Abstract

In recent years, biodegradable porous Zn-based scaffolds employed as bone tissue engineering scaffolds to treat large bone defects have attracted attention of many researchers. Although porous Zn-based scaffolds have acceptable biocompatibility in vivo and more reasonable degradation rates than degradable Mg-based and Fe-based scaffolds, there is still a certain distance between the porous Zn-based scaffolds that have been developed and the ideal bone tissue engineering scaffolds. In this paper, the methods that had been used to prepare porous Zn-based scaffolds were summarized, and the advantages and disadvantages of each method were analysed. The mechanical properties of porous Zn-based scaffolds were reviewed, and the compressive, tensile, and fatigue behaviors of the scaffolds were also discussed. The degradation properties of porous Zn-based scaffolds in vitro were summarized, and the degradation rules were found. Comparing the degradation properties of bulk Zn-based materials and porous Zn-based scaffolds, the degradations of porous Zn-based scaffolds were more deeply understood. In addition, the degradation behaviors of porous Zn-based scaffolds in vivo were also reviewed. The antibacterial properties of porous Zn-based scaffolds were summarized. Reviewing the experimental results of the biocompatibility of porous Zn-based scaffolds in vitro and in vivo, the main factor affecting the biocompatibility was identified, and the reasons for the large gap between the biocompatibility results in vivo and in vitro were discussed. At last, the problems faced by the current porous Zn-based scaffolds used as bone tissue engineering scaffolds were proposed, and the potential solutions to these problems were also suggested.

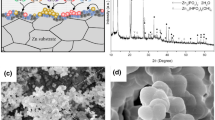

Graphical abstract

Reproduced with permission from reference [5]. Copyright 2016, Elsevier

Reproduced with permission from reference [5]. Copyright 2016, Elsevier

Reproduced with permission from reference [15]. Copyright 2018, Elsevier

Reproduced with permission from reference [17]. Copyright 2020, Elsevier

Reproduced with permission from reference [36]. Copyright 2020, Elsevier

Reproduced with permission from reference [28]. Copyright 2020, Elsevier

Reproduced with permission from reference [23]. Copyright 2022, Elsevier

Reproduced with permission from reference [27]. Copyright 2022, Elsevier

Reproduced with permission from reference [60]. Copyright 2020, Elsevier

Reproduced with permission from reference [17]. Copyright 2020, Elsevier

Reproduced with permission from reference [17]. Copyright 2020, Elsevier

Reproduced with permission from reference [48]. Copyright 2018, Elsevier

Reproduced with permission from reference [4]. Copyright 2021, Elsevier

Reproduced from Xia et al. [25] under the CC BY-NC-ND 4.0 terms. Copyright 2023 Bioactive materials. Open access. b Porous Fe and Fe@Zn scaffolds. Reproduced with permission from reference [4]. Copyright 2021, Elsevier. c Porous Zn–Mg scaffolds. Reproduced with permission from reference [24]. Copyright 2022, Elsevier. d Porous Zn–Cu scaffolds. Reproduced with permission from reference [28]. Copyright 2020, Elsevier

Similar content being viewed by others

Data availability

All data pertaining to this work will be available on reasonable requests.

References

Kiernan C, Knuth C, Farrell E (2018) Endochondral ossification: recapitulating bone development for bone defect repair. In: Stoddart MJ, Craft AM, Pattappa G, Gardner OFW (eds) Developmental biology and musculoskeletal tissue engineering principles and applications. Academic Press, Salt Lake City, pp 125–148

Zhang T, Wei QG, Zhou H, Jing ZH, Liu XG, Zheng YF, Cai H, Wei F et al (2021) Three-dimensional-printed individualized porous implants: a new “implant-bone” interface fusion concept for large bone defect treatment. Bioact Mater 6:3659–3670

Van Bael S, Chai YC, Truscello S, Moesen M, Kerckhofs G, Van Oosterwyck H, Kruth J-P, Schrooten J (2012) The effect of pore geometry on the in vitro biological behavior of human periosteum-derived cells seeded on selective laser-melted Ti6Al4V bone scaffolds. Acta Biomater 8:2824–2834

He J, Fang J, Wei P, Li YL, Guo H, Mei QS, Ren FZ (2021) Cancellous bone-like porous Fe@Zn scaffolds with core-shell-structured skeletons for biodegradable bone implants. Acta Biomater 121:665–681

