Abstract

Grain and precipitate morphologies, orientations, and distributions in precipitation hardened nickel alloy 718 are directly affected by material processing, thermal and mechanical history, and tailored to optimize its thermo-mechanical behavior in service. A computational approach based on a dislocation-density crystalline plasticity formulation, was used to investigate and identify dominant microstructural mechanisms and defects, such as perfect and partial dislocation-densities, in an experimentally characterized specification of 718 alloy. The role of perfect and partial dislocation densities and their interaction with the material microstructure, affecting the mechanical behavior of the alloy were investigated. Different precipitate volume fractions were used to characterize and identify these interactions and behavior. Using an integrated experimental and modeling approach, the δ phase precipitated along grain boundaries in the form of elongated rods is shown to be a source of dislocation-density accumulations. Interactions include strengthening, achieved by impeding the motion of dislocations by the coherent precipitates, and shear deformation competition, associated with shear slip or plasticity accumulation between the preferentially oriented slip systems of the precipitates and the matrix.

Similar content being viewed by others

Data availability

All the relevant experimental and computational data for the manuscript can be provided upon request.

References

Winchell PG, Speich GR (1970) Point-defect-supported martensite tetragonality. Acta Metall 18:53–62. https://doi.org/10.1016/0001-6160(70)90068-4

Patil RP, Doan D, Aitken ZH, Chen S, Kiani MT, Barr CM, Hattar K, Zhang Y-W, Gu XW (2020) Hardening in Au-Ag nanoboxes from stacking fault-dislocation interactions. Nat Commun 11:2923. https://doi.org/10.1038/s41467-020-16760-1

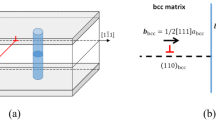

Pitts SA, Jiang W, Pizzocri D, Barker EI, Zbib HM (2022) A Continuum Dislocation dynamics crystal plasticity approach to irradiated body-centered cubic α-iron. J Eng Mater Technol 144:011018. https://doi.org/10.1115/1.4052256

Flanagan TJ, Vijayan S, Galitskiy S, Davis J, Bedard BA, Williams CL, Dongare AM, Aindow M, Lee S-W (2020) Shock-induced deformation twinning and softening in magnesium single crystals. Mater Design. 194:108884. https://doi.org/10.1016/j.matdes.2020.108884

Hyzak JM, Bernstein IM (1976) The role of microstructure on the strength and toughness of fully pearlitic steels. MTA 7:1217–1224. https://doi.org/10.1007/BF02656606

De Moor E, Lacroix S, Clarke AJ, Penning J, Speer JG (2008) Effect of retained austenite stabilized via quench and partitioning on the strain hardening of martensitic steels. Metall and Mat Trans A 39:2586–2595. https://doi.org/10.1007/s11661-008-9609-z

Amato KN, Gaytan SM, Murr LE, Martinez E, Shindo PW, Hernandez J, Collins S, Medina F (2012) Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater 60:2229–2239. https://doi.org/10.1016/j.actamat.2011.12.032

Tucho WM, Hansen V (2019) Characterization of SLM-fabricated Inconel 718 after solid solution and precipitation hardening heat treatments. J Mater Sci 54:823–839. https://doi.org/10.1007/s10853-018-2851-x

Knorovsky GA, Cieslak MJ, Headley TJ, Romig AD, Hammetter WF (1989) INCONEL 718: a solidification diagram. MTA 20:2149–2158. https://doi.org/10.1007/BF02650300

Bond DM, Zikry MA (2018) Differentiating between intergranular and transgranular fracture in polycrystalline aggregates. J Mater Sci 53:5786–5798. https://doi.org/10.1007/s10853-017-1847-2

Zhang RY, Qin HL, Bi ZN, Tang YT, Araújo de Oliveira J, Lee TL, Panwisawas C, Zhang SY, Zhang J, Li J, Dong HB (2022) γ″ variant-sensitive deformation behaviour of Inconel 718 superalloy. J Mater Sci Technol 126:169–181. https://doi.org/10.1016/j.jmst.2022.03.018

S Mahadevan, S Nalawade, JB Singh, A Verma, B Paul, K Ramaswamy, (2010) Evolution of δ phase microstructure in alloy 718, In: Proceedings of the 7th International Symposium on Superalloy, 718: 737–750.

