Abstract

H1.6Mn1.6O4 lithium-ion sieve with spinel structure was successfully prepared by hydrothermal, high-temperature calcination and ion exchange reaction. XRD, SEM, TEM, N2 ad/desorption and FTIR methods were employed to characterize the microstructure and morphology of the synthesized materials in detail. The experimental results show that H1.6Mn1.6O4 has the characteristics of mesoporous structure and nanotube morphology with length of ∼ 10 μm and diameter of 500–700 nm, and the spiny structure was grown on the surface of the nanotube uniformly. The effect of Al3+ doping on the structure and morphology of H1.6Mn1.6O4 was studied. The results show that Al3+ doping does not change the microstructure and morphology of H1.6Mn1.6O4, but the specific surface area and pore volume are increased to a certain extent. H1.6Mn1.6O4 and H1.6Mn1.6−xAlxO4 were used as lithium-ion adsorbents to study the adsorption properties of Li+ in solution. The adsorption experiment results show that the adsorption capacity of H1.6Mn1.6O4 increased with increasing solution pH value, indicating that the strong alkaline solution with higher pH value is more favorable for Li+ adsorption. The adsorption isotherm results show that Li+ adsorption process was fitted well by Langmuir model, indicating that Li+ maybe adsorbed on the surface of manganese oxides lithium-ion sieves via a monolayer adsorption. The theoretical maximum adsorption capacity of H1.6Mn1.6O4 and H1.6Mn1.6−xAlxO4 can reach 39.54 mg/g and 40.54 mg/g, respectively. The results of adsorption kinetics show that the adsorption rate of both H1.6Mn1.6O4 and H1.6Mn1.6−xAlxO4 is fast, and the adsorption capacity of H1.6Mn1.6−xAlxO4 (24.65 mg/g) is slightly better than H1.6Mn1.6O4 (24.33 mg/g). Li+ adsorption process can be well described by the pseudo-second-order model, suggesting adsorption behavior is mainly controlled by chemical sorption. Additionally, the free energy change (ΔGΘ) was determined by Van't Hoff equation is negative, which confirms the adsorption process is spontaneous and feasible. The positive value of ΔSΘ of adsorption reaction reflects there is a certain of affinity between manganese oxides lithium-ion sieves and Li+ in solution.

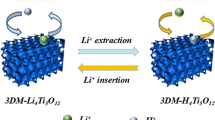

Graphical Abstract

The regular spiny structure on the surface of H1.6Mn1.6O4 nanotube lithium-ion sieve was synthesized. This special morphology not only keeps the nanotube pore structure to increase the adsorption ability and also increases the outer surface area to accelerate the Li+ diffusion speed without any substrate.

Similar content being viewed by others

Data and code availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Lyu X, Yang K, Fang J (2022) Utilization of resources in abandoned coal mines for carbon neutrality. Sci Total Environ 822:153646–153672

Wang Y, Guo C, Chen X et al (2021) Carbon peak and carbon neutrality in China: goals, implementation path and prospects. China Geol 4:720–746

Battistel A, Palagonia MS, Brogioli D et al (2020) electrochemical methods for lithium recovery: a comprehensive and critical review. Adv Mater 32:1905440–1925162

Baudino L, Santos C, Pirri CF et al (2022) Recent advances in the lithium recovery from water resources: from passive to electrochemical methods. Adv Sci 9:2201380–2201380

National Minerals Information Center (2022) Mineral commodity summaries 2022 data release: U.S. Geological Survey data release. https://doi.org/10.5066/P9KKMCP4

Grosjean C, Miranda PH, Perrin M et al (2012) Assessment of world lithium resources and consequences of their geographic distribution on the expected development of the electric vehicle industry. Renew Sustain Energy Rev 16:1735–1744

Zhang Y, Hu Y, Wang L et al (2019) Systematic review of lithium extraction from salt-lake brines via precipitation approaches. Miner Eng 139:105868–105881

Ji K (2004) Development and utilization of Lithium. Qinghai People’s Press, Xining

Zhou Z, Fan J, Liu X et al (2020) Recovery of lithium from salt-lake brines using solvent extraction with TBP as extractant and FeCl3 as co-extraction agent. Hydrometallurgy 191:105244–105251

Mori H (2003) Extraction of silicon dioxide from waste colored glasses by alkali fusion using potassium hydroxide. J Mater Sci 38:3461–3468

Xiong J, He L, Liu D et al (2021) Olivine-FePO4 preparation for lithium extraction from brines via Electrochemical De-intercalation/Intercalation method. Desalination 520:115326–115337

Wang J, Yue X, Wang P et al (2022) Electrochemical technologies for lithium recovery from liquid resources: a review. Renew Sustain Energy Rev 154:111813–111827

Palagonia MS, Brogioli D, Mantia FL (2020) Lithium recovery from diluted brine by means of electrochemical ion exchange in a flow-through-electrodes cell. Desalination 475:114192–114199