Zhao LC, Zhang Z, Song YT, Liu SJ, Qi YM, WangX WQZ, Cui CX (2016) Mechanical properties and in vitro biodegradation of newly developed porous Zn scaffolds for biomedical applications. Mater Des 108:136–144

Li HF, Xie XH, Zheng YF, Cong Y, Zhou FY, Qiu KJ, Wang X, Chen SH et al (2015) Development of biodegradable Zn-1X binary alloys with nutrient alloying elements Mg, Ca and Sr. Sci Rep 5:10719

Bowen PK, Drelich J, Goldman J (2013) Zinc exhibits ideal physiological corrosion behavior for bioabsorbable stents. Adv Mater 25:2577–2582

Zhang ZX, Gu BB, Zhang WJ, Kan GY, Sun JY (2012) The enhanced characteristics of osteoblast adhesion to porous Zinc–TiO2 coating prepared by plasma electrolytic oxidation. Appl Surf Sci 258:6504–6511

Moonga BS, Dempster DW (1995) Zinc is a potent inhibitor of osteoclastic bone resorption in vitro. J Bone Miner Res 10:453–457

Vojtěch D, Kubásek J, Šerák J, Novák P (2011) Mechanical and corrosion properties of newly developed biodegradable Zn-based alloys for bone fixation. Acta Biomater 7:3515–3522

Li HF, Yang HT, Zheng YF, Zhou FY, Qiu KJ, Wang X (2015) Design and characterizations of novel biodegradable ternary Zn-based alloys with IIA nutrient alloying elements Mg, Ca and Sr. Mater Des 83:95–102

Fosmire GJ (1990) Zinc toxicity. Am J Clin Nutr 51:225–227

Zhao LC, Wang X, Wang TB, Xia YH, Cui CX (2019) Mechanical properties and biodegradation of porous Zn–1Al alloy scaffolds. Mater Lett 247:75–78

Xie Y, Zhao LC, Zhang Z, Wang X, Wang R, Cui CX (2018) Fabrication and properties of porous Zn–Ag alloy scaffolds as biodegradable materials. Mater Chem Phys 219:433–443

Hou Y, Jia GZ, Yue R, Chen CX, Pei J, Zhang H, Huang H, Xiong MP et al (2018) Synthesis of biodegradable Zn-based scaffolds using NaCl templates: relationship between porosity, compressive properties and degradation behavior. Mater Charact 137:162–169

Ren HZ, Pan C, Liu YC, Liu DB, He XH, Li XH, Sun XH (2022) Fabrication, in vitro and in vivo properties of porous Zn–Cu alloy scaffolds for bone tissue engineering. Mater Chem Phys 289:126458

Li Y, Pavanram P, Zhou J, Lietaert K, Taheri P, Li W, San H, Leeflang MA et al (2020) Additively manufactured biodegradable porous zinc. Acta Biomater 101:609–623

Li Y, Pavanram P, Zhou J, Lietaert K, Bobbert FSL, Kubo Y, Leeflang MA, Jahr H (2020) Additively manufactured functionally graded biodegradable porous zinc. Biomater Sci 8:2404–2419

Yang YW, Cheng Y, Peng SP, Xu L, He CX, Qi FW, Zhao MC, Shuai CJ (2021) Microstructure evolution and texture tailoring of reduced graphene oxide reinforced Zn scaffold. Bioact Mater 6:1230–1241

Lietaert K, Zadpoor AA, Sonnaert M, Schrooten J, Weber L, Mortensen A, Vleugels J (2020) Mechanical properties and cytocompatibility of dense and porous Zn produced by laser powder bed fusion for biodegradable implant applications. Acta Biomater 110:289–302

Wen P, Qin Y, Chen YZ, Voshage M, Jauer L, Poprawe R, Schleifenbaum J-H (2019) Laser additive manufacturing of Zn porous scaffolds: shielding gas flow, surface quality and densification. J Mater Sci Technol 35:368–376

Qin Y, Wen P, Voshage M, Chen YZ, Schückler PG, Jauer L, Xia DD, Guo H et al (2019) Additive manufacturing of biodegradable Zn-xWE43 porous scaffolds: formation quality, microstructure and mechanical properties. Mater Des 181:107937

