Abstract

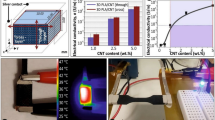

Incorporation of rigid nanoparticles is the most effective means of improving polymer properties. Montmorillonite (MMT) and multi-walled carbon nanotubes (MWCNTs) are legendary in this field for their individual exceptional properties. A synergistic phenomenon is induced between these two particles when they are simultaneously incorporated into polymers. At a definite nanofillers concentration, called the percolation threshold, there is a sudden change in nanocomposite properties due to the formation of a 3D-structured network of the nanoparticles within the matrix. In this work, the properties of poly(lactic acid) (PLA) nanocomposites filled with different fractions of MMT/MWCNTs hybrid (0.5–2.0 wt%) were analyzed. In particular, the percolation threshold of the MMT/MWCNTs hybrid was uniquely identified by differential scanning calorimetry, thermogravimetric analysis and dynamic mechanical thermal analysis. The structural studies by X-ray diffraction and Fourier-transform infrared spectroscopy were also associated with the percolation threshold of MMT/MWCNTs in PLA. At 1.0 wt% MMT/MWCNTs concentration, the complete exfoliation of the particles was maintained, and the thermal characteristics such as glass transition, crystallization and melting temperatures reached their plateau at this hybrid concentration. Moreover, the thermal degradation and viscoelastic parameters showed their peak values at this critical point, which is correlated with the formation of the percolation threshold within the matrix. The morphological studies confirmed the homogeneous dispersion of MMT/MWCNTs in PLA up to a concentration of 1.0 wt%. At 2.0 wt% MMT/MWCNTs, few aggregations occurred in the PLA-based composite, confirming that the percolation threshold was formed at a lower concentration of MMT/MWCNTs nanoparticles.

Similar content being viewed by others

References

Pitchan MK, Bhowmik S, Balachandran M, Abraham M (2017) Process optimization of functionalized MWCNT/polyetherimide nanocomposites for aerospace application. Mater Des 127:193–203. https://doi.org/10.1016/j.matdes.2017.04.081

da Rocha SAC, Rodrigues Menezes L, da Silva EO, Pedrosa MCG (2020) Synergistic effect of carbon nanoparticles on the mechanical and thermal properties of poly(lactic acid) as promising systems for packaging. J Compos Mater 54:4133–44. https://doi.org/10.1177/0021998320927779

Sanusi OM, Komolafe OD, Ogundana TO, Olaleke MO, Sanni YY (2016) Development of wood-ash/resin polymer matrix composite for body armour application. FUOYE J Eng Technol 1:10–14. https://doi.org/10.46792/fuoyejet.v1i1.4

Hosseini SM, Yousefi AA (2017) Piezoelectric sensor based on electrospun PVDF-MWCNT-Cloisite 30B hybrid nanocomposites. Org Electron 50:121–129. https://doi.org/10.1016/j.orgel.2017.07.035

Cao M, Du C, Guo H, Songa S, Li X, Li B (2019) Continuous network of CNTs in poly(vinylidene fluoride) composites with high thermal and mechanical performance for heat exchangers. Compos Sci Technol 173:33–40. https://doi.org/10.1016/j.compscitech.2019.01.023

Al Sheheri SZ, Al-Amshany ZM, Al Sulami QA, Tashkandi NY, Hussein MA, El-Shishtawy RM (2019) The preparation of carbon nanofillers and their role on the performance of variable polymer nanocomposites. Des Monomers Polym 22:8–53. https://doi.org/10.1080/15685551.2019.1565664

Papadopoulos L, Klonos PA, Terzopoulou Z, Psochia E, Sanusi OM, Aït Hocine N et al (2021) Comparative study of crystallization, semicrystalline morphology, and molecular mobility in nanocomposites based on polylactide and various inclusions at low filler loadings. Polymer 217:123457. https://doi.org/10.1016/j.polymer.2021.123457

Liu S, Wu G, Chen X, Zhang X, Yu J, Liu M et al (2019) Degradation behavior in vitro of carbon nanotubes (CNTs)/poly(lactic acid) (PLA) composite suture. Polymers 11:1015. https://doi.org/10.3390/polym11061015

Katiyar V, Gerds N, Koch CB, Risbo J, Hansen HCB, Plackett D (2010) Poly l-lactide-layered double hydroxide nanocomposites via in situ polymerization of l-lactide. Polym Degrad Stab 95:2563–2573. https://doi.org/10.1016/j.polymdegradstab.2010.07.031

