Abstract

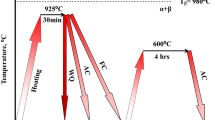

Titanium alloys are preferred in many engineering applications due to their high specific strength and superior corrosion resistance. However, its abrasion resistance is not very high and it limits the use of titanium alloys. The aim of this study is to examine the effect of solutionizing temperature on microstructure, hardness, wear, cavitation resistance and corrosion behavior of the Ti6Al4V alloy. For this purpose, quenching in water (WQ) was carried out by solutionizing the Ti6Al4V alloy at the temperatures 1050 and 960 °C containing the β-transus and β + α regions, respectively. The hardness of Ti6Al4V alloy increased with increasing heat treatment (HT) temperature. Depending on the increased hardness value, the highest wear resistance was observed in the specimen, which was heat treated at 1050 °C for 1 h and quenched. However, maximum cavitation resistance was observed in the specimen, which was heat treated at 960 °C for 1 h and quenched. The non-heat treated specimen exhibited the minimum cavitation resistance. Corrosion rate values were determined as 1.85, 0.66 and 0.46 × 10–3 mm/year for non-heat treated, 960 and 1050 °C heat treated + quenched specimens, respectively. It has been determined that heat treatment reduces the corrosion rate 3–4 times.

Graphical abstract

Similar content being viewed by others

References

Monshi A, Foroughi MR, Monshi MR (2012) Modified scherrer equation to estimate more accurately nano-crystallite size using XRD. World J Nano Sci Eng 02:154–160. https://doi.org/10.4236/WJNSE.2012.23020

Langford JI, Wilson AJC (1978) Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J Appl Crystallogr 11:102–113. https://doi.org/10.1107/S0021889878012844

Bregliozzi G, Di Schino A, Ahmed SIU et al (2005) Cavitation wear behaviour of austenitic stainless steels with different grain sizes. Wear 258:503–510. https://doi.org/10.1016/J.WEAR.2004.03.024

Youssef SS, Ibrahim KM, Abdel-Karim M (2013) Effect of heat treatment process on tribological behavior of Ti-6Al-4V alloy. Int J Mech Eng Robot Res 2:385–394

Vogel SC, Bhattacharyya D, Viswanathan GB et al (2005) Phase transformation textures in Ti-6Al-4V alloy. Mater Sci Forum 495–497:681–686. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/MSF.495-497.681

Qiao Y, Xu D, Wang S, Ma Y, Chen J, Wang Y, Zhou H (2019) Corrosion and tensile behaviors of Ti-4Al-2V-1Mo-1Fe and Ti-6Al-4V titanium alloys. Metals 9:1213

Feng Z, Yang Y, Xu Z, Shi Q (2018) Effect of martensitic transformation on elastic modulus anisotropy of Ti-6Al-4V Alloy. Mater Res. https://doi.org/10.1590/1980-5373-mr-2018-0197

Yi H-J, Kim J-W, Kim Y-L, Shin S (2020) Effects of cooling rate on the microstructure and tensile properties of wire-arc additive manufactured Ti–6Al–4V alloy. Met Mater Int 26:1235–1246. https://doi.org/10.1007/s12540-019-00563-1

Zhang S, Lin X, Chen J, Huang W (2009) Effect of solution temperature and cooling rate on microstructure and mechanical properties of laser solid forming Ti-6Al-4V alloy. Chin Opt Lett 7:498–501. https://doi.org/10.3788/COL20090706.0498

Dai J, Xia J, Chai L et al (2020) Correlation of microstructural, textural characteristics and hardness of Ti–6Al–4V sheet β-cooled at different rates. J Mater Sci 55:8346–8362. https://doi.org/10.1007/s10853-020-04603-9

Seo S, Choi H, Lee G et al (2021) Effect of cooling rate on microstructure and hardness during solution treatment and aging process of Ti-6Al-4V alloy for aerospace components. J Mater Eng Perform 30:3406–3415. https://doi.org/10.1007/s11665-021-05618-2

Kaschel FR, Vijayaraghavan RK, McNally PJ et al (2021) In-situ XRD study on the effects of stress relaxation and phase transformation heat treatments on mechanical and microstructural behaviour of additively manufactured Ti-6Al-4V. Mater Sci Eng A 819:141534. https://doi.org/10.1016/j.msea.2021.141534