Voshage M, Megahed S, Schückler PG, Wen P, Qin Y, Jauer L, Poprawe R, Schleifenbaum J-H (2022) Additive manufacturing of biodegradable Zn–xMg alloys: effect of Mg content on manufacturability, microstructure and mechanical properties. Mater Today Commun 32:103805

Qin Y, Liu AB, Guo H, Shen YN, Wen P, Lin H, Xia DD, Voshage M et al (2022) Additive manufacturing of Zn–Mg alloy porous scaffolds with enhanced osseointegration: in vitro and in vivo studies. Acta Biomater 145:403–415

Xia DD, Qin Y, Guo H, Wen P, Lin H, Voshage M, Schleifenbaum J-H, Cheng Y et al (2023) Additively manufactured pure zinc porous scaffolds for critical-sized bone defects of rabbit femur. Bioact Mater 19:12–23

Qin Y, Yang HT, Liu AB, Dai JB, Wen P, Zheng YF, Tian Y, Li S et al (2022) Processing optimization, mechanical properties, corrosion behavior and cytocompatibility of additively manufactured Zn–0.7Li biodegradable metals. Acta Biomater 142:388–401

Yang Y, Cheng Y, Yang M, Qian G, Peng S, Qi F, Shuai C (2022) Semicoherent strengthens graphene/zinc scaffolds. Mater Today Nano 17:100163

Tong X, Shi ZM, Xu LC, Lin J, Zhang DC, Wang K, Li YC, Wen CE (2020) Degradation behavior, cytotoxicity, hemolysis, and antibacterial properties of electro-deposited Zn–Cu metal foams as potential biodegradable bone implants. Acta Biomater 102:481–492

Yao RH, Han SY, Sun YH, Zhao YY, Shan RF, Liu L, Yao XH, Hang RQ (2022) Fabrication and characterization of biodegradable Zn scaffold by vacuum heating-press sintering for bone repair. Biomater Adv 138:212968

Čapek J, Jablonská E, Lipov J, Kubatík TF, Vojtěch D (2018) Preparation and characterization of porous zinc prepared by spark plasma sintering as a material for biodegradable scaffolds. Mater Chem Phys 203:249–258

Čapek J, Pinc J, Msallamová Š, Jablonská E, Veřtát P, Kubásek J, Vojtěch D (2019) Thermal plasma spraying as a new approach for preparation of zinc biodegradable scaffolds: a complex material characterization. J Therm Spray Technol 28:826–841

Yusop AH, Bakir AA, Shaharom NA, AbdulKadir MR, Hermawan H (2012) Porous biodegradable metals for hard tissue scaffolds: a review. Int J Biomater 2012:1–10

Lietaert K, Deursen J-V, Lapauw T, Weber L, Mortensen A, Vleugels J (2019) Mechanical properties of replicated cellular Zn and Zn1.5Mg in uniaxial compression. Mater Charact 157:109895

Wang XJ, Xu SQ, Zhou SW, Xu W, Leary M, Choong P, Qian M, Brandt M et al (2016) Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: a review. Biomaterials 83:127–141

Zadpoor AA (2017) Mechanics of additively manufactured biomaterials. J Mech Behav Biomed Mater 70:1–6

Cockerill I, Su YC, Sinha S, Qin YX, Zheng YF, Young M-L, Zhu DH (2020) Porous zinc scaffolds for bone tissue engineering applications: a novel additive manufacturing and casting approach. Mater Sci Eng C 110:110738

Nogueira ID, Maçoas EM, Montemor MF, Alves MM (2022) Biomedical potential of 3D Zn and ZnCu foams produced by dynamic hydrogen bubble template. Appl Surf Sci 580:152207

Zhao LC, Song YT, Zhang Z, Wang X, Wang TB, Cui CX (2018) Fabrication and investigation on properties of degradable Zn–1Al alloy for biomedical applications. Mater Rep 32:1192–1196

Huang H, Liu H, Ren KX, Shi JH, Ju J, Wu HR, Jiang JH, Ma AB et al (2021) Improvement of ductility and work hardening ability in a high strength Zn–Mg–Y alloy via micron-sized and submicron-sized YZn12 particles. J Alloys Compd 877:160268

