Abstract

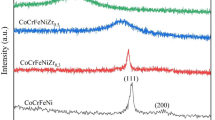

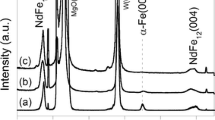

CrCoFeNiMn is a well-known high-entropy alloy (HEA) that has been extensively investigated in both bulk and millimeter-thick layer structures using various methods. In this study, we present the thermal hydrogen reduction synthesis and structural characterization of submicron thick CrCoFeNiMnx (0 ≤ x ≤ 1) HEA thin films. Crystallographic analysis revealed the coexistence of Cr2O3 and γ-phase HEA at x = 0. As the value of x was increased to 0.25, both Cr2O3 and (CryMn1-y)3O4 were synthesized alongside the γ-phase HEA in the thin films. When x was further increased to ≥ 0.5, the Cr2O3 crystallites disappeared, and the thin films consisted of (CryMn1-y)3O4 and γ-phase HEA. We observed the presence of mudcracks and particle domains (PDs), with their area densities increasing with higher Mn compositions. Energy-dispersive X-ray spectroscopy confirmed the presence of Co-, Fe-, and Ni-rich elements in the PDs, while the flat domains (FDs) surrounding the PDs exhibited higher concentrations of Cr, Mn, and O. Chemical etching in HCl solution (10%) revealed that the γ-phase HEA exhibited a tendency to dissolve, and its dissolution rate was faster than that of the oxide. The structural and phase evolutions observed and provide valuable insights into the thermal reduction synthesis of HEA thin films, offering potential for advanced functional applications.

Graphical Abstract

Similar content being viewed by others

Data availability

Data available on requirements.

Change history

20 July 2023

A Correction to this paper has been published: https://doi.org/10.1007/s10853-023-08772-1

References

Gong N, Meng TL, Cao J, Wang Y, Karyappa R, Ivan Tan CK, Suwardi A, Zhu Q, Ngo ACY, Misra KP, Misra RDK, Liu H (2023) Laser-cladding of high entropy alloy coatings: an overview. Mater Technol 38(1):2151696

Cantor B, Chang ITH, Knight P, Vincent AJB (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng, A 375–377:213–218

Yeh J-W, Chen S-K, Lin S-J, Gan J-Y, Chin T-S, Shun T-T, Tsau C-H, Chang S-Y (2004) Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6(5):299–303

Ye YF, Wang Q, Lu J, Liu CT, Yang Y (2016) High-entropy alloy: challenges and prospects. Mater Today 19(6):349–362

Seol JB, Bae JW, Kim JG, Sung H, Li Z, Lee HH, Shim SH, Jang JH, Ko W-S, Hong SI, Kim HS (2020) Short-range order strengthening in boron-doped high-entropy alloys for cryogenic applications. Acta Mater 194:366–377

Moschetti M, Burr PA, Obbard E, Kruzic JJ, Hosemann P, Gludovatz B (2022) Design considerations for high entropy alloys in advanced nuclear applications. J Nucl Mater 567:153814

Wang Y, Gong N, Liu H, Ma W, Hippalgaonkar K, Liu Z, Huang Y (2023) Ordering-dependent hydrogen evolution and oxygen reduction electrocatalysis of high-entropy intermetallic Pt4FeCoCuNi. Adv Mater. https://doi.org/10.1002/adma.202302067

Zhang W, Liaw PK, Zhang Y (2018) Science and technology in high-entropy alloys. Sci China Mater 61(1):2–22

Li S-Y, Nguyen TX, Su Y-H, Lin C-C, Huang Y-J, Shen Y-H, Liu C-P, Ruan J-J, Chang K-S, Ting J-M (2022) Sputter-deposited high entropy alloy thin film electrocatalyst for enhanced oxygen evolution reaction performance. Small 18(39):2106127

Jung S-G, Han Y, Kim JH, Hidayati R, Rhyee J-S, Lee JM, Kang WN, Choi WS, Jeon H-R, Suk J, Park T (2022) High critical current density and high-tolerance superconductivity in high-entropy alloy thin films. Nat Commun 13(1):3373

Ling Y, Chen J, He A, Wang G, Yu X, Xu M, Han Z, Du J, Xu Q (2022) Epitaxial growth of high-entropy alloy thin film with spontaneous exchange bias. J Appl Phys 131(23):233904

Pavithra CLP, Janardhana RKSK, Reddy KM, Murapaka C, Joardar J, Sarada BV, Tamboli RR, Hu Y, Zhang Y, Wang X, Dey SR (2021) An advancement in the synthesis of unique soft magnetic CoCuFeNiZn high entropy alloy thin films. Sci Rep 11(1):8836

Alvi S, Jarzabek DM, Kohan MG, Hedman D, Jenczyk P, Natile MM, Vomiero A, Akhtar F (2020) Synthesis and mechanical characterization of a CuMoTaWV high-entropy film by magnetron sputtering. ACS Appl Mater Interfaces 12(18):21070–21079

