Abstract

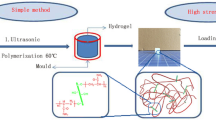

Magnetic hydrogels have been widely utilized in the fields of biomedical devices, flexible electronics, and soft robotics. Unfortunately, current strategies to synthesize magnetic hydrogels are difficult to achieve high mechanical properties. Herein, we have presented a biomimetic strategy to synthesize a strong, tough and elastic cellulose enhanced magnetic hydrogel (CEMH). The cellulose skeleton containing magnetic nanoparticles was first generated by self-assembly of cellulose chains as the enhancement filler, while elastic polyacrylamide formed by in situ polymerization functioned as the elastic matrix. The mechanical and physicochemical properties of CEMH, as well as the effect of Fe3O4 and acrylamide concentration on the performance, were systematically investigated. The highest tensile strength and toughness of CEMH could reach 1.1 MPa and 2.9 MJ/m3, respectively. Furthermore, CEMH showed a high elastic recovery of 94.5% (10th cycle), accompanies by a certain swelling resistance ability. All these advantages were accomplished mainly owing to the synergetic contribution of biomimetic design and enhanced non-covalent interactions.

Similar content being viewed by others

References

Li Y, Huang G, Zhang X et al (2013) Magnetic hydrogels and their potential biomedical applications. Adv Funct Mater 23:660–672. https://doi.org/10.1002/adfm.201201708

Liao J, Huang H (2020) Review on magnetic natural polymer constructed hydrogels as vehicles for drug delivery. Biomacromolecules 21:2574–2594. https://doi.org/10.1021/acs.biomac.0c00566

Veloso SRS, Andrade RGD, Castanheira EMS (2021) Review on the advancements of magnetic gels: towards multifunctional magnetic liposome-hydrogel composites for biomedical applications. Adv Colloid Interface Sci 288:102351. https://doi.org/10.1016/j.cis.2020.102351

Liu Z, Liu J, Cui X, Wang X, Zhang L, Tang P (2020) Recent advances on magnetic sensitive hydrogels in tissue engineering. Front Chem. https://doi.org/10.3389/fchem.2020.00124

Li C, Jiang S, Liang XZH (2017) Supplementary materials: Co-Immobilization of enzymes and magnetic nanoparticles by metal-nucleotide hydrogel nanofibers for improving stability and recycling. Molecules 22:179

Li Z, Li Y, Chen C, Cheng Y (2021) Magnetic-responsive hydrogels: from strategic design to biomedical applications. J Controlled Release 335:541–556. https://doi.org/10.1016/j.jconrel.2021.06.003

Haider H, Yang CH, Zheng WJ et al (2015) Exceptionally tough and notch-insensitive magnetic hydrogels. Soft Matter 11:8253–8261. https://doi.org/10.1039/C5SM01487E

Tang J, Tong Z, Xia Y et al (2018) Super tough magnetic hydrogels for remotely triggered shape morphing. J Mater Chem B 6:2713–2722. https://doi.org/10.1039/C8TB00568K

Wang Y, Zhu Y, Xue Y et al (2020) Sequential in-situ route to synthesize novel composite hydrogels with excellent mechanical, conductive, and magnetic responsive properties. Mater Des 193:108759. https://doi.org/10.1016/j.matdes.2020.108759

Hu X, Nian G, Liang X et al (2019) Adhesive tough magnetic hydrogels with high Fe3O4 content. ACS Appl Mat Interfaces 11:10292–10300. https://doi.org/10.1021/acsami.8b20937

Wang Y, Zhang J, Qiu C et al (2018) Self-recovery magnetic hydrogel with high strength and toughness using nanofibrillated cellulose as a dispersing agent and filler. Carbohydr Polym 196:82–91. https://doi.org/10.1016/j.carbpol.2018.05.023

Tang J, Qiao Y, Chu Y et al (2019) Magnetic double-network hydrogels for tissue hyperthermia and drug release. J Mater Chem B 7:1311–1321. https://doi.org/10.1039/C8TB03301C

Zhang W, Wang R, Sun Z et al (2020) Catechol-functionalized hydrogels: biomimetic design, adhesion mechanism, and biomedical applications. Chem Soc Rev 49:433–464. https://doi.org/10.1039/C9CS00285E

Wang Y, Huang X, Zhang X (2021) Ultrarobust, tough and highly stretchable self-healing materials based on cartilage-inspired noncovalent assembly nanostructure. Nat Commun 12(1):1–10

Zhang X, Sheng N, Wang L et al (2019) Supramolecular nanofibrillar hydrogels as highly stretchable, elastic and sensitive ionic sensors. Mater Horiz 6:326–333. https://doi.org/10.1039/C8MH01188E

