Abstract

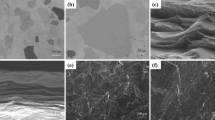

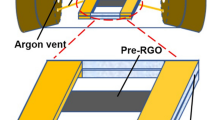

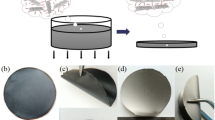

With the rapid evolvement of microelectronic devices, the accompanying high amount of heat should be transferred in time by the thermal management system to ensure the desired performance. The design of the thermal management system that possesses high thermal conductivity with flexibility is still a challenge that needs to be overcome. Here, we propose a two-step liquid-phase repairing method using hydriodic acid to remove the defects from large graphene oxide sheets produced by a modified Hummers method to make the structure intact. Compared to thermally reducing method, our method can work under much lower temperature so that it is easier to apply in mass production with much better energy conservation effects. In our research, transverse dimensions of the graphene oxide sheets with range from 50 to 270 μm were obtained by a modified Hummers method, which effectively reduces the interlayer thermal resistance; then flexible, highly thermally conductive graphene films can be developed by a two-step liquid-phase repairing method with hydriodic acid. This process produces a flat reduced graphene oxide film with a powder-free surface that is highly thermally conductive and flexible, can be folded at 180° for 1000 times without breaking and has a thermal diffusion coefficient of 1737 mm2 s−1. Multifunctional reduced graphene oxide graphene films can easily transfer large amount of heat from miniaturised, densely packed electronics for efficient thermal management.

Similar content being viewed by others

References

Lin L, Peng HL, Liu ZF (2019) Synthesis challenges for graphene industry. Nat Mater 18(6):520–524. https://doi.org/10.1080/01457632.2018.1426265

Moore AL, Shi L (2014) Emerging challenges and materials for thermal management of electronics. Mater Today 17(4):163–174. https://doi.org/10.1016/j.mattod.2014.04.003

Mallik S, Ekere N, Best C, Bhatti R (2011) Investigation of thermal management materials for automotive electronic control units. Appl Therm Eng 31(2–3):355–362. https://doi.org/10.1016/j.applthermaleng.2010.09.023

Xu ZW, Deng JY, Lai YJ et al (2022) Study on the exfoliation mechanism of graphene nanoplatelets in the polypropylene/graphene nanoplatelets composites under the elongational flow generated by convergent-divergent channels. J Mater Sci 57(9):5467–5481. https://doi.org/10.1007/s10853-022-07005-1

You R, Liu YQ, Hao YL, Han DD, Zhang YL (2020) Laser fabrication of graphene-based flexible electronics. Adv Mater 32(15):1901981. https://doi.org/10.1002/adma.201901981

Smoyer JL, Norris PM (2020) Brief historical perspective in thermal management and the shift toward management at the nanoscale. Heat Transf Eng 40(3–4):269–282. https://doi.org/10.1080/01457632.2018.1426265

Qu XH, Zhang L, Wu M, Ren SB (2011) Review of metal matrix composites with high thermal conductivity for thermal management applications. Prog Nat Sci Mater 21(3):189–197. https://doi.org/10.1016/S1002-0071(12)60029-X

Inagaki M, Kaburagi Y, Hishiyama Y (2014) Thermal management material: graphite. Adv Eng Mater 16(5):494–506. https://doi.org/10.1002/adem.201300418

Chen SJ, Wang QL, Zhang MM, Huang RZ, Huang YY, Tang J, Liu JH (2020) Scalable production of thick graphene films for next generation thermal management applications. Carbon 167(167):270–277. https://doi.org/10.1016/j.carbon.2020.06.030

Gutierrez-Cruz A, Ruiz-Hernandez AR, Vega-Clemente JF, Luna-Gazcon DG, Campos-Delgado J (2022) A review of top-down and bottom-up synthesis methods for the production of graphene, graphene oxide and reduced graphene oxide. J Mater Sci 57(31):14543–14578. https://doi.org/10.1007/s10853-022-07514-z

Geim AK (2022) Graphene: status and prospects. Science 324(5934):1530–1534. https://doi.org/10.1126/science.1158877

Tiwari SK, Sahoo S, Wang N, Huczko A (2022) Graphene research and their outputs: status and prospect. J Sci Adv Mater Dev 5(1):10–29. https://doi.org/10.1016/j.jsamd.2020.01.006

Drmosh QA, Hendi AH, Hossain MK, Yamani ZH, Moqbel RA, Hezam A, Gondal M (2019) UV-activated gold decorated rGO/ZnO heterostructured nanocomposite sensor for efficient room temperature H-2 detection. Sensor Actuat B Chem 290:666–675. https://doi.org/10.1016/j.snb.2019.03.077

