Abstract

Understanding the oxidation of Ni-based single crystal (SX) superalloys is significantly important because oxidation can damage the microstructure and eventually lead to failure of the alloy. Using advanced scanning/transmission electron microscopy, oxidation effects on the microstructure of a SX superalloy during heat treatment and simulated service (stress/temperature coupling) conditions are systematically investigated in order to reveal oxide microstructures and oxidation mechanisms. Heat treatment in argon results in less weight loss, thinner γ′-free layer and fewer internal oxidation than that treated in air. But the oxide layer structures and influence depths of oxidation in both atmospheres are similar. External tensile stress not only accelerates the oxidation of alloy but also affects the oxide microstructures. Moreover, stress effects on the oxidation microstructure depend on temperature. At 750 °C, Ni–Co oxides are formed on the alloy surface, followed by the inner layer of Ni–Co–Mo–Re–W oxides at the location of original γ phase under stress free condition. As the stress increases, an oxide layer mainly containing Al, Cr, Nb, Mo and Re elements is formed between the above two oxide layers. When temperature increases to 1050 °C, as applied tensile stress increases, the thickness of oxide layer increases but the structure of oxide layer is not obviously changed.

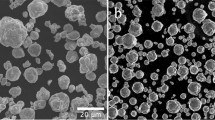

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Reed RC (2006) The superalloys: fundamentals and applications. Cambridge University Press, Cambridge, p 1–5. https://doi.org/10.1017/CBO9780511541285

Pollock TM, Tin S (2006) Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. J Propuls Power 22:361–374. https://doi.org/10.2514/1.18239

Giamei AF, Tschinkel JG (1976) Liquid metal cooling: a new solidification technique. MTA 7:1427–1434. https://doi.org/10.1007/BF02658829

Yang C, Xia H, Xu Q, Liu B (2021) Multiphase-field simulation of the solution heat treatment process in a Ni-based superalloy. Comput Mater Sci 196:110550. https://doi.org/10.1016/j.commatsci.2021.110550

Rakoczy Ł, Cygan R (2018) Analysis of temperature distribution in shell mould during thin-wall superalloy casting and its effect on the resultant microstructure. Arch Civ Mech Eng 18:1441–1450. https://doi.org/10.1016/j.acme.2018.05.008

Rettig R, Ritter NC, Müller F, Franke MM, Singer RF (2015) Optimization of the homogenization heat treatment of nickel-based superalloys based on phase-field simulations: numerical methods and experimental validation. Metall Mat Trans A 46:5842–5855. https://doi.org/10.1007/s11661-015-3130-y

Fuchs GE (2001) Solution heat treatment response of a third generation single crystal Ni-base superalloy. Mater Sci Eng, A 300:52–60. https://doi.org/10.1016/S0921-5093(00)01776-7

Ding Q, Bei H, Zhao X, Gao Y, Zhang Z (2020) Processing, microstructures and mechanical properties of a Ni-based single crystal superalloy. Crystals 10:572. https://doi.org/10.3390/cryst10070572

Su X, Xu Q, Wang R, Xu Z, Liu S, Liu B (2018) Microstructural evolution and compositional homogenization of a low Re-bearing Ni-based single crystal superalloy during through progression of heat treatment. Mater Des 141:296–322. https://doi.org/10.1016/j.matdes.2017.12.020

Van Sluytman JS, Pollock TM (2012) Optimal precipitate shapes in nickel-base γ–γ′ alloys. Acta Mater 60:1771–1783. https://doi.org/10.1016/j.actamat.2011.12.008

Erickson GL (1995) A new, third-generation, single-crystal, casting superalloy. JOM 47:36–39. https://doi.org/10.1007/BF03221147

Li JR, Zhong ZG, Liu SZ, Tang DZ, Wei P, Wei PY, Wu ZT, Huang D, Han M (2000) A low-cost second generation single crystal superalloy DD6. In: Pollock TM, Kissinger RD (eds) Superalloys 2000. Minerals, Warrendale, pp 777–783. https://doi.org/10.7449/2000/Superalloys_2000_777_783

Jiang W, Dong J, Wang L, Lou L (2011) Effect of casting modulus on microstructure and segregation in K441 superalloy casting. J Mater Sci Technol 27:831–840. https://doi.org/10.1016/S1005-0302(11)60151-5

Zhai Y, Chen Y, Zhao Y, Long H, Li X, Deng Q, Lu H, Yang X et al (2021) Initial oxidation of Ni-based superalloy and its dynamic microscopic mechanisms: the interface junction initiated outwards oxidation. Acta Mater 215:116991. https://doi.org/10.1016/j.actamat.2021.116991

Huang L, Sun XF, Guan HR, Hu ZQ (2006) Effect of rhenium addition on isothermal oxidation behavior of single-crystal Ni-based superalloy. Surf Coat Technol 200:6863–6870. https://doi.org/10.1016/j.surfcoat.2005.10.037

