Abstract

To effectively and simply characterize the macroscale dispersion of nanoparticles was vital for understanding the intrinsic connection between the properties and the structure of composites. In this study, fluorescent MWCNTs–FITC was successfully synthesized via grafting fluorescein isothiocyanate on the MWCNTs with protection of polyglycidyl methacrylate, which opened new avenues to in situ visualize the dispersion of carbon-based materials under confocal laser scanning microscopy. With the aid of this noninvasive method, macroscale 3D spatial dispersion of MWCNTs–FITC in both matrix and interfacial phases of quartz fibers/epoxy (QFs/EP) composites was quantitatively evaluated by integrating Morisita’s index, particle spacing probability density theory, 2D fractal dimension and Einstein’s Stokes theory. The results showed that the threshold for uniform dispersion of MWCNTs–FITC was 0.05 wt% due to the interactions of inter-particle van der Waals forces and physical entanglement. The highest particle spacing coefficient of MWCNTs–FITC (\(\overline{x}/s\) = 1.69) was achieved curing at 25 °C, which indicated that MWCNTs–FITC was well dispersed in matrix, while for the dispersion in QFs/EP interface, the optimal curing temperature was 40 °C where the actual average diffusion distance (\(\overline{{l_{{\text{m}}} }}\)) was as high as 6.3 µm. The purpose of the established quantification method in this study was to provide viable opportunities and inspirations for quantitatively evaluating the dispersion of nanoparticles.

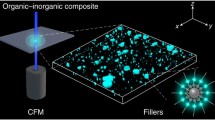

Graphical abstract

Similar content being viewed by others

References

Vryonis O, Andritsch T, Vaughan AS, Lewin PL (2019) An alternative synthesis route to graphene oxide: influence of surface chemistry on charge transport in epoxy-based composites. J Mater Sci 54:8302–8318. https://doi.org/10.1007/s10853-019-03477-w

Nie H-J, Xu Z, Tang B-L, Dang C-Y, Yang Y-R, Zeng X-L (2021) The effect of graphene oxide modified short carbon fiber on the interlaminar shear strength of carbon fiber fabric/epoxy composites. J Mater Sci 56:488–496. https://doi.org/10.1007/s10853-020-05286-y

Gao Y, Jing H, Zhou Z, Chen W, Li L, Shi X (2020) Graphene oxide-assisted multi-walled carbon nanotube reinforcement of the transport properties in cementitious composites. J Mater Sci 55:603–618. https://doi.org/10.1007/s10853-019-04040-3

Kumar A, Sharma K, Dixit AR (2020) Carbon nanotube- and graphene-reinforced multiphase polymeric composites: review on their properties and applications. J Mater Sci 55:2682–2724. https://doi.org/10.1007/s10853-019-04196-y

Aslan A, Salur E, Düzcükoğlu H, Şahin ÖS, Ekrem M (2021) The effects of harsh aging environments on the properties of neat and MWCNT reinforced epoxy resins. Construct Build Mater 272:121929. https://doi.org/10.1016/j.conbuildmat.2020.121929

Gu H, Zhang H, Ma C, Xu X, Wang Y, Wang Z (2019) Trace electrosprayed nanopolystyrene facilitated dispersion of multiwalled carbon nanotubes: simultaneously strengthening and toughening epoxy. Carbon 142:131–140

Pantano A, Montinaro N, Cerniglia D, Micciulla F, Bistarelli S, Cataldo A (2019) Novel non-destructive evaluation technique for the detection of poor dispersion of carbon nanotubes in nanocomposites. Compos B Eng 163:52–58

Wang M, Ma L, Shi L, Feng P, Wang X, Zhu Y (2019) Chemical grafting of nano-SiO2 onto graphene oxide via thiol-ene click chemistry and its effect on the interfacial and mechanical properties of GO/epoxy composites. Compos Sci Technol 182:107751. https://doi.org/10.1016/j.compscitech.2019.107751

Scaffaro R, Maio A (2019) Integrated ternary bionanocomposites with superior mechanical performance via the synergistic role of graphene and plasma treated carbon nanotubes. Compos B Eng 168:550–559

