Abstract

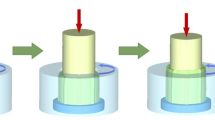

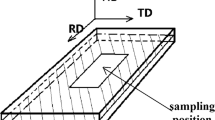

In this study, the gradient microstructure of Mg-Y-Nd-Zr alloy processed by an ultrasonic surface rolling process (USRP) is characterized by electron backscatter diffraction analysis and transmission electron microscopy. The mechanism of microstructure evolution and its effect on mechanical properties of the alloy are discussed in detail. The grain size and orientation of Mg-Y-Nd-Zr alloy after USRP treatment changed gradually along the processing depth. The grain refinement mechanism was elucidated as follows: First, the coarse-grained matrix was subdivided by dislocation slip and twins and further refined into sub-structures by multiple techniques, such as mutual intersection and fragmentation between twins, the interaction between twins and dislocations, and the entanglement of dislocations. Finally, equiaxed nanocrystals with high-angle grain boundaries were formed by sub-grain rotation and recrystallization. The strength improvement of the alloy was mainly attributed to the contributions of grain refinement and dislocation strengthening. The synergistic deformation between the gradient structures is the main reason for the excellent strength and plasticity matching of the alloy.

Similar content being viewed by others

Data availability

Data will be made available upon request.

References

Dong J, Lin T, Shao H et al (2022) Advances in degradation behavior of biomedical magnesium alloys: a review. J Alloys Compound 908:164600

Song J, Chen J, Xiong X et al (2022) Research advances of magnesium and magnesium alloys worldwide in 2021. J Magnes Alloys 10(4):863–898

Zeng Z, Salehi M, Kopp A et al (2022) Recent progress and perspectives in additive manufacturing of magnesium alloys. J Magnes Alloy 10(6):1511–1541

Mansoor A, Du W, Yu Z, Ding N, Fu J, Lou F, Liu K, Li S (2022) Effects of grain refinement and precipitate strengthening on mechanical properties of double-extruded Mg-12Gd-2Er-04 Zr alloy. J Alloy Compound 25(898):162873

Sun W, Wu B, Fu H et al (2022) Combining gradient structure and supersaturated solid solution to achieve superior mechanical properties in WE43 magnesium alloy. J Mater Sci Technol 99:223–238

Zheng R, Gong W, Du J-p et al (2022) Rediscovery of Hall-Petch strengthening in bulk ultrafine grained pure Mg at cryogenic temperature: a combined in-situ neutron diffraction and electron microscopy study [J]. Acta Mater 238:11842

Zuo J, Nakata T, Xu C et al (2022) Effect of grain boundary segregation on microstructure and mechanical properties of ultra-fine grained Mg–Al–Ca–Mn alloy wires. Mater Sci Eng A 848:143483

Chen X, Li Q, Chen J et al (2019) Microstructure and mechanical properties of Mg-Gd-Y-Sm-Al alloy and analysis of grain refinement and strengthening mechanism. J Rare Earths 37(12):1351–1358

Peng P, Zhang L, Zhao J et al (2023) Simultaneous improvement of strength and ductility in ZK60 magnesium alloy by constructing the bimodal grain structure. J Market Res 22:1026–1038

Li Z-G, Miao Y, Jia H-L et al (2022) Designing a low-alloyed Mg–Al–Sn–Ca alloy with high strength and extraordinary formability by regulating fine grains and unique texture. Mater Sci Eng: A 852:143687

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51(4):427–556

Weertman JR, Farkas D, Hemker K et al (2013) Structure and mechanical behavior of bulk nanocrystalline materials. MRS Bull 24(2):44–53

Chen L, Yuan F, Jiang P et al (2017) Mechanical properties and deformation mechanism of Mg-Al-Zn alloy with gradient microstructure in grain size and orientation. Mater Sci Eng, A 694:98–109

Shen M, Jia J, Ying T et al (2019) Fracture mechanism of nano- and submicron-SiCp/Mg composite during room temperature tensile test: Interaction between double sized particles and dislocations. J Alloy Compd 791:452–460

Shi XY, Liu Y, Li DJ et al (2015) Microstructure evolution and mechanical properties of an Mg–Gd alloy subjected to surface mechanical attrition treatment. Mater Sci Eng, A 630:146–154

