Abstract

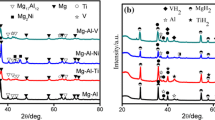

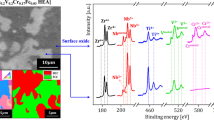

Non-stoichiometric AB2 alloys with (Ti0.75Zr0.25)1.05Mn0.8CrTM0.2 (TM = Cr, Mo, and Nb) formulation were synthesized using an arc-melting method in an argon atmosphere to optimize storage, activation, and kinetic reaction properties of hydrogen. The structural, morphological, and hydrogen storage properties of the alloys were examined using X-ray diffraction, field-emission scanning electron microscopy, energy-dispersive X-ray mapping, and volumetric method, respectively. The results indicate that the Mo sample exhibits the highest hydrogen storage capacity at 1.34 wt%. This result is due to the solid solution phase (TiMo), which acts as a catalyst and facilitates hydrogen absorption. The best value of the plateau slope for the Nb sample at room temperature was 0.65, and the hysteresis coefficient was 0.239 for the Mo sample. In addition, the dissociation enthalpy (∆HDES) and entropy (∆SDES) for the Nb sample were 31.04 kJ mol−1 and 103.93 J mol−1 K−1, respectively. From the analysis of the hydrogen absorption kinetic curves, it was found that the reaction kinetic behavior is consistent with the Jander model. Furthermore, activation energy values of the alloys were calculated at a pressure of 13 bar and the range of temperature from 298 to 328 K. We obtained Ea(Cr) = 14.02, Ea(Mo) = 10.92, and Ea(Nb) = 10.23 kJ mol−1. Based on the results, the Nb sample showed good absorption/desorption plateau pressure properties with small hysteresis and slope.

Graphical abstract

Similar content being viewed by others

Data and code availability

Upon on the request, they can be obtained in an electronic file.

References

Abe JO, Popoola AP, Ajenifuja E, Popoola OM (2019) Hydrogen energy, economy and storage: review and recommendation. Int J Hydrog Energy 44:15072–15086. https://doi.org/10.1016/j.ijhydene.2019.04.068

Dogan B (2006) Hydrogen storage tank systems and materials selection for transport applications. In: ASME pressure vessels and piping conference. 47578: 571–578. https://doi.org/10.1115/PVP2006-ICPVT-11-93868

Ogden JM (1999) Developing an infrastructure for hydrogen vehicles: a Southern California case study. Int J Hydrog Energy 24:709–730. https://doi.org/10.1016/S0360-3199(98)00131-1

Sakintuna B, Lamari-Darkrim F, Hirscher M (2007) Metal hydride materials for solid hydrogen storage: a review. Int J Hydrog Energy 32:1121–1140. https://doi.org/10.1016/j.ijhydene.2006.11.022

Niemann MU, Srinivasan SS, Phani AR, Kumar A, Goswami DY, Stefanakos EK (2008) Nanomaterials for hydrogen storage applications: a review. J Nanomaterials 2008:1–9. https://doi.org/10.1155/2008/950967

Murshidi JA, Paskevicius M, Sheppard DA, Buckley CE (2011) Structure, morphology and hydrogen storage properties of a Ti0.97Zr0.019V0.439Fe0.097Cr0.045Al0.026Mn1.5 alloy. Int J Hydrog Energy 36:7587–7593. https://doi.org/10.1016/j.ijhydene.2011.03.137

Young K, Nei J, Huang B, Fetcenko MA (2011) Studies of off-stoichiometric AB2 metal hydride alloy: Part2. Hydrogen storage and electrochemical properties. Int J Hydrog Energy 36:11146–11154. https://doi.org/10.1016/j.ijhydene.2011.05.056

Mishra SS, Yadav TP, Srivastava ON, Mukhopadhyay NK, Biswas K (2020) Formation and stability of C14 type Laves phase in multi component high-entropy alloys. J Alloy Compd 832:153764. https://doi.org/10.1016/j.jallcom.2020.153764

Moriwaki Y, Gamo T, Iwaki T (1991) Control of hydrogen equilibrium pressure for C14-type laves phase alloys. J Less Common Met 172:1028–1035. https://doi.org/10.1016/S0022-5088(06)80008-1

Marinin VS, Umerenkova KR, Volovchuk OV (2011) Hydrogen sorption properties of hexagonal laves phase TiMn1.5 intermetallic compound. Int J Hydrog Energy 36:1359–1363. https://doi.org/10.1016/j.ijhydene.2010.06.129

Xu YH, Wang G, Chen CP, Wang QD, Wang X (2007) The structure and electrode properties of non-stoichiometric A1.2B2 type C14 Laves alloy and the effect of surface modification. Int J Hydrog Energy 32:1050–1058. https://doi.org/10.1016/j.ijhydene.2006.07.007