Zhang C, Tang Z, Guo B, Zhang L (2019) Concurrently improved dispersion and interfacial interaction in rubber/nanosilica composites via efficient hydrosilane functionalization. Compos Sci Technol 169:217–223

Montinaro N, Fustaino M, Pantano A (2020) Carbon nanotubes dispersion assessment in nanocomposites by means of a pulsed thermographic approach. Materials 13:5649. https://doi.org/10.3390/ma13245649

Raimondo M, Naddeo C, Vertuccio L, Lafdi K, Sorrentino A, Guadagno L (2019) Carbon-based aeronautical epoxy nanocomposites: effectiveness of atomic force microscopy (AFM) in investigating the dispersion of different carbonaceous nanoparticles. Polymers 11:832. https://doi.org/10.3390/polym11050832

Xia T, Guo X, Lin Y, Xin B, Li S, Yan N (2019) Aggregation of oxidized multi-walled carbon nanotubes: interplay of nanomaterial surface O-functional groups and solution chemistry factors. Environ Pollut 251:921–929

Li F, Li L, Zhong G, Zhai Y, Li Z (2019) Effects of ultrasonic time, size of aggregates and temperature on the stability and viscosity of Cu-ethylene glycol (EG) nanofluids. Int J Heat Mass Transfer 129:278–286

Rodríguez HA, Kriven WM, Casanova H (2019) Development of mechanical properties in dental resin composite: effect of filler size and filler aggregation state. Mater Sci Eng C 101:274–282

Kobashi K, Sekiguchi A, Yamada T, Muroga S, Okazaki T (2020) Dispersions of high-quality carbon nanotubes with narrow aggregate size distributions by viscous liquid for conducting polymer composites. ACS Appl Nano Mater 3:1391–1399

Ghoderao P, Sahare S, Alegaonkar P, Kulkarni AA, Bhave T (2018) Multiwalled carbon nanotubes decorated with Fe3O4 nanoparticles for efficacious doxycycline delivery. ACS Appl Nano Mater 2:607–616

Zhao Z, Katai H, Higashi K, Ueda K, Kawakami K, Moribe K (2019) Cryo-TEM and AFM observation of the time-dependent evolution of amorphous probucol nanoparticles formed by the aqueous dispersion of ternary solid dispersions. Mol Pharm 16:2184–2198

Schneider S, Lefebvre J, Diercks NJ, Berger FJ, Fo Lapointe, Schleicher J (2020) Phenanthroline additives for enhanced semiconducting carbon nanotube dispersion stability and transistor performance. ACS Appl Nano Mater. https://doi.org/10.1021/acsanm.0c02813

Sun L, Zhang D, Sun Y, Wang S, Cai J (2018) Facile fabrication of highly dispersed Pd@ Ag core–shell nanoparticles embedded in spirulina platensis by electroless deposition and their catalytic properties. Adv Funct Mater 28:1707231. https://doi.org/10.1002/adfm.201707231

Hanifah MFR, Jaafar J, Othman M, Ismail A, Rahman M, Yusof N (2019) One-pot synthesis of efficient reduced graphene oxide supported binary Pt-Pd alloy nanoparticles as superior electro-catalyst and its electro-catalytic performance toward methanol electro-oxidation reaction in direct methanol fuel cell. J Alloys Compd 793:232–246

Liu X, Bu Y, Cheng T, Gao W, Jiang Q (2019) Flower-like carbon supported Pd–Ni bimetal nanoparticles catalyst for formic acid electrooxidation. Electrochim Acta 324:134816. https://doi.org/10.1016/j.electacta.2019.134816

Zhao F, Ling L, Liu L, Zafar A, Ni Z (2017) The dispersion of graphene in conductive epoxy composites investigated by Raman spectroscopy. J Raman Spectrosc 48:432–436

Chen M, Fan G, Tan Z, Yuan C, Xiong D, Guo Q (2019) Tailoring and characterization of carbon nanotube dispersity in CNT/6061Al composites. Mater Sci Eng A 757:172–181

Rishi K, Narayanan V, Beaucage G, McGlasson A, Kuppa V, Ilavsky J (2019) A thermal model to describe kinetic dispersion in rubber nanocomposites: the effect of mixing time on dispersion. Polymer 175:272–282

