Abstract

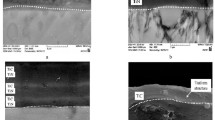

Multilayer TiZrN/TiSiN coatings were deposited on steel substrate by the cathodic-arc evaporation technique. The TiZr (75:25 at. %) and TiSi (95:5 at. %) alloy cathodes served as evaporation sources. Scanning electron microscopy with energy-dispersive spectroscopy, secondary ion mass-spectrometry, X-ray diffraction and X-ray photoelectron spectroscopy were employed to investigate the microstructure, elemental composition, phase state and bonding structure of the deposited coatings. Nanoindentation and ball-on-disk tribology tests were used to measure the mechanical and tribological features of the coatings, such as hardness, elastic modulus, toughness, friction coefficient and wear rate. The results show that all multilayers were fcc structures with a strong preferred orientation along (111) plane. The coherent growth of the multilayers contributed to the formation of the fine-grained structure with crystallites of 9.2–11.6 nm size and a low level of residual stresses of− (3.5–5.3) GPa. All multilayer coatings exhibited high hardness up to 38.2 ± 1.15 GPa and elastic modulus up to 430 ± 12.9 GPa, indicating higher resistance against plastic deformation compared to TiZrN and TiSiN films. The result of ball-on-disk wear tests showed that the multilayer sample with the best structural features (modulation period of 20.4 nm, 0.86 at. % of Si, the crystallite size of 9.2 nm and residual stress of− 3.5 GPa) demonstrated the lowest friction coefficient of 0.844 and better wear rate of 3.32·10–5 mm3/N m.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations. Data will be made available on request of the readers.

References

Uddin GM, Jawad M, Ghufran M (2019) Experimental investigation of tribo-mechanical and chemical properties of TiN PVD coating on titanium substrate for biomedical implants manufacturing. Int J Adv Manuf Technol 102:1391–1404. https://doi.org/10.1007/s00170-018-03244-2

Yeh TS, Wu JM, Hu LJ (2008) The properties of TiN thin films deposited by pulsed direct current magnetron sputtering. Thin Solid Films 516:7294–7298. https://doi.org/10.1016/j.tsf.2008.01.001

Mubarak A, Akhter P, Hamzah E et al (2008) Effect of coating thickness on the properties of TiN coatings deposited on tool steels using cathodic arc pvd technique. Surf Rev Lett 15:104–410. https://doi.org/10.1142/S0218625X08011524

Veprek S, Veprek-Heijman MGJ, Karvankova P, Prochazka J (2005) Different approaches to superhard coatings and nanocomposites. Thin Solid Films 476:1–29. https://doi.org/10.1016/j.tsf.2004.10.053

Cheng YH, Browne T, Heckerman B, Meletis EI (2010) Mechanical and tribological properties of nanocomposite TiSiN coatings. Surf Coatings Technol 204:2123–2129. https://doi.org/10.1016/j.surfcoat.2009.11.034

Hasegawa H, Kimura A, Suzuki T (2000) Microhardness and structural analysis of (Ti, Al)N, (Ti, Cr)N, (Ti, Zr)N and (Ti, V)N films. J Vac Sci Technol A Vacuum, Surfaces, Film 18:1038. https://doi.org/10.1116/1.582296

Lin YW, Huang GH, Yu GP (2010) Microstructure and corrosion resistance of nanocrystalline TiZrN filmson AISI 304 stainless steel substrate. J Vac Sci Technol A 25:774–778. https://doi.org/10.1116/1.3305963

Pogrebnjak AD, Bagdasaryan AA, Yakushchenko IV, Beresnev VM (2014) The structure and properties of high-entropy alloys and nitride coatings based on them. Russ Chem Rev 83:1027–1061. https://doi.org/10.1070/rcr4407

Maksakova OV, Simoẽs S, Pogrebnjak AD et al (2019) Multilayered ZrN/CrN coatings with enhanced thermal and mechanical properties. J Alloys Compd 776(2019):679–690. https://doi.org/10.1016/j.jallcom.2018.10.342

Maksakova OV, Webster RF, Tilley RD et al (2020) Nanoscale architecture of (CrN/ZrN)/(Cr/Zr) nanocomposite coatings: Microstructure, composition, mechanical properties and first-principles calculations. J Alloys Compd 831:154808. https://doi.org/10.1016/j.jallcom.2020.154808