Mayandi J, Schrade M, Vajeeston P, Stange M, Lind AM, Sunding MF, Deuermeier J, Fortunato E, Løvvik OM, Ulyashin AG, Diplas S, Carvalho PA, Finstad TG (2022) High entropy alloy CrFeNiCoCu sputter deposited films: structure, electrical properties, and oxidation. J Vac Sci Technol, A 40(2):023402

Chuang-Shi Feng T-WL, Wang T-L, Lin M-Z, Hou J, Wenjun L, Liao W-B (2021) A novel high-entropy amorphous thin film with high electrical resistivity and outstanding corrosion resistance. Acta Metallurgica Sinica (English Letters) 34(11):1537–1545

Lu T-W, Feng C-S, Wang Z, Liao K-W, Liu Z-Y, Xie Y-Z, Hu J-G, Liao W-B (2019) Microstructures and mechanical properties of CoCrFeNiAl0.3 high-entropy alloy thin films by pulsed laser deposition. Appl Surface Sci 494:72–79

Cropper MD (2018) Thin films of AlCrFeCoNiCu high-entropy alloy by pulsed laser deposition. Appl Surf Sci 455:153–159

Ustinov AI, Demchenkov SA, Melnychenko TV, Skorodzievskii VS, Polishchuk SS (2021) Effect of structure of high entropy CrFeCoNiCu alloys produced by EB PVD on their strength and dissipative properties. J Alloy Compd 887:161408

Liu HF, Wong SL, Chi DZ (2015) CVD growth of MoS2-based two-dimensional materials. Chem Vap Deposition 21(10-11–12):241–259

Liu H, Ansah Antwi KK, Ying J, Chua S, Chi D (2014) Towards large area and continuous MoS2 atomic layers via vapor-phase growth: thermal vapor sulfurization. Nanotechnology 25(40):405702

Liu H (2016) Recent progress in atomic layer deposition of multifunctional oxides and two-dimensional transition metal dichalcogenides. J Mol Eng Mater 04(04):1640010

Liu H, Yang RB, Yang W, Jin Y, Lee CJJ (2018) Atomic layer deposition and post-growth thermal annealing of ultrathin MoO3 layers on silicon substrates: formation of surface nanostructures. Appl Surf Sci 439:583–588

Yang W, Kawai H, Bosman M, Tang B, Chai J, Tay WL, Yang J, Seng HL, Zhu H, Gong H, Liu H, Goh KEJ, Wang S, Chi D (2018) Interlayer interactions in 2D WS2/MoS2 heterostructures monolithically grown by in situ physical vapor deposition. Nanoscale 10(48):22927–22936

Liu HF, Hu GX, Gong H, Zang KY, Chua SJ (2008) Effects of oxygen on low-temperature growth and band alignment of ZnO/GaN heterostructures. J Vac Sci Technol, A 26(6):1462–1468

Liu H, Chi D (2012) Magnetron-sputter deposition of Fe3S4 thin films and their conversion into pyrite (FeS2) by thermal sulfurization for photovoltaic applications. J Vac Sci Technol, A 30(4):04D102

Li H, Zhang Y, Liu H, Wang J (2011) Large ZnO mesocrystals of hexagonal columnar morphology derived from liquid crystal templates. J Am Ceram Soc 94(10):3267–3275

Liu HF, Lim ES, Tung PKH, Xiang N (2011) Fabrication and transfer of nanoporous alumina thin films for templating applications: metal dots array deposition and porous ZnO film growth. Thin Solid Films 519(10):3050–3054

Liu HF, Wang YD, Lin M, Ong LT, Tee SY, Chi DZ (2015) Cobalt sulfide nanoparticles decorated on TiO2 nanotubes via thermal vapor sulfurization of conformal TiO2-coated Co(CO3)0.5(OH)·0.11H2O core–shell nanowires for energy storage applications. RSC Adv 5(60):48647–48653

Yao Y, Huang Z, Xie P, Lacey SD, Jacob RJ, Xie H, Chen F, Nie A, Pu T, Rehwoldt M, Yu D, Zachariah MR, Wang C, Shahbazian-Yassar R, Li J, Hu L (2018) Carbothermal shock synthesis of high-entropy-alloy nanoparticles. Science 359(6383):1489–1494

Zhang D, Zhao H, Wu X, Deng Y, Wang Z, Han Y, Li H, Shi Y, Chen X, Li S, Lai J, Huang B, Wang L (2021) Multi-Site Electrocatalysts Boost pH-Universal Nitrogen Reduction by High-Entropy Alloys. Adv Func Mater 31(9):2006939

Li K, Chen W (2021) Recent progress in high-entropy alloys for catalysts: synthesis, applications, and prospects. Materials Today Energy 20:100638

Liu H, Wei Y, Tan CKI, Ardi DT, Tan DCC, Lee CJJ (2020) XRD and EBSD studies of severe shot peening induced martensite transformation and grain refinements in austenitic stainless steel. Mater Charact 168:110574

