Abstract

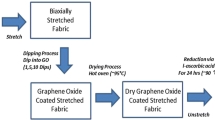

Fabric strain sensors have attracted significantly increased interest as wearable electronics for their flexibility, softness, and wearing comfort in recent years. However, most of the fabric strain sensors fail to pay attention to directionality (negative piezoresistivity) and it remains a big challenge to fabricate wearable fabric strain sensors with a broad sensing range. Here, the strain sensing fabric comprising reduced graphene oxide is developed by using a facile dip-dry-reduce method. Compared to the prior textile strain sensors, the remarkable deformation capacity and a broad reversible strain sensing range (up to 450% strain without breaking) of our treated fabric are with special attention. Meanwhile, it owns great sensitivity (gauge factor of -5.92 under 10.7% strain), stability (> 1000 cycles) and reliability. In addition, sensing strain such as tensile, twist, shear and poke is quantitatively determined. Moreover, the sensing fabric exhibits resistance strain anisotropy (ΔR/R0 at the wale direction / ΔR/R0 at the course direction = 5.23), electric thermal behavior (about 60 °C under a voltage of 10 V). Finally, the equivalent electrical circuit is provided based on the structure, which is presented for the analysis of electromechanical behaviors, structure–activity relationship, transport models and mechanism. Based on this work, the strain sensing fabric comprising reduced graphene oxide can be knitted to shape for application in human motion detection and electric heater as a kind of flexible smart electronic.

Similar content being viewed by others

References

Jia Y, Yue X, Wang Y, Yan C, Zheng G, Dai K, Liu C, Shen C (2020) Multifunctional stretchable strain sensor based on polydopamine/ reduced graphene oxide/ electrospun thermoplastic polyurethane fibrous mats for human motion detection and environment monitoring. Compos B Eng 183:107696. https://doi.org/10.1016/j.compositesb.2019.107696

Yi F-L, Meng F-C, Li Y-Q, Huang P, Hu N, Liao K, Fu S-Y (2020) Highly stretchable CNT Fiber/PAAm hydrogel composite simultaneously serving as strain sensor and supercapacitor. Compos B Eng 198:108246. https://doi.org/10.1016/j.compositesb.2020.108246

Matsuzaki R, Todoroki A, Kobayashi H, Shimamura Y (2005) Passive wireless strain monitoring of a tire using capacitance and electromagnetic induction change. Adv Compos Mater 14(2):147–164. https://doi.org/10.1163/1568551053970663

Ozer B, Piskin H, Akdogan N (2019) Shapeable planar hall sensor with a stable sensitivity under concave and convex bending. IEEE Sens J 19(14):5493–5498. https://doi.org/10.1109/JSEN.2019.2907616

Nguyen T-K, Phan H-P, Han J, Dinh T, Mdfoisal AR, Zhu Y, Nguyen N-T, Dao DV (2018) Utilizing large hall offset voltage for conversion free 4H-SiC strain sensor. In: IEEE Micro Electro Mechanical Systems, pp 882–885. https://doi.org/10.1109/MEMSYS.2018.8346697

Eom J-H, Choi H-J, Pammi SVN, Tran V-D, Kim Y-J, Kim H-J, Yoon S-G (2018) Self-powered pressure and light sensitive bimodal sensors based on long-term stable piezo-photoelectric MAPbI3 thin films. Journal of Materials Chemistry C 6(11):2786–2792. https://doi.org/10.1039/c8tc00081f

Huo Z, Wang X, Zhang Y, Wan B, Wu W, Xi J, Yang Z, Hu G, Li X, Pan C (2020) High-performance Sb-doped p-ZnO NW films for self-powered piezoelectric strain sensors. Nano Energy 73:104744. https://doi.org/10.1016/j.nanoen.2020.104744

Kozioł M, Toroń B, Szperlich P, Jesionek M (2019) Fabrication of a piezoelectric strain sensor based on SbSI nanowires as a structural element of a FRP laminate. Compos B Eng 157:58–65. https://doi.org/10.1016/j.compositesb.2018.08.105

Yu R, Zhu C, Wan J, Li Y, Hong X (2021) Review of graphene-based textile strain sensors with emphasis on structure activity relationship. Polymers. https://doi.org/10.3390/polym13010151

