl. Polym. Sci. 103(6), 3491 (2007)

T. Omata, M. Kita, H. Okada, S. Otsuka-Yao-Matsuo, N. Ono, H. Ikawa, Thin Solid Films 503, 22 (2006)

P. Lippens, A. Segers, J. Haemrs, R. De Gryse, Thin Solid Films 317, 405 (1998)

B.L. Gehman, S. Jonsson, T. Rudolph, M. Schere, M. Weigert, R. Werner, Thin Solid Films 220, 333 (1992)

N. Neves, A. Lagoa, J. Calado, A.M. Botelho do Rego, E. Fortunato, R. Martinsb, I. Ferreira, J. Eur. Ceram. Soc. 34, 2325 (2014)

K. Nakashima, Y. Kumahara, Vacuum 66, 221 (2002)

S.H. Cho, Y.M. Kang, J.R. Lee, B.K. Ryu, P.K. Song, J. Korean Phys. Soc. 54(3), 1315 (2009)

C.P. Udawatte, K. Yanagisawa, J. Solid State Chem. 154, 444 (2000)

K. Iwasa, T. Isobe, M. Senna, Solid State Ion. 101, 71 (1997)

N. Nadaud, M. Nanot, P. Boch, J. Am. Ceram. Soc. 77(3), 843 (1994)

G. Zhu, Z. Yang, L. Zhi, H. Yang, H. Xu, A. Yu, J. Am. Ceram. Soc. 93(9), 2511 (2010)

C. Liu, J. Liu, Y. Wang, Rare Met. 30(2), 126 (2011)

T.O.L. Sunde, M. Einarsrud, T. Grande, J. Eur. Ceram. Soc. 33(3), 565 (2013)

K.Y. Kim, S.B. Park, Mater. Chem. Phys. 86, 210 (2004)

S. Chen, C. Li, W. Xiong, L. Liu, H. Wang, Mater. Lett. 58, 294 (2004)

Y. Zhang, H. Ago, J. Liu, M. Yumura, K. Uchida, S. Ohshima, S. Iijima, J. Zhu, X. Zhang, J. Cryst. Growth 264(1–3), 363 (2004)

T. Kayukawa, H. Shigetani, M. Senna, J. Mater. Sci. Lett. 14, 252 (1995)

S. Tang, J. Yao, J. Chen, J. Luo, J. Mater. Process. Technol. 137, 82 (2003)

R.M. Hussein, O.I. Abd, Indian J. Mater. Sci. 2014, 1 (2014)

I.W. Chen, X.H. Wang, Nature 404, 168 (2000)

X.H. Wang, P.L. Chen, I.W. Chen, J. Am. Ceram. Soc. 89, 431 (2006)

Z.R. Hesabi, M. Haghighatzadeh, M. Mazaheri, D. Galusek, S.K. Sadrnezhaad, J. Eur. Ceram. Soc. 29, 1371 (2009)

M. Mazaheri, A.M. Zahedi, S.K. Sadrnezhaad, J. Am. Ceram. Soc. 91, 56 (2008)

M. Mazaheri, M. Valefi, Z.R. Hesabi, S.K. Sadrnezhaad, Ceram. Int. 35, 13 (2009)

Acknowledgments

This work is jointly supported by the National Natural Science Foundation of China (21176051), Guangxi Natural Science Foundation (2013GXNSFBA019234), Guangxi Key Laboratory of Information Material (1210908-204-Z, 131024-Z) and Guangxi Experiment Center of Information Science (YB1511).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J., Yang, L., Wang, H. et al. Sintering behavior and refining grains of high density tin doped indium oxide targets with low tin oxide content. J Mater Sci: Mater Electron 27, 3298–3304 (2016). https://doi.org/10.1007/s10854-015-4158-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-4158-x