Abstract

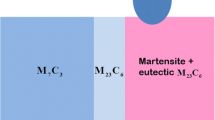

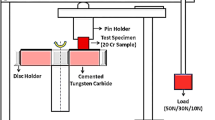

As a category of crucial wear-resistant alloys, high-chromium cast irons (HCCIs) are widely used in mining, minerals and cementation industries. The large volume fraction of coarse primary M7C3 carbides (PC) imparts excellent wear resistance. However, coarse carbides also induce brittleness, resulting in high cracking susceptibility, and early failure of components, particularly under impact. To minimize the brittleness and increase the service life of HCCI parts, different techniques have been developed through modifying the carbide morphology and refining its size. This paper comprehensively reviews the currently available methods that have either been used in industry production or in laboratory development to modify the primary M7C3 carbides in various HCCIs. The possible mechanisms that govern the refinement of primary carbides are also discussed in-depth. Based on previously published work, the mechanical performance of HCCIs is correlated with the microstructure of the matrix, and with the size, shape, volume fraction and distribution of primary carbides. This may provide solid fundamental to develop more effective techniques and/or new alloys to further improve the properties of this type of materials, increasing their engineering service life and to tailor their wider applications. In addition, the present work also seeks theoretical feasibility to apply the recently well-established theories/models of grain refinement for cast metals to refinement of the primary carbides in HCCIs.

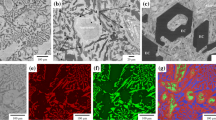

Adapted with permission from reference [42]. Copyright 2012, The Iron and Steel Institute of Japan

Adapted with permission from reference [40]. Copyright 2012, Taylor & Francis

Adapted with permission from reference [43]. Copyright 1996, Taylor & Francis

Adapted with permission from reference [46]. Copyright 2012, Trans Tech Publications

Adapted with permission from reference [47]. Copyright 2019, MDPI

Adapted with permission from reference [47]. Copyright 2019, MDPI

Adapted with permission from reference [47]. Copyright 2019, MDPI

Adapted with permission from reference [64]. Copyright 2010, Trans Tech Publications

Adapted with permission from reference [78]. Copyright 2012, The Iron and Steel Institute of Japan

Adapted with permission from reference [93]. Copyright 2009, Springer Nature

Adapted with permission from reference [116]. Copyright 2014, Elsevier

Adapted with permission from reference [42]. Copyright 2012, The Iron and Steel Institute of Japan

Adapted with permission from reference [125]. Copyright 2008, Elsevier

Adapted with permission from reference [150]. Copyright 2014, The Japan Institute of Metals and Materials

Adapted with permission from reference [150]. Copyright 2014, The Japan Institute of Metals and Materials

Adapted with permission from reference [95]. Copyright 2014, Elsevier

Adapted with permission from reference [129]. Copyright 2013, Elsevier

Adapted with permission from reference [178]. Copyright 1954, Metals Park, Ohio, American Society for Metals

Adapted with permission from reference [185]. Copyright 1977, American Foundrymen’s Society

Adapted with permission from reference [43]. Copyright 1996, Taylor & Francis

Adapted with permission from reference [43]. Copyright 1996, Taylor & Francis

Adapted with permission from reference [167]. Copyright 2011, Elsevier

Adapted with permission from reference [219]. Copyright 2006, Springer Nature

Similar content being viewed by others

References

Read JA (1970) The effects of aluminum and manganese on the structure and properties of cast iron

George L, Richard G, Klaus R (2000) Abrasion-resistant cast iron handbook. American Foundry Society, Illinois

Sare IR, Arnold BK (1995) The effect of heat treatment on the gouging abrasion resistance of alloy white cast irons. Metall Mater Trans A 1995(26A):357–370

K.H. Andrews, A.R.M.I.T., M.I.B.F (1972) Cast Wear-Resistant Materials for the Mining Industry. Inst. British Foundrymen, Australian Branch, 23:75–93.

Liu H-N, Sakamoto M, Nomura M, Ogi K (2001) Abrasion resistance of high Cr cast irons at an elevated temperature. Wear 250:71–75

Powell GLF, Laird II G (1992) Structure, nucleation, growth and morphology of secondary carbides in high chromium and Cr-Ni white cast irons. J Mater Sci 27:29–35. https://doi.org/10.1007/BF00553833

Porter DA, Easterling KE (2009) Phase transformations in metals and alloys (revised reprint). CRC press

Tabrett CP, Sare IR, Ghomashchi MR (1996) Microstructure-property relationships in high chromium white iron alloys. Int Mater Rev 41:59–82

Anon, Cast Iron- A review of recent developments. Eng Mater Des, 1978. 22(3): 60–65.