Santos C, Mantia FL (2022) Recent advances in reactor design and control for lithium recovery by means of electrochemical ion pumping. Curr Opin Electrochem 35:101089–101096

Wang Y, Yang X, Gao L et al (2022) Towards high adsorption performance and cycling stability for spinel lithium ion-sieve H1.6Mn1.6O4 by coating Li2ZrO3 and doping Zr. Colloids Surf, A 638:128283–128292

Zhong J, Lin S, Yu J (2021) Li+ adsorption performance and mechanism using lithium/aluminum layered double hydroxides in low grade brines. Desalination 505:114983–114995

Kamran U, Park SJ (2020) Functionalized titanate nanotubes for efficient lithium adsorption and recovery from aqueous media. J Solid State Chem 283:121157–121166

Ryu JC, Shin J, Lim C et al (2022) Lithium ion adsorption characteristics of porous Li1.33Mn1.67O4 adsorbent prepared using petroleum-based pitch as a binder. Hydrometallurgy 209:105837–105846

Chen J, Lin S, Yu J (2021) High-selective cyclic adsorption and magnetic recovery performance of magnetic lithium-aluminum layered double hydroxides (MLDHs) in extracting Li+ from ultrahigh Mg/Li ratio brines. Sep Purif Technol 255:117710–117719

Pu X, Du X, Jing P et al (2021) Interface and defect engineering enable fast and high-efficiency Li extraction of metatitanic acid adsorbent. Chem Eng J 425:130550–130563

Morita K, Matsumoto T, Hoshino T (2022) Efficient lithium extraction via electrodialysis using acid-processed lithium-adsorbing lithium lanthanum titanate. Desalination 543:116117–116125

Lawagon CP, Nisola GM, Cuevas RA et al (2019) Development of high capacity Li+ adsorbents from H2TiO3/polymer nanofiber composites: systematic polymer screening, characterization and evaluation. J Ind Eng Chem 70:124–135

Chitrakar R, Kanoh H, Miyai Y et al (2000) A new type of manganese oxide (MnO2·0.5H2O) derived from Li1.6Mn1.6O4 and its lithium ion-sieve properties. Chem Mater 12:3151–3157

Xiao J, Nie X, Sun S et al (2015) Lithium ion adsorption–desorption properties on spinel Li4Mn5O12 and pH-dependent ion-exchange model. Adv Powder Technol 26:589–594

Cheng M, Yao C, Su Y et al (2021) Synthesis of membrane-type graphene oxide immobilized manganese dioxide adsorbent and its adsorption behavior for lithium ion. Chemosphere 279:130487–130495

Baudino L, Pedico A, Bianco S et al (2022) Crown-ether functionalized graphene oxide membrane for lithium recovery from water. Membranes 12:233–244

Chen Q, Tian E, Luo Z et al (2022) Adsorption film with sub-milli-interface morphologies via direct ink writing for indoor formaldehyde removal. J Hazard Mater 427:128190–128200

Patra T, Mohanty A, Singh L et al (2022) Effect of calcination temperature on morphology and phase transformation of MnO2 nanoparticles: a step towards green synthesis for reactive dye adsorption. Chemosphere 288:132472–132481

Chitrakar R, Makita Y, Oil K et al (2014) Synthesis of iron-doped manganese oxides with an ion-sieve property: lithium adsorption from bolivian brine. Ind Eng Chem Res 53:3682–3688

Chitrakar R, Makita Y, Oil K et al (2013) Magnesium-doped manganese oxide with lithium ion-sieve property: lithium adsorption from Salt Lake brine. Bull Chem Soc Jpn 86:850–855

Varghese SP, Babu AT, Babu B et al (2017) γ-MnOOH nanorods: efficient adsorbent for removal of methylene blue from aqueous solutions. J Water Process Eng 19:1–7

Zhao H, Wang J, Wang G et al (2017) Facile synthesis of orthorhombic LiMnO2 nanorods by in-situ carbothermal reduction: Promising cathode material for Li ion batteries. Ceram Int 43:10585–10589

Pulido R, Naveas N, Graber T et al (2021) Hydrothermal control of the lithium-rich Li2MnO3 phase in lithium manganese oxide nanocomposites and their application as precursors for lithium adsorbents. Dalton Trans 50:10765–10778

Pulido R, Naveas N, Martín-Palma RJ et al (2022) Experimental and density functional theory study of the Li+ desorption in spinel/layered lithium manganese oxide nanocomposites using HCl. Chem Eng J 441:136019–136022

Qian F, Guo M, Qian Z et al (2021) Enabling highly structure stability and adsorption performances of Li1.6Mn1.6O4 by Al-gradient surface doping. Sep Purif Technol 264:118433–118442

Xu N, Li S, Guo M et al (2019) Synthesis of H4Mn5O12 nanotubes lithium ion sieve and its adsorption properties for Li+ from aqueous solution. ChemistrySelect 4(33):9562–9569