Zhuang W, Liu J, Zhang JH, Hu BX, Shen J (2009) Preparation, characterization, and properties of TiO2/PLA nanocomposites by in situ polymerization. Polym Compos 30:1074–1080. https://doi.org/10.1002/pc.20658

Sanusi OM, Benelfellah A, Bikiaris DN, Aït Hocine N (2021) Effect of rigid nanoparticles and preparation techniques on the performances of poly(lactic acid) nanocomposites: a review. Polym Adv Technol 32:444–460. https://doi.org/10.1002/pat.5104

Liu C, Shen J, Yeung KWK, Tjong SC (2017) Development and antibacterial performance of novel polylactic acid-graphene oxide-silver nanoparticle hybrid nanocomposite mats prepared by electrospinning. ACS Biomater Sci Eng 3:471–486. https://doi.org/10.1021/acsbiomaterials.6b00766

Thirunavukarasu K, Purushothaman S, Sridevi J, Aarthy M, Gowthaman MK, Nakajima-Kambe T et al (2016) Degradation of poly(butylene succinate) and poly(butylene succinate-co-butylene adipate) by a lipase from yeast Cryptococcus sp. grown on agro-industrial residues. Int Biodeterior Biodegrad 110:99–107. https://doi.org/10.1016/j.ibiod.2016.03.005

Wu Y, Xiong W, Zhou H, Li H, Xu G, Zhao J (2016) Biodegradation of poly(butylene succinate) film by compost microorganisms and water soluble product impact on mung beans germination. Polym Degrad Stab 126:22–30. https://doi.org/10.1016/j.polymdegradstab.2016.01.009

Aghjeh MR, Nazari M, Khonakdar HA, Jafari SH, Wagenknecht U, Heinrich G (2015) In depth analysis of micro-mechanism of mechanical property alternations in PLA/EVA/clay nanocomposites: a combined theoretical and experimental approach. Mater Des 88:1277–1289. https://doi.org/10.1016/j.matdes.2015.09.081

Aydoğan B, Usta N (2019) Fire behaviour assessment of rigid polyurethane foams containing nanoclay and intumescent flame retardant based on cone calorimeter tests. J Chem Technol Metall 54:55–63

Boumbimba RM, Coulibaly M, Peng Y, N’souglo EK, Wang K, Gerard P (2018) Investigation of the impact response of PMMA-based nano-rubbers under various temperatures. J Polym Res 25:76. https://doi.org/10.1007/s10965-018-1479-5

Sanusi OM, Papadopoulos L, Klonos PA, Terzopoulou Z, Aït Hocine N, Benelfellah A et al (2020) Calorimetric and dielectric study of renewable poly(hexylene 2,5-furan-dicarboxylate)-based nanocomposites in situ filled with small amounts of graphene platelets and silica nanoparticles. Polymers 12:1239. https://doi.org/10.3390/POLYM12061239

López-Barroso J, Martínez-Hernández AL, Rivera-Armenta JL, Velasco-Santos C (2018) Multidimensional nanocomposites of epoxy reinforced with 1D and 2D carbon nanostructures for improve fracture resistance. Polymers 10:281. https://doi.org/10.3390/polym10030281

Hassanabadi HM, Wilhelm M, Rodrigue D (2014) A rheological criterion to determine the percolation threshold in polymer nano-composites. Rheol Acta 53:869–882. https://doi.org/10.1007/s00397-014-0804-0

Chatterjee S, Nafezarefi F, Tai NH, Schlagenhauf L, Nüesch FA, Chu BTT (2012) Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon 50:5380–5386. https://doi.org/10.1016/j.carbon.2012.07.021

Haghgoo M, Hassanzadeh-Aghdam MK, Ansari R (2020) A comprehensive evaluation of piezoresistive response and percolation behavior of multiscale polymer-based nanocomposites. Compos Part A Appl Sci Manuf 130:105735. https://doi.org/10.1016/j.compositesa.2019.105735

Xu D, Wang Z (2008) Role of multi-wall carbon nanotube network in compositesto crystallization of isotactic polypropylene matrix. Polymer 49:330–338. https://doi.org/10.1016/j.polymer.2007.11.041

Sa K, Mahakul PC, Subramanyam BVRS, Raiguru J, Das S, Alam I, et al (2018) Effect of reduced graphene oxide-carbon nanotubes hybrid nanofillers in mechanical properties of polymer nanocomposites. IOP Conf Ser Mater Sci Eng 338:012055. https://doi.org/10.1088/1757-899X/338/1/012055

