Abstract

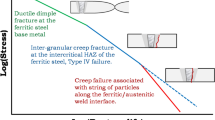

The creep-fatigue (CF) response of 316H steel base metal (BM) and welded joint (WJ) as a function of holding time, along with corresponding deformation mechanism and failure mode are studied. The CF response of both BM and WJ exhibits initial hardening followed by gradual softening. Correspondingly, the hardening degree of BM is higher than that of WJ, while WJ has a faster softening rate, which is due to their different initial microstructure and microstructure evolution during the cyclic process. Due to the enhanced recovery process, the deformation mechanism changes from primarily planar to wavy slip, which explains the difference in cyclic softening. With the increase in holding time, the nucleation and growth of intergranular cavities and cracks lead to the transformation of the failure mode from transgranular to intergranular. The failure location of WJ occurs in the WM region, and the ferrite transformation plays an important role in the initiation and propagation of cracks.

Similar content being viewed by others

References

Eaton-Mckay J, Yan K, Callaghan MD, Jimenez-Melero E (2022) Creep performance of carburized 316H stainless steel at 550 °C. J Nucl Mater 558:153329

Lee H, Eoh J, Jeong J (2019) Elevated temperature design and integrity evaluation of a large-scale sodium test facility, STELLA-2. Nucl Eng Des 346:54–66

Aoto K, Dufour P, Hongyi Y, Glatz JP, Kim Y, Ashurko Y, Hill R, Uto N (2014) A summary of sodium-cooled fast reactor development. Prog Nucl Energ 77:247–265

Murty KL, Charit I (2008) Structural materials for Gen-IV nuclear reactors: challenges and opportunities. J Nucl Mater 383:189–195

Song Y, Pan Z, Li Y, Jin W, Gao Z, Wu Z, Ma Y (2022) Nanoindentation characterization on the temperature-dependent fracture mechanism of Chinese 316H austenitic stainless steel under creep-fatigue interaction. Mater Charact 186:111806

Zhao J, Li B, Chen G, Itoh T, Chen X (2022) Effects of dwell time on the isothermal and thermomechanical fatigue behavior of 316LN stainless steel. Int J Fatigue 162:106989

Xu L, Bao F, Zhao L, Han Y, Jing H, Yu H, Gong X (2021) Characterizing microstructural evolution and low cycle fatigue behavior of 316H austenitic steel at high-temperatures. J Nucl Mater 546:152758

Li B, Zheng Y, Li Q, Liu C, Chen X (2020) Thermomechanical fatigue properties and microstructural damage of nitrogen alloyed 316LN stainless steel. Int J Fatigue 138:105704

Prasad Reddy GV, Kannan R, Mariappan K, Sandhya R, Sankaran S, Bhanu Sankara Rao K (2015) Effect of strain rate on low cycle fatigue of 316LN stainless steel with varying nitrogen content: part-I cyclic deformation behavior. Int J Fatigue 81:299–308

Prasad Reddy GV, Nagesha A, Sandhya R, Sankaran S, Mathew MD, Bhanu Sankara Rao K (2015) thermomechanical and isothermal fatigue behavior of 316LN stainless steel with varying nitrogen content. Metall Mater Trans A 46:695–707

Prasad Reddy GV, Sandhya R, Sankaran S, Mathew MD (2014) Low cycle fatigue behavior of 316LN stainless steel alloyed with varying nitrogen content. Part I: cyclic deformation behavior. Metall Mater Trans A 45:5044–5056

Kim DW, Chang J, Ryu W (2008) Evaluation of the creep–fatigue damage mechanism of type 316L and type 316LN stainless steel. Int J Pres Ves Pip 85:378–384

Srinivasan VS, Sandhya R, Valsan M, Bhanu Sankara RaoMannan KSL (2004) Comparative evaluation of strain controlled low cycle fatigue behaviour of solution annealed and prior cold worked 316L(N) stainless steel. Int J Fatigue 26:1295–1302

Srinivasan VS, Valsan M, Bhanu Sankara RaoMannanRaj KSLB (2003) Low cycle fatigue and creep–fatigue interaction behavior of 316L(N) stainless steel and life prediction by artificial neural network approach. Int J Fatigue 25:1327–1338

Sasikala G, Mathew MD, Bhanu SankaraRao K, Mannan SL (1999) Creep deformation and fracture behaviour of a nitrogen-bearing type 316 stainless steel weld metal. J Nucl Mater 273:257–264

Xu L, Li C, Zhao L, Han Y, Hao K (2022) Investigation on the creep-fatigue crack growth behavior of 316H welded joints in sodium-cooled fast reactors. Eng Fail Anal 141:106684