Suo Y, Zhang Z, Yang X (2016) Residual stress analysis with stress-dependent growth rate and creep deformation during oxidation. J Mater Res 31:2384–2391. https://doi.org/10.1557/jmr.2016.262

Dong X, Fang X, Feng X, Hwang K-C (2013) Diffusion and stress coupling effect during oxidation at high temperature. J Am Ceram Soc 96:44–46. https://doi.org/10.1111/jace.12105

Akhtar A, Hook MS, Reed RC (2005) On the oxidation of the third-generation single-crystal superalloy CMSX-10. Metall Mater Trans A 36:3001–3017. https://doi.org/10.1007/s11661-005-0073-8

Greene GA, Finfrock CC (2001) Oxidation of inconel 718 in air at high temperatures. Oxid Met 55:505–521. https://doi.org/10.1023/A:1010359815550

Pei H, Wen Z, Zhang Y, Yue Z (2017) Oxidation behavior and mechanism of a Ni-based single crystal superalloy with single α-Al2O3 film at 1000 °C. Appl Surf Sci 411:124–135. https://doi.org/10.1016/j.apsusc.2017.03.116

Pei H, Wen Z, Yue Z (2017) Long-term oxidation behavior and mechanism of DD6 Ni-based single crystal superalloy at 1050 °C and 1100 °C in air. J Alloy Compd 704:218–226. https://doi.org/10.1016/j.jallcom.2017.02.031

Shi Z, Li J, Liu S (2012) Isothermal oxidation behavior of single crystal superalloy DD6. Trans Nonferrous Metals Soc China 22:534–538. https://doi.org/10.1016/S1003-6326(11)61210-7

Edmonds IM, Evans HE, Jones CN, Broomfield RW (2008) Intermediate temperature internal oxidation in fourth generation Ru-bearing single-crystal nickel-base superalloys. Oxid Met 69:95–108. https://doi.org/10.1007/s11085-007-9085-7

Evangelou A, Soady KA, Lockyer S, Gao N, Reed PAS (2018) Oxidation behaviour of single crystal nickel-based superalloys: intermediate temperature effects at 450–550 °C. Mater Sci Technol 34:1679–1692. https://doi.org/10.1080/02670836.2018.1471436

Akhtar A, Hegde S, Reed RC (2006) The oxidation of single-crystal nickel-based superalloys. JOM 58:37–42. https://doi.org/10.1007/s11837-006-0066-0

Ma S, Ding Q, Wei X, Zhang Z, Bei H (2022) The effects of alloying elements Cr, Al, and Si on oxidation behaviors of Ni-based superalloys. Materials 15:7352. https://doi.org/10.3390/ma15207352

Pei H, Li M, Wang P, Yao X, Wen Z, Yue Z (2021) The effect of tensile stress on oxidation behavior of nickel-base single crystal superalloy. Corros Sci 191:109737. https://doi.org/10.1016/j.corsci.2021.109737

Dye D, Ma A, Reed RC (2008) Numerical modelling of creep deformation in a CMSX-4 single crystal superalloy turbine blade. In: Superalloys 2008. TMS, Berkeley, pp 911–919. https://doi.org/10.7449/2008/Superalloys_2008_911_919.

Ma D (2018) Novel casting processes for single-crystal turbine blades of superalloys. Front Mech Eng 13:3–16. https://doi.org/10.1007/s11465-018-0475-0

Ding Q, Bei H, Yao X, Zhao X, Wei X, Wang J, Zhang Z (2021) Temperature effects on deformation substructures and mechanisms of a Ni-based single crystal superalloy. Appl Mater Today 23:101061. https://doi.org/10.1016/j.apmt.2021.101061

Elliott AJ, Pollock TM (2007) Thermal analysis of the bridgman and liquid-metal-cooled directional solidification investment casting processes. Metall Mater Trans A 38:871–882. https://doi.org/10.1007/s11661-006-9085-2

Pollock TM (2016) Alloy design for aircraft engines. Nat Mater 15:809–815. https://doi.org/10.1038/nmat4709

Liu L, Zhang J, Ai C (2022) Nickel-based superalloys. In: Caballero FG (ed) Encyclopedia of materials: metals and alloys. Elsevier, Amsterdam, pp 294–304. https://doi.org/10.1016/B978-0-12-803581-8.12093-4

Bensch M, Konrad CH, Fleischmann E, Rae CMF, Glatzel U (2013) Influence of oxidation on near-surface γ′ fraction and resulting creep behaviour of single crystal Ni-base superalloy M247LC SX. Mater Sci Eng A 577:179–188. https://doi.org/10.1016/j.msea.2013.04.032