Li Z, Gu A, Zhou Q (2016) Facile hydrothermal synthesis of MnOOH nanorods and their application. Rare Metal Mater Eng 45(4):863–868

Xu N, Liu Z, Dong Y et al (2016) Controllable synthesis of mesoporous alumina with large surface area for high and fast fluoride removal. Ceram Int 42(14):15253–15260

Huang Y, Liu Z, Liu F et al (2022) Bimodal mesoporous CeO2–ZrO2-based materials prepared by PMMA nanosphere assisted co-precipitation and its thermal stability. Microporous Mesoporous Mater 344:112213–112224

Wu YH, Ma YL, Sun YG et al (2021) Effects of acid ionization on the formation mechanism of bimodal mesoporous Al-MCM-41s from coal gasification fine residue and evaluation of adsorption capabilities. J Hazard Mater 417:126052–126070

Wang Y, Jiang ZH, Yang FJ (2006) Effect of Fe-doping on the pore structure of mesoporous titania. Mater Sci Eng, B 134:76–79

Zhang G, Zhang J, Zhou Y (2019) Synthesis of aluminum-doped ion-sieve manganese oxides powders with enhanced adsorption performance. Colloids Surf A 583:123950–123957

Zhang G, Zhang J, Zhon Y (2021) Practical synthesis of manganese oxide MnO2⋅0.5H2O for an advanced and applicable lithium ion-sieve. J Solid State Chem 293:121768–121776

Xu N, Liu Z, Bian S et al (2016) Template-free synthesis of mesoporous γ-alumina with tunable structural properties. Ceram Int 42:4072–4079

Kang L, Zhang M, Liu ZH et al (2007) IR spectra of manganese oxides with either layered or tunnel structures. Spectrochim Acta Part A Mol Biomol Spectrosc 67:864–869

Zhu G, Wang P, Qi P et al (2014) Adsorption and desorption properties of Li+ on PVC-H1.6Mn1.6O4 lithium ion-sieve membrane. Chem Eng J 235:340–348

Wang L, Meng CG, Ma W (2009) Study on Li+ uptake by lithium ion-sieve via the pH technique. Colloids Surf A 334:34–39

Qian F, Zhao B, Guo M et al (2020) Enhancing the Li+ adsorption and anti-dissolution properties of Li1.6Mn1.6O4 with Fe, Co doped. Hydrometallurgy 193:105291–105302

ullah Rather S, Taimoor AA, Muhammad A et al (2016) Kinetics of hydrogen adsorption on MgH2/CNT composite. Mater Res Bull 77:23–28

Park H, Singhal N, Jho EH (2015) Lithium sorption properties of HMnO in seawater and wastewater. Water Res 87:320–327

Wang J, Liu Y, Xi X et al (2022) Microwave-assisted synthesis of hierarchical WO3·H2O and its selective adsorption: kinetics, isotherm and mechanism. J Mater Sci 57:6881–6899

Na CK, Park HJ (2010) Defluoridation from aqueous solution by lanthanum hydroxide. J Hazard Mater 183:512–520

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465

Masinga T, Moyo M, Pakade VE (2022) Removal of hexavalent chromium by polyethyleneimine impregnated activated carbon: intra-particle diffusion, kinetics and isotherms. J Market Res 18:1333–1344

Tang D, Zhang G (2016) Efficient removal of fluoride by hierarchical Ce–Fe bimetal oxides adsorbent: thermodynamics, kinetics and mechanism. Chem Eng J 283:721–729

Jiang S, Yu T, Xia R et al (2019) Realization of super high adsorption capability of 2D δ-MnO2/GO through intra-particle diffusion. Mater Chem Phys 232:374–381

Ryu T, Shin J, Lee DH et al (2015) Improvement of lithium adsorption capacity of porous cylinder-type lithium manganese oxide through introduction of additive. Mater Chem Phys 167:225–230

Kannan N, Sundaram MM (2001) Kinetics and mechanism of removal of methylene blue by adsorption on various carbons—a comparative study. Dyes Pigm 51:25–40

Wu CH (2007) Adsorption of reactive dye onto carbon nanotubes: equilibrium, kinetics and thermodynamics. J Hazard Mater 144:93–100

Acknowledgements

This research was supported by the Natural Science Foundation of Qinghai Province (2022-ZJ-723), “Light of the West” for Young Scholars Program of Chinese Academy of Sciences (1-13), and “Thousand Talents Program” for high-end innovation of Qinghai Provincial.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest for this work.

Ethical approval

Not Applicable.

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, N., Liu, J., Han, L. et al. Preparation, modification and adsorption properties of spinel-type H1.6Mn1.6O4 lithium-ion sieves with spiny nanotube morphology. J Mater Sci 58, 4707–4725 (2023). https://doi.org/10.1007/s10853-023-08327-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08327-4