Kandavel M, Bhat VV, Rougier A, Aymard L, Nazri GA, Tarascon JM (2008) Improvement of hydrogen storage properties of the AB2 Laves phase alloys for automotive application. Int J Hydrog Energy 33:3754–3761. https://doi.org/10.1016/j.ijhydene.2008.04.042

Au M, Pourarian F, Sankar SG, Wallace WE, Zhang L (1995) TiMn2-based alloys as high hydrogen storage materials. Mater Sci Eng B 33:53–57. https://doi.org/10.1016/0921-5107(94)01212-1

Gamo T, Moriwaki Y, Yanagihara N, Yamashita T, Iwaki T (1985) Formation and properties of titanium-manganese alloy hydrides. Int J Hydrog Energy 10:39–47. https://doi.org/10.1016/0360-3199(85)90134-X

Liu BH, Kim DM, Lee KY, Lee JY (1996) Hydrogen storage properties of TiMn2-based alloys. J Alloy Compd 240:214–218. https://doi.org/10.1016/0925-8388(96)02245-1

Yadav TP, Shahi RR, Srivastava ON (2012) Synthesis, characterization and hydrogen storage behaviour of AB2 (ZrFe2, Zr(Fe0.75V0.25) 2, Zr (Fe0.5V0.5) 2 type materials. Int J Hydrog Energy 37:3689–3696. https://doi.org/10.1016/j.ijhydene.2011.04.210

Yadav TP, Mukhopadhyay S, Mishra SS, Mukhopadhyay NK, Srivastava ON (2017) Synthesis of a single phase of high-entropy laves intermetallics in the Ti–Zr–V–Cr–Ni equiatomic alloy. Philos Mag Lett 97:494–503. https://doi.org/10.1080/09500839.2017.1418539

Xu YH, Chen CP, Geng WX, Wang QD (2001) The hydrogen storage properties of Ti–Mn-based C14 Laves phase intermetallics as hydrogen resource for PEMFC. Int J Hydrog Energy 26:593–596. https://doi.org/10.1016/S0360-3199(00)00124-5

Park JG, Jang HY, Han SC, Lee PS, Lee JY (2002) Hydrogen storage properties of TiMn2-based alloys for metal hydride heat pump. Mater Sci Eng A 329:351–355. https://doi.org/10.1016/S0921-5093(01)01598-2

Komeili M, Arabi H, Yusupov RV, Ghorbani SR, Vagizov FG, Pourarian F (2021) Structural and hydrogen absorption/desorption properties of Zr2 (Co0.5Fe0.2Ni0.2V0.1) intermetallic alloy. Int J Hydrog Energy 46:19060–19073. https://doi.org/10.1016/j.ijhydene.2021.03.045

Lototsky MV, Yartys VA, Marinin VS, Lototsky NM (2003) Modelling of phase equilibria in metal–hydrogen systems. J Alloy Compd 356:27–31. https://doi.org/10.1016/S0925-8388(03)00095-1

Beeri O, Cohen D, Gavra Z, Johnson JR, Mintz MH (1998) High-pressure studies of the TiCr1.8-H2 system statistical thermodynamics above the critical temperature. J Alloy Compd 267:113–120. https://doi.org/10.1016/S0925-8388(97)00521-5

Song X, Zhang Z, Zhang X, Lei Y, Wang Q (1999) Effect of Ti substitution on the microstructure and properties of Zr–Mn–V–Ni AB2 type hydride electrode alloys. J Mater Res 14:1279–1285. https://doi.org/10.1557/JMR.1999.0174

Huot J, Akiba E, Ishido Y (1995) Crystal structure of multiphase alloys (Zr, Ti)(Mn, V)2. J Alloy Compd 231:85–89. https://doi.org/10.1016/0925-8388(95)01842-5

Ulmer U, Dieterich M, Pohl A, Dittmeyer R, Linder M, Fichtner M (2017) Study of the structural, thermodynamic and cyclic effects of vanadium and titanium substitution in laves-phase AB2 hydrogen storage alloys. Int J Hydrog Energy 42:20103–20110. https://doi.org/10.1016/j.ijhydene.2017.06.137

Prabhu YT, Rao KV, Kumar VS, Kumari BS (2014) X-ray analysis by Williamson-Hall and size-strain plot methods of ZnO nanoparticles with fuel variation. World J Nano Sci Eng. https://doi.org/10.4236/wjnse.2014.41004

Jiang L, Tu Y, Tu H, Chen L (2015) Microstructures and hydrogen storage properties of ZrFe2.05−xVx (x= 0.05–0.20) alloys with high dissociation pressures for hybrid hydrogen storage vessel application. J Alloy Compd 627:161–165. https://doi.org/10.1016/j.jallcom.2014.12.045

Kumar A, Yadav TP, Mukhopadhyay NK (2022) Notable hydrogen storage in Ti–Zr–V–Cr–Ni high entropy alloy. Int J Hydrog Energy 47:22893–22900. https://doi.org/10.1016/j.ijhydene.2022.05.107