Li L, Liu CF, Jiao HZ, Yang L, Cao FL, Wang XJ, Cui JZ (2021) Investigation on microstructures, mechanical properties and in vitro corrosion behavior of novel biodegradable Zn–2Cu–0.01Ti–xLi alloys. J Alloys Compd 888:161529

Zhang L, Liu XY, Huang H, Zhan W (2019) Effects of Ti on microstructure, mechanical properties and biodegradation behavior of Zn–Cu alloy. Mater Lett 244:119–122

Li Y, Jahr H, Lietaert K, Pavanram P, Yilmaz A, Fockaert L, Leeflang MA, Pouran B et al (2018) Additively manufactured biodegradable porous iron. Acta Biomater 77:380–393

Li Y, Jahr H, Pavanram P, Bobbert FSL, Puggi U, Zhang XY, Pouran B, Leeflang MA et al (2019) Additively manufactured functionally graded biodegradable porous iron. Acta Biomater 96:646–661

Wu F, Liu CS, O’Neill B, Wei J, Ngothai Y (2012) Fabrication and properties of porous scaffold of magnesium phosphate/polycaprolactone biocomposite for bone tissue engineering. Appl Surf Sci 258:7589–7595

Wu SL, Liu XM, Yeung KWK, Liu CS, Yang XJ (2014) Biomimetic porous scaffolds for bone tissue engineering. Mater Sci Eng R 80:1–36

Kubásek J, Pospíšilová I, Vojtěch D, Jablonská E, Ruml T (2014) Structural, mechanical and cytotoxicity characterization on as-cast biodegradable Zn–xMg (x=0.8-8.3%) alloys. Mater Technol 48:623–629

Staigera MP, Pietaka AM, Huadmai J, Dias G (2006) Magnesium and its alloys as orthopedic biomaterials: a review. Biomaterials 27:1728–1734

Zhao LC, Xie Y, Zhang Z, Wang X, Qi YM, Wang TB, Wang R, Cui CX (2018) Fabrication and properties of biodegradable ZnO nano-rods/porous Zn scaffold. Mater Charact 144:227–238

Wu HZ, Xie XX, Wang J, Ke GZ, Huang H, Liao Y, Kong QQ (2021) Biological properties of Zn–0.04Mg–2Ag: a new degradable zinc alloy scaffold for repairing large-scale bone defects. J Mater Res Technol 13:1779–1789

Zhao DL, Han CJ, Peng B, Cheng T, Fan JX, Yang L, Chen LL, Wei QS (2022) Corrosion fatigue behavior and anti-fatigue mechanisms of an additively manufactured biodegradable zinc-magnesium gyroid scaffold. Acta Biomater 153:614–629

Qiu S, Sun FD, You C, Tang CK, Zhou BL, Zhang SQ, Feng JT, Tian AX et al (2023) Preparation of porous Zn–Li alloy scaffolds for bone repair and its degradation behavior in vitro and in vivo. Mater Today Commun 35:105605

Chen BX, Sun XH, Liu DB, Tian H, Gao JJ (2023) A novel method combining VAT photopolymerization and casting for the fabrication of biodegradable Zn–1Mg scaffolds with triply periodic minimal surface. J Mech Behav Biomed Mater 141:105763

Yuan PK, Zhang MS, Wang X, Qi YM, Wang TB, Zhao LC, Cui CX (2023) Effects of polylactic acid coating on properties of porous Zn scaffolds as degradable materials. Mater Charact 199:112852

Gu XN, Zhou WR, Zheng YF, Cheng Y, Wei SC, Zhong SP, Xi TF, Chen LJ (2010) Corrosion fatigue behaviors of two biomedical Mg alloys—AZ91D and WE43—in simulated body fluid. Acta Biomater 6:4605–4613

Li GN, Yang HT, Zheng YF, Chen XH, Yang JA, Zhu DH, Ruan LQ, Takashima K (2019) Challenges in the use of zinc and its alloys as biodegradable metals: perspective from biomechanical compatibility. Acta Biomater 97:23–45

Li HF, Huang Y, Ji XJ, Wen CE, Wang LN (2022) Fatigue and corrosion fatigue behaviors of biodegradable Zn–Li and Zn–Cu–Li under physiological conditions. J Mater Sci Technol 131:48–59