Dorozhkin KV, Dunaevsky GE, Sarkisov SY, Suslyaev VI, Tolbanov OP, Zhuravlev VA et al (2017) Terahertz dielectric properties of multiwalled carbon nanotube/polyethylene composites. Mater Res Express 4:106201. https://doi.org/10.1088/2053-1591/aa8f06

Khan S, Bedi HS, Agnihotri PK (2018) Augmenting mode-II fracture toughness of carbon fiber/epoxy composites through carbon nanotube grafting. Eng Fract Mech 204:211–220. https://doi.org/10.1016/j.engfracmech.2018.10.014

Abidin MSZ, Herceg T, Greenhalgh ES, Shaffer M, Bismarck A (2019) Enhanced fracture toughness of hierarchical carbon nanotube reinforced carbon fibre epoxy composites with engineered matrix microstructure. Compos Sci Technol 170:85–92. https://doi.org/10.1016/j.compscitech.2018.11.017

Al-Saleh MH (2015) Electrical and mechanical properties of graphene/carbon nanotube hybrid nanocomposites. Synth Met 209:41–46. https://doi.org/10.1016/j.synthmet.2015.06.023

Al-Saleh MH (2017) Clay/carbon nanotube hybrid mixture to reduce the electrical percolation threshold of polymer nanocomposites. Compos Sci Technol 149:34–40. https://doi.org/10.1016/j.compscitech.2017.06.009

Koo J (2016) Environmental and health impacts for nanomaterials and polymer nanocomposites. In: Koo J (ed) Fundamentals, properties, and applications of polymer nanocomposites. Cambridge University Press, Cambridge, pp 605–47

Stloukal P, Pekařová S, Kalendova A, Mattausch H, Laske S, Holzer C et al (2015) Kinetics and mechanism of the biodegradation of PLA/clay nanocomposites during thermophilic phase of composting process. Waste Manag 42:31–40. https://doi.org/10.1016/j.wasman.2015.04.006

Castro-Aguirre E, Auras R, Selke S, Rubino M, Marsh T (2018) Impact of nanoclays on the biodegradation of poly(lactic acid) nanocomposites. Polymers 10:1–21. https://doi.org/10.3390/polym10020202

Gorrasi G, D’Ambrosio S, Patimo G, Pantani R (2014) Hybrid clay-carbon nanotube/PET composites: preparation, processing, and analysis of physical properties. J Appl Polym Sci 131:1–7. https://doi.org/10.1002/app.40441

Ma R, Zhu B, Zeng Q, Wang P, Wang Y, Liu C et al (2019) Melt-processed poly(ether ether ketone)/carbon nanotubes/montmorillonite nanocomposites with enhanced mechanical and thermomechanical properties. Materials 12:1–14. https://doi.org/10.3390/ma12030525

Azam MU, Samad MA (2018) UHMWPE hybrid nanocomposite coating reinforced with nanoclay and carbon nanotubes for tribological applications under water with/without abrasives. Tribol Int 124:145–155. https://doi.org/10.1016/j.triboint.2018.04.003

Stern N, Dyamant I, Shemer E, Hu X, Marom G (2018) Hybrid effects in the fracture toughness of polyvinyl butyral-based nanocomposites. Nanocomposites 4:1–9. https://doi.org/10.1080/20550324.2018.1447827

Mumtazah Z, Priyangga A, Atmaja L (2019) Some properties of membrane based on chitosan/phthalic anhydride matrices using montmorillonite/multi-walled carbon nanotubes filler for DMFC application. Int Conf Sci Appl Sci 020066:1–6. https://doi.org/10.1063/1.5141679.

Pandey P, Mohanty S, Nayak SK (2014) Improved flame retardancy and thermal stability of polymer/clay nanocomposites, with the incorporation of multiwalled carbon nanotube as secondary filler: evaluation of hybrid effect of nanofillers. High Perform Polym 26:826–836. https://doi.org/10.1177/0954008314531802

Khajehpour M, Arjmand M, Sundararaj U (2014) Dielectric properties of multiwalled carbon nanotube/clay/polyvinylidene fluoride nanocomposites: effect of clay incorporation. Polym Compos 37:161–167. https://doi.org/10.1002/pc.23167

Hosseini SM, Yousefi AA (2017) Electrospun PVDF/MWCNT/OMMT hybrid nanocomposites: preparation and characterization. Iran Polym J 26:331–339. https://doi.org/10.1007/s13726-017-0522-4