Maji D, Das S (2014) Analysis of plasma-induced morphological changes in sputtered thin films over compliant elastomer. J Phys D Appl Phys 47(10):105401

Seghir R, Arscott S (2015) Controlled mud-crack patterning and self-organized cracking of polydimethylsiloxane elastomer surfaces. Sci Rep 5(1):14787

Linke R, Schreiner M, Demortier G (2004) The application of photon, electron and proton induced X-ray analysis for the identification and characterisation of medieval silver coins. Nucl Instrum Methods Phys Res, Sect B 226(1):172–178

Roodbar Shojaei T, Soltani S, Derakhshani M (2022) Chapter 6 - Synthesis, properties, and biomedical applications of inorganic bionanomaterials. In: Barhoum A, Jeevanandam J, Danquah MK (eds) Fundamentals of Bionanomaterials. Elsevier, Amsterdam, pp 139–174

Liu HF, Antwi KKA, Wang YD, Ong LT, Chua SJ, Chi DZ (2014) Atomic layer deposition of crystalline Bi2O3 thin films and their conversion into Bi2S3 by thermal vapor sulfurization. RSC Adv 4(102):58724–58731

Liu HF, Huang A, Chi DZ (2010) Thermal annealing of nanocrystalline Fe3S4 films deposited on Si substrates by dc-magnetron sputtering at room temperature. J Phys D Appl Phys 43(45):455405

Liu H, Iskander A, Yakovlev NL, Chi D (2015) Anomalous SiO2 layer formed on crystalline MoS2 films grown on Si by thermal vapor sulfurization of molybdenum at elevated temperatures. Mater Lett 160:491–495

Poirier DR, Ganesan S, Andrews M, Ocansey P (1991) Isothermal coarsening of dendritic equiaxial grains in Al 15.6wt.% Cu alloy. Mater Sci Eng A 148(2):289–297

Terzi S, Salvo L, Suery M, Dahle AK, Boller E (2010) Coarsening mechanisms in a dendritic Al–10% Cu alloy. Acta Mater 58(1):20–30

Luidold S, Antrekowitsch H (2007) Hydrogen as a reducing agent: State-of-the-art science and technology. JOM 59(6):20–26

Rigg T (1964) Kinetics of the reduction of ferrous chloride with hydrogen. Can J Chem Eng 42(6):247–253

Shibayama R, Tsuchida N, Tanaka T (1980) Studies on the pyrohydrolysis of metal chlorides I. The pyrohydrolysis of NiCl2, CoCl2, and FeCl2. Denki Kagaku oyobi Kogyo Butsuri Kagaku 48(10):545–553

El-Geassy AA, Nasr MI, Omar AA, Mousa EA (2008) Isothermal reduction behaviour of MnO2 doped Fe2O3 compacts with H2 at 1073–1373 K. Ironmak Steelmak 35(7):531–538

Liu F, Liu J, Li Y, Fang R (2021) Theoretical study of reduction mechanism of Fe2O3 by H2 during chemical looping combustion. Chin J Chem Eng 37:175–183

Haver FP, Wong MM (1971) Recovery of copper, iron, and sulfur from chalcopyrite concentrate using a ferric chloride leach. JOM 23(2):25–29

Chen K, Bothwell A, Guthrey H, Hartenstein MB, Polzin J-I, Feldmann F, Nemeth W, Theingi S, Page M, Young DL, Stradins P, Agarwal S (2022) Measurement of poly-Si film thickness on textured surfaces by X-ray diffraction in poly-Si/SiOx passivating contacts for monocrystalline Si solar cells. Sol Energy Mater Sol Cells 236:111510

Eisenstein A (1946) An X-Ray Method for Measuring the Thickness of Thin Crystalline Films. J Appl Phys 17(11):874–878

Chaudhuri J, Shah S (1991) Thickness measurement of thin films by x-ray absorption. J Appl Phys 69(1):499–501

Acknowledgements

This work is partly supported by A*STAR RIE2020 advanced manufacturing and engineering (AME) programmatic grant through the structural metal alloys program (SMAP, Grant no. A18B1b0061, Project no. SC25/18-8R1715-PRJ6).

Author information

Authors and Affiliations

Contributions

NG, RK, TLM, YW, SLT, JC, ML, XH, CKIT, and AS were contributed to experimental investigation, formal analysis, writing—original draft, writing—review and editing. Hongfei Liu was contributed to funding acquisition, resources, conceptualization, methodology, investigation, formal analysis, writing—original draft, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors are here declaring no conflict of interest in this work for publication.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gong, N., Karyappa, R., Meng, T.L. et al. Synthesis and structural characterizations of CrCoFeNiMnx (0 ≤ x ≤ 1) high-entropy-alloy thin films by thermal reduction in hydrogen. J Mater Sci 58, 12058–12069 (2023). https://doi.org/10.1007/s10853-023-08731-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08731-w