Azadian S, Wei L-Y, Warren R (2004) Delta phase precipitation in Inconel 718. Mater Charact 53:7–16. https://doi.org/10.1016/j.matchar.2004.07.004

R Thodla, (2018) Environmentally assisted cracking of high strength nickel based alloys under cathodic protection, In: NACE International Corrosion Conference Proceedings NACE International.

Arcari A, Horton DJ, Zikry M, Chen M (2023) Subcritical crack growth of alloy 718 in marine exposure conditions and microstructural modeling, In: Proceedings of the 10th International Symposium on Superalloy 718 and Derivatives, Springer Nature Switzerland, Cham. https://doi.org/10.1007/978-3-031-27447-3_19.

Zhang Z (2020) Data for strain localisation and failure at twin-boundary complexions in nickel-based superalloys. Nat Commun. https://doi.org/10.5281/ZENODO.3964486

Thodla R, Chandra A, Li X, Taylor CD, Ke H, Sridhar N (2020) Hydrogen embrittlement of 718 under cathodic polarization. Corros Sci 165:108361

Zhang Z, Yang Z, Lu S, Harte A, Morana R, Preuss M (2020) Strain localisation and failure at twin-boundary complexions in nickel-based superalloys. Nat Commun 11:4890. https://doi.org/10.1038/s41467-020-18641-z

MR0175 (2003) Petroleum and natural gas industries-Materials for use in H2S-containing environments in oil and gas production, National Association of Corrosion Engineers.

Muller JF, Donachie MJ (1975) The effects of solution and intermediate heat treatments on the notch-rupture behavior of Inconel 718. MTA 6:2221. https://doi.org/10.1007/BF02818647

Valle LCM, Araújo LS, Gabriel SB, Dille J, de Almeida LH (2013) The effect of δ Phase on the mechanical properties of an inconel 718 superalloy. J of Materi Eng Perform 22:1512–1518. https://doi.org/10.1007/s11665-012-0433-7

Zhang H, Li C, Guo Q, Ma Z, Huang Y, Li H, Liu Y (2018) Hot tensile behavior of cold-rolled Inconel 718 alloy at 650 °C: the role of δ phase. Mater Sci Eng, A 722:136–146. https://doi.org/10.1016/j.msea.2018.02.093

Zhu Q, Chen G, Wang C, Cheng L, Qin H, Zhang P (2019) Effect of the δ Phase on the tensile properties of a nickel-based superalloy. Metals 9:1153. https://doi.org/10.3390/met9111153

E28 Committee, test methods for tension testing of metallic materials, ASTM International, n.d. https://doi.org/10.1520/E0008_E0008M-15.

Saithala JR, Kharusi A, Suryanarayana M, Behlani N, Nabhani T (2021) Implications of failure of alloy 718 (UNS N07718) tubing hanger in sour well. Eng Failure Anal 120:105060. https://doi.org/10.1016/j.engfailanal.2020.105060

Kagay B, Findley K, Coryell S, Nissan AB (2016) Effects of alloy 718 microstructure on hydrogen embrittlement susceptibility for oil and gas environments. Mater Sci Technol 32:697–707. https://doi.org/10.1080/02670836.2016.1139225

C Duret-Thual, D Thierry, C Mendibide, I Salvatori, L Alleva, E Trillo, JW Martin, (2019) Assessment of the hydrogen induced stress cracking resistance of precipitation hardened nickel-based alloys using the slow strain rate tensile test method – review of a three years test program, In: NACE International Corrosion Conference Proceedings-2019, NACE International.

L Foroni, C Malara, (2014) Hydrogen embrittlement susceptibility of precipitation hardened Ni-alloys, In: NACE Corrosion, 2014–3948.