Song SH (2016) Synergistic effect of clay platelets and carbon nanotubes in styrene–butadiene rubber nanocomposites. Macromol Chem Phys 217:2617–2625. https://doi.org/10.1002/macp.201600344

Al-Saleh MH (2015) Effect of clay addition on the properties of carbon nanotubes-filled immiscible polyethylene/polypropylene blends. J Macromol Sci Part B Phys 54:1259–1266. https://doi.org/10.1080/00222348.2015.1085753

Sanusi OM, Benelfellah A, Papadopoulos L, Terzopoulou Z, Malletzidou L, Vasileiadis IG et al (2021) Influence of montmorillonite/carbon nanotube hybrid nanofillers on the properties of poly(lactic acid). Appl Clay Sci 201:105925. https://doi.org/10.1016/j.clay.2020.105925

Szeluga U, Kumanek B, Trzebicka B (2015) Synergy in hybrid polymer/nanocarbon composites. A review. Compos Part A Appl Sci Manuf 73:204–231. https://doi.org/10.1016/j.compositesa.2015.02.021

Sanusi OM, Benelfellah A, Aït Hocine N (2020) Clays and carbon nanotubes as hybrid nanofillers in thermoplastic-based nanocomposites—A review. Appl Clay Sci 185:105408. https://doi.org/10.1016/j.clay.2019.105408

Santangelo S, Gorrasi G, Di Lieto R, De Pasquale S, Patimo G, Piperopoulos E et al (2011) Polylactide and carbon nanotubes/smectite-clay nanocomposites: preparation, characterization, sorptive and electrical properties. Appl Clay Sci 53:188–194. https://doi.org/10.1016/j.clay.2010.12.013

Gorrasi G, Milone C, Piperopoulos E, Lanza M, Sorrentino A (2013) Hybrid clay mineral-carbon nanotube-PLA nanocomposite films. Preparation and photodegradation effect on their mechanical, thermal and electrical properties. Appl Clay Sci 71:49–54. https://doi.org/10.1016/j.clay.2012.11.004

Bai T, Zhu B, Liu H, Wang Y, Song G, Liu C et al (2020) Biodegradable poly(lactic acid) nanocomposites reinforced and toughened by carbon nanotubes/clay hybrids. Int J Biol Macromol 151:628–634. https://doi.org/10.1016/j.ijbiomac.2020.02.209

Hapuarachchi TD, Peijs T (2010) Multiwalled carbon nanotubes and sepiolite nanoclays as flame retardants for polylactide and its natural fibre reinforced composites. Compos Part A Appl Sci Manuf 41:954–963. https://doi.org/10.1016/j.compositesa.2010.03.004

Zhu B, Bai T, Wang P, Wang Y, Liu C, Shen C (2020) Selective dispersion of carbon nanotubes and nanoclay in biodegradable poly(ε-caprolactone)/poly(lactic acid) blends with improved toughness, strength and thermal stability. Int J Biol Macromol 153:1272–1280. https://doi.org/10.1016/j.ijbiomac.2019.10.262

Hassan H, Hocine NA, Médéric P, Deffarges MP, Poirot N (2015) Thermal and mechanical properties of PA12/C30B nanocomposites in relationship with nanostructure. J Appl Polym Sci 132:1–10. https://doi.org/10.1002/app.41938

Gorrasi G, Piperopoulos E, Lanza M, Milone C (2013) Effect of morphology of the filler on the electrical behaviour of poly(L-lactide) nanocomposites. J Phys Chem Solids 74:1–6. https://doi.org/10.1016/j.jpcs.2012.08.006

Galimberti M, Coombs M, Pandini S, Riccò T, Cipolletti V, Conzatti L et al (2015) Delamination of organically modified montmorillonite for reducing the filler networking with carbon black in poly(1,4-cis-isoprene) based nanocomposites. Appl Clay Sci 104:8–17. https://doi.org/10.1016/j.clay.2014.11.017

Ha CS (2016) Poly(butylene terephthlate) (PBT) based nanocomposites. In: Mai Y-W, Yu Z-Z (eds) Polymer nanocomposites. Woodhead Publishing, England, pp 234–255

Shabanian M, Hajibeygi M, Hedayati K, Khaleghi M, Khonakdar HA (2016) New ternary PLA/organoclay-hydrogel nanocomposites: design, preparation and study on thermal, combustion and mechanical properties. Mater Des 110:811–820. https://doi.org/10.1016/j.matdes.2016.08.059

