Abstract

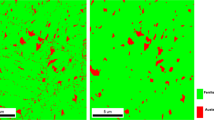

In this paper, the deformation mechanisms of a Fe–2.25%Cr–1%Mo (P22) steel are studied after tensile tests at room temperature (RT) and 550 °C (HT), creep-fatigue tests at 550 °C and stress relaxation test at 550 °C (HTSR). The RT, HT and HTSR tests produced permanent strain of about 2.5% by different processes. Deformation features such as the orientation of the grains, local misorientation, grain boundary type and distribution, etc., were characterized using electron backscatter diffraction. Transmission electron microscopy was done subsequently to obtain greater insight into the dislocation substructures. The as-received sample had a ferritic–bainitic microstructure, and a large amount of local misorientation was found in the bainite, indicating plastic strain due to phase transformation. After tensile strain to 2.5% at room temperature, the dislocations formed very small substructures (~100–200 nm) in the ferrite grains, and most of the retained plastic strain seemed to be concentrated in the bainite after deformation. Both the ferrite and bainite showed much lower local misorientation and dislocation wall content after a tensile test to 2.5% strain at 550 °C. Compared to the RT tensile sample, after creep-fatigue at 550 °C, the substructures in ferrite opened up considerably and formed small-angle grain boundaries, with clean areas as large as 20–25 μm. After stress relaxation at 550 °C, the ferrite displayed even less substructure, while the bainite seemed to have greater amounts of local misorientation than in the creep-fatigue case. However, the degree of misorientation was less pronounced than in the room temperature tensile case. These results have been discussed with respect to the causes behind the phenomena observed herein and their possible effects on mechanical behaviour.

Graphical Abstract

Similar content being viewed by others

References

ASTM (1984) ASTM A335—Seamless ferritic alloy steel pipe for high temperature service, ASTM

Corwin WR, Burchell TD, Halsey WG, Hayner GO, Katoh Y, Klett JW, McGreevy TE, Nanstad RK, Ren W, Snead LL, Stoller RE, Wilson DF (2005) Updated generation IV reactors integrated materials program plan (Revision 2), In: Hadley PJ (ed) Oak Ridge National Laboratory

Dieter GE (1988) Mechanical metallurgy, Metric. McGraw-Hill, Singapore

Payten WM, Snowden KU, Dean DW (2013) Effects of prior stress relaxation on the prediction of creep life using time and strain based methods. J Press Vessel Technol 135(4):41201

Glover G, Sellars CM (1973) Recovery and recrystallization during high temperature deformation of α-iron. Metall Trans 4(3):765–775

Ouchi C, Okita T (1983) Dynamic recovery and static recrystallization of 1.8% al steel in hot deformation. Trans Iron Steel Ins Jpn 23(2):128–136

Storojeva L, Ponge D, Kaspar R, Raabe D (2004) Development of microstructure and texture of medium carbon steel during heavy warm deformation. Acta Mater 52(8):2209–2220

Liang S, Fazeli F, Zurob HS (2019) Effects of solutes and temperature on high-temperature deformation and subsequent recovery in hot-rolled low alloy steels. Mater Sci Eng A 765:138324

Humphries SR, Yeung WY, Callaghan MD (2011) The effect of stress relaxation loading cycles on the creep behaviour of 2.25Cr–1Mo pressure vessel steel. Mater Sci Eng: A 528(3):1216–1220

Fournier B, Sauzay M, Caës C, Noblecourt M, Mottot M, Allais L, Tournie I, Pineau A (2009) Creep-fatigue interactions in a 9 Pct cr-1 Pct Mo martensitic steel: part I. Mech Test Res Metall Mater Trans A 40(2):321–329

Alsmadi ZY, Abouelella H, Alomari AS, Murty KL (2022) Stress-controlled creep-fatigue of an advanced austenitic stainless steel at elevated temperatures. Materials 15(11):3984

Porter TD, Findley KO, Kaufman MJ, Wright RN (2019) Assessment of creep-fatigue behavior, deformation mechanisms, and microstructural evolution of alloy 709 under accelerated conditions. Int J Fatigue 124:205–216

Pohja R (2015) Creep-fatigue design of GEN IV high temperature reactor plants

IAEA (1996) Creep-fatigue damage rules for advanced fast reactor design, IAEA, Vienna

Bueno LO, Sobrinho JFR (2012) Correlation between creep and hot tensile behaviour for 2.25Cr-1Mo steel from 500 °C to 700 °C Part 1: an assessment according to usual relations involving stress, temperature, strain rate and rupture time revista. Materia 17(3):1098–1108

Ye W, Hu X, Song Y (2020) The relationship between creep and tensile properties of a nickel-based superalloy. Mater Sci Eng A 774:138847

Wei S, Kim J, Tasan CC (2022) In-situ investigation of plasticity in a Ti-Al-V-Fe (α+β) alloy: slip mechanisms, strain localization, and partitioning. Int J Plast 148:103131

Rui S-S, Niu L-S, Shi H-J, Wei S, Tasan CC (2019) Diffraction-based misorientation mapping: a continuum mechanics description. J Mech Phys Solids 133:103709

