Abstract

A commercial purity of an Al-2mass% Mg alloy (A5052) was processed by severe plastic deformation using high-pressure sliding (HPS) for grain refinement. Mechanical properties and microstructures were examined after the HPS processing and subsequent annealing. Dislocation density decreased and grain growth occurred by the annealing. However, annealing at 150 °C led to an increase in the yield stress \({\sigma }_{y}\) to 420 MPa as well as the strain hardening coefficient (n = 0.49) defined in Ludwik’s equation in comparison with \(\sigma_{y} = 375 \;{\text{MPa}}\) and n = 0.25 in the as-HPS-processed state. It was shown that a Hall–Petch relation holds with a coefficient, k = 0.16 MPa m−1/2. The ratio of Vickers harness to tensile stress (\(Hv /{\sigma }_{{\text{TS}}}\)) was ~ 3, while the ratio to the yield stress (\(Hv/{\sigma }_{y}\)) was 3.3–4.8. Furthermore, plotting of several SPD methods including this study for tensile strength against equivalent strain resulted in a linear relationship and indicated that the HPS process yielded the highest strengthening. The strengthening mechanism was evaluated for the HPS-processed A5052 alloy so that the dominant contribution to the strengthening was from the grain boundary hardening due to significant grain refinement, which was up to 70% of the total strength.

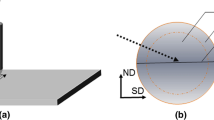

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

References

Moradpour M, KhodabakhshiEskandari FH (2019) Dynamic strain aging behavior of an ultra-fine grained Al–Mg alloy (AA5052) processed via classical constrained groove pressing. J Mater Res Technol 8(1):630–643. https://doi.org/10.1016/j.jmrt.2018.04.016

Zhou P, Deng L, Guo P, Rao W, Wang X, Zhang M (2020) Influence of microstructure heterogeneity on the corrosion resistance and microhardness of 5052 Al–Mg alloy. JOM 72(12):4305–4314. https://doi.org/10.1007/s11837-020-04364-5

Howeyze M, Arabi H, Eivani AR, Jafarian HR (2018) Strengthening of AA5052 aluminum alloy by equal channel angular pressing followed by softening at room temperature. Mater Sci Eng A 720:160–168. https://doi.org/10.1016/j.msea.2018.02.054

Hall EO (1951) The deformation and ageing of mild steel: III discussion of results. Proc Phys Soc B 64(9):747–753. https://doi.org/10.1088/0370-1301/64/9/303

Petch NJ (1953) The cleavage strength of polycrystals. J Iron Steel Res Int 174:25–28.

Ryen Ø, Nijs O, Sjölander E, Holmedal B, Ekström HE, Nes E (2006) Strengthening mechanisms in solid solution aluminum alloys. Metall Mater Trans A Phys Metall Mater Sci 37(6):1999–2006. https://doi.org/10.1007/s11661-006-0142-7

Zander J, Sandström R, Vitos L (2007) Modelling mechanical properties for non-hardenable aluminium alloys. Comput Mater Sci 41(1):86–95. https://doi.org/10.1016/j.commatsci.2007.03.013

Fleischer RL (1963) Substitutional solution hardening. Acta Metall 11(3):203–209. https://doi.org/10.1016/0001-6160(63)90213-X

Labusch R (1972) Statistical theories of solid solution hardening. Acta Metall 20:917–927. https://doi.org/10.1002/pssb.19700410221

Bailey JE, Hirsch PB (1960) The dislocation distribution flow stress and stored energy in cold worked crystalline silver. Philos Mag 5(53):485–497. https://doi.org/10.1080/14786436008238300

Orowan E. (1948) Discussion on internal stresses. In: Symposium on internal stresses in metals and alloys, London: The institute of metals. 451–453

Ebrahimi M, Par MA (2019) Twenty-year uninterrupted endeavor of friction stir processing by focusing on copper and its alloys. J Alloys Compd 781:1074–1090. https://doi.org/10.1016/j.jallcom.2018.12.083