Löf D, Hamieau G, Zalich M, Ducher P, Kynde S, Midtgaard SR (2020) Dispersion state of TiO2 pigment particles studied by ultra-small-angle X-ray scattering revealing dependence on dispersant but limited change during drying of paint coating. Prog Org Coat 142:105590. https://doi.org/10.1016/j.porgcoat.2020.105590

Chen K, Kang M, Lu A, Chen L, Song L, Sun R (2019) Visualization of silica dispersion states in silicone rubber by fluorescent labeling. J Mater Sci 54:5149–5159. https://doi.org/10.1007/s10853-018-03191-z

Lv X, Kang M, Chen K, Yuan L, Shen S, Sun R (2020) Preparation of fluorescent calcium carbonate and visualization of its dispersion states in polypropylene. J Compos Mater 54:913–921

Guan W, Wang S, Lu C, Tang BZ (2016) Fluorescence microscopy as an alternative to electron microscopy for microscale dispersion evaluation of organic–inorganic composites. Nat Commun 7:11811. https://doi.org/10.1038/ncomms11811

Hackley PC, Jubb AM, Burruss RC, Beaven AE (2020) Fluorescence spectroscopy of ancient sedimentary organic matter via confocal laser scanning microscopy (CLSM). Int J Coal Geol 223:103445. https://doi.org/10.1016/j.coal.2020.103445

Teng X, Li F, Lu C (2020) Visualization of materials using the confocal laser scanning microscopy technique. Chem Soc Rev 49:2408–2425

Wang C, Hao Y, Wang Y, Song H, Hussain S, Gao R (2021) Multiwall carbon nanotubes non-covalently functionalized by porphyrin–sn networks for protein adsorption. ACS Appl Nano Mater. https://doi.org/10.1021/acsanm.0c03215

Ballesteros B, de la Torre G, Ehli C, Aminur Rahman G, Agulló-Rueda F, Guldi DM (2007) Single-wall carbon nanotubes bearing covalently linked phthalocyanines photoinduced electron transfer. J Am Chem Soc 129:5061–5068

Siddiqui AS, Hayat A, Nawaz MH, Ahmad MA, Nasir M (2020) Effect of sulfur doping on graphene oxide towards amplified fluorescence quenching based ultrasensitive detection of hydrogen peroxide. Appl Surf Sci 509:144695. https://doi.org/10.1016/j.apsusc.2019.144695

Zhang M, Wang W, Wu F, Yuan P, Chi C, Zhou N (2017) Magnetic and fluorescent carbon nanotubes for dual modal imaging and photothermal and chemo-therapy of cancer cells in living mice. Carbon 123:70–83

Lorne T, Jiménez-Ruiz M, Rols S, Escudier J-M, Rubio-Zuazo J, Zbiri M (2017) Competition between covalent and non-covalent grafting of fluorescein isothiocyanate on double-walled carbon nanotubes: a quantitative approach. Carbon 123:735–743

Kumawat MK, Thakur M, Bahadur R, Kaku T, Prabhuraj R, Ninawe A (2019) Preparation of graphene oxide-graphene quantum dots hybrid and its application in cancer theranostics. Mater Sci Eng C 103:109774. https://doi.org/10.1016/j.msec.2019.109774

Ilčíková M, Danko M, Doroshenko M, Best A, Mrlík M, Csomorová K (2016) Visualization of carbon nanotubes dispersion in composite by using confocal laser scanning microscopy. Eur Polym J 79:187–197

Zhang R, Shang T, Yang G, Jia X, Cai Q, Yang X (2016) Direct fabrication of hybrid nanofibres composed of SiO2-PMMA nanospheres via electrospinning. Colloids Surf B 144:238–249

Jia X, Li W, Xu X, Li W, Cai Q, Yang X (2015) Numerical characterization of magnetically aligned multiwalled carbon nanotube–Fe3O4 nanoparticle complex. ACS Appl Mater Interfaces 7:3170–3179

Adnan MM, Tveten EG, Glaum J, Ese MHG, Hvidsten S, Glomm W (2019) Epoxy-based nanocomposites for high-voltage insulation: a review. Adv Electron Mater 5:1800505. https://doi.org/10.1002/aelm.201800505