Raihan MM, Otsuka Y, Tsuchida K, Manonukul A, Ohnuma K, Miyashita Y (2021) Damage evaluation of HAp-coated porous titanium foam in simulated body fluid based on compression fatigue behavior. J Mech Behav Biomed Mater 117:104383

Li Y, Jahr H, Zhang XY, Leeflang MA, Li W, Pouran B, Tichelaar FD, Weinans H et al (2019) Biodegradation-affected fatigue behavior of additively manufactured porous magnesium. Addit Manuf 28:299–311

Teoh SH (2000) Fatigue of biomaterials: a review. Int J Fatigue 22:825–837

Li Y, Li W, Bobbert FSL, Lietaert K, Dong JH, Leeflang MA, Zhou J, Zadpoor AA (2020) Corrosion fatigue behavior of additively manufactured biodegradable porous zinc. Acta Biomater 106:439–449

Zhuang HY, Han Y, Feng AL (2008) Preparation, mechanical properties and in vitro biodegradation of porous magnesium scaffolds. Mater Sci Eng C 28:1462–1466

Seyedraoufi ZS, Mirdamadi S (2014) Effects of pulse electrodeposition parameters and alkali treatment on the properties of nano hydroxyapatite coating on porous Mg–Zn scaffold for bone tissue engineering application. Mater Chem Phys 148:519–527

Gu XN, Zhou WR, Zheng YF, Liu Y, Li YX (2010) Degradation and cytotoxicity of lotus-type porous pure magnesium as potential tissue engineering scaffold material. Mater Lett 64:1871–1874

Bonithon R, Lupton C, Roldo M, Dunlop J-N, Blunn G-W, Witte F, Tozzi G (2023) Open-porous magnesium-based scaffolds withstand in vitro corrosion under cyclic loading: a mechanistic study. Bioact Mater 19:406–417

Zhang YX, Lin T, Meng HY, Wang XT, Peng H, Liu GB, Wei S, Lu Q et al (2022) 3D gel-printed porous magnesium scaffold coated with dibasic calcium phosphate dihydrate for bone repair in vivo. J Orthop Transl 33:13–23

Liu JG, Liu BC, Min SY, Yin BZ, Peng B, Yu ZS, Wang CM, Ma XL et al (2022) Biodegradable magnesium alloy WE43 porous scaffolds fabricated by laser powder bed fusion for orthopedic applications: process optimization, in vitro and in vivo investigation. Bioact Mater 16:301–319

Garimella A, Rathi D, Jangid R, Ghosh S-B, Bandyopadhyay-Ghosh S (2022) Investigation of bio-degradation behaviour of porous magnesium alloy based bone scaffolds. Mater Today Proc 50:2276–2279

Xie K, Wang NQ, Guo Y, Zhao S, Tan J, Wang L, Li GY, Wu JX et al (2022) Additively manufactured biodegradable porous magnesium implants for elimination of implant-related infections: an in vitro and in vivo study. Bioact Mater 8:140–152

Putra NE, Borg KGN, Diaz-Payno PJ, Leeflang MA, Klimopoulou M, Taheri P, Mol JMC, Fratila-Apachitei LE et al (2022) Additive manufacturing of bioactive and biodegradable porous iron-akermanite composites for bone regeneration. Acta Biomater 148:355–373

Chen Q, Zhao XY, Lai WJ, Li Z, You DQ, Yu ZT, Li W, Wang XJ (2022) Surface functionalization of 3D printed Ti scaffold with Zn-containing mesoporous bioactive glass. Surf Coat Technol 435:128236

Kirkland NT, Birbilis N, Staiger MP (2012) Assessing the corrosion of biodegradable magnesium implants: a critical review of current methodologies and their limitations. Acta Biomater 8:925–936

Liu LJ, Meng Y, Dong CF, Yan Y, Volinsky AA, Wang LN (2018) Initial formation of corrosion products on pure zinc in simulated body fluid. J Mater Sci Technol 34:2271–2282

Sikora-Jasinska M, Mostaed E, Mostaed A, Beanland R, Mantovani D, Vedani M (2017) Fabrication, mechanical properties and in vitro degradation behavior of newly developed Zn–Ag alloys for degradable implant applications. Mater Sci Eng C 77:1170–1181