Ebrahimi M, Wang Q, Attarilar S (2023) A comprehensive review of magnesium-based alloys and composites processed by cyclic extrusion compression and the related techniques. Prog Mater Sci 131:101016. https://doi.org/10.1016/j.pmatsci.2022.101016

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53(6):893–979. https://doi.org/10.1016/j.pmatsci.2008.03.002

Rogl G, Ghosh S, Renk O, Yubuta K, Grytsiv A, Schafler E, Zehetbauer M, Mallik RC, Bauer E, Rogl P (2021) HPT production of large bulk skutterudites. J Alloys Compd 854:15667810.

PandaTothFundenbergerPerroudGuyonZouGrosdidier SLSJJOJJT (2017) Analysis of heterogeneities in strain and microstructure in aluminum alloy and magnesium processed by high-pressure torsion. Mater Charact 123:159–165.

Fujioka T, Horita Z (2009) Development of high-pressure sliding process for microstructural refinement of rectangular metallic sheets. Mater Trans 50(4):930–933. https://doi.org/10.2320/matertrans.MRP2008445

Takizawa Y, Masuda T, Fujimitsu K (2016) Scaling up of high-pressure sliding (hps) for grain refinement and superplasticity. Metall Mater Trans A 47:4669–4681. https://doi.org/10.1007/s11661-016-3623-3

Horita Z, Tang Y, Masuda T, Takizawa Y (2020) Severe plastic deformation under high pressure: upsizing sample dimensions. Mater Trans 61(7):1177–1190. https://doi.org/10.2320/matertrans.MT-M2020074

Takizawa Y, Sumikawa K, Watanabe K, Masuda T, Yumoto M, Kanai Y, Otagiri Y, Horita Z (2018) Incremental feeding high-pressure sliding for grain refinement of large-scale sheets: application to Inconel 718. Metall Mater Trans A 49:1830–1840. https://doi.org/10.1007/s11661-018-4534-2

Komatsu T, Masuda T, Tang Y, Mohamed IF, Yumoto M, Takizawa Y, Horita Z (2023) Production of ultrafine-grained aluminum alloys in upsized sheets using process of incremental feeding high-pressure sliding (IF-HPS). Mater Trans 64(2):436–442. https://doi.org/10.2320/matertrans.mt-la2022032

Takizawa Y, Horita Z (2023) Incremental feeding high-pressure sliding (IF-HPS) process for upscaling highly strained areas in metallic materials with enhanced mechanical properties. Mater Trans 64(7):1364–1375. https://doi.org/10.2320/matertrans.mt-mf2022025

Masuda T, Fujimitsu K, Takizawa Y, Horita Z (2015) High-pressure sliding using rod samples for grain refinement and superplasticity in Al and Mg alloys. Lett Mater 5(3):258–263. https://doi.org/10.22226/2410-3535-2015-3-258-263

Masuda T, Takizawa Y, Yumoto M, Otagiri Y, Horita Z (2017) Extra strengthening and superplasticity of ultrafine-grained A2024 alloy produced by high-pressure sliding. Mater Trans 58(12):1647–1655. https://doi.org/10.2320/matertrans.M2017242

Lewandowska M, Kurzydłowski KJ (2005) Thermal stability of a nanostructured aluminium alloy. Mater Charact 55(4–5):395–401. https://doi.org/10.1016/j.matchar.2005.08.005

Edalati K, Hashiguchi Y, Iwaoka H, Matsunaga H, Valiev RZ, Horita Z (2018) Long-time stability of metals after severe plastic deformation: Softening and hardening by self-annealing versus thermal stability. Mater Sci Eng A 729:340–348. https://doi.org/10.1016/j.msea.2018.05.079

Duan YL, Qian J, Xiao D, Cui XM, Xu GF (2016) Effect of Sc and Er additions on superplastic ductilities in Al–Mg–Mn-Zr alloy. J Cent South Univ 23(6):1283–1292.