Oh HS, Biggs K, Güvenç O, Ghassemi-Armaki H, Pottore N, Tasan CC (2021) In-situ investigation of strain partitioning and microstructural strain path development up to and beyond necking. Acta Mater 215:117023

Tu X, Shi X, Yan W, Li C, Shi Q, Shan Y, Yang K (2022) Tensile deformation behavior of ferrite-bainite dual-phase pipeline steel. Mater Sci Eng A 831:142230

Muránsky O, Zhu H, Lim S-L, Short K, Cairney J, Drew M (2020) On the evolution of mechanical properties and microstructure of ferritic-bainitic (FB) 2.25Cr-1Mo (Grade 22) steel during high-temperature creep. Materialia 9:100513

Fujita N, Ishikawa N, Roters F, Tasan CC, Raabe D (2018) Experimental–numerical study on strain and stress partitioning in bainitic steels with martensite–austenite constituents. Int J Plast 104:39–53

Humphries SR, Snowden KU, Yeung W (2010) The effect of repeated loadings on the stress relaxation properties of 2.25Cr–1Mo steel at 550 °C and the influence on the Feltham ‘a’ and ‘b’ parameters. Mater Sci Eng A 527(13):3240–3244

Humphries SR (2009) High temperature stress relaxation properties of ferritic pressure vessel steel, Faculty of Science, University of Technology Sydney, Sydney, 2009, pp 147

Bachmann F, Hielscher R, Schaeben H (2010) Texture analysis with MTEX—free and open source software toolbox. Solid State Phenom 160:63–68

Bacon R, Nutting J (1959) The tempering of 225Cr-1Mo steel after quenching and normalizing. J Iron Steel Ins 192(3):257–268

Hodgson DK, Dai T, Lippold JC (2015) Transformation and tempering behavior of the heat-affected zone of 2.25Cr-1Mo steel. Weld J 94:250-s–256-s

He SH, He BB, Zhu KY, Huang MX (2018) Evolution of dislocation density in bainitic steel: modeling and experiments. Acta Mater 149:46–56

Alsagabi S, Shrestha T, Charit I (2014) High temperature tensile deformation behavior of grade 92 steel. J Nucl Mater 453(1):151–157

Olmsted DL, Hector LG, Curtin WA, Clifton RJ (2005) Atomistic simulations of dislocation mobility in Al Ni andAl/Mg alloys. Model Simul Mater Sci Eng 13(3):371–388

Yu X-X, Wang C-Y (2009) The effect of alloying elements on the dislocation climbing velocity in Ni: a first-principles study. Acta Mater 57(19):5914–5920

McQueen HJ (1977) The production and utility of recovered dislocation substructures. Metall Trans A 8(6):807–824

Murty KL, Gollapudi S, Ramaswamy K, Mathew MD, Charit I (2013) Creep deformation of materials in light water reactors (LWRs), In: Murty KL (ed), Materials ageing and degradation in light water reactors, Woodhead Publishing2013, pp 81–148

Carroll MC, Carroll LJ (2013) Developing dislocation subgrain structures and cyclic softening during high-temperature creep-fatigue of a nickel alloy. Metall Mater Trans A Phys Metall Mater Sci 44(8):3592–3607

Fournier B, Sauzay M, Barcelo F, Rauch E, Renault A, Cozzika T, Dupuy L, Pineau A (2009) Creep-fatigue interactions in a 9 Pct Cr-1 Pct Mo martensitic steel: Part II. Microstruct Evolut, Metall Mater Trans A 40(2):330–341

Reed-Hill RE, Abbaschian R (1994) Elements of grain boundaries, Physical metallurgy principles, PWS Publishing Company, Boston

Panwisawas C, D’Souza N, Collins DM, Bhowmik A (2017) The contrasting roles of creep and stress relaxation in the time-dependent deformation during in-situ cooling of a nickel-base single crystal superalloy. Sci Rep 7(1):11145

Xiao X, Xu H, Huang J, Wang J, Zhang J (2018) Stress relaxation properties and microscopic deformation structure in bending of the C7025 and C7035 alloy. Crystals 8(8):324

McQueen HJ (2001) Dynamic recovery and recrystallization. In: Buschow KHJ, Cahn RW, Flemings MC, Ilschner B, Kramer EJ, Mahajan S, Veyssière P (eds) Encyclopedia of materials: science and technology. Elsevier, Oxford, pp 2375–2381

Acknowledgements

The authors would like to acknowledge Mr. Tim Palmer and Mr. Kimbal Lu of NMDC, ANSTO, for their valuable support in sample preparation. The authors would like to acknowledge P. Dayal for his assistance in performing a few of the EBSD scans.

This work has been funded by internal funding from Institute of Materials Engineering and Nuclear Fuel Cycle Research, ANSTO. The authors would also like to express their gratitude to the Nuclear Materials Development and Characterization platform (NMDC) for providing the characterization facilities essential for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors do not have any known conflict of interest in the publication of this work.

Ethical approval

Not applicable.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhattacharyya, D., Drew, M., Humphries, S.R. et al. Characterization of deformation structures in P-22 Cr–Mo steel through electron backscatter diffraction and transmission electron microscopy. J Mater Sci 58, 11286–11309 (2023). https://doi.org/10.1007/s10853-023-08698-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08698-8