Lovell AJ, Chin BA, Gilbert ER (1981) In-reactor creep rupture of 20% cold-worked AISI 316 stainless steel. J Mater Sci 16:870–876. https://doi.org/10.1007/BF00542729

Mahalingam S, Flewitt PEJ, Knott JF (2012) Effect of pre-strain on grain size distributions in 316H austenitic stainless steel. J Mater Sci 47:960–968. https://doi.org/10.1007/s10853-011-5875-z

Mao J, Li X, Wang D, Zhong F, Luo L, Bao S, Ding Z (2021) Experimental study on creep-fatigue behaviors of chinese P92 steel with consideration of several important factors. Int J Fatigue 142:105900

Riedel H, Maier G, Oesterlin H (2021) A lifetime model for creep-fatigue interaction with applications to the creep resistant steel P92. Int J Fatigue 150:106308

Zhang W, Wang X, Kang Z, Zhang T, Jiang Y, Zhang X, Gong J (2021) Damage behaviour in different micro-regions of P92 steel weldment under sequential low cycle fatigue and creep loading. Eng Fract Mech 254:107935

Song Y, Ma Y, Chen H, He Z, Chen H, Zhang T, Gao Z (2021) The effects of tensile and compressive dwells on creep-fatigue behavior and fracture mechanism in welded joint of P92 steel. Mater Sci Eng A 813:141129

Gao Z, Song Y, Pan Z, Chen J, Ma Y (2020) Nanoindentation investigation on the creep behavior of P92 steel weld joint after creep-fatigue loading. Int J Fatigue 134:105506

Li L, Jin S, Wang D, Zhang P, Qiao Y, Tang R, Chen Y, Zhao J, Zhao L, Li L, Cao X, Wang B (2020) Characterization of oxide film in P92 ferritic-martensitic steel exposed to high temperature and pressure water. J Nucl Mater 541:152406

Chen G, Wang GZ, Zhang JW, Xuan FZ, Tu ST (2015) Effects of initial crack positions and load levels on creep failure behavior in P92 steel welded joint. Eng Fail Anal 47:56–66

Song Y, Pan Z, Chen J, Qin F, Gao Z, Zhang T, Ma Y (2021) The effects of prior creep–fatigue on the strain rate sensitivity of a P92 welded joint. J Mater Sci 56:7111–7128. https://doi.org/10.1007/s10853-020-05665-5

Liu Z, Gong J, Zhao P, Zhang X, Xuan F (2022) Creep-fatigue interaction and damage behavior in 9–12%Cr steel under stress-controlled cycling at elevated temperature: effects of holding time and loading rate. Int J Fatigue 156:106684

Alsmadi ZY, Alomari A, Kumar N, Murty KL (2020) Effect of hold time on high temperature creep-fatigue behavior of Fe–25Ni–20Cr (wt.%) austenitic stainless steel (Alloy 709). Mater Sci Eng A 771:138591. https://doi.org/10.1016/j.msea.2019.138591

Goyal S, Mariappan K, Shankar V, Sandhya R, Laha K, Bhaduri AK (2018) Studies on creep-fatigue interaction behaviour of Alloy 617M. Mater Sci Eng A 730:16–23. https://doi.org/10.1016/j.msea.2018.05.037

Zhou H, Zhang H, Bai F, Song M, Chen Y, Zhang L, Fang X, He Y (2020) Planar dislocation structure during creep-fatigue interactions of TP347H heat-resistant austenitic steel at 600 °C. Mater Sci Eng A 779:139141

Lan X, Hu B, Wang S, Luo W, Fu P (2022) Magnetic characteristics and mechanism of 304 austenitic stainless steel under fatigue loading. Eng Fail Anal 136:106182

Mankari K, Acharyya SG (2018) Failure analysis of AISI 321 stainless steel welded pipes in solar thermal power plants. Eng Fail Anal 86:33–43

Ando M, Isobe N, Kikuchi K, Enuma Y (2012) Effect of ratchet strain on fatigue and creep–fatigue strength of Mod. 9Cr–1Mo steel. Nucl Eng Des 247:66–75

Meng LJ, Sun J, Xing H, Yu WW, Xue F (2011) Study of low-cycle fatigue of AL6XN austenitic stainless steel. Nucl Eng Des 241:2839–2842

Mao X, Chun Y, Han C, Jang J (2017) Precipitation behavior of oxide dispersion strengthened Alloy 617. J Mater Sci 52:13626–13635. https://doi.org/10.1007/s10853-017-1437-3