Lee S, Tazoe K, Mohamed IF, Horita Z (2015) Strengthening of AA7075 alloy by processing with high-pressure sliding (HPS) and subsequent aging. Mater Sci Eng A 628:56–61.

Duchaussoy A, Sauvage X, Deschamps A, De Geuser F, Renou G, Horita Z (2023) Compared microstructure and properties of an AlZnMgCu alloy processed by high pressure sliding and high-pressure torsion. J Alloys Compd 942:169060. https://doi.org/10.1016/j.jallcom.2023.169060

Tang Y, Tomita Y, Horita Z (2023) Mechanical properties and microstructures of highly Fe-Containing AlMgSi alloys processed by severe plastic deformation under high pressure. Mater Trans 64(2):448–457. https://doi.org/10.2320/matertrans.MT-LA2022054

Horita Z, Edalati K (2020) Severe plastic deformation for nanostructure controls. Mater Trans 61(11):2241–2247. https://doi.org/10.2320/matertrans.MT-M2020134

Song HR, Kim YS, Nam WJ (2006) Mechanical properties of ultrafine grained 5052 Al alloy produced by accumulative roll-bonding and cryogenic rolling. Metals (Basel) 12(1):7–12. https://doi.org/10.1007/BF03027516

Kim YS, Yua HS, Shin DH (2009) Low sliding-wear resistance of ultrafine-grained Al alloys and steel having undergone severe plastic deformation. Int J Mater Res 100(6):871–874. https://doi.org/10.3139/146.110109

Tsai TL, Sun PL, Kao PW, Chang CP (2003) Microstructure and tensile properties of a commercial 5052 aluminum alloy processed by equal channel angular extrusion. Mater Sci Eng A 342(1–2):144–151. https://doi.org/10.1016/S0921-5093(02)00283-6

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall 1:22–31. https://doi.org/10.1016/0001-6160(53)90006-6

Afifi MA, Pereira PHR, Wang YC, Wang Y, Li S, Langdon TG (2017) Effect of ECAP processing on microstructure evolution and dynamic compressive behavior at different temperatures in an Al–Zn–Mg alloy. Mater Sci Eng A 684:617–625. https://doi.org/10.1016/j.msea.2016.12.099

Changela K, Krishnaswamy H, Digavalli R (2019) Development of combined groove pressing and rolling to produce ultra-fine grained Al alloys and comparison with cryorolling. Mater Sci Eng A 760:7–18. https://doi.org/10.1016/j.msea.2019.05.088

Tański T, Snopiński P, Prusik K, Sroka M (2017) The effects of room temperature ECAP and subsequent aging on the structure and properties of the Al–3%Mg aluminium alloy. Mater Charact 133:185–195. https://doi.org/10.1016/j.matchar.2017.09.039

Summers PT, Case SW, Lattimer BY (2014) Residual mechanical properties of aluminum alloys AA5083-H116 and AA6061-T651 after fire. Eng Struct 76:49–61. https://doi.org/10.1016/j.engstruct.2014.06.033

Dhal A, Panigrahi SK, Shunmugam MS (2017) Insight into the microstructural evolution during cryo-severe plastic deformation and post-deformation annealing of aluminum and its alloys. J Alloys Compd 726:1205–1219. https://doi.org/10.1016/j.jallcom.2017.08.062

Huang X, Hansen N (1979) Tsuji N (2006) Hardening by annealing and softening by deformation in nanostructured metals. Science 312(5771):249–251. https://doi.org/10.1126/science.1124268

Furukawa M, Horita Z, Nemoto M, Valiev RZ, Langdon TG (1998) Factors influencing the flow and hardness of materials with ultrafine grain sizes. Philos Mag A 78(1):203–216. https://doi.org/10.1080/014186198253769

