Abstract

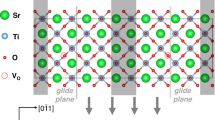

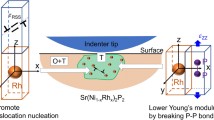

Understanding the irreversible deformation (dislocation activation and crack formation) of functional oxides, based on which various advanced electronic devices are fabricated, is critical for the optimal structural design and mechanical reliability. Here, we demonstrate the dislocation-based crack initiation and propagation in a model perovskite, single-crystal SrTiO3, at small scale. Using nanoindentation tests with spherical tips and etch pit study, we identify the sequence of the irreversible deformation events occurred in single-crystal (001) SrTiO3. For a locally stressed volume that is free of pre-existing cracks, the material undergoes the following processes: (1) purely elastic deformation; (2) dislocation activation on primary slip planes that are 45° inclined to the surface; (3) dislocation activation on secondary slip planes perpendicular to the surface; (4) crack initiation by dislocation pile-up; followed by (5) concurrent crack propagation and dislocation multiplication and motion at higher loads. Specifically, we focus on the crack formation caused by the dislocation pile-up beneath the spherical indenter. We also identify the favorable crack propagation planes to be {110} when the (001) surface is indented. These findings in cubic SrTiO3 are believed to be applicable for other ceramic materials with cubic structure.

Similar content being viewed by others

References

Nakamura A, Matsunaga K, Tohma J, Yamamoto T, Ikuhara Y (2003) Conducting nanowires in insulating ceramics. Nat Mater 2(7):453–456

Ikuhara Y (2009) Nanowire design by dislocation technology. Prog Mater Sci 54(6):770–791

Szot K, Speier W, Bihlmayer G, Waser R (2006) Switching the electrical resistance of individual dislocations in single-crystalline SrTiO3. Nat Mater 5(4):312–320

Sun B, Haunschild G, Polanco C, Ju JZ, Lindsay L, Koblmuller G, Koh YK (2019) Dislocation-induced thermal transport anisotropy in single-crystal group-III nitride films. Nat Mater 18(2):136–140

Khafizov M, Pakarinen J, He L, Hurley DH (2019) Impact of irradiation induced dislocation loops on thermal conductivity in ceramics. J Am Ceram Soc 102:7533–7542

Kim SI, Lee KH, Amun H, Kim HS, Hwang SW, Roh JW, Yang DJ, Shin WH, Li XS, Lee YH, Snyder GJ, Kim SW (2015) Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 348:109–114

Ren P, Höfling M, Koruza J, Lauterbach S, Jiang X, Frömling T, Khatua DK, Dietz C, Porz L, Ranjan R, Kleebe HJ, Rödel J (2019) High temperature creep-mediated functionality in polycrystalline barium titanate. J Am Ceram Soc 103:1891–1902

Di Maio D, Roberts SG (2005) Measuring fracture toughness of coatings using focused-ion-beam-machined microbeams. J Mater Res 20(02):299–302

Jaya BN, Kirchlechner C, Dehm G (2015) Can microscale fracture tests provide reliable fracture toughness values? A case study in silicon. J Mater Res 30(05):686–698

Uchic MD, Dimiduk DM, Florando JN, Nix WD (2004) Sample dimensions influence strength and crystal plasticity. Science 305:986

Li J, Wang H, Zhang X (2019) Nanoscale stacking fault–assisted room temperature plasticity in flash-sintered TiO2. Sci Adv 5:eaaw5519

Fang X, Rasinski M, Kreter A, Kirchlechner C, Linsmeier C, Dehm G, Brinckmann S (2019) Plastic deformation of tungsten due to deuterium plasma exposure: Insights from micro-compression tests. Scripta Mater 162:132–135

Ghidelli M, Sebastiani M, Johanns KE, Pharr GM (2017) Effects of indenter angle on micro-scale fracture toughness measurement by pillar splitting. J Am Ceram Soc 100(12):5731–5738

Bruns S, Petho L, Minnert C, Michler J, Durst K (2019) Fracture toughness determination of fused silica by cube corner indentation cracking and pillar splitting. Mater Des. https://doi.org/10.1016/j.matdes.2019.108311

Sebastiani M, Johanns KE, Herbert EG, Carassiti F, Pharr GM (2014) A novel pillar indentation splitting test for measuring fracture toughness of thin ceramic coatings. Phil Mag 95(16–18):1928–1944

Lodes MA, Hartmaier A, Göken M, Durst K (2011) Influence of dislocation density on the pop-in behavior and indentation size effect in CaF2 single crystals: Experiments and molecular dynamics simulations. Acta Mater 59(11):4264–4273

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(6):1564–1583

Freund LB, Suresh S (2003) Thin film materials-Stress, Defect formation and surface evolution. Cambridge University Press, Cambridge