He J, Sandström R (2016) Formation of creep cavities in austenitic stainless steels. J Mater Sci 51:6674–6685. https://doi.org/10.1007/s10853-016-9954-z

Dai Y, Zheng X, Ding P (2021) Review on sodium corrosion evolution of nuclear-grade 316 stainless steel for sodium-cooled fast reactor applications. Nucl Eng Technol 53:3474–3490

Suresh Kumar T, Nagesha A, Mariappan K, Kumar Dash M (2021) Deformation and failure behaviour of 316 LN austenitic stainless steel weld joint under thermomechanical low cycle fatigue in as-welded and thermally aged conditions. Int J Fatigue 149:106269

Kumar TS, Yadav SD, Nagesha A, Kannan R, Reddy GVP (2020) Isothermal and thermomechanical fatigue behaviour of type 316LN austenitic stainless steel base metal and weld joint. Mater Sci Eng A 772:138627

Suresh Kumar T, Nagesha A, Kannan R (2019) Thermal cycling effects on the creep-fatigue interaction in type 316LN austenitic stainless steel weld joint. Int J Pres Ves Pip 178:104009

Kumar Y, Venugopal S, Sasikala G, Parida PK, Moitra A (2018) Study of creep crack growth behaviour of a type 316(N) stainless steel weld and its mechanism. Mater Sci Eng A 731:551–560. https://doi.org/10.1016/j.msea.2018.06.096

Wang H, Jing H, Zhao L, Han Y, Lv X, Xu L (2017) Dislocation structure evolution in 304L stainless steel and weld joint during cyclic plastic deformation. Mater Sci Eng A 690:16–31. https://doi.org/10.1016/j.msea.2017.02.090

Shang Y, Shi H, Wang Z, Zhang G (2015) In-situ SEM study of short fatigue crack propagation behavior in a dissimilar metal welded joint of nuclear power plant. Mater Design 88:598–609

Valsan M, Sundararaman D, Rao KBS, Mannan SL (1995) A comparative evaluation of low-cycle fatigue behavior of type 316LN base metal, 316 weld metal, and 316LN/316 weld joint. Metall Mater Trans A 26:1207–1219

Srinivasan VS, Nagesha A, Valsan M, Rao KBS, Mannan SL, Sastry DH (1999) Effect of hold-time on low cycle fatigue behaviour of nitrogen bearing 316L stainless steel. Int J Pres Ves Pip 76:863–870

Hormozi R, Biglari F, Nikbin K (2015) Experimental and numerical creep–fatigue study of Type 316 stainless steel failure under high temperature LCF loading condition with different hold time. Eng Fract Mech 141:19–43

Suresh Kumar T, Dash MK, Nagesha A (2022) Deformation and damage assessment in type 316 LN stainless steel weld joint under isothermal and thermomechanical cyclic loading. Mater Sci Eng A 849:143494. https://doi.org/10.1016/j.msea.2022.143494

Shankar V, Mariappan K, Sandhya R, Laha K (2016) Understanding low cycle fatigue and creep–fatigue interaction behavior of 316 L(N) stainless steel weld joint. Int J Fatigue 82:487–496

Pham MS, Holdsworth SR, Janssens KGF, Mazza E (2013) Cyclic deformation response of AISI 316L at room temperature: mechanical behaviour, microstructural evolution, physically-based evolutionary constitutive modelling. Int J Plasticity 47:143–164

Pham MS, Solenthaler C, Janssens KGF, Holdsworth SR (2011) Dislocation structure evolution and its effects on cyclic deformation response of AISI 316L stainless steel. Mater Sci Eng A 528:3261–3269. https://doi.org/10.1016/j.msea.2011.01.015

Prasad Reddy GV, Sandhya R, Sankaran S, Parameswaran P, Laha K (2015) Creep–fatigue interaction behavior of 316LN austenitic stainless steel with varying nitrogen content. Mater Design 88:972–982

Sarkar A, Dash MK, Nagesha A, Dasgupta A, Sandhya R, Okazaki M (2018) EBSD based studies on various modes of cyclic deformation at 923 K in a type 316LN stainless steel. Mater Sci Eng A 723:229–237. https://doi.org/10.1016/j.msea.2018.02.101

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (52025052).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service, and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled, “Study on creep-fatigue response, failure mode and deformation mechanism of 316H steel welded joint”.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, L., Luo, X., Zhao, L. et al. Study on creep-fatigue response, failure mode and deformation mechanism of 316H steel welded joint. J Mater Sci 57, 22099–22118 (2022). https://doi.org/10.1007/s10853-022-07998-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07998-9