Tang ZB, Niu JL, Huang H, Zhang H, Pei J, Ou JM, Yuan GY (2017) Potential biodegradable Zn–Cu binary alloys developed for cardiovascular implant applications. J Mech Behav Biomed Mater 72:182–191

Shi ZZ, Yu J, Liu XF, Wang LN (2018) Fabrication and characterization of novel biodegradable Zn–Mn–Cu alloys. J Mater Sci Technol 34:1008–1015

Wang K, Tong X, Lin JX, Wei AP, Li YC, Dargusch M, Wen CE (2021) Binary Zn–Ti alloys for orthopedic applications: corrosion and degradation behaviors, friction and wear performance, and cytotoxicity. J Mater Sci Technol 74:216–229

Sun J, Zhang X, Shi ZZ, Gao XX, Li HY, Zhao FY, Wang JQ, Wang LN (2021) Development of a high-strength Zn–Mn–Mg alloy for ligament reconstruction fixation. Acta Biomater 119:485–498

Jia B, Yang HT, Han Y, Zhang ZC, Qu XH, Zhuang YF, Wu Q, Zheng YF et al (2020) In vitro and in vivo studies of Zn–Mn biodegradable metals designed for orthopedic applications. Acta Biomater 108:358–372

Tong X, Cai WH, Lin JX, Wang K, Jin LF, Shi ZM, Zhang DC, Lin JG et al (2021) Biodegradable Zn–3Mg–0.7Mg2Si composite fabricated by high-pressure solidification for bone implant applications. Acta Biomater 123:407–417

Shi ZZ, Gao XX, Chen HT, Liu XF, Li A, Zhang HJ, Wang LN (2020) Enhancement in mechanical and corrosion resistance properties of a biodegradable Zn–Fe alloy through second phase refinement. Mater Sci Eng C 116:111197

Yang N, Balasubramani N, Venezuela J, Almathami S, Wen CE, Dargusch M (2021) The influence of Ca and Cu additions on the microstructure, mechanical and degradation properties of Zn–Ca–Cu alloys for absorbable wound closure device applications. Bioact Mater 6:1436–1451

Lin JX, Tong X, Sun QX, Luan YN, Zhang DC, Shi ZM, Wang K, Lin JG et al (2020) Biodegradable ternary Zn–3Ge–0.5X (X=Cu, Mg, and Fe) alloys for orthopedic applications. Acta Biomater 115:432–446

Dambatta M-S, Izman S, Kurniawan D, Hermawan H (2017) Processing of Zn-3Mg alloy by equal channel angular pressing for biodegradable metal implants. J King Saud Univ Sci 29:455–461

Tong X, Zhang DC, Lin JX, Dai YL, Luan YN, Sun QX, Shi ZM, Wang K et al (2020) Development of biodegradable Zn–1Mg-0.1RE (RE = Er, Dy, and Ho) alloys for biomedical applications. Acta Biomater 117:384–399

Yang HT, Qu XH, Lin WJ, Chen DF, Zhu DH, Dai KR, Zheng YF (2019) Enhanced osseointegration of Zn–Mg composites by tuning the release of Zn ions with sacrificial Mg-rich anode design. ACS Biomater Sci Eng 5:453–467

Su YC, Yang HT, Gao JL, Qin YX, Zheng YF, Zhu DH (2019) Interfacial zinc phosphate is the key to controlling biocompatibility of metallic zinc implants. Adv Sci 6:1900112

Yang HT, Jia B, Zhang ZC, Qu XH, Li GN, Lin WJ, Zhu DH, Dai KR et al (2020) Alloying design of biodegradable zinc as promising bone implants for load-bearing applications. Nat Commun 11:401

Yang HT, Wang C, Liu CQ, Chen HW, Wu YF, Han JT, Jia ZC, Lin WJ et al (2017) Evolution of the degradation mechanism of pure zinc stent in the one-year study of rabbit abdominal aorta model. Biomaterials 145:92–105

Drelich AJ, Zhao S, Guillory RJ II, Drelich JW, Goldman J (2017) Long-term surveillance of zinc implant in murine artery: surprisingly steady biocorrosion rate. Acta Biomater 58:539–549

Niu JL, Tang ZB, Huang H, Pei J, Zhang H, Yuan GY, Ding WJ (2016) Research on a Zn–Cu alloy as a biodegradable material for potential vascular stents application. Mater Sci Eng C 69:407–413