Tabor D (1951) The hardness of metals. Claredon Press, Oxford

Song M, Sun C, Chen Y, Shang Z, Li J, Fan Z, Hartwig KT, Zhang X (2019) Grain refinement mechanisms and strength-hardness correlation of ultra-fine grained grade 91 steel processed by equal channel angular extrusion. Int J Press Vessel Pip 172:212–219. https://doi.org/10.1016/j.ijpvp.2019.03.025

Hasegawa H, Komura S, Utsunomiya A, Horita Z, Furukawa M, Nemoto M, Langdon TG (1999) Thermal stability of ultrafine-grained aluminum in the presence of Mg and Zr additions. Mater Sci Eng A 265(1–2):188–196. https://doi.org/10.1016/s0921-5093(98)01136-8

Lloyd DJ, Court SA (2003) Influence of grain size on tensile properties of Al-Mg alloys. Mater Sci Technol 19:1349–1354. https://doi.org/10.1179/026708303225006088

Malopheyev S, Kaibyshev R (2015) Strengthening mechanisms in a Zr-modified 5083 alloy deformed to high strains. Mater Sci Eng A 620:246–252. https://doi.org/10.1016/j.msea.2014.10.030

Kalsar R, Yadav D, Sharma A, Brokmeier HG, May J, Hoppel HW, Skrotzki W, Suwas S (2020) Effect of Mg content on microstructure, texture and strength of severely equal channel angular pressed aluminium-magnesium alloys. Mater Sci Eng A 797:140088. https://doi.org/10.1016/j.msea.2020.140088

Huang T, Shuai L, Wakeel A, Wu G, Hansen N, Huang X (2018) Strengthening mechanisms and Hall–Petch stress of ultrafine grained Al-0.3%Cu. Acta Mater 156:369–378. https://doi.org/10.1016/j.actamat.2018.07.006

Edalati K, Akama D, Nishio A, Lee S, Yonenaga Y, Cubero-Sesin JM, Horita Z (2014) Influence of dislocation-solute atom interactions and stacking fault energy on grain size of single-phase alloys after severe plastic deformation using high-pressure torsion. Acta Mater 69:68–77. https://doi.org/10.1016/j.actamat.2014.01.036

Mohamed IF, Masuda T, Lee S, Edalati K, Horita Z, Hirosawa S, Matsuda K, Terada D, Omar MZ (2017) Strengthening of A2024 alloy by high-pressure torsion and subsequent aging. Mater Sci Eng A 704:112–118. https://doi.org/10.1016/j.msea.2017.07.083

Mohamed IF, Lee S, Edalati K, Horita Z, Hirosawa S, Matsuda K, Terada D (2015) Aging behavior of Al 6061 alloy processed by high-pressure torsion and subsequent aging. Metall Mater Trans A Phys Metall Mater Sci 46(6):2664–2673. https://doi.org/10.1007/s11661-015-2840-5

Li M, Guo Q, Chen L, Li L, Hou H, Zhao Y (2022) Microstructure and properties of graphene nanoplatelets reinforced AZ91D matrix composites prepared by electromagnetic stirring casting. J Mater Res Technol 21:4138–4150. https://doi.org/10.1016/j.jmrt.2022.11.033

Acknowledgement

The authors would like to express their gratitude and thanks to Universiti Kebangsaan Malaysia for funding this research under Geran Universiti Penyelidikan, GUP-2022-014. This study was supported partly by Institute of Light Metals (ILM) Joint Usage/Research Grant, Kumamoto University & University of Toyama.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

Details on potential conflicts of interest are included under publishing ethics.

Ethical approval

Not applicable.

Additional information

Handling Editor:MK.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aziz, A.M., Mohamed, I.F., Horita, Z. et al. Strengthening of A5052 aluminum alloy by high-pressure sliding process. J Mater Sci 59, 5754–5770 (2024). https://doi.org/10.1007/s10853-024-09334-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09334-9