Demetriou V, Robson JD, Preuss M, Morana R (2017) Study of the effect of hydrogen charging on the tensile properties and microstructure of four variant heat treatments of nickel alloy 718. Int J Hydrogen Energy 42:23856–23870. https://doi.org/10.1016/j.ijhydene.2017.02.149

A Arcari, DJ Horton, M Zikry, M Chen, (2023) Subcritical Crack Growth of Alloy 718 in Marine Exposure Conditions and Microstructural Modeling, in: E.A. Ott, J. Andersson, C. Sudbrack, Z Bi, K Bockenstedt, I Dempster, M Fahrmann, P Jablonski, M Kirka, X Liu, D Nagahama, T Smith, M Stockinger, A Wessman (Eds.).In: Proceedings of the 10th International Symposium on Superalloy 718 and Derivatives, Springer Nature Switzerland, Cham, 291–305. https://doi.org/10.1007/978-3-031-27447-3_19.

A Arcari, DJ Horton, JP Moran, R Thodla, R McCoy, (2023) The Effect of Marine Exposure Condition on Fracture Toughness of High Strength Alloys, in: DoD Corrosion 2023

Obasi GC, Zhang Z, Sampath D, Morana R, Akid R, Preuss M (2018) Effect of microstructure and alloy chemistry on hydrogen embrittlement of precipitation-hardened Ni-based alloys. Metall Mater Trans A 49:1167–1181. https://doi.org/10.1007/s11661-018-4483-9

X Li, GB Viswanathan, R Thodla, (2019) Hydrogen embrittlement study of three heats of UNS N07718 in subsea applications, In: NACE CORROSION-2019–13057.

Shanthraj P, Zikry MA (2011) Dislocation density evolution and interactions in crystalline materials. Acta Mater 59:7695–7702. https://doi.org/10.1016/J.ACTAMAT.2011.08.041

Zikry MA, Kao M (1995) Large-scale crystal plasticity computations of microstructural failure modes. Comput Syst Eng 6:225–240. https://doi.org/10.1016/0956-0521(95)00024-T

Granger L, Chen M-J, Brenner D, Zikry M (2022) The challenges of modeling defect behavior and plasticity across spatial and temporal scales: a case study of metal bilayer impact. Metals 12:2036. https://doi.org/10.3390/met12122036

Chen MJ, Xie D, Li N, Zikry MA (2023) Dislocation-density evolution and pileups in bicrystalline systems. Mater Sci Eng: A 870:144812. https://doi.org/10.1016/j.msea.2023.144812

Saleem B, Dong HB, Patel V (2020) Alloy 718 subsea bolt in relation to surface cracking: a microstructural perspective. MSA 11:787–816. https://doi.org/10.4236/msa.2020.1112053

Bond DM, Zikry MA (2020) Effects of electron beam manufacturing induced defects on fracture in Inconel 718. Add Manufact. 32:101059. https://doi.org/10.1016/j.addma.2020.101059

Xiong ZY, Xu WW, Gong XG, Li ZN, Gao X, Guo YH, Chen LJ, You YC, Ruan JJ (2022) Accelerating optimization of IN718 by mapping alloying effects on phase stabilities and mechanical properties using high-throughput calculations. Mater Design. 217:110603. https://doi.org/10.1016/j.matdes.2022.110603

Funding

The authors acknowledge support by the Office of Naval Research through the Naval Research Laboratory’s core funding.

Author information

Authors and Affiliations

Contributions

All four authors contributed equally to this investigation.

Corresponding author

Ethics declarations

Conflict of interest

The Authors declare no Competing Financial or Non-Financial Interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Handling Editor: Tariq Khraishi.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arcari, A., Horton, D., Chen, MJ. et al. Precipitate and dislocation-density interactions affecting strength and ductility in inconel alloys. J Mater Sci 59, 4965–4977 (2024). https://doi.org/10.1007/s10853-023-08822-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08822-8