Hetrick EM, Schoenfisch MH (2006) Reducing implant-related infections: active release strategies. Chem Soc Rev 35:780–789

Guo ZJ, Chen C, Gao Q, Li YB, Zhang L (2014) Fabrication of silver-incorporated TiO2 nanotubes and evaluation on its antibacterial activity. Mater Lett 137:464–467

Su YC, Wang K, Gao JL, Yang Y, Qin YX, Zheng YF, Zhu DH (2019) Enhanced cytocompatibility and antibacterial property of zinc phosphate coating on biodegradable zinc materials. Acta Biomater 98:174–185

Yuan W, Xia DD, Wu SL, Zheng YF, Guan ZP, Rau JV (2022) A review on current research status of the surface modification of Zn-based biodegradable metals. Bioact Mater 7:192–216

Liu Y, Zheng YF, Chen XH, Yang JA, Pan HB, Chen DF, Wang LN, Zhang JL et al (2019) Fundamental theory of biodegradable metals-definition, criteria, and design. Adv Funct Mater 29:1805402

Kubásek J, Vojtěch D, Jablonská E, Pospíšilová I, Lipov J, Ruml T (2016) Structure, mechanical characteristics and in vitro degradation, cytotoxicity, genotoxicity and mutagenicity of novel biodegradable Zn–Mg alloys. Mater Sci Eng C 58:24–35

Zhuang Y, Liu QC, Jia GZ, Li HL, Yuan GY, Yu HB (2021) A biomimetic zinc alloy scaffold coated with brushite for enhanced cranial bone regeneration. ACS Biomater Sci Eng 7:893–903

Guo H, Xia DD, Zheng YF, Zhu Y, Liu YS, Zhou YS (2020) A pure zinc membrane with degradability and osteogenesis promotion for guided bone regeneration: in vitro and in vivo studies. Acta Biomater 106:396–409

Wang JL, Witte F, Xi TF, Zheng YF, Yang K, Yang YS, Zhao DW, Meng J et al (2015) Recommendation for modifying current cytotoxicity testing standards for biodegradable magnesium-based materials. Acta Biomater 21:237–249

Yang HT, Qu XH, Lin WJ, Wang C, Zhu DH, Dai KR, Zheng YF (2018) In vitro and in vivo studies on zinc-hydroxyapatite composites as novel biodegradable metal matrix composite for orthopedic applications. Acta Biomater 71:200–214

He J, Li DW, He FL, Liu YY, Liu YL, Zhang CY, Ren FZ, Ye YJ et al (2020) A study of degradation behaviour and biocompatibility of Zn–Fe alloy prepared by electrodeposition. Mater Sci Eng C 117:111295

Yuan W, Xia DD, Zheng YF, Liu XM, Wu SL, Li B, Han Y, Jia ZJ et al (2020) Controllable biodegradation and enhanced osseointegration of ZrO2-nanofilm coated Zn–Li alloy: in vitro and in vivo studies. Acta Biomater 105:290–303

Williams DF (2008) On the mechanisms of biocompatibility. Biomaterials 29:2941–2953

Marsell R, Einhorn TA (2011) The biology of fracture healing. Inj Int J Care Inj 42:551–555

Su YC, Fu JY, Du SK, Georgas E, Qin YX, Zheng YF, Wang YD, Zhu DH (2022) Biodegradable Zn–Sr alloys with enhanced mechanical and biocompatibility for biomedical applications. Smart Mater Med 3:117–127

Jia B, Yang HT, Zhang ZC, Qu XH, Jia XF, Wu Q, Han Y, Zheng YF et al (2021) Biodegradable Zn–Sr alloy for bone regeneration in rat femoral condyle defect model: in vitro and in vivo studies. Bioact Mater 6:1588–1604

Yan TL, Wang X, Fan JL, Nie QD (2021) Microstructure and properties of biodegradable co-continuous (HA+β-TCP)/Zn–3Sn composite fabricated by vacuum casting-infiltration technique. Trans Nonferrous Met Soc China 31:3075–3086

Young J, Reddy R-G (2020) Synthesis, mechanical properties, and in vitro corrosion behavior of biodegradable Zn–Li–Cu alloys. J Alloys Compd 844:156257