Kurbatov D, Opanasyuk A, Khlyap H (2009) Substrate-temperature effect on the microstructural and optical properties of ZnS thin films obtained by close-spaced vacuum sublimation. Phys Status Solidi Appl Mater Sci 206:1549–1557. https://doi.org/10.1002/pssa.200824472

Voznyi A, Kosyak V, Opanasyuk A et al (2016) Structural and electrical properties of SnS2 thin films. Mater Chem Phys 173:52–61. https://doi.org/10.1016/j.matchemphys.2016.01.036

Zukowski P, Koltunowicz TN, Bondariev V et al (2016) Determining the percolation threshold for (FeCoZr)x(CaF2)(100–x) nanocomposites produced by pure argon ion-beam sputtering. J Alloys Compd 683:62–66. https://doi.org/10.1016/j.jallcom.2016.05.070

Bagdasaryan AA, Pshyk AV, Coy LE et al (2018a) Structural and mechanical characterization of (TiZrNbHfTa)N/WN multilayered nitride coatings. Mater Lett 229:364–367. https://doi.org/10.1016/j.matlet.2018.07.048

Bagdasaryan AA, Pshyk AV, Coy LE et al (2018b) A new type of (TiZrNbTaHf)N/MoN nanocomposite coating: microstructure and properties depending on energy of incident ions. Compos Part B Eng 146:132–144. https://doi.org/10.1016/j.compositesb.2018.04.015

Pogrebnyak AD, Shpak AP, Azarenkov NA, Beresnev VM (2009) Structures and properties of hard and superhard nanocomposite coatings. Phys Usp 52:29–54. https://doi.org/10.3367/ufne.0179.200901b.0035

Barshilia HC, Deepthi B, Rajam KS (2010) Transition metal nitride-based nanolayered multilayer coatings and nanocomposite coatings as novel superhard materials. In: Zhang S (ed) Nanostructured thin films and coatings: mechanical properties. CRC Press, Boca Raton, рр 427–481. https://doi.org/10.1201/b11764

Jehn HA (2000) Multicomponent and multiphase hard coatings for tribological applications. Surf Coat Technol 131:433–440. https://doi.org/10.1016/S0257-8972(00)00783-0

Khadem M, Penkov OV, Yang HK, Kim DE (2017) Tribology of multilayer coatings for wear reduction: a review. Friction 5:248–262. https://doi.org/10.1007/s40544-017-0181-7

Maksakova OV, Pogrebnjak OD, Beresnev VM (2018) Features of investigations of multilayer nitride coatings based on Cr and Zr. Prog Phys Met 19:25–48. https://doi.org/10.15407/ufm.19.01.025

Sadki ES, Barber ZH, Lloyd SJ et al (2000) Effects of interlayer coupling on the irreversibility lines of NbN/AlN superconducting multilayers. Phys Rev Lett 85:4168–4171. https://doi.org/10.1103/PhysRevLett.85.4168

Pogrebnjak AD, Bondar OV, Abadias G et al (2016) Structural and mechanical properties of NbN and Nb-Si-N films: experiment and molecular dynamics simulations. Ceram Int 42:11743–11756. https://doi.org/10.1016/j.ceramint.2016.04.095

Pogrebnjak A, Smyrnova K, Bondar O (2019) Nanocomposite multilayer binary nitride coatings based on transition and refractory metals: structure and properties. Coatings 9:155. https://doi.org/10.3390/coatings9030155

Smallman RE, Ngan AHW (2014) Surfaces Grain Boundaries and Interfaces. Modern Physical Metallurgy. Elsevier, Amsterdam, pp 415–442

Makhlouf ASH (2014) Handbook of smart coatings for materials protection. Elsevier Inc, Amsterdam

Hansen N (2004) Hall-petch relation and boundary strengthening. Scr Mater 51:801–806. https://doi.org/10.1016/j.scriptamat.2004.06.002

Wan H, Shen Y, Jin X et al (2012) Effects of coherency stress and vacancy sources/sinks on interdiffusion across coherent multilayer interfaces - Part II: interface sharpening and intermixing rate. Acta Mater 60:2539–2553. https://doi.org/10.1016/j.actamat.2012.01.022