Fang X, Kreter A, Rasinski M, Kirchlechner C, Brinckmann S, Linsmeier C, Dehm G (2018) Hydrogen embrittlement of tungsten induced by deuterium plasma: Insights from nanoindentation tests. J Mater Res 33(20):3530–3536

Schuh CA, Mason JK, Lund AC (2005) Quantitative insight into dislocation nucleation from high-temperature nanoindentation experiments. Nat Mater 4(8):617–621

Mason JK, Lund AC, Schuh CA (2006) Determining the activation energy and volume for the onset of plasticity during nanoindentation. Phys Rev B 73(5):054102

Gao Y, Bei H (2016) Strength statistics of single crystals and metallic glasses under small stressed volumes. Prog Mater Sci 82:118–150

Johnston WG (1960) An observation of crack formation in MgO. Phil Mag 5(52):407–408

Ku RC, Johnston TL (1964) Fracture strength of MgO bicrystals. Phil Mag 9(98):231–247

Swain MV, Lawn BR (1969) A study of dislocation arrays at spherical indentations in LiF as a function of indentation stress and strain. Phys Stat Sol 35:909–923

Hagan JT (1979) Micromechanics of crack nucleation during indentations. J Mater Sci 14:1975–2980. https://doi.org/10.1007/BF00611482

Lewin M, Baeumer C, Gunkel F, Schwedt A, Gaussmann F, Wueppen J, Meuffels P, Jungbluth B, Mayer J, Dittmann R, Waser R, Taubner T (2018) Nanospectroscopy of infrared phonon resonance enables local quantification of electronic properties in doped SrTiO3 ceramics. Adv Func Mater 28(42):1802834

Heisig T, Baeumer C, Gries UN, Mueller MP, La Torre C, Luebben M, Raab N, Du H, Menzel S, Mueller DN, Jia CL, Mayer J, Waser R, Valov I, De Souza RA, Dittmann R (2018) Oxygen exchange processes between oxide memristive devices and water molecules. Adv Mater 30(29):1800957

Taeri S, Brunner D, Sigle W, Rühle M (2004) Deformation behaviour of strontium titanate between room temperature and 1800 K under ambient pressure. Z Mettllkd 95(6):433

Gumbsch P, Taeri-Baghbadrani S, Brunner D, Sigle W, Ruhle M (2001) Plasticity and an inverse brittle-to-ductile transition in strontium titanate. Phys Rev Lett 87(8):085505

Patterson EA, Major M, Donner W, Durst K, Webber KG, Rodel J (2016) Temperature-dependent deformation and dislocation density in SrTiO3 (001) single crystals. J Am Ceram Soc 99(10):3411–3420

Fang X, Ding K, Janocha S, Minnert C, Rheinheimer W, Frömling T, Durst K, Nakamura A, Rödel J (2020) Nanoscale to microscale reversal in room-temperature plasticity in SrTiO3 by tuning defect concentration. Scripta Mater 188:228–232

Fang X, Porz L, Ding K, Nakamura A (2020) Bridging the gap between bulk compression and indentation test on room-temperature plasticity in oxides: case study on SrTiO3. Crystals https://doi.org/10.3390/cryst10100933

Javaid F, Stukowski A, Durst K (2017) 3D Dislocation structure evolution in strontium titanate: spherical indentation experiments and MD simulations. J Am Ceram Soc 100(3):1134–1145

Javaid F, Johanns KE, Patterson EA, Durst K (2018) Temperature dependence of indentation size effect, dislocation pile-ups, and lattice friction in (001) strontium titanate. J Am Ceram Soc 101(1):356–364

Javaid F, Bruder E, Durst K (2017) Indentation size effect and dislocation structure evolution in (001) oriented SrTiO3 Berkovich indentations: HR-EBSD and etch-pit analysis. Acta Mater 139:1–10

Kondo S, Mitsuma T, Shibata N, Ikuhara Y (2016) Direct observation of individual dislocation interaction processes with grain boundary. Sci Adv 2:e1501926

Shim S, Bei H, George EP, Pharr GM (2008) A different type of indentation size effect. Scripta Mater 59(10):1095–1098

Bei H, Xia YZ, Barabash RI, Gao YF (2016) A tale of two mechanisms: Strain-softening versus strain-hardening in single crystals under small stressed volumes. Scripta Mater 110:48–52

Gaillard Y, Tromas C, Woirgard J (2010) Pop-in phenomenon in MgO and LiF: Observation of dislocation structures. Philos Mag Lett 83(9):553–561

Tromas C, Gaillard Y, Woirgard J (2006) Nucleation of dislocations during nanoindentation in MgO. Phil Mag 86(33–35):5595–5606

Gaillard Y, Tromas C, Woirgard J (2003) Study of the dislocation structure involved in a nanoindentation test by atomic force microscopy and controlled chemical etching. Acta Mater 51(4):1059–1065

Li W, Bei H, Qu J, Gao Y (2013) Effects of machine stiffness on the loading–displacement curve during spherical nano-indentation. J Mater Res 28(14):1903–1911