Lee S, Kim M-O, Kang T, Park J, Choi Y (2018) Knit band sensor for myoelectric control of surface emg-based prosthetic hand. IEEE Sens J 18(20):8578–8586. https://doi.org/10.1109/JSEN.2018.2865623

Qian Q, Wang Y, Zhang M, Chen L, Feng J, Wang Y, Zhou Y (2019) Ultrasensitive paper-based polyaniline/graphene composite strain sensor for sign language expression. Compos Sci Technol 181:107660. https://doi.org/10.1016/j.compscitech.2019.05.017

Costa P, Nunes-Pereira J, Oliveira J, Silva J, Moreira JA, Carabineiro SAC, Buijnsters JG, Lanceros-Mendez S (2017) High-performance graphene-based carbon nanofiller/polymer composites for piezoresistive sensor applications. Compos Sci Technol 153:241–252. https://doi.org/10.1016/j.compscitech.2017.11.001

Yang Z, Pang Y, Han XL, Yang Y, Ling J, Jian M, Zhang Y, Yang Y, Ren TL (2018) Graphene textile strain sensor with negative resistance variation for human motion detection. ACS Nano 12(9):9134–9141. https://doi.org/10.1021/acsnano.8b03391

Zahid M, Papadopoulou EL, Athanassiou A, Bayer IS (2017) Strain-responsive mercerized conductive cotton fabrics based on PEDOT:PSS/graphene. Mater Des 135:213–222. https://doi.org/10.1016/j.matdes.2017.09.026

Huang Y, Gao L, Zhao Y, Guo X, Liu C, Liu P (2017) Highly flexible fabric strain sensor based on graphene nanoplatelet-polyaniline nanocomposites for human gesture recognition. J Appl Polym Sci 134(39):45340. https://doi.org/10.1002/app.45340

Zhang M, Wang C, Wang Q, Jian M, Zhang Y (2016) Sheath-core graphite/silk fiber made by dry-meyer-rod-coating for wearable strain sensors. ACS Appl Mater Interfaces 8(32):20894–20899. https://doi.org/10.1021/acsami.6b06984

Tian M, Zhao R, Qu L, Chen Z, Chen S, Zhu S, Song W, Zhang X, Sun Y, Fu R (2019) Stretchable and designable textile pattern strain sensors based on graphene decorated conductive nylon filaments. Macromol Mater Eng 304(10):1900244. https://doi.org/10.1002/mame.201900244

Wang S, Ning H, Hu N, Liu Y, Liu F, Zou R, Huang K, Wu X, Weng S, Alamusi, (2019) Environmentally-friendly and multifunctional graphene-silk fabric strain sensor for human-motion detection. Adv Mater Interfaces 7(1):1901507. https://doi.org/10.1002/admi.201901507

Jiang X, Ren Z, Fu Y, Liu Y, Zou R, Ji G, Ning H, Li Y, Wen J, Qi HJ, Xu C, Fu S, Qiu J, Hu N (2019) Highly compressible and sensitive pressure sensor under large strain based on 3D porous reduced graphene oxide fiber fabrics in wide compression strains. ACS Appl Mater Interfaces 11(40):37051–37059. https://doi.org/10.1021/acsami.9b11596

Du D, Li P, Ouyang J (2016) Graphene coated nonwoven fabrics as wearable sensors. J Mater Chem C 4(15):3224–3230. https://doi.org/10.1039/c6tc00350h

Liu X, Liu D, Lee JH, Zheng Q, Du X, Zhang X, Xu H, Wang Z, Wu Y, Shen X, Cui J, Mai YW, Kim JK (2019) Spider-web-inspired stretchable graphene woven fabric for highly sensitive, transparent, wearable strain sensors. ACS Appl Mater Interfaces 11(2):2282–2294. https://doi.org/10.1021/acsami.8b18312

Tang Z, Yao D, Du D, Ouyang J (2020) Highly machine-washable e-textiles with high strain sensitivity and high thermal conduction. Journal of Materials Chemistry C 8(8):2741–2748. https://doi.org/10.1039/c9tc06155j

Kim SJ, Song W, Yi Y, Min BK, Mondal S, An KS, Choi CG (2018) High durability and waterproofing rgo/swcnt-fabric-based multifunctional sensors for human-motion detection. ACS Appl Mater Interfaces 10(4):3921–3928. https://doi.org/10.1021/acsami.7b15386