Li SL, Chen W, Chen DM, Yang K (2009) Effect of long-term hydrogen absorption/desorption cycling on hydrogen storage properties of MmNi3.55Co0.75Mn0.4Al0.3. J Alloy Compd 474:164–168. https://doi.org/10.1016/j.jallcom.2008.06.154

Broom DP (2011) Hydrogen storage materials: the characterisation of their storage properties. Springer, London

Checchetto R, Trettel G, Miotello A (2003) Sievert-type apparatus for the study of hydrogen storage in solids. Meas Sci Technol 15:127. https://doi.org/10.1088/0957-0233/15/1/017

Zhang TB, Wang XF, Hu R, Li JS, Yang XW, Xue X (2012) Hydrogen absorption properties of Zr(V1−xFex)2 intermetallic compounds. Int J Hydrog Energy 37:2328–2335. https://doi.org/10.1016/j.ijhydene.2011.10.089

Akiba E, Iba H (1998) Hydrogen absorption by Laves phase related BCC solid solution. Intermetallics 6:461–470. https://doi.org/10.1016/S0966-9795(97)00088-5

Ponsoni JB, Aranda V, da Silva NT, Strozi RB, Botta WJ, Zepon G (2022) Design of multicomponent alloys with C14 Laves phase structure for hydrogen storage assisted by computational thermodynamic. Acta Mater 240:118317. https://doi.org/10.1016/j.actamat.2022.118317

Gross Karl J, et al (2016) Recommended best practices for the characterization of storage properties of hydrogen storage materials. EMN-HYMARC (EMN-HyMARC); National Renewable Energy Lab. Golden, United States

Chen Z, Xiao X, Chen L, Fan X, Liu L, Li S, Ge H, Wang Q (2014) Influence of Ti super-stoichiometry on the hydrogen storage properties of Ti1+xCr1.2Mn0.2Fe0.6 (x= 0–0.1) alloys for hybrid hydrogen storage application. J Alloy Compd 585:307–311. https://doi.org/10.1016/j.jallcom.2013.09.141

Yang XW, Zhang TB, Hu R, Li JS, Xue XY, Fu HZ (2010) Microstructure and hydrogenation thermokinetics of ZrTi0.2V1.8 alloy. Int J Hydrog Energy 35:11981–11985. https://doi.org/10.1016/j.ijhydene.2010.08.065

Komeili M, Arabi H, Pourarian F (2023) Structural investigation and hydrogenation properties of TiZrXMnFeNi (X= Cr, Mo, and W) high entropy alloys. J Alloy Compd 967:171672. https://doi.org/10.1016/j.jallcom.2023.171672

Shelyapina MG (2019) Metal hydrides for energy storage. In: Handbook of ecomaterials. pp 775–810. https://doi.org/10.1007/978-3-319-68255-6

Kumar A, Yadav TP, Shaz MA, Mukhopadhyay NK (2023) Hydrogen storage in C14 type TiVZrMnCoFe high entropy alloy. arXiv preprint arXiv:2301.04942. https://doi.org/10.48550/arXiv.2301.04942

Huheey JE, et al (2006) Inorganic chemistry: principles of structure and reactivity. 2006: Pearson Education India

Cekić B, Ćirić K, Iordoc M, Marković S, Mitrić M, Stojić D (2013) Kinetics of hydrogen absorption in Zr-based alloys. J Alloy Compd 559:162–166. https://doi.org/10.1016/j.jallcom.2013.01.104

Jander W (1927) Reaktionen im festen Zustande bei höheren Temperaturen. Reaktionsgeschwindigkeiten endotherm verlaufender Umsetzungen. Z Anorg Allg Chem 163:1–30. https://doi.org/10.1002/zaac.19271630102

Hariyadi A, Suwarno S, Denys RV, von Colbe JB, Sætre TO, Yartys V (2022) Modeling of the hydrogen sorption kinetics in an AB2 laves type metal hydride alloy. J Alloy Compd 893:162135. https://doi.org/10.1016/j.jallcom.2021.162135

Acknowledgements

The work was supported by the Ferdowsi University of Mashhad (Grand no. 3/58195).

Author information

Authors and Affiliations

Contributions

KA contributed to the conceptualization, methodology, visualization, formal analysis, investigation, and writing—original draft. HA was involved in the supervision of the research, validation, resources, methodology, and writing—review and final editing. SG assisted in the supervision and writing—review and editing. MK contributed to the validation, formal analysis, and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Not Applicable.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alnssar, K., Arabi, H., Ghorbani, S. et al. Structural, morphology, and hydrogenation properties of non-stoichiometric alloy (Ti0.75 Zr0.25)1.05 Mn0.8CrTM0.2 (TM = Cr, Mo, and Nb). J Mater Sci 59, 1665–1678 (2024). https://doi.org/10.1007/s10853-023-09265-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09265-x