Pogrebnjak AD, Ivashchenko VI, Skrynskyy PL et al (2018) Experimental and theoretical studies of the physicochemical and mechanical properties of multi-layered TiN/SiC films: temperature effects on the nanocomposite structure. Compos Part B Eng 142:85–94. https://doi.org/10.1016/j.compositesb.2018.01.004

Kravchenko YO, Coy LE, Peplińska B et al (2018) Nano-multilayered coatings of (TiAlSiY)N/MeN (Me=Mo, Cr and Zr): influence of composition of the alternating layer on their structural and mechanical properties. J Alloys Compd 767:483–495. https://doi.org/10.1016/j.jallcom.2018.07.090

Stueber M, Holleck H, Leiste H et al (2009) Concepts for the design of advanced nanoscale PVD multilayer protective thin films. J Alloys Compd 483:321–333. https://doi.org/10.1016/j.jallcom.2008.08.133

Boing D, de Oliveira AJ, Schroeter RB (2018) Limiting conditions for application of PVD (TiAlN) and CVD (TiCN/Al2O3/TiN) coated cemented carbide grades in the turning of hardened steels. Wear 416:54–61. https://doi.org/10.1016/j.wear.2018.10.007

Wang T, Zhang G, Jiang B (2015) Microstructure, mechanical and tribological properties of TiMoN/Si3N4 nano-multilayer films deposited by magnetron sputtering. Appl Surf Sci 326:162–167. https://doi.org/10.1016/j.apsusc.2014.11.125

Chang YY, Chang H, Jhao LJ, Chuang CC (2018) Tribological and mechanical properties of multilayered TiVN/TiSiN coatings synthesized by cathodic arc evaporation. Surf Coat Technol 350:1071–1079. https://doi.org/10.1016/j.surfcoat.2018.02.040

Pogrebnjak AD, Beresnev VM, Smyrnova KV et al (2018) The influence of nitrogen pressure on the fabrication of the two-phase superhard nanocomposite (TiZrNbAlYCr)N coatings. Mater Lett 211:316–318. https://doi.org/10.1016/j.matlet.2017.09.121

Ward L, Pilkington A, Dowey S (2017) Studies on the effect of arc current mode and substrate rotation configuration on the structure and corrosion behavior of PVD TiN coatings. Coatings 7:50. https://doi.org/10.3390/coatings7040050

Gilewicz A, Warcholinski B (2015) Deposition and characterisation of Mo2N/CrN multilayer coatings prepared by cathodic arc evaporation. Surf Coat Technol 279:126–133. https://doi.org/10.1016/j.surfcoat.2015.08.042

Pogrebnjak AD, Kong CH, Webster RF et al (2019) Antibacterial effect of au implantation in ductile nanocomposite multilayer (TiAlSiY)N/CrN coatings. ACS Appl Mater Interfaces 11:48540–48550. https://doi.org/10.1021/acsami.9b16328

Pogrebnjak A, Maksakova O, Kozak C et al (2016) Physical and mechanical properties of nanostructured (Ti-Zr-Nb)N coatings obtained by vacuum-arc deposition method. Prz Elektrotechniczny 2016:180–183. https://doi.org/10.15199/48.2016.08.49

Noyan IC, Cohen JB (1987) Residual Stress Measurement by Diffraction and Interpretation. Springer Verlag, New York

Shirley DA (1972) High-resolution x-ray photoemission spectrum of the valence bands of gold. Phys Rev B 5:4709. https://doi.org/10.1103/PhysRevB.5.4709

Engberg D (2015) Atom probe tomography of TiSiN thin films. Linköping University Electronic Press, Linköping

Pshyk AV, YaO K, Coy LE et al (2018) Microstructure, phase composition and mechanical properties of novel nanocomosite (TiAlSiY)N and nano-scale multilayer (TiAlSiY)N/MoN functional coatings. Surf Coat Technol 350:376–390. https://doi.org/10.1016/j.surfcoat.2018.07.010

Gates-Rector SD, Blanton TN (2019) The powder diffraction file: a quality materials characterization database. Powder Diffr 34:352–360. https://doi.org/10.1017/S0885715619000812

Hoerling A, Sjölén J, Willmann H et al (2008) Thermal stability, microstructure and mechanical properties of Ti1-xZrxN thin films. Thin Solid Films 516:6421–6431. https://doi.org/10.1016/j.tsf.2007.12.133

Martin PM (2010) Handbook of deposition technologies for films and coatings. Elsevier Inc, Amsterdam