Liu H, Li Q, Bu Y, Zhang N, Wang C, Pan C, Mi L, Guo Z, Liu C, Shen C (2019) Stretchable conductive nonwoven fabrics with self-cleaning capability for tunable wearable strain sensor. Nano Energy 66:104143. https://doi.org/10.1016/j.nanoen.2019.104143

Chun S, Son W, Kim DW, Lee J, Min H, Jung H, Kwon D, Kim AH, Kim YJ, Lim SK, Pang C, Choi C (2019) Water-resistant and skin-adhesive wearable electronics using graphene fabric sensor with octopus-inspired microsuckers. ACS Appl Mater Interfaces 11(18):16951–16957. https://doi.org/10.1021/acsami.9b04206

Liu X, Tang C, Du X, Xiong S, Xi S, Liu Y, Shen X, Zheng Q, Wang Z, Wu Y, Horner A, Kim J-K (2017) A highly sensitive graphene woven fabric strain sensor for wearable wireless musical instruments. Mater Horiz 4(3):477–486. https://doi.org/10.1039/c7mh00104e

Ren J, Wang C, Zhang X, Carey T, Chen K, Yin Y, Torrisi F (2017) Environmentally-friendly conductive cotton fabric as flexible strain sensor based on hot press reduced graphene oxide. Carbon 111:622–630. https://doi.org/10.1016/j.carbon.2016.10.045

Hong X, Peng T, Zhu C, Wan J, Li Y (2021) Electromagnetic shielding, resistance temperature-sensitive behavior, and decoupling of interfacial electricity for reduced graphene oxide paper. J Alloy Compd 882:160756. https://doi.org/10.1016/j.jallcom.2021.160756

Liu Y, Xia L, Zhang Q, Guo H, Wang A, Xu W, Wang Y (2019) Structure and properties of carboxymethyl cotton fabric loaded by reduced graphene oxide. Carbohyd Polym 214:117–123. https://doi.org/10.1016/j.carbpol.2019.03.028

Cheng H, Dong Z, Hu C, Zhao Y, Hu Y, Qu L, Chen N, Dai L (2013) Textile electrodes woven by carbon nanotube-graphene hybrid fibers for flexible electrochemical capacitors. Nanoscale 5(8):3428–3434. https://doi.org/10.1039/c3nr00320e

Balandin AA, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau CN (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8(3):902–907. https://doi.org/10.1021/nl0731872

Reddy KR, Gandla S, Gupta D (2019) Highly sensitive, rugged, and wearable fabric strain sensor based on graphene clad polyester knitted elastic band for human motion monitoring. Adv Mater Interfaces 6(16):1900409. https://doi.org/10.1002/admi.201900409

Liu Y, Zhang D, Wang K, Liu Y, Shang Y (2016) A novel strain sensor based on graphene composite films with layered structure. Compos A Appl Sci Manuf 80:95–103. https://doi.org/10.1016/j.compositesa.2015.10.010

Liu H, Li Y, Dai K, Zheng G, Liu C, Shen C, Yan X, Guo J, Guo Z (2016) Electrically conductive thermoplastic elastomer nanocomposites at ultralow graphene loading levels for strain sensor applications. Journal of Materials Chemistry C 4(1):157–166. https://doi.org/10.1039/c5tc02751a

Cai G, Yang M, Xu Z, Liu J, Tang B, Wang X (2017) Flexible and wearable strain sensing fabrics. Chem Eng J 325:396–403. https://doi.org/10.1016/j.cej.2017.05.091

Shao F, Bian SW, Zhu Q, Guo MX, Liu S, Peng YH (2016) Fabrication of polyaniline/graphene/polyester textile electrode materials for flexible supercapacitors with high capacitance and cycling stability. Chem Asian J 11(13):1906–1912. https://doi.org/10.1002/asia.201600411

He S, Xin B, Chen Z, Liu Y (2018) Flexible and highly conductive Ag/G-coated cotton fabric based on graphene dipping and silver magnetron sputtering. Cellulose 25(6):3691–3701. https://doi.org/10.1007/s10570-018-1821-4

Niu B, Hua T, Hu H, Xu B, Tian X, Chan K, Chen S (2019) A highly durable textile-based sensor as a human-worn material interface for long-term multiple mechanical deformation sensing. Journal of Materials Chemistry C 7(46):14651–14663. https://doi.org/10.1039/c9tc04006d