Zhang D, Jian J, Xie Y et al (2022) Mimicking skin cellulose hydrogels for sensor applications. Chem Eng J 427:130921. https://doi.org/10.1016/j.cej.2021.130921

Kaco H, Baharin KW, Zakaria S et al (2017) Preparation and characterization of Fe3O4/regenerated cellulose membrane. Sains Malaysiana 46:623–628. https://doi.org/10.17576/jsm-2017-4604-15

Zhang Y, Huang R, Peng S, Ma Z (2015) MWCNTs/cellulose hydrogels prepared from NaOH/urea aqueouss solution with improved mechanical properties. J Chem 2015:413497. https://doi.org/10.1155/2015/413497

Qi H, Liu J, Gao S, Mäder E (2013) Multifunctional films composed of carbon nanotubes and cellulose regenerated from alkaline–urea solution. J Mater Chem A 1:2161–2168. https://doi.org/10.1039/C2TA00882C

Shin SR, Jung SM, Zalabany M et al (2013) Carbon-nanotube-embedded hydrogel sheets for engineering cardiac constructs and bioactuators. ACS Nano 7:2369–2380. https://doi.org/10.1021/nn305559j

Filho E, Brito E, Silva R, Streck L, Bohn F, Fonseca J (2021) Superparamagnetic polyacrylamide/magnetite composite gels. J Dispers Sci Technol 42(10):1504–1512

Shao C, Chang H, Wang M, Xu F, Yang J (2017) High-strength, tough, and self-healing nanocomposite physical hydrogels based on the synergistic effects of dynamic hydrogen bond and dual coordination bonds. ACS Appl Mat Interfaces 9:28305–28318. https://doi.org/10.1021/acsami.7b09614

Roeinfard M, Bahari A (2017) Nanostructural characterization of the Fe3O4/ZnO magnetic nanocomposite as an application in medicine. J Supercond Novel Magn 30:3541–3548. https://doi.org/10.1007/s10948-017-4154-x

Xu J, Jin R, Ren X, Gao G (2019) Cartilage-inspired hydrogel strain sensors with ultrahigh toughness, good self-recovery and stable anti-swelling properties. J Mater Chem A 7:25441–25448. https://doi.org/10.1039/C9TA09170J

Hu X, Nian G, Liang X et al (2019) Adhesive tough magnetic hydrogels with high Fe3O4 content. ACS Appl Mater Interfaces 11:10292–10300. https://doi.org/10.1021/acsami.8b20937

Hu H, Zhong X, Yang S, Fu H (2020) Tough and stretchable Fe3O4/MoS2/PAni composite hydrogels with conductive and magnetic properties. Compos B. https://doi.org/10.1016/j.compositesb.2019.107623

Lee JH, Han WJ, Jang HS, Choi HJ (2019) Highly tough, biocompatible, and magneto-responsive Fe3O4/laponite/PDMAAm nanocomposite hydrogels. Sci Rep 9(1):1–13

Liu K, Han L, Tang P et al (2019) An anisotropic hydrogel based on mussel-inspired conductive ferrofluid composed of electromagnetic nanohybrids. Nano Lett 19:8343–8356. https://doi.org/10.1021/acs.nanolett.9b00363

Sun Y, Wang Y, Yao J, Gao L, Li DS, Liu Y (2017) Highly magnetic sensitivity of polymer nanocomposite hydrogels based on magnetic nanoparticles. Compos Sci Technol 141:40–47. https://doi.org/10.1016/j.compscitech.2017.01.006

Ramanujan RV, Lao LL (2006) The mechanical behavior of smart magnet–hydrogel composites. Smart Mater Struct 15:952–956. https://doi.org/10.1088/0964-1726/15/4/008

Acknowledgements

We acknowledge the supports from Fundamental Research Funds for the Central Nonprofit Research Institution of Chinese Academy of Forestry (CAFYBB2021QB004), Jiangsu Provincial Engineering Laboratory for Biomass Conversion and Process Integration (JPELBCPI2018002), and National Natural Science Foundation of China (30271724, 32001283, 31770604).

Funding

The Supporting Information is available free of charge.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict were declared.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file2 (MP4 1310 KB)

Supplementary file3 (MP4 2601 KB)

Supplementary file4 (MP4 2620 KB)

Rights and permissions

About this article

Cite this article

Liu, Y., Jian, J., Xie, Y. et al. Biomimetic strategy to synthesize a strong, tough and elastic cellulose enhanced magnetic hydrogel. J Mater Sci 57, 12138–12146 (2022). https://doi.org/10.1007/s10853-022-07323-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07323-4