Becket FM (1916) Alloy. Electro Metallurgical Co, US

Zum Gahr KH, Scholz WG (1980) Fracture toughness of white cast irons. J Metals 32:38–44

Wiengmoon A et al (2005) Microstructural and crystallographical study of carbides in 30wt.%Cr cast irons. Acta Mater 53(15):4143–4154. https://doi.org/10.1016/j.actamat.2005.05.019

Coronado JJ (2011) Effect of (Fe, Cr)7C3 carbide orientation on abrasion wear resistance and fracture toughness. Wear 270(3–4):287–293. https://doi.org/10.1016/j.wear.2010.10.070

Filipovic M, Romhanji E, Kamberovic Z (2012) Chemical composition and morphology of M7C3 eutectic carbide in high chromium white cast iron alloyed with vanadium. ISIJ Int 52(12):2200–2204. https://doi.org/10.2355/isijinternational.52.2200

Tabrett CP, Sare IR (2000) Fracture toughness of high-chromium white irons- Influence of cast structure. J Mater Sci 35:2069–2077. https://doi.org/10.1023/A:1004755511214

Lu L, Soda H, McLean A (2003) Microstructure and mechanical properties of Fe-Cr-C eutectic composites. Mater Sci Eng A 347:214–222

Hongsug OH, Lee S, Jung J-Y, Ahn S (2001) Correlation of microstructure with the wear resistance and fracture toughness of duocast materials composed of high-chromium white cast iron and low-chromium steel. Metall Mater Trans A 32A:515–524

Adachi Y, Hakata K, Tsuzaki K (2005) Crystallographic analysis of grain boundary Bcc-precipitates in a Ni–Cr alloy by FESEM/EBSD and TEM/Kikuchi line methods. Mater Sci Eng A 412(1–2):252–263. https://doi.org/10.1016/j.msea.2005.09.033

Laird G, Nielsen RL, MacMillan NH (1991) On the nature of eutectic carbides in Cr-Ni white cast irons. Metall Trans A 22A:1709–1719

Neville A, Reza F, Chiovelli S, Revega T (2006) Characterization and corrosion behavior of high-chromium white cast irons. Metall Mater Trans A 37A:2339–2347

Maratray FF (1971) Choice of appropriate compositions for chromium-molybdenum white irons. Trans Am Foundrymen’s Soc 79:121–124

Standard AS. E963 (2010) Standard practice for electrolytic extraction of phases from Ni and Ni-Fe base superalloys using a hydrochloric-methanol electrolyte. ASTM International, West Conshohocken

Xu ML (2012), Secondary carbide dissolution and coarsening in 13% Cr martensitic stainless steel during austenitizing. In: Department of Mechanical and Industrial Engineering. Northeastern Univeristy, Boston, Massachusetts.

Dogan ÖN, Hawk JA, Laird II G (1997) Solidification structure and abrasion resistance of high chromium white irons. Metall Mater Trans A 28A:1315–1328

Kitaigora NI (1975) Impact-abrasion wear resistance of high-chromium cast iron. Met Sci Heat Treat 17(5–6):417–420

Hebbar BM, Seshan S (1994) Fracture toughness of high-chromium cast irons. In: AFS Transactions pp. 349–356

Adler TA, Dogan ON (2002) Erosive wear and impact damage of high-Cr white cast irons. AFS Transactions 110:495–500

Adler TA, Dogan ON (1999) Erosive wear and impact damage of high-chromium white cast irons. Wear 225–229:174–180

Magnée A (1995) Generalised law of erosion: application to various alloys and intermetallics. Wear 181:500–510

ASTM International. E604-18 (2018) Standard test method for dynamic tear testing of metallic materials. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/E0604-18

Fulcher JK, Kosel TH, Fiore NF (1983) The effect of carbide volume fraction on the low stress abrasion resistance of high Cr-Mo white cast irons. Wear 84:313–325

Svensson LE, Gretoft B, Ulander B, Bhadeshia HKDH (1986) Fe-Cr-C hardfacing alloys for high-temperature applications. J Mater Sci 21:1015–1019. https://doi.org/10.1007/BF01117388

Atamert S, Bhadeshia HKDH (1990) Silicon modification of iron base hardfacing alloys. In: David A, Vitek JM (eds) Recent trends in welding science and technology (TWR'89). Materials Park, Ohio, pp 273–278

Norman TE (1985) Abrasion resistant refrigeration hardenable ferrous alloys. US4547221A