Johnson KL (1985) Contact Mechanics. Cambridge University Press, Cambridge, London

Lawn BR, Cook RF (2011) Probing material properties with sharp indenters: a retrospective. J Mater Sci 47(1):1–22. https://doi.org/10.1007/s10853-011-5865-1

Morris JR, Bei H, Pharr GM, George EP (2011) Size effects and stochastic behavior of nanoindentation pop in. Phys Rev Lett 106(16):165502

Wachtman JB, Cannon WR, Matthewson MJ (2009) Mechanical properties of ceramics. Wiley, Hoboken

Moon W-J, Saka H (2000) Toughening of a brittle material by means of dislocation subboundaries. Philos Mag Lett 80(7):461–466

Moon W-J, Ito T, Uchimura S, Saka H (2004) Toughening of ceramics by dislocation sub-boundaries. Mater Sci Eng A 387–389:837–839

Xu G, Argon AS, Ortiz M (1997) Critical configurations for dislocation nucleation from crack tips. Philos Mag A 75(2):341–367

Meyer K, Gragert E (1964) Deformations- und RiBstrukturen in NaCl-Kristallen bei der StoBbearbeitung. Phys Stat Sol 6:803–815

Stroh AN (1957) A theory of the fracture of metals. Adv Phys 6(24):418–465

Koehler JS (1952) The production of large tensile stresses by dislocations. Phys Rev 85(3):480–481

Zener C (1948) The micro-mechanism of fracture, Fracturing of metals. Cleveland, American Society for Metals , Cleveland, pp 3–31

Stroh AN (1954) The formation of cracks as a result of plastic flow. Proc R Soc A Math Phys Eng Sci 223:404–414

Stroh AN (1955) The Formation of Cracks in Plastic Flow II. Proc R Soc A Math Phys Eng Sci 232:548–560

Xiao ZM, Chen BJ (2001) Stress analysis for a Zener-Stroh crack interacting with a coated inclusion. Int J Solids Struct 38:5007–5018

Fan H, Xiao ZM (1997) A Zener-Stroh crack near an interface. Int J Solids Struct 34(22):2829–2842

Zhang Y, Ma L (2019) Surface Zener-Stroh crack model to slip band due to contact. Arch Appl Mech 90(2):221–234

Woo S, Jeong H, Lee SA, Seo H, Lacotte M, David A, Kim HY, Prellier W, Kim Y, Choi WS (2015) Surface properties of atomically flat poly-crystalline SrTiO3. Sci Rep 5:8822

Lathabai S, Rödel J, Dabbs T, Lawn BR (1991) Fracture mechanics model for subthreshold indentation flaws: Part I Equilibrium fracture. J Mater Sci 26:2157–2168. https://doi.org/10.1007/BF00549183

Hagan JT (1980) Shear deformation under pyramidal indentations in soda-lime glass. J Mater Sci 15:1417–1424. https://doi.org/10.1007/BF00752121

Swain MV, Hagan JT (1976) Indentation plasticity and the ensuing fracture of glass. J Phys D Appl Phys 9:2201

Basu S, Barsoum MW, Kalidindi SR (2006) Sapphire: a kinking nonlinear elastic solid. J Appl Phys 99(6):063501

Barsoum MW, Murugaiah A, Kalidindi SR, Zhen T (2004) Kinking nonlinear elastic solids, nanoindentations, and geology. Phys Rev Lett 92:255508

Lawn B (1993) Fracture of brittle solids. Cambridge University Press, Cambridge

Anderson TL (2005) Fracture Mechanics_Fundamentals and Applications. CRC Press, New York

Frank FC, Lawn BR (1967) On the theory of Hertzian fracture. Proc R Soc A Math Phys Eng Sci 299:291–307

Weertman J (1996) Dislocation based Fracture Mechanics. World Scientific Publishing Co Pte Ltd, New York

Sudharshan Phani P, Oliver WC (2020) Critical examination of experimental data on strain bursts (pop-in) during spherical indentation. J Mater Res. https://doi.org/10.1557/jmr.2019.416

Acknowledgements

X. Fang gratefully acknowledges the financial support of Athene Young Investigator Programme (TU Darmstadt) and the Deutsche Forschungsgemeinschaft (DFG, No. 414179371). K. Ding thanks the DFG for financial support (FA 1662/1-1). K. Durst thanks the DFG for financial support (DU 424/11-1). A. Nakamura acknowledges the financial support of JST PRESTO Grant Number JPMJPR199A and JSPS KAKENHI Grant Numbers JP19H05786, JP17H06094 and JP18H03840, Japan. We thank Prof. J. Rödel for the helpful discussion and comments. The helpful comments from the anonymous reviewers are also gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Shen Dillon.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fang, X., Ding, K., Minnert, C. et al. Dislocation-based crack initiation and propagation in single-crystal SrTiO3. J Mater Sci 56, 5479–5492 (2021). https://doi.org/10.1007/s10853-020-05587-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05587-2