Ji H, Peng Z, Huang X et al (2021) Characterization of the microstructures and dynamic recrystallization behavior of Ti-6Al-4V titanium alloy through experiments and simulations. J Mater Eng Perform 30:8257–8275. https://doi.org/10.1007/s11665-021-06044-0

Kherrouba N, Carron D, Kouba R et al (2022) Gleeble-assisted investigation and thermokinetics simulation of α phase isothermal precipitation during short-time duplex heat treatment of Ti-6Al-4V alloy. J Mater Eng Perform 31:7517–7526. https://doi.org/10.1007/s11665-022-06775-8

Liao Y, Bai J, Chen F et al (2022) Microstructural strengthening and toughening mechanisms in Fe-containing Ti-6Al-4V: A comparison between homogenization and aging treated states. J Mater Sci Technol 99:114–126. https://doi.org/10.1016/j.jmst.2021.04.063

Yan X, Yin S, Chen C et al (2018) Effect of heat treatment on the phase transformation and mechanical properties of Ti6Al4V fabricated by selective laser melting. J Alloys Compd 764:1056–1071. https://doi.org/10.1016/j.jallcom.2018.06.076

Karimi J, Antonov M, Kollo L, Prashanth KG (2022) Role of laser remelting and heat treatment in mechanical and tribological properties of selective laser melted Ti6Al4V alloy. J Alloys Compd 897:163207. https://doi.org/10.1016/j.jallcom.2021.163207

Kumar P, Ramamurty U (2019) Microstructural optimization through heat treatment for enhancing the fracture toughness and fatigue crack growth resistance of selective laser melted Ti 6Al 4V alloy. Acta Mater 169:45–59. https://doi.org/10.1016/j.actamat.2019.03.003

Liang Z, Sun Z, Zhang W et al (2019) The effect of heat treatment on microstructure evolution and tensile properties of selective laser melted Ti6Al4V alloy. J Alloys Compd 782:1041–1048. https://doi.org/10.1016/j.jallcom.2018.12.051

Gu K, Zhang H, Zhao B et al (2013) Effect of cryogenic treatment and aging treatment on the tensile properties and microstructure of Ti–6Al–4V alloy. Mater Sci Eng, A 584:170–176. https://doi.org/10.1016/j.msea.2013.07.021

Çakir FH, Çelik ON (2020) Influence of cryogenic treatment on microstructure and mechanical properties of Ti6Al4V alloy. J Mater Eng Perform 29:6974–6984. https://doi.org/10.1007/s11665-020-05177-y

Omoniyi PO, Akinlabi ET, Mahamood RM, Jen TC (2021) Corrosion resistance of heat treated Ti6Al4V in NaCl. Chem Data Collect 36:100780. https://doi.org/10.1016/j.cdc.2021.100780

Karimzadeh F, Heidarbeigy M, Saatchi A (2008) Effect of heat treatment on corrosion behavior of Ti–6Al–4V alloy weldments. J Mater Process Technol 206:388–394. https://doi.org/10.1016/j.jmatprotec.2007.12.065

Li DG, Long Y, Liang P, Chen DR (2017) Effect of micro-particles on cavitation erosion of Ti6Al4V alloy in sulfuric acid solution. Ultrason Sonochem 36:270–276. https://doi.org/10.1016/j.ultsonch.2016.12.003

Wang Y, Hao E, Zhao X et al (2022) Effect of microstructure evolution of Ti6Al4V alloy on its cavitation erosion and corrosion resistance in artificial seawater. J Mater Sci Technol 100:169–181. https://doi.org/10.1016/j.jmst.2021.06.005

de Formanoir C, Brulard A, Vivès S et al (2017) A strategy to improve the work-hardening behavior of Ti–6Al–4V parts produced by additive manufacturing. Mater Res Lett 5:201–208. https://doi.org/10.1080/21663831.2016.1245681

Oh S-T, Woo K-D, Kim J-H, Kwak S-M (2017) Effect of retained β phase on mechanical properties of Cast Ti-6Al-4V alloy. Mater Trans 58:1145–1149. https://doi.org/10.2320/matertrans.L-M2017818

Oh ST, Do WK, Kim JH, Kwak SM (2017) The effect of Al and V on microstructure and transformation of β phase during solution treatments of cast Ti-6Al-4V alloy. Korean J Metals Mater 55:150–155. https://doi.org/10.3365/KJMM.2017.55.3.150

Poondla N, Srivatsan TS, Patnaik A, Petraroli M (2009) A study of the microstructure and hardness of two titanium alloys: commercially pure and Ti–6Al–4V. J Alloys Compd 486:162–167. https://doi.org/10.1016/J.JALLCOM.2009.06.172