Zhang L, Chen Z, Mao J, Wang S, Zheng Y (2020) Quantitative evaluation of inclusion homogeneity in composites and the applications. J Mater Res Technol 9:6790–6807

Luo Z, Koo JH (2007) Quantifying the dispersion of mixture microstructures. J Microsc 225:118–125

Shin JI, Cho SJ, Jeon J, Lee KH, Wie JJ (2019) Three-dimensional micropatterning of semiconducting polymers via capillary force-assisted evaporative self-assembly. Soft Matter 15:3854–3863

Jiang S, Zhao J, Förster R, Weidlich S, Plidschun M, Kobelke J (2020) Three dimensional spatiotemporal nano-scale position retrieval of the confined diffusion of nano-objects inside optofluidic microstructured fibers. Nanoscale 12:3146–3156

Sutter E, Zhang B, Sutter S, Sutter P (2019) In situ electron microscopy of the self-assembly of single-stranded DNA-functionalized Au nanoparticles in aqueous solution. Nanoscale 11:34–44

Karatrantos A, Composto RJ, Winey KI, Clarke N (2019) Nanorod diffusion in polymer nanocomposites by molecular dynamics simulations. Macromolecules 52:2513–2520

Barcia FL, Amaral TP, Soares BG (2003) Synthesis and properties of epoxy resin modified with epoxy-terminated liquid polybutadiene. Polymer 44:5811–5819

Huang Z, Ma Y, Jing W, Zhang Y, Jia X, Cai Q (2020) Tracing carbon nanotubes (CNTs) in rat peripheral nerve regenerated with conductive conduits composed of poly (lactide-co-glycolide) and fluorescent CNTs. ACS Biomater Sci Eng 6:6344–6355

Niu Y, Wang H (2019) Dielectric nanomaterials for power energy storage: surface modification and characterization. ACS Appl Nano Mater 2:627–642

Wang X, Chen D, Zhong W, Zhang L, Fan X, Cai Z (2020) Experimental and theoretical evaluations of the interfacial interaction between carbon nanotubes and carboxylated butadiene nitrile rubber: mechanical and damping properties. Mater Des 186:108318. https://doi.org/10.1016/j.matdes.2019.108318

Vryonis O, Andritsch T, Vaughan AS, Lewin PL (2020) Effect of surfactant molecular structure on the electrical and thermal performance of epoxy/functionalized-graphene nanocomposites. Polym Compos 41:2753–2767

Ren J, Yu D, Feng L, Wang G, Lv G (2017) Nanocable-structured polymer/carbon nanotube composite with low dielectric loss and high impedance. Compos Part A Appl Sci Manuf 98:66–75

Kaewsaneha C, Opaprakasit P, Polpanich D, Smanmoo S, Tangboriboonrat P (2012) Immobilization of fluorescein isothiocyanate on magnetic polymeric nanoparticle using chitosan as spacer. J Colloid Interface Sci 377:145–152

Kundelev EV, Tepliakov NV, Leonov MY, Maslov VG, Baranov AV, Fedorov AV (2019) Amino functionalization of carbon dots leads to red emission enhancement. J Phys Chem Lett 10:5111–5116

Hirata E, Yudasaka M, Ushijima N, Sakaguchi N, Maeda Y, Tanaka T (2019) Fate of Carbon Nanotubes Locally Implanted in Mice Evaluated by Near-Infrared Fluorescence Imaging: Implications for Tissue Regeneration. ACS Appl Nano Mater 2:1382–1390

Chiu CF, Dementev N, Borguet E (2011) Fluorescence quenching of dyes covalently attached to single-walled carbon nanotubes. J Phys Chem A 115:9579–9584

Yang H, Pan S, Ma D, He D, Wang Y, Xie S (2016) Light-harvesting dendrimer zinc-phthalocyanines chromophores labeled single-wall carbon nanotube nanoensembles: Synthesis and photoinduced electron transfer. J Lumin 179:588–594

Subramanian N, Rai A, Chattopadhyay A (2017) Atomistically derived cohesive behavior of interphases in carbon fiber reinforced CNT nanocomposites. Carbon 117:55–64

