Abstract

It is well documented that the hot-pressing procedures used for many strategic ceramics may introduce microstructural texturing that can lead to anisotropic mechanical properties. Therefore, knowing the existence and extent of anisotropy and any potential impact on properties is important to proper application of these ceramics. Many hot-pressed ceramics are produced as plates that are relatively thin (around 25 mm or less). This makes it challenging to identify anisotropy in commonly measured properties such as flexure strength and fracture toughness since the standard beam specimens used to determine these properties are typically more than 25 mm in length. However, the use of a small dumbbell-shaped specimen has been successfully useful to determine the compression strength of several advanced ceramics. In this study, small dumbbell specimens were machined from a hot-pressed boron carbide and three hot-pressed silicon carbides. The major axis of the specimen was aligned at 0° (vertical), 45°, or 90° (horizontal) to the hot-pressing direction to determine any potential intrinsic anisotropy in the compression strength. Specimens were tested across a range of strain rates to discern the presence of rate effects on the compressive strength and fracture behavior of these strategic materials.

Similar content being viewed by others

Data and code availability

Not applicable.

Notes

The detailed microstructural analysis needed to determine the presence and extent of any microstructural texturing would require extensive microstructural analysis of each ceramic using computed tomography (micro or nano) which beyond the scope of this effort.

Wyoming Test Fixtures, Inc 2960 Mill Creek Canyon Rd, Salt Lake City, UT 84109.

References

Brace WF, Bombolakis EG (1963) A note on brittle crack growth in compression. J Geophys Res (1896–1977) 68(12):3709–3713

Brace WF, Paulding BW, Scholz CH (1966) Dilatancy in the fracture of crystalline rocks. J Geophys Res 71(16):3939–3953

Ashby M, Sammis C (1990) The damage mechanics of brittle solids in compression. Pure Appl Geophys 133(3):489–521

Horii H, Nemat-Nasser S (1986) Brittle failure in compression: splitting, faulting and brittle-ductile transition. Philos Trans R Soc Lond Ser A Math Phys Sci 319(1549):337–374

Nemat-Nasser S, Horii H (1982) Compression-induced nonplanar crack extension with application to splitting, exfoliation, and rockburst. J Geophys Res Solid Earth 87(B8):6805–6821

Nemat-Nasser S, Horii H (1984) Rock failure in compression. Int J Eng Sci 22(8–10):999–1011

Horii H, Nemat-Nasser S (1985) Compression-induced microcrack growth in brittle solids: axial splitting and shear failure. J Geophys Res 90(B4):3105

Horii H, Nemat-Nasser S (1983) Overall moduli of solids with microcracks: load-induced anisotropy. J Mech Phys Solids 31(2):155–171

Griffith AA (1921) The phenomena of rupture and flow in solids. Philos Trans R Soc Lond Ser A Contain Pap Math Phys Charact 221(582–593):163–198

Weibull W (1939) A Statistical theory of the strength of materials. Proc R Swedish Inst Eng Res 151

Weibull W (1939) The phenomenon of rupture in solids. Proc R Swedish Inst Eng Res 153

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 293–97

Rudnick A, Marschall CW, Duckworth WH, Emrich BR (1968) The evaluation and interpretation of mechanical properties of brittle materials. U.S. Air Force Materials Laboratory Technical Report 67–316, Battelle Memorial Institute, Defense Ceramic Information Center Report 68–3, April 19

Mordfin L, Kerper MJ (1969) Strength testing of ceramics—a survey. In: Wachtman J (ed) Mechanical and thermal properties of ceramics, NBS Special Publication 303, May 1969, Proc. Symposium at the National Bureau of Standards, Washington, DC, pp 243–262

Sines G, Adams M (1978) Compression testing of ceramics. In: Bradt RC, Hasselman DPH (eds) Lange FF fracture mechanics of ceramics, vol 8. Plenum Press, New York, pp 403–449

Peng SD (1971) Stresses within elastic circular cylinders loaded uniaxially and triaxially. Int J Rock Mech Min 8(5):399–432

Rice RW (1971) The compression strength of ceramics. In: Kriegel WW, Palmour H III (eds) Ceramics for severe environments. Plenum, New York, pp 195–227

Lankford J (1991) The compressive strength of strong ceramics: microplasticity versus microfracture. J Hard Mater 2(1–2):55–75

Tracy CA (1987) A compression test for high strength ceramics. J Test Eval 15(1):14–19

Tracy CA, Slavin MJ, Viechnicki DJ (1988) Ceramic fracture during ballistic impact. Fractography Glasses Ceram 22:295–306

Dunlay WA, Tracy CA, Perrone PJ (1989) A proposed uniaxial compression test of high strength ceramics. U.S. Army Materials Technology Laboratory, Watertown, Ma, Technical Report TR 89–89

Swab JJ, Meredith CS, Casem DT, Gamble WR (2017) Static and dynamic compression strength of hot-pressed boron carbide using a dumbbell-shaped specimen. J Mat Sci 52(17):10073–10084. https://doi.org/10.1007/s10853-017-1210-7

Swab JJ, Quinn GD (2019) Dynamic compression strength of ceramics: results from an interlaboratory round-robin exercise. US Army Combat Capabilities Development Command Army Research Laboratory

Swab JJ et al (2020) Dynamic compression strength of ceramics: what was learned from an interlaboratory round robin exercise? J Dyn Behav Mater 7(1):34–47

