Abstract

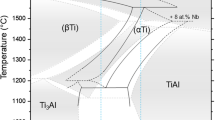

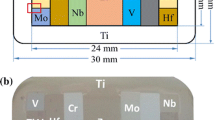

TiAl- or Ti3Al-based alloys have gained industrial applications in recent years. The incorporation of β-stabilizing element Ta has demonstrated to better adjust their microstructures and properties by introduce β and O. However undesirable phases B2 and ωo are also triggered. Phase equilibrium information and the formation mechanisms of phases B2, ωo and O including solubility limit and stability range can provide a necessary basis for selecting alloy composition and heat treatment process of excellent Ti–Al–Ta alloys. In this work, several isothermal sections from 973 to 1373 K in Ti–Al–Ta system are investigated using highly efficient method integrated equilibrated alloys and diffusion triples. Based on the present results, solubility of Al changes from 35.7 at.% at 1456 K to 6.5 at.% at 973 K in β(Ti)/B2. The β(Ti)/B2 phase region shrinks with the decrease of temperature, while Al-rich B2 phase is separated from β(Ti)/B2 to form an island-like region at the temperature between 1373 and 1273 K. At about 1182.3 K, B2 transforms into ωo-Ti3Al2Ta, leading to the obvious change of microhardness. Meanwhile, O-Ti2AlTa phase occurs via reaction β(Ti)/B2 + Ti3Al + Ta2Al → O at 1185.5 ± 12.5 K. As temperature drops, the compositional ranges of ωo and O expand, extending along the direction parallel to the ligature of Ta and Ti3Al. The phase region of ωo covers 11.3–20.6 at.% Ta and 29.7–33.6 at.% Al at 973 K. According to the evolution of phase relations, both invariant reactions Ti3Al + Ta2Al → ωo + O and Ti3Al + Ta2Al → ωo + TiAl can be defined.

Similar content being viewed by others

References

Yamaguchi M, Inui H, Ito K (2000) High-temperature structural intermetallics. Acta Mater 48:307–322

Clemens H, Mayer S (2013) Design processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv Eng Mater 15:191–215

Djanarthany S, Viala JC, Bouix J (2001) An overview of monolithic titanium aluminides based on Ti3Al and TiAl. Mater Chem Phys 72:301–319

Pollock TM (2016) Alloy design for aircraft engines. Nat mater 15:809–815

Kim YW, Kim SL (2018) Advances in gammalloy materials–processes–application technology: Successes, dilemmas and future. Jom 70:553–560

Leyens C, Peters M (2003) Titanium and titanium alloys: fundamentals and applications. Wiley-vch Weinheim

Zhang F, Zhang C, Chen SL, Cao W (1997) A thermodynamic description of the Ti-Al system. Intermetallics 5:471–482

Wu Y, Song GM (2000) The formation mechanism of the O phase in a Ti3Al–Nb alloy. Intermetallics 8:629–632

Wu Y, Zhen L, Yang DZ, Kim MS, Hwang SK, Umakoshi Y (2004) In situ tensile deformation and fracture behavior of Ti–24Al–14Nb–3V–0.5 Mo alloy with various microstructures. Intermetallics 12:43–53

Clemens H, Wallgram W, Kremmer S, Guther V, Otto A, Bartels A (2008) Design of novel β-solidifying TiAl alloys with adjustable β/B2-phase fraction and excellent hot workability. Adv Eng Mater 10:707–713

Mayer S, Erdely P, Fischer FD, Holec D, Kastenhuber M, Klein T, Clemens H (2017) Intermetallic β-Solidifying γ-TiAl Based Alloys-From Fundamental Research to Application. Adv Eng Mater 19:1600735

Rackel MW, Stark A, Gabrisch H, Schell N, Schreyer A, Pyczak F (2016) Orthorhombic phase formation in a Nb-rich γ-TiAl based alloy–an in situ synchrotron radiation investigation. Acta Mater 121:343–351

Song L, Appel F, Wang L, Oehring M, Hu XG, Stark A, He JY, Lorenz U, Zhang TB, Lin JP, Pyczak F (2020) New insights into high-temperature deformation and phase transformation mechanisms of lamellar structures in high Nb-containing TiAl alloys. Acta Mater 186:575–586

Saage H, Huang A, Hu D, Loretto MH, Wu XH (2009) Microstructures and tensile properties of massively transformed and aged Ti46Al8Nb and Ti46Al8Ta alloys. Intermetallics 17:32–38

Lapin J, Gabalcová Z, Pelachová T, Bajana O (2010) Microstructure and mechanical properties of a cast intermetallic Ti-46Al-8Ta alloy. Mater Sci Forum Trans Tech Pub Ltd 638:1368–1373

Lapin J, Pelachová T, Witusiewicz VT, Dobroka E (2011) Effect of long-term ageing on microstructure stability and lattice parameters of coexisting phases in intermetallic Ti–46Al–8Ta alloy. Intermetallics 19:121–124

Han T, Huang ZW (2013) Microstructures and tensile properties of Ti-46Al-8Ta after heat treatment and thermal exposure. Mater Sci Tech 2:90–95

Schloffer M, Rashkova B, Schoberl T, Schwaighofer E, Zhang ZL, Clemens H, Maye S (2014) Evolution of the ωo phase in a β-stabilized multi-phase TiAl alloy and its effect on hardness. Acta mater 64:241–252

Song L, Xu XJ, You L, Liang YF, Wang YL, Lin JP (2015) Ordered α2 to ωo phase transformations in high Nb-containing TiAl alloys. Acta Mater 91:330–339