Feng C, Khan TI (2008) The effect of quenching medium on the wear behaviour of a Ti-6Al-4V alloy. J Mater Sci 43:788–792. https://doi.org/10.1007/S10853-007-2298-Y/TABLES/1

Molinari A, Straffelini G, Tesi B, Bacci T (1997) Dry sliding wear mechanisms of the Ti6Al4V alloy. Wear 208:105–112. https://doi.org/10.1016/S0043-1648(96)07454-6

Mehdi B, Badji R, Ji V et al (2016) Microstructure and residual stresses in Ti-6Al-4V alloy pulsed and unpulsed TIG welds. J Mater Process Technol 231:441–448. https://doi.org/10.1016/j.jmatprotec.2016.01.018

Wang Y, Hao E, An Y et al (2021) Effects of microstructure and mechanical properties on cavitation erosion resistance of NiCrWMoCuCBFe coatings. Appl Surf Sci 547:149125. https://doi.org/10.1016/J.APSUSC.2021.149125

Jiang X, Overman N, Smith C, Ross K (2020) Microstructure, hardness and cavitation erosion resistance of different cold spray coatings on stainless steel 316 for hydropower applications. Mater Today Commun 25:101305. https://doi.org/10.1016/J.MTCOMM.2020.101305

Espitia LA, Toro A (2010) Cavitation resistance, microstructure and surface topography of materials used for hydraulic components. Tribol Int 43:2037–2045. https://doi.org/10.1016/j.triboint.2010.05.009

Zhang X-F, Fang L (2002) The effect of stacking fault energy on the cavitation erosion resistance of α-phase aluminum bronzes. Wear 253:1105–1110. https://doi.org/10.1016/S0043-1648(02)00168-0

Liu Y, Li M (2016) Nanocrystallization mechanism of beta phase in Ti-6Al-4V subjected to severe plastic deformation. Mater Sci Eng, A 669:7–13. https://doi.org/10.1016/j.msea.2016.05.088

Wang Y, An Y, Hou G et al (2023) Effect of cooling rate during annealing on microstructure and ultrasonic cavitation behaviors of Ti6Al4V alloy. Wear 512–513:204529. https://doi.org/10.1016/j.wear.2022.204529

Kulkarni G, Hiwarkar V, Singh R (2019) Texture evolution of Ti6Al4V during cold deformation. Int J Mater Mech Manuf https://doi.org/10.18178/ijmmm.2019.7.6.469

Bai Y, Gai X, Li S et al (2017) Improved corrosion behaviour of electron beam melted Ti-6Al–4V alloy in phosphate buffered saline. Corros Sci 123:289–296. https://doi.org/10.1016/j.corsci.2017.05.003

Atapour M, Pilchak A, Frankel GS et al (2010) Corrosion behavior of Ti-6Al-4V with different thermomechanical treatments and microstructures. Corrosion 66:065004-065004–065009. https://doi.org/10.5006/1.3452400

Zhang H, Man C, Wang L et al (2020) Different corrosion behaviors between α and β phases of Ti6Al4V in fluoride-containing solutions: ınfluence of alloying element Al. Corros Sci 169:108605. https://doi.org/10.1016/j.corsci.2020.108605

Trifonov DB, Toshev YE (2006) Experimental study on the free-sintering process of a micro-porous HDPE membrane. In: 4M 2006 - Second International Conference on Multi-Material Micro Manufacture. Elsevier, pp 301–304

Acknowledgements

Not Applicable.

Author information

Authors and Affiliations

Contributions

All authors contributed to the manuscript preparation and the interpretation of test results. NÇ carried out the heat treatment of Ti6Al4V alloy, wear, hardness, and corrosion tests of samples. MY focused on microstructural examinations, SEM and SEM–EDX analyses after the wear and cavitation tests. HD performed the cavitation test and calculated the cavitation resistance.

Corresponding author

Ethics declarations

Conflict of interest

The researchers affirm that no financial or commercial relations that might be viewed as having a conflict of interest existed during the research's conduction.

Ethical approval

This study has no ethical issues.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Çömez, N., Yurddaskal, M. & Durmuş, H. Effect of solutionizing and quenching treatment on Ti6Al4V alloy: a study on wear, cavitation erosion and corrosion resistance. J Mater Sci 58, 10201–10216 (2023). https://doi.org/10.1007/s10853-023-08688-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08688-w