Jia L, Zhang W, Tong B, Yang R (2019) Crystallization, flame-retardant, and mechanical behaviors of poly(lactic acid)\9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide–calcium montmorillonite nanocomposite. J Appl Polym Sci 136:46982. https://doi.org/10.1002/app.46982

Barrau S, Vanmansart C, Moreau M, Addad A, Stoclet G, Lefebvre JM et al (2011) Crystallization behavior of carbon nanotube-polylactide nanocomposites. Macromolecules 44:6496–6502. https://doi.org/10.1021/ma200842n

Das K, Ray D, Banerjee I, Bandyopadhyay NR, Sengupta S, Mohanty AK et al (2010) Crystalline morphology of PLA/clay nanocomposite films and its correlation with other properties. J Appl Polym Sci 118:143–151. https://doi.org/10.1002/app.32345

Shameli K, Bin AM, Yunus MZWW, Ibrahim NA, Rahman RA, Jokar M et al (2010) Silver/poly (lactic acid) nanocomposites: preparation, characterization, and antibacterial activity. Int J Nanomed 5:573–579. https://doi.org/10.2147/ijn.s12007

Huang Z, Wan Y, Peng M, Yang Z, Luo H (2020) Incorporating nanoplate-like hydroxyapatite into polylactide for biomimetic nanocomposites via direct melt intercalation. Compos Sci Technol 185:107903. https://doi.org/10.1016/j.compscitech.2019.107903

Golovnev NN, Molokeev MS, Lesnikov MK, Atuchin VV (2016) First outer-sphere 1, 3-diethyl-2-thiobarbituric compounds [M(H2O)6] spectroscopic and thermal properties. Chem Phys Lett 653:54–59. https://doi.org/10.1016/j.cplett.2016.04.059

Golovnev NN, Molokeev MS, Vereshchagin SN, Atuchin VV, Sidorenko MY, Dmitrushkov MS (2014) Crystal structure and properties of the precursor [Ni(H2O)6](HTBA)2.2H2O and the complexes M(HTBA)2(H2O)2 (M = Ni Co, Fe). Polyhedron 70:71–76. https://doi.org/10.1016/j.poly.2013.12.021

Golovnev NN, Molokeev MS, Vereshchagin SN, Atuchin VV (2013) Calcium and strontium thiobarbiturates with discrete and polymeric structures. J Coord Chem 66:4119–4130. https://doi.org/10.1080/00958972.2013.860450

Choksi N, Desai H (2017) Synthesis of biodegradable polylactic acid polymer by using lactic acid monomer. Int J Appl Chem 13:377–84

Hu C, Li Z, Wang Y, Gao J, Dai K, Zheng G (2017) Comparative assessment of the strain-sensing behaviors of polylactic acid nanocomposites: reduced graphene oxide or carbon nanotubes. J Mater Chem C 5:2318–2328. https://doi.org/10.1039/c6tc05261d

Arjmandi R, Hassan A, Eichhorn SJ, Mohamad Haafiz MK, Zakaria Z, Tanjung FA (2015) Enhanced ductility and tensile properties of hybrid montmorillonite/cellulose nanowhiskers reinforced polylactic acid nanocomposites. J Mater Sci 50:3118–3130. https://doi.org/10.1007/s10853-015-8873-8

Chen N, Feng H, Guo J, Luo H, Qiu J (2011) Biodegradable poly(lactic acid)/TDI-montmorillonite nanocomposites: preparation and characterization. Adv Mater Res 221:211–215

Zhang X, Xu R, Wu Z, Zhou C (2003) The synthesis and characterization of polyurethane/clay nanocomposites. Polym Int 52:790–794. https://doi.org/10.1002/pi.1152

Molinaro S, Cruz Romero M, Boaro M, Sensidoni A, Lagazio C, Morris M et al (2013) Effect of nanoclay-type and PLA optical purity on the characteristics of PLA-based nanocomposite films. J Food Eng 117:113–123. https://doi.org/10.1016/j.jfoodeng.2013.01.021

Arjmandi R, Hassan A, Haafiz MKM, Zakaria Z (2015) Partial replacement effect of montmorillonite with cellulose nanowhiskers on polylactic acid nanocomposites. Int J Biol Macromol 81:91–99. https://doi.org/10.1016/j.ijbiomac.2015.07.062