Ye LH, Wang H, Zhou G, Hu QM, Yang R (2020) Phase stability of TiAl-X (X= V, Nb, Ta, Cr, Mo, W, and Mn) alloys. J Alloys Compd 819:153291

Witusiewicz VT, Bondar AA, Hecht U, Velikanova TY (2009) The Al–B–Nb–Ti system: IV. Experimental study and thermodynamic re-evaluation of the binary Al–Nb and ternary Al–Nb–Ti systems. J Alloys Compd 472:133–161

Li L, Liu LB, Zhang LG, Zeng LJ, Zhao Y, Bai WM, Jiang YR (2018) Phase Equilibria of the Ti-Al-Nb System at 1000, 1100 and 1150 C. J Phase Equilib Diff 39:549–561

Das K, Das S (2005) A review of the Ti-Al-Ta (titanium-aluminum-tantalum) system. J Phase Equilib Diff 26:322–329

Raghavan V (2005) Al-Ta-Ti (aluminum-tantalum-titanium). J Phase Equilib Diff 26:629–634

Velikanova T, Turchanin M, Ilyenko S, Effenberg G, Tomashik V, Pavlyuchkov D (2009) Aluminium–Tantalum–Titanium. Refractory metal systems Springer Berlin Heidelberg 331–356

Raman A (1966) X-ray studies of some T-T5-Al systems. Z Metallked 57:535–540

Das S, Jewett TJ, Perepezko JH (1993) High temperature phase equilibria of some ternary titanium aluminides. Structural intermetallics 93

Weaver ML, Kaufman MJ (1995) Phase relationships and transformations in the ternary aluminum-titanium-tantalum system. Acta metall Mater 43:2625–2640

Kainuma R, Fujita Y, Mitsui H, Ohnuma I, Ishida K (2000) Phase equilibria among α(hcp), β(bcc) and γ(L10) phases in Ti-Al base ternary alloys. Intermetallics 8:855–867

Witusiewicz VT, Bondar AA, Hecht U, Voblikov VM, Fomichov OS, Petyukh VM, Rex S (2011) Experimental study and thermodynamic modelling of the ternary Al–Ta–Ti system. Intermetallics 19:234–259

Witusiewicz VT, Bondar AA, Hecht U, Rex S, Velikanova TY (2008) The Al–B–Nb–Ti system: III. Thermodynamic re-evaluation of the constituent binary system Al–Ti. J Alloys Compd 465:64–77

Massalsky TB (Ed.) (1996) Binary Alloy Phase Diagrams (second ed.). ASM International Materials Park OH

Witusiewicz VT, Bondar AA, Hecht U, Zollinger J, Petyukh VM, Fomichov OS, Voblikov VM, Rex S (2010) Experimental study and thermodynamic re-assessment of the binary Al–Ta system. Intermetallics 18:92–106

Zhao JC (2011) Methods for phase diagram determination. Elsevier, USA

Jin ZP (1981) A study of the range of stability of phase in some ternary systems. Scand J Metall 10279–10287

Liu JL, Huang XM, Li GH, Cai GM, Liu HS, Jin ZP (2018) Experimental investigation on phase equilibria of Cu-Ti-Hf system and performance of Cu(Ti, Hf)2 phase. J Mater Sci 53:7809–7821

Wu D, Liu LB, Zeng LJ, Zhu WG, Wang WL, Zhang XY, Hou JF, Liu BL, Lei JF, Zhou KC (2021) Design high-strength titanium alloy using Pseudo-spinodal mechanism through diffusion mutiple experimental and CALPHAD calcution. J Mater Sci Technol 74:78–88

Huang XM, Cai GM, Zhang J, Zheng F, Liu HS, Jin ZP (2021) Phase equilibria and transition in the Ti-Al-Mn system. J Alloys Compd 861:158578

Huang XM, Zhu LL, Cai GM, Liu HS, Jin ZP (2017) Experimental investigation of phase equilibria in the Ti-Al-Mo ternary system. J Mater Sci 52:2270–2284

Shoemaker CB, Shoemaker DP, Bendersky LA (1990) Structure of ω-Ti3Al2.25Nb0.75. Acta cryst Sect C 46:374–377

Huang ZW, Lin JP, Sun HL (2017) Microstructural changes and mechanical behaviour of a near lamellar γ-TiAl alloy during long-term exposure at 700 °C. Intermetallics 85:59–68

Stark A, Oehring M, Pyczak F, Schreyer A (2011) In Situ Observation of various phase transformation paths in Nb-Rich TiAl alloys during quenching with different rates. Adv Eng Mater 13:700–704

Wu Y, Yang DZ, Song GM (2000) The formation mechanism of the O phase in a Ti3Al-Nb alloy. Intermetallics 8:629–632

Kazantseva NV, Demakov SL, Popov AA (2007) Microstructure and plastic deformation of orthorhomic titanium aluminides Ti2AlNb. III. Formation of transformation twins upon the B2-O phase transformation. Phys Met Metallogr 103:378–387

Acknowledgements

Financial supports by grants from the National MCF Energy R&D Program of China (No. 2018YFE0306100) and the National Key Research and Development Plan (No. 2016YFB0701301), are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest, the raw data required to reproduce these findings are available.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Huang, XM., Cai, GM. & Liu, HS. Phase equilibria and transformation in the Ti–Al–Ta system. J Mater Sci 57, 2163–2179 (2022). https://doi.org/10.1007/s10853-021-06655-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06655-x