Song J, She J, Chen D et al (2020) Latest research advances on magnesium and magnesium alloys worldwide. J Magnes Alloy 8(1):1–41

Sun LG, Wu G, Wang Q et al (2020) Nanostructural metallic materials: structures and mechanical properties. Mater Today 38:114–135

Fang TH, Li WL, Tao NR et al (2011) Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 331(6024):1587–1590

Jin Z-Z, Zha M, Jia H-L et al (2021) Balancing the strength and ductility of Mg–6Zn–0.2Ca alloy via sub-rapid solidification combined with hard-plate rolling. J Mater Sci Technol 81:219–228

Chen A, Li D, Zhang J et al (2008) Make nanostructured metal exceptionally tough by introducing non-localized fracture behaviors. Scripta Mater 59(6):579–582

Moering J, Ma X, Malkin J et al (2016) Synergetic strengthening far beyond rule of mixtures in gradient structured aluminum rod. Scripta Mater 122:106–109

Wu X, Jiang P, Chen L et al (2014) Extraordinary strain hardening by gradient structure. Proc Natl Acad Sci USA 111(20):7197–7201

Wu XL, Jiang P, Chen L et al (2014) Synergetic strengthening by gradient structure. Mater Res Lett 2(4):185–191

Hua Z-M, Zha M, Meng Z-Y et al (2022) Rapid dislocation-mediated solute repartitioning towards strain-aging hardening in a fine-grained dilute magnesium alloy. Mater Res Lett 10(1):21–28

Wang T, Zha M, Du C et al (2022) High strength and high ductility achieved in a heterogeneous lamella-structured magnesium alloy. Mater Res Lett 11(3):187–195

Liu H, Wei X, Xing S et al (2021) Effect of stress shot peening on the residual stress field and microstructure of nanostructured Mg-8Gd-3Y alloy. J Market Res 10:74–83

Liu C, Chen X, Zhang W et al (2020) Microstructural evolution in the ultrafine-grained surface layer of Mg-Zn-Y-Ce-Zr alloy processed by sliding friction treatment. Mate Character 166:110423

Fu H, Zhou X, Wu B et al (2021) Atomic-scale dissecting the formation mechanism of gradient nanostructured layer on Mg alloy processed by a novel high-speed machining technique. J Mater Sci Technol 82:227–238

Gui Y, Cui Y, Bian H et al (2021) Role of slip and 10–12 twin on the crystal plasticity in Mg-RE alloy during deformation process at room temperature. J Mater Sci Technol 80:279–296

Jamalian M, Field DP (2020) Gradient microstructure and enhanced mechanical performance of magnesium alloy by severe impact loading. J Mater Sci Technol 36:45–49

Mao B, Liao Y, Li B (2018) Gradient twinning microstructure generated by laser shock peening in an AZ31B magnesium alloy. Appl Surf Sci 457:342–351

Mao B, Siddaiah A, Zhang X et al (2019) The influence of surface pre-twinning on the friction and wear performance of an AZ31B Mg alloy. Appl Surf Sci 480:998–1007

Wang H-T, Yao H-L, Zhang M-X et al (2019) Surface nanocrystallization treatment of AZ91D magnesium alloy by cold spraying shot peening process. Surf Coat Technol 374:485–492

Wei Y-h, Liu B-s, Hou L-f et al (2008) Characterization and properties of nanocrystalline surface layer in Mg alloy induced by surface mechanical attrition treatment. J Alloy Compd 452(2):336–342

Xu Y, Liang Y, Peng G (2020) Effect of a compound modification process on the microstructure and mechanical properties of ZK60 magnesium alloys. Mater Sci Eng A 778:139117

Ye H, Sun X, Liu Y et al (2019) Effect of ultrasonic surface rolling process on mechanical properties and corrosion resistance of AZ31B Mg alloy. Surf Coat Technol 372:288–298

Zhang Q, Li J, Jiang K, et al (2021) Gradient structure induced simultaneous enhancement of strength and ductility in AZ31 Mg alloy with twin-twin interactions. J Magnes Alloys

Xiong Z, Jiang Y, Yang M et al (2022) Achieving superior strength and ductility in 7075 aluminum alloy through the design of multi-gradient nanostructure by ultrasonic surface rolling and aging. J Alloy Compound 918:1656669