Hummers WS Jr, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80(6):1339

Hong X, Yu W, Wang A, Chung D (2016) Graphite oxide paper as a polarizable electrical conductor in the through-thickness direction. Carbon 109:874–882

Park TH, Yu S, Koo M, Kim H, Kim EH, Park JE, Ok B, Kim B, Noh SH, Park C, Kim E, Koo CM, Park C (2019) Shape-Adaptable 2D Titanium Carbide (MXene) Heater. ACS Nano 13(6):6835–6844. https://doi.org/10.1021/acsnano.9b01602

Jeong HK, Yun PL, Lahaye RJWE, Park MH, Kay HA, Ick JK, Yang CW, Chong YP, Ruoff RS, Young HL (2008) Evidence of graphitic AB stacking order of graphite oxides. J Am Chem Soc 130(4):1362–1366. https://doi.org/10.1021/ja076473o

Zhou X, Shi T, Wu J, Zhou H (2013) (001) Facet-exposed anatase-phase TiO2 nanotube hybrid reduced graphene oxide composite: Synthesis, characterization and application in photocatalytic degradation. Appl Surf Sci 287:359–368. https://doi.org/10.1016/j.apsusc.2013.09.156

Mecozzi M, Nisini L (2019) The differentiation of biodegradable and non-biodegradable polyethylene terephthalate (PET) samples by FTIR spectroscopy: A potential support for the structural differentiation of PET in environmental analysis. Infrared Phys Technol 101:119–126. https://doi.org/10.1016/j.infrared.2019.06.008

Razavizadeh M, Jamshidi M (2016) Adhesion of nitrile rubber (NBR) to polyethylene terephthalate (PET) fabric. Part 1: PET surface modification by methylenediphenyl di-isocyanate (MDI). Appl Surf Sci 360:429–435. https://doi.org/10.1016/j.apsusc.2015.10.137

Fuente E, Menéndez JA, Díez MA, Suárez D, Montes-Morán MA (2003) Infrared spectroscopy of carbon materials: A quantum chemical study of model compounds. J Phys Chem B 107(26):6350–6359

Xu L-L, Guo M-X, Liu S, Bian S-W (2015) Graphene/cotton composite fabrics as flexible electrode materials for electrochemical capacitors. RSC Adv 5(32):25244–25249. https://doi.org/10.1039/c4ra16063k

Szabó T, Berkesi O, Forgó P, Josepovits K, Sanakis Y, Petridis D, Dékány I (2006) Evolution of surface functional groups in a series of progressively oxidized graphite oxides. Chem Mater 18(11):2740–2749. https://doi.org/10.1021/cm060258+

Babaahmadi V, Montazer M (2016) Reduced graphene oxide/SnO2 nanocomposite on PET surface: Synthesis, characterization and application as an electro-conductive and ultraviolet blocking textile. Colloids Surf, A 506:507–513. https://doi.org/10.1016/j.colsurfa.2016.07.025

Tian M, Hu X, Qu L, Zhu S, Sun Y, Han G (2016) Versatile and ductile cotton fabric achieved via layer-by-layer self-assembly by consecutive adsorption of graphene doped PEDOT: PSS and chitosan. Carbon 96:1166–1174. https://doi.org/10.1016/j.carbon.2015.10.080

Seyedin S, Razal JM, Innis PC, Jeiranikhameneh A, Beirne S, Wallace GG (2015) Knitted strain sensor textiles of highly conductive all-polymeric fibers. ACS Appl Mater Interfaces 7(38):21150–21158. https://doi.org/10.1021/acsami.5b04892

Acknowledgements

This research was supported by the National Natural Science Foundation of China (NSFC 51803185), Public Welfare Project of Zhejiang Province (LGF21E030005), China Postdoctoral Science Foundation (2020M681917), Postdoctoral Foundation of Zhejiang Sci-Tech University Tongxiang Research Institute (TYY202013), the Science Foundation of Zhejiang Sci-Tech University (No. 18012107-Y).

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Dale Huber.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hong, X., Yu, R., Hou, M. et al. Smart fabric strain sensor comprising reduced graphene oxide with structure-based negative piezoresistivity. J Mater Sci 56, 16946–16962 (2021). https://doi.org/10.1007/s10853-021-06365-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06365-4