Pyczak F, Devrient B, Mughrabi H (2004) The effects of different alloying elements on the thermal expansion coefficients, lattice constants and misfit of nickel-based superalloys investigated by X-ray diffraction. In: Green KA, Pollock TM (eds) Superalloys 2004. TMS, pp 827–836

Ding Q, Shen Z, Xiang S, Tian H, Li J, Zhang Z (2015) In-situ environmental TEM study of γ′-γ phase transformation induced by oxidation in a nickel-based single crystal superalloy. J Alloy Compd 651:255–258. https://doi.org/10.1016/j.jallcom.2015.07.017

Fährmann M, Fratzl P, Paris O, Fährmann E, Johnson WC (1995) Influence of coherency stress on microstructural evolution in model Ni–A1–Mo alloys. Acta metall mater 43:1007–1022. https://doi.org/10.1016/0956-7151(94)00337-H

Haftbaradaran H, Gao H, Curtin WA (2010) A surface locking instability for atomic intercalation into a solid electrode. Appl Phys Lett 96:091909. https://doi.org/10.1063/1.3330940

Evans HE (1995) Stress effects in high temperature oxidation of metals. Int Mater Rev 40:1–40. https://doi.org/10.1179/imr.1995.40.1.1

Wen J, Cao R, Gao Y (2020) Mysterious failure in load-free superalloys under repeated thermal shocks. Acta Mater 194:276–282. https://doi.org/10.1016/j.actamat.2020.05.002

Niu W, Gao Y (2021) Concomitant oxidation-diffusion-creep processes for stress generation and suppression of oxide-alloy interfacial instabilities. J Mech Phys Solids 146:104218. https://doi.org/10.1016/j.jmps.2020.104218

Xu C, Gao W (2000) Pilling-bedworth ratio for oxidation of alloys. Mater Res Innov 3:231–235. https://doi.org/10.1007/s100190050008

Yu L, Jiang Y, He Y, Liu X, Zhang H (2015) Fabrication of porous nickel–copper alloy with controlled micro-sized pore structure through the Kirkendall effect. Mater Chem Phys 163:355–361. https://doi.org/10.1016/j.matchemphys.2015.07.050

Yu H-C, Yeon D-H, Van der Ven A, Thornton K (2007) Substitutional diffusion and Kirkendall effect in binary crystalline solids containing discrete vacancy sources and sinks. Acta Mater 55:6690–6704. https://doi.org/10.1016/j.actamat.2007.08.031

Paul A, van Dal MJH, Kodentsov AA, van Loo FJJ (2004) The Kirkendall effect in multiphase diffusion. Acta Mater 52:623–630. https://doi.org/10.1016/j.actamat.2003.10.007

Fu LB, Zhang WL, Li SM, Li YT, Li W, Sun J, Wang TG, Jiang SM et al (2022) Oxidation behavior of NiCrAlYSi coatings with Re-based diffusion barriers on two superalloys. Corros Sci 198:110096. https://doi.org/10.1016/j.corsci.2022.110096

Liu H, Chen W (2007) Cyclic oxidation behaviour of electrodeposited Ni3Al–CeO2 base coatings at 1050 °C. Corros Sci 49:3453–3478. https://doi.org/10.1016/j.corsci.2007.05.002

Pieraggi B, Dabosi F (1987) High-temperature oxidation of a single crystal Ni-base superalloy. Mater Corros 38:584–590. https://doi.org/10.1002/maco.19870381006

Acknowledgements

This work is supported by the Basic Science Center Program for Multiphase Media Evolution in Hypergravity of the National Natural Science Foundation of China (No. 51988101), the Key R & D Project of Zhejiang Province (No. 2020C01002), Natural Science Foundation of Zhejiang Province (No. LQ20E010008), National Science and Technology Major Project of China (J2019-III-0008-0051), and National Natural Science Foundation of China (Nos. 52201027 & 91960201).

Author information

Authors and Affiliations

Contributions

ZL: Formal analysis, Investigation, Writing—original draft, Writing—review & editing. QD: Conceptualization, Methodology, Formal analysis, Investigation, Resources, Writing—original draft, Writing—review & editing. QZ: Investigation, Writing—Writing—review & editing. XY: Investigation, Writing—Writing—review & editing. XW: Resources, Writing—review & editing. XZ: Resources, Writing—review & editing. YW: Resources, Writing—review & editing. ZZ: Conceptualization, Formal analysis, Resources, Writing—review & editing, Supervision. HB: Conceptualization, Methodology, Formal analysis, Investigation, Resources, Writing—original draft, Writing—review & editing, Supervision. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Ethical approval

Not applicable.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Z., Ding, Q., Zhou, Q. et al. The effect of oxidation on microstructures of a Ni-based single crystal superalloy during heat-treatment and simulated service conditions. J Mater Sci 58, 6343–6360 (2023). https://doi.org/10.1007/s10853-023-08412-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08412-8