Abstract

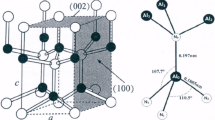

Scandium aluminum nitride (ScAlN) alloy thin films were deposited on (100) silicon substrates by DC reactive magnetron sputtering method using a scandium aluminum alloy (Sc0.06Al0.94) target. The influences of N2/Ar-flow ratio, substrate temperature, sputtering power and sputtering pressure on the film’s crystal orientation and surface morphology were investigated systematically. The c-axis preferred orientation degree changes obviously, firstly increasing to the maximum and then decreasing, with increasing each of the sputtering parameters. Meanwhile, the surface morphology of ScAlN films performs a similar variation. Then, the relationship between the crystal orientation and piezoelectric response is determined. Finally, it is demonstrated that highly c-axis oriented ScAlN thin films, with FWHM value of the rocking curve of 2.9°, RMS roughness of 2.612 nm and piezoelectric constant d33 of 8.9 pC/N, can be obtained with a N2/Ar-flow ratio of 3.3:7, a substrate temperature of 650 °C, a sputtering power of 130 W and a sputtering pressure of 0.5 Pa.

Similar content being viewed by others

References

F. Goericke, M. Chan, G. Vigevani, I. Izyumin, B. Boser, A. Pisano, in Proceedings of 16th International Conference Solid-State Sens. Actuators Microsystems, Beijing, China, Jun. 2011, pp. 1994–1997 (2011)

C. Zuniga, M. Rinaldi, S.M. Khamis, A.T. Johnson, G. Piazza, Appl. Phys. Lett. 94(22), 223122 (2009)

M. Akiyama, T. Kamohara, A. Teshigahara, Y. Takeuchi, N. Kawahara, Adv. Mater. 21, 593 (2009)

P. Muralt, J. Am. Ceram. Soc. 91(5), 1385 (2008)

S. Strite, H. Morkoc, J. Vac. Sci. Technol. B 10, 1237 (1992)

H. Jin, F. Bin, S.R. Dong, C.J. Zhou, J. Zhou, Y. Yang, et al. J. Electron. Mater. 41, 1948 (2012)

M. Akiyama, T. Kamohara, K. Kano, A. Teshigahara, N. Kawahara, Appl. Phys. Lett. 93, 021903 (2008)

M. Akiyama, T. Tabaru, K. Nishikubo, A. Teshigahara, J. Ceram. Soc. Jpn. 118, 1166 (2010)

R. Matloub, A. Artieda, C. Sandu, E. Milyutin, P. Muralt, Appl. Phys. Lett. 99, 092903 (2011)

F. Tasnádi, B. Alling, C. Höglund, G. Wingqvist, J. Birch, L. Hultman et al., Phys. Rev. Lett. 104, 137601 (2010)

G. Wingqvist, F. Tasnádi, A. Zukauskaite, J. Birch, H. Arwin, L. Hultman, Appl. Phys. Lett. 97, 112902 (2010)

Z. Vashaei, T. Aikawa, M. Ohtsuka, H. Kobatake, H. Fukuyama, S. Ikeda et al., J. Cryst. Growth 311, 459 (2009)

J. Soh, S. Jang, I. Jeong, W. Lee, Thin Solid Films 279, 17–22 (1996)

K. Hashimoto, S. Sato, A. Teshigahara, T. Nakamura, K. Kano, IEEE Trans. Ultrason. Ferroelectr. Freq. Control 60(3), 637–642 (2013)

D.T. Phan, G.S. Chung, Appl. Surf. Sci. 257, 4339–4343 (2011)

S. Fujii, T. Odawara, H. Yamada, T. Omori, K. Hashimoto, H. Torii, H. Umezawa, S. Shikata, IEEE Trans. Ultrason. Ferroelectr. Freq. Control 60(5), 986–992 (2013)

J.C. Yang, X.Q. Meng, C.T. Yang, Y. Zhang, Appl. Surf. Sci. 287, 355–358 (2013)

S.T. Mckinstry, P. Muralt, J. Electroceram. 12, 7–17 (2004)

Acknowledgments

This article is supported by project supported by the Fundamental Research Funds for the Central Universities of Ministry of Education of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Zhu, W., Zhou, D. et al. The preparation of ScAlN(002) alloy thin films deposited on Si(100) substrates by DC reactive magnetron sputtering. J Mater Sci: Mater Electron 26, 2151–2160 (2015). https://doi.org/10.1007/s10854-014-2661-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-2661-0