Cui S, Li L, Wang Q (2020) Improved molecular chain constraint of poly (propylene carbonate) composites by the synergistic effect of poly (vinyl alcohol) and carbon nanotubes. Compos B Eng 194:108074. https://doi.org/10.1016/j.compositesb.2020.108074

Imre AR (2006) Artificial fractal dimension obtained by using perimeter–area relationship on digitalized images. Appl Math Comput 173:443–449

Florio BJ, Fawell PD, Small M (2019) The use of the perimeter-area method to calculate the fractal dimension of aggregates. Powder Technol 343:551–559

Zhang J, Yang M, Mazi W, Adhikari K, Fang M, Xie F (2016) Unusual fluorescent responses of morpholine-functionalized fluorescent probes to pH via manipulation of BODIPY’s HOMO and LUMO energy orbitals for intracellular pH detection. ACS sens 1:158–165

Wang J, Liao K-S, Früchtl D, Tian Y, Gilchrist A, Alley NJ (2012) Nonlinear optical properties of carbon nanotube hybrids in polymer dispersions. Mater Chem Phys 133:992–997

Basiuk EV, Huerta L, Basiuk VA (2019) Noncovalent bonding of 3d metal (II) phthalocyanines with single-walled carbon nanotubes: a combined DFT and XPS study. Appl Surf Sci 470:622–630

Campidelli S, Sooambar C, Lozano Diz E, Ehli C, Guldi DM, Prato M (2006) Dendrimer-functionalized single-wall carbon nanotubes: synthesis, characterization, and photoinduced electron transfer. J Am Chem Soc 128:12544–12552

Zhang W, Li H, Gao L, Zhang Q, Zhong W, Sui G (2018) Molecular simulation and experimental analysis on thermal and mechanical properties of carbon nanotube/epoxy resin composites with different curing agents at high-low temperature. Polym Compos 39:E945–E954

Pimenta Teixeira K, Perdigão Rocha I, De Sá CL, Flores J, Dauer EA, Ghahremaninezhad A (2016) The effect of curing temperature on the properties of cement pastes modified with TiO2 nanoparticles. Materials 9:952. https://doi.org/10.3390/ma9110952

Charlot B, Desgarceaux R, Giani A, Bardin F (2017) PLL-FITC fluorescence thermography on dry surfaces. In: 2017 Symposium on design, test, integration and packaging of MEMS/MOEMS (DTIP)IEEE, pp 1–5

Imhof A, Megens M, Engelberts J, De Lang D, Sprik R, Vos W (1999) Spectroscopy of fluorescein (FITC) dyed colloidal silica spheres. J Phys Chem B 103:1408–1415

Ma L, Zhu Y, Feng P, Song G, Huang Y, Liu H (2019) Reinforcing carbon fiber epoxy composites with triazine derivatives functionalized graphene oxide modified sizing agent. Compos B Eng 176:107078. https://doi.org/10.1016/j.compositesb.2019.107078

Li L, Yan C, Xu H, Liu D, Shi P, Zhu Y (2019) Improving the interfacial properties of carbon fiber–epoxy resin composites with a graphene-modified sizing agent. J Appl Polym Sci 136:47122

Acknowledgements

The authors are very pleased to acknowledge financial support from Beijing Natural Science Foundation (Grant No. 2192044), National Key R&D Program of China (No. 2019YFB1504800), Fundamental Research Funds for the Central Universities (Grant No. XK1802-2), BUCT Youth Talent Plan, 2020 Open Project of State Key Laboratory of Organic-Inorganic Composites (Grant No. Oic-202001008), Consulting Research Project of Chinese Academy of Engineering (No. 2020-XY-81), National Natural Science Foundation of China (Grant No. U1362205, 5157031049, 51373016) and Natural Science Foundation of Jiangsu Province (Grant No. SBK2014040489).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work; there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Additional information

Handling Editor: Andrea de Camargo.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, C., Meng, L., Huan, X. et al. In situ characterization on macroscale 3D spatial dispersion of MWCNTs in matrix and interfacial phases of quartz fibers/epoxy composites via fluorescence imaging. J Mater Sci 56, 16399–16421 (2021). https://doi.org/10.1007/s10853-021-06350-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06350-x