Meredith CS, Swab JJ (2020) Compression strength of borosilicate and soda-lime silicate glasses using a dumbbell-shaped specimen. In: ARL Technical Report Series. Aberdeen Proving Ground, MD

Swab JJ, Pittari JJ III (2022) Compression strength tungsten carbide-cobalt hard metals. Int J Appl Ceram Technol. https://doi.org/10.1111/ijac.14208

Pelz J, Ku N, Shoulders T, Guziewski M, Figueroa S, Swab JJ, Vargas-Gonzalez L, Meyers MA. Mechanical performance of carbide ceramics produced via multi-material additive manufacturing. Unpublished, submitted to Acta Materialia

Chen W, Subhash G, Ravichandran G (1994) Evaluation of ceramic specimen geometries used in split Hopkinson pressure bar. DYMAT J 1(3):193–210

ASTM International (2019) Standard test method for monotonic compressive strength of advanced ceramics at ambient temperature, ASTM C1424. ASTM International, West Conshohocken

Blumenthal WR (2005) High strain rate compression testing of ceramics and ceramic composites

Blumenthal WR, Gray G, Claytor T (1994) Response of aluminum-infiltrated boron carbide cermets to shock wave loading. J Mater Sci 29(17):4567–4576. https://doi.org/10.1007/BF00376280

Pickup I (2005) The correlation of microstructural and mechanical characteristics of silicon carbide with ballistic performance. In: Advances in ceramic armor: a collection of papers presented at the 29th international conference on advanced ceramics and composites, Jan 23–28, 2005, Cocoa Beach, FL. John Wiley & Sons

Cosculluela A, Cagnoux J, Collombet F (1991) Uniaxial compression of alumina: structure, microstructure and strain rate. Le Journal de Physique IV 01(C3):C3-109-C3-116

Cosculluela A, Cagnoux J, Collombet F (1992) Two types of experiments for studying uniaxial dynamic compression of alumina. Shock compression of condensed matter–1991. Elsevier, pp 951–954

Awaji H, Watanabe T, Nagano Y (1994) Compressive testing of ceramics. Ceram Int 20(3):159–167

Li H, Wong LNY (2012) Influence of flaw inclination angle and loading condition on crack initiation and propagation. Int J Solids Struct 49(18):2482–2499

Moorehead CA, Sietins JM, Swab JJ (2018) Meso-scale microstructural agglomerate quantification in boron carbide using X-ray microcomputer tomography. Mat Charact 141:177–185

Sano T, Chin ESC, Paliwal B, Chen MW (2009) Comparison of slip cast to hot pressed boron carbide. ARL-RP-240, February 2009

Hogan JD, Farbaniec L, Shaeffer M, Ramesh KT (2015) The effects of microstructure and confinement on the compressive fragmentation of an advanced ceramic. J Am Ceram Soc 98(3):902–912

Farbaniec L, Hogan JD, Ramesh KT (2015) Micromechanisms associated with the dynamic compressive failure of hot-pressed boron carbide. Scripta Mater 106:52–56

Hogan JD et al (2016) The effects of defects on the uniaxial compressive strength and failure of an advanced ceramic. Acta Mater 102:263–272

Farbaniec L et al (2016) Anisotropy of mechanical properties in a hot-pressed boron carbide. Int J Appl Ceram Technol 13(6):1008–1016

Swab JJ, Pittari JJ III, Gamble WR (2019) Uniaxial tensile strength and fracture analysis of a hot-pressed boron carbide. J Eur Ceram Soc 29:1965–1973. https://doi.org/10.1016/j.jeurceramsoc.2019.01.031

Wereszczak AA, Vuono DJ, Bortle KP, Ritt PJ, Swab JJ, Campbell J (2013) Mechanical response anisotropy in hot-pressed silicon carbide. In: Advances in ceramic armor IX, Ceram. Eng. Sci. Proc., vol. 34, number 5, pp 75–84

Nemat-Nassar S, Deng H (1994) Strain-rate effect on brittle failure in compression. Acta Metall Mater 42(3):1013–1024. https://doi.org/10.1016/0956-7151(94)90295-X

Ravichandran G, Subhash G (1995) A micromechanical mode for high strain rate behavior of ceramics. Int J Solids Struct 32(17–18):2627–2646. https://doi.org/10.1016/0020-7683(94)00286-6

Shih CJ, Meyers MA, Nesterenko VF, Chen SJ (2000) Damage evolution in dynamic deformation of silicon carbide. Acta Mater 48:2399–2420

Sarva S, Nemat-Nassar S (2001) Dynamic compressive strength of silicon carbide under uniaxial compression. Mat Sci Eng A317:140–144

Parker JD (2023) Dynamic strength and fragmentation of silicon carbide. Master’s Thesis, Colorado School of Mines

Wang H, Ramesh KT (2004) Dynamic strength and fragmentation of hot-pressed silicon carbide under uniaxial compression. Acta Mater 52:355–367

Acknowledgements

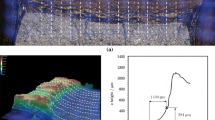

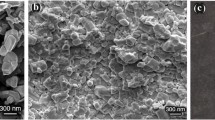

The authors would like to acknowledge the support from Mr. Tucker Moore, SURVICE Engineering Company, to obtain the microstructural images in Fig. 1.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest or competing interests.

Ethical approval

Not applicable.

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Swab, J.J., Pittari, J.J. & Meredith, C.S. Anisotropy in the compression strength of hot-pressed ceramics. J Mater Sci 58, 15603–15616 (2023). https://doi.org/10.1007/s10853-023-09011-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09011-3