Chen L, Li W, Luo M (2022) Effect of stacking faults in nanograins on the tensile properties of Mg–Y–Nd–Gd–Zr alloys subjected to ultrasonic surface rolling processing. Surf Coat Technol 436:128305

Zhao X, Liu K, Xu D et al (2020) Effects of ultrasonic surface rolling processing and subsequent recovery treatment on the wear resistance of AZ91D Mg Alloy. Materials 13(24):5705

Zheng GY, Luo X, Kou ZD et al (2022) Microstructural evolution of Al-Zn-Mg-Cu alloy during ultrasonic surface rolling process. Mater Character 194:112248

Li H, Zhang J, Ao N et al (2023) Influence of residual stress and its relaxation on the corrosion bending fatigue resistance of EA4T axle steel treated by ultrasonic surface rolling. Int J Fatigue 170:10756

Xu Q, Zhou J, Jiang D et al (2023) Improved low-temperature mechanical properties of FH36 marine steel after ultrasonic surface rolling process. J Alloy Compound 937:168401

Zheng GY, Luo X, Kou ZD et al (2023) stability of nanocrystalline surface layer in an aged Al–Zn–Mg–Cu alloy induced by ultrasonic surface rolling processing. Mater Character 199:112776

Liu H, Zhu W, Jiang C et al (2020) Microstructure evolution and residual stress distribution of nanostructured Mg-8Gd-3Y alloy induced by severe shot peening. Surf Coat Technol 404:126465

Wei H, Cui Y, Cui H et al (2018) Evolution of grain refinement mechanism in Cu-4wt.%Ti alloy during surface mechanical attrition treatment. J Alloy Compd 763:835–843

Duan M, Luo L, Liu Y (2020) Microstructural evolution of AZ31 Mg alloy with surface mechanical attrition treatment: Grain and texture gradient. J Alloy Compound 823:153691

Nanomaterials LuK (2014) Making strong nanomaterials ductile with gradients. Science 345(6203):1455–1456

Ting W, Dongpo W, Gang L et al (2008) Investigations on the nanocrystallization of 40Cr using ultrasonic surface rolling processing. Appl Surf Sci 255(5 Part 1):1824–1829

Guo H, Fan J, Zhang H et al (2020) The preparation and mechanical properties of nano-magnesium alloy bulks. J Alloy Compound 819:153253

Kang YH, Huang ZH, Wang SC et al (2020) Effect of pre-deformation on microstructure and mechanical properties of WE43 magnesium alloy II: aging at 250 and 300 °C. J Magnes Alloy 8(1):103–110

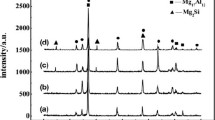

Chen L, Li W, Sun Y et al (2022) Effect of microstructure evolution on the mechanical properties of a Mg–Y–Nd–Zr alloy with a gradient nanostructure produced via ultrasonic surface rolling processing. J Alloy Compound 923:166495

R S A, A W. (2002) The diffraction of X-Rays by distorted crystal aggregates–I. Proc Phys Soc 56:173

Bailey JE, Hirsch PB (1960) The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Phil Mag 5(53):485–497

Caceres CH, Lukac P (2008) Strain hardening behaviour and the Taylor factor of pure magnesium. Phil Mag 88(7):977–989

Mayumi S (1998) Creep behavior and deformation microstructures of Mg–Y alloys at 550 K. Mater Sci Eng: A 252:248

Yang Z, Li JP, Guo YC et al (2007) Precipitation process and effect on mechanical properties of Mg–9Gd–3Y–0.6Zn–0.5Zr alloy. Mater Sci Eng A 454–455:274–280

Acknowledgements

This work was supported by the National Natural Science Foundation of China (51661007), the central government guides local science and technology development special project ([2019] 4011), and the Guizhou University cultivation project ([2019] No. 15). Guiyang science and technology talent training project (Construction Contract [ 2023 ] 48-1)

Author information

Authors and Affiliations

Contributions

YL did writing—original draft. WL done writing—review & editing and supervision. YS and LC investigated the study. GC and GD gave software.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships influencing the work reported in this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Li, W., Sun, Y. et al. Effect of ultrasonic surface rolling process on microstructure and properties of rolled Mg-Y-Nd-Zr alloy. J Mater Sci 58, 9362–9381 (2023). https://doi.org/10.1007/s10853-023-08615-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08615-z