Jiang JM, Qian Y, Huang H, Niu JL, Yuan GY (2022) Biodegradable Zn–Cu–Mn alloy with suitable mechanical performance and in vitro degradation behavior as a promising candidate for vascular stents. Biomater Adv 133:112652

Qu XH, Yang HT, Jia B, Yu ZF, Zheng YF, Dai K (2020) Biodegradable Zn–Cu alloys show antibacterial activity against MRSA bone infection by inhibiting pathogen adhesion and biofilm formation. Acta Biomater 117:400–417

Zou YL, Chen X, Chen B (2018) Effects of Ca concentration on degradation behavior of Zn–x Ca alloys in Hank’s solution. Mater Lett 218:193–196

Wątroba M, Mech K, Bednarczyk W, Kawałko J, Marciszko-Wiąckowska M, Marzec M, Shepherd DET, Bała P (2022) Long-term in vitro corrosion behavior of Zn–3Ag and Zn–3Ag–05Mg alloys considered for biodegradable implant applications. Mater Des 213:110289

Tang ZB, Huang H, Niu JL, Zhang L, Zhang H, Pei J, Tan JY, Yuan GY (2017) Design and characterizations of novel biodegradable Zn–Cu–Mg alloys for potential biodegradable implants. Mater Des 117:84–94

Lin JX, Tong X, Wang K, Shi ZM, Li YC, Dargusch M, Wen CE (2021) Biodegradable Zn–3Cu and Zn–3Cu–0.2Ti alloys with ultrahigh ductility and antibacterial ability for orthopedic applications. J Mater Sci Technol 68:76–90

Chen C, Yue R, Zhang J, Huang H, Niu JL, Yuan GY (2020) Biodegradable Zn–1.5Cu–1.5Ag alloy with anti-aging ability and strain hardening behavior for cardiovascular stents. Mater Sci Eng C 116:111172

Li GN, Zhu SM, Nie JF, Zheng YF, Sun ZL (2021) Investigating the stress corrosion cracking of a biodegradable Zn–0.8 wt%Li alloy in simulated body fluid. Bioact Mater 6:1468–1478

Zhang WT, Li P, Shen G, Mo XS, Zhou C, Alexander D, Rupp F, Geis-Gerstorfer J et al (2021) Appropriately adapted properties of hot-extruded Zn–0.5Cu–xFe alloys aimed for biodegradable guided bone regeneration membrane application. Bioact Mater 6:975–989

Guo H, He Y, Zheng YF, Cui Y (2020) In vitro studies of biodegradable Zn–0.1Li alloy for potential esophageal stent application. Mater Lett 275:128190

Lin JX, Tong X, Shi ZM, Zhang DC, Zhang LS, Wang K, Wei AP, Jin LF et al (2020) A biodegradable Zn–1Cu–0.1Ti alloy with antibacterial properties for orthopedic applications. Acta Biomater 106:410–427

Dambatta MS, Izman S, Kurniawan D, Farahany S, Yahaya B, Hermawan H (2015) Influence of thermal treatment on microstructure, mechanical and degradation properties of Zn–3Mg alloy as potential biodegradable implant material. Mater Des 85:431–437

Acknowledgements

This work was supported by Science and Technology Research Project of Hebei Province Colleges and Universities with No. ZD2021034.

Author information

Authors and Affiliations

Contributions

LZ: Conceptualization, Data curation, Funding acquisition, Writing – original draft, Writing – review and editing. PY: Data curation. MZ: Data curation. XW: Conceptualization, Formal analysis, Writing – review and editing. YQ: Conceptualization, Data curation. TW: Formal analysis. BC: Writing – original draft. CC: Conceptualization, Formal analysis, Writing – review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that we have no known conflict of interest or competing interests.

Ethical standards

This work is a review article, and no ethical approval is required.

Additional information

Handling Editor: Annela M. Seddon.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Table 7.

Appendix 2

Table 8.

Appendix 3

Table 9.

Appendix 4

Table 10.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, L., Yuan, P., Zhang, M. et al. Preparation and properties of porous Zn-based scaffolds as biodegradable implants: a review. J Mater Sci 58, 8275–8316 (2023). https://doi.org/10.1007/s10853-023-08561-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08561-w