Abujabal M, Abunahla H, Mohammad B, Alazzam A (2022) Tunable switching behavior of GO-based memristors using thermal reduction. Nanomater Basel 12(11):1812–1812. https://doi.org/10.3390/nano12111812

Kiran SK, Shukla S, Struck A, Saxena S (2022) Surface enhanced 3D rGO hybrids and porous rGO nano-networks as high performance supercapacitor electrodes for integrated energy storage devices. Carbon 158:527–535. https://doi.org/10.1016/j.carbon.2019.11.021

Li P, Han Y, Wang MH et al (2021) Multifunctional macroassembled graphene nanofilms with high crystallinity. Adv Mater 33(49):2104195-e2104195. https://doi.org/10.1002/adma.202104195

Wang B, Cunning BV, Kim NY et al (2019) Ultrastiff, strong, and highly thermally conductive crystalline graphitic films with mixed stacking order. Adv Mater 31(29):1903039. https://doi.org/10.1002/adma.201903039

Peng L, Xu Z, Liu Z, Guo Y, Li P, Gao C (2017) Ultrahigh thermal conductive yet superflexible graphene films. Adv Mater 29(27):1700589–1700589. https://doi.org/10.1002/adma.201700589

Zhang XD, Guo Y, Liu YJ et al (2020) Ultrathick and highly thermally conductive graphene films by self-fusion. Carbon 167:249–255. https://doi.org/10.1016/j.carbon.2020.05.051

Li J, Lai JF, Liu JL, Lei RB, Chen YX (2020) Carbonized dehydroascorbic acid: aim for targeted repair of graphene defects and bridge connection of graphene sheets with small size. Nanomater-Basel 10(3):531–531. https://doi.org/10.3390/nano10030531

Li J, Chen XY, Lei RB, Lai JF, Ma TM, Li Y (2019) Highly thermally conductive graphene film produced using glucose under low-temperature thermal annealing. J Mater Sc 54(10):7553–7562. https://doi.org/10.1007/s10853-019-03406-x

Li J, Liu JL, Liu JS, Lai JF, Chen YX, Li WJ (2021) Graphene-based composite membrane prepared from solid carbon source catalyzed by Ni nanoparticles. Nanomater Basel 11(12):3392–3392. https://doi.org/10.3390/NANO11123392

Dong L, Chen ZX, Lin S, Wang K, Ma C, Lu HB (2017) Reactivity-controlled preparation of ultralarge graphene oxide by chemical expansion of graphite. Chem Mater 29(2):564–572. https://doi.org/10.1021/acs.chemmater.6b03748

Chen J, Zhang G, Li BW (2013) Substrate coupling suppresses size dependence of thermal conductivity in supported graphene. Nanoscale 5(2):532–536. https://doi.org/10.1039/c2nr32949b

Nika DL, Askerov AS, Balandin AA (2012) Anomalous size dependence of the thermal conductivity of graphene ribbons. Nano Lett 12(6):3238–3244. https://doi.org/10.1021/nl301230g

De Silva KKH, Huang HH, Joshi RK, Yoshimura M (2017) Chemical reduction of graphene oxide using green reductant. Carbon 119:190–199. https://doi.org/10.1016/j.carbon.2017.04.025

Nissanka B, Kottegoda N, Jayasundara DR (2020) Probing structural variations of graphene oxide and reduced graphene oxide using methylene blue adsorption method. J Mater Sci 55(5):1996–2005. https://doi.org/10.1007/s10853-019-04087-2

Ferrari AC, Meyer JC, Scardaci V et al (2006) Raman spectrum of graphene and graphene layers. Phys Rev Lett 97(18):187401. https://doi.org/10.1103/PhysRevLett.97.187401

Cancado LG, Takai K, Enoki T et al (2006) General equation for the determination of the crystallite size L-a of nanographite by Raman spectroscopy. Appl Phys Lett 88(16):163106. https://doi.org/10.1063/12196057

Tian JP, Yang JP, Yang C, Hao SJ (2019) Compression and reduction of graphene oxide aerogels into flexible, porous and functional graphene films. J Mater Sci 54(20):13147–13156. https://doi.org/10.1007/s10853-019-03828-7

Pei SF, Zhao JP, Du JH, Ren WC, Cheng HM (2010) Direct reduction of graphene oxide films into highly conductive and flexible graphene films by hydrohalic acids. Carbon 48(15):4466–4474. https://doi.org/10.1016/j.carbon.2010.08.006

Acknowledgements

The authors acknowledge financial support by the Research project on novel magneto-thermal ablation mechanism and precise temperature control method for solid tumours (ZH22017003210078PW).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, J., Liu, J., Zhang, H. et al. Highly thermally conductive and flexible reduced graphene oxide films produced using two-step liquid-phase repairing method with hydriodic acid. J Mater Sci 58, 2209–2221 (2023). https://doi.org/10.1007/s10853-022-08138-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-08138-z