Zukowski P, Kołtunowicz T, Partyka J et al (2009) Electrical properties of nanostructures (CoFeZr)x+(Al2O3)1–x with use of alternating current. Vacuum 83:S275–S279. https://doi.org/10.1016/j.vacuum.2009.01.081

Kołtunowicz TN, Zhukowski P, Fedotov AK et al (2013) Influence of matrix type on negative capacitance effect in nanogranular composite films FeCoZr-insulator. Elektron ir Elektrotechnika 19:37–40. https://doi.org/10.5755/j01.eee.19.4.1693

Xu Y, Li L, Cai X, Chu PK (2007) Hard nanocomposite Ti-Si-N films prepared by DC reactive magnetron sputtering using Ti-Si mosaic target. Surf Coat Technol 201:6824–6827. https://doi.org/10.1016/j.surfcoat.2006.09.078

Vepřek S, Reiprich S (1995) A concept for the design of novel superhard coatings. Thin Solid Films 268:64–71. https://doi.org/10.1016/0040-6090(95)06695-0

Lin YW, Huang JH, Cheng WJ, Yu GP (2018) Effect of Ti interlayer on mechanical properties of TiZrN coatings on D2 steel. Surf Coat Technol 350:745–754. https://doi.org/10.1016/j.surfcoat.2018.04.077

Vaz F, Rebouta L, Goudeau P et al (2000) Characterization of Ti1-xSixNy nanocomposite films. Surf Coat Technol 133–134:307–313. https://doi.org/10.1016/S0257-8972(00)00947-6

Bhowmick S, Kale AN, Jayaram V, Biswas SK (2003) Contact damage in TiN coatings on steel. Thin Solid Films 436:250–258. https://doi.org/10.1016/S0040-6090(03)00598-4

Leyland A, Matthews A (2000) On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246:1–11. https://doi.org/10.1016/S0043-1648(00)00488-9

Komarov FF, Konstantinov VM, Kovalchuk AV et al (2016) The effect of steel substrate pre-hardening on structural, mechanical, and tribological properties of magnetron sputtered TiN and TiAlN coatings. Wear 352:92–101. https://doi.org/10.1016/j.wear.2016.02.007

Musil J, Jirout M (2007) Toughness of hard nanostructured ceramic thin films. Surf Coat Technol 201:5148–5152. https://doi.org/10.1016/j.surfcoat.2006.07.020

Ou YX, Lin J, Tong S et al (2016) Structure, adhesion and corrosion behavior of CrN/TiN superlattice coatings deposited by the combined deep oscillation magnetron sputtering and pulsed dc magnetron sputtering. Surf Coat Technol 293:21–27. https://doi.org/10.1016/j.surfcoat.2015.10.009

Zhang S, Wang HL, Ong SE et al (2007) Hard yet tough nanocomposite coatings - present status and future trends. Plasma Process Polym 4:219–228. https://doi.org/10.1002/ppap.200600179

Kravchenko Y, Maksakova O, Drodziel P, Loboda V (2016) Effect of thermal annealing and deposition conditions on the structure and mechanical properties of a multilayer nitride coating based on Ta. High Temp Mater Process 20:85–92. https://doi.org/10.1615/HighTempMatProc.2016017252

Acknowledgements

This project was financially supported by the state budget programs of Ukraine, Grants No. 0118U003579 and No. 0119U100787. Furthermore, the project was financed in the framework of the project Lublin University of Technology regional Excellence imitative funded by Polish Ministry of Science and High Education (contract /030/RD/2018,2019).

Author information

Authors and Affiliations

Contributions

OVM helped in writing, reviewing and editing, SZ and SVP helped in data curation, PK helped in conceptualization, YOK and PB helped in data acquisition, investigation, ADP helped in supervision, VMB and BOM helped in resources, NAM and AIK helped in formal analysis.

Corresponding author

Ethics declarations

Conflict of interest

The author declares that she has no conflict of interest.

Additional information

Handling Editor: Joshua Tong.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maksakova, O.V., Zhanyssov, S., Plotnikov, S.V. et al. Microstructure and tribomechanical properties of multilayer TiZrN/TiSiN composite coatings with nanoscale architecture by cathodic-arc evaporation. J Mater Sci 56, 5067–5081 (2021). https://doi.org/10.1007/s10853-020-05606-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05606-2