Seligra PG, Lamanna M, Fama L (2016) Promising PLA-functionalized MWCNT composites to use in nanotechnology. Polym Compos 37:915–924. https://doi.org/10.1002/pc.23504

Terzopoulou Z, Klonos PA, Kyritsis A, Tziolas A, Avgeropoulos A, Papageorgiou GZ et al (2019) Interfacial interactions, crystallization and molecular mobility in nanocomposites of poly(lactic acid) filled with new hybrid inclusions based on graphene oxide and silica nanoparticles. Polymer 166:1–12. https://doi.org/10.1016/j.polymer.2019.01.041

Chattopadhyay PK, Basuli U, Chattopadhyay S (2009) Studies on novel dual filler based epoxidized natural rubber nanocomposite. Polym Compos 31:835–846. https://doi.org/10.1002/pc.20866

Vukić N, Ristić IS, Marinović-Cincović M, Radičević R, Pilić B, Cakić S et al (2019) Influence of different functionalization methods of multi-walled carbon nanotubes on the properties of poly(L-lactide) based nanocomposites. Hem Ind 73:183–196. https://doi.org/10.2298/HEMIND190402016V

Sibeko MA (2012) Preparation and characterization of vinylsilane crosslinked high-density polyethylene composites filled with nanoclays. Polym compos 34(10):1720–1727. https://doi.org/10.1002/pc.22575

Chu CC, Liu P, White KL, Sue HJ (2012) Electrical conductivity and thermal stability of polypropylene containing disentangled carbon nanotubes. Carbon 50:4711–4722. https://doi.org/10.1016/j.carbon.2012.05.063

Singla RK, Maiti SN, Ghosh AK (2016) Mechanical, morphological, and solid-state viscoelastic responses of poly(lactic acid)/ethylene-co-vinyl-acetate super-tough blend reinforced with halloysite nanotubes. J Mater Sci 51:10278–10292. https://doi.org/10.1007/s10853-016-0255-3

Prashantha K, Soulestin J, Lacrampe MF, Krawczak P (2014) Processing and characterization of polypropylene filled with multiwalled carbon nanotube and clay hybrid nanocomposites. Int J Polym Anal Charact 19:363–371. https://doi.org/10.1080/1023666X.2014.902715

Zhang X, Zhang Y (2016) Reinforcement effect of poly(butylene succinate) (PBS)-grafted cellulose nanocrystal on toughened PBS/polylactic acid blends. Carbohydr Polym 140:374–382. https://doi.org/10.1016/j.carbpol.2015.12.073

Jesuarockiam N, Jawaid M, Zainudin ES, Hameed Sultan MT, Yahaya R (2019) Enhanced thermal and dynamic mechanical properties of synthetic/natural hybrid composites with graphene nanoplateletes. Polymers 11:1085. https://doi.org/10.3390/polym11071085

Krishnaiah P, Ratnam CT, Manickam S (2017) Development of silane grafted halloysite nanotube reinforced polylactide nanocomposites for the enhancement of mechanical, thermal and dynamic-mechanical properties. Appl Clay Sci 135:583–595. https://doi.org/10.1016/j.clay.2016.10.046

Coppola B, Cappetti N, Di ML, Scarfato P, Incarnato L (2018) 3D printing of PLA/clay nanocomposites: Influence of printing temperature on printed samples properties. Materials 11:1–17. https://doi.org/10.3390/ma11101947

Salmoria GV, Leite JL, Vieira LF, Pires ATN, Roesler CRM (2012) Mechanical properties of PA6_PA12 blend specimens prepared by selective laser sintering. Polym Test 31:411–416. https://doi.org/10.1016/jpolymertesting.2011.12.006

Levchenko V, Mamunya Y, Boiteux G, Lebovka M, Alcouffe P, Seytre G et al (2011) (2011) Influence of organo-clay on electrical and mechanical properties of PP/MWCNT/OC nanocomposites. Eur Polym J 47:1351–1360. https://doi.org/10.1016/j.eurpolymj.2011.03.012

Acknowledgements

Petroleum Technology Development Fund (PTDF), Nigeria, is acknowledged for providing the doctoral grant (Grant Number: 18GFC/PHD/065).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Handling Editor: Yaroslava Yingling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sanusi, O.M., Benelfellah, A., Papadopoulos, L. et al. Properties of poly(lactic acid)/montmorillonite/carbon nanotubes nanocomposites: determination of percolation threshold. J Mater Sci 56, 16887–16901 (2021). https://doi.org/10.1007/s10853-021-06378-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06378-z