Hornung J, Zikin A, Pichelbauer K, Kalin M, Kirchgaßner M (2013) Influence of cooling speed on the microstructure and wear behaviour of hypereutectic Fe–Cr–C hardfacings. Mater Sci Eng A 576:243–251. https://doi.org/10.1016/j.msea.2013.04.029

Lei TS, Chang WS, Dong SY (2006) The effect of fluid convection on microstructures of directionally solidified castings. Mater Sci Forum 508:473–478. https://doi.org/10.4028/www.scientific.net/MSF.508.473

Laird II G (1991) Microstructures of Ni-hard I Ni-hard IV and high-Cr white cast irons. AFS Trans 99:339–357

Laird II G (1993) Some comments on white cast iron microstructures and wear properties. AFS Trans 101:497–504

Yang DS et al (2014) The effect of directionally chilled microstructure on hypereutectic high-chromium white cast iron. Adv Mater Res 912–914:399–403. https://doi.org/10.4028/www.scientific.net/AMR.912-914.399

Yang D-S, Lei T-S (2012) Investigating the influence of mid-chilling on microstructural development of high-chromium cast iron. Mater Manuf Process 27(9):919–924. https://doi.org/10.1080/10426914.2011.602793

Zhi XH et al (2013) Effect of fluctuation, modification and surface chill on structure of 20%Cr hypereutectic white cast iron. Mater Sci Technol 25(1):56–60. https://doi.org/10.1179/174328407x245139

Liu Q et al (2012) Effect of cooling rate and Ti addition on the microstructure and mechanical properties in as-cast condition of hypereutectic high chromium cast irons. ISIJ Int 52(12):2210–2219. https://doi.org/10.2355/isijinternational.52.2210

Laird G, Doğan ÖN (1996) Solidification structure versus hardness and impact toughness in high-chromium white cast irons. Int J Cast Met Res 9(2):83–102. https://doi.org/10.1080/13640461.1996.11819648

Huang Z, Xing J, Zhang A (2006) Investigation of microstructure and impact toughness of semisolid hypereutectic high chromium cast iron prepared by slope cooling body method. J Appl Sci 6:1635–1640

Powell GLF, Carlson RA, Randle V (1994) The morphology and microtexture of M7C3 carbides in Fe-Cr-C and Fe-Cr-C-Si alloys of near eutectic composition. J Mater Sci 29:4889–4896. https://doi.org/10.1007/BF00356539

Chen H et al (2012) Effect of electric current pulse on carbide in hypereutectic high chromium cast iron. Adv Mater Res 457–458:174–180. https://doi.org/10.4028/www.scientific.net/AMR.457-458.174

Geng B et al (2018) Change in primary (Cr, Fe)(7)C(3) carbides induced by electric current pulse modification of hypereutectic high chromium cast iron melt. Materials (Basel). https://doi.org/10.3390/ma12010032

Räbiger D et al (2014) The relevance of melt convection to grain refinement in Al–Si alloys solidified under the impact of electric currents. Acta Mater 79:327–338. https://doi.org/10.1016/j.actamat.2014.07.037

Zhang Y et al (2016) Comparative study on the grain refinement of Al-Si alloy solidified under the impact of pulsed electric current and travelling magnetic field. Metals. https://doi.org/10.3390/met6070170

Zhou RF, Jiang YH, Zhou R, Zhang L (2014) Effect of Electric Current Pulse on Solidification Microstructure of Hypereutectic High Chromium Cast Iron Cooling from the Temperature between Liquidus and Solidus.

Lv H, Zhou R, Li L, Ni H, Zhu J, Feng T (2018) Effect of electric current pulse on microstructure and corrosion resistance of hypereutectic high chromium cast iron. Materials 11(11):2220. https://doi.org/10.3390/ma11112220

Zhang Z et al (2008) The cluster size transformation model of molten alloy under pulse electric field. Sci China Ser E Technol Sci 51(3):302–307. https://doi.org/10.1007/s11431-008-0017-9

Qi J et al (2011) An investigation for structure transformation in electric pulse modified liquid aluminum. Phys B Condens Matter 406(4):846–849. https://doi.org/10.1016/j.physb.2010.12.010

Wang J-Z et al (2013) Effects of electric pulse modification on liquid structure of Al–5%Cu alloy. Trans Nonferrous Met Soc China 23(9):2792–2796. https://doi.org/10.1016/s1003-6326(13)62799-5

Conrad H, Sprecher AF, Cao WD, Lu XP (1990) Electroplasticity—the effect of electricity on the mechanical properties of metals. J Metals 42:28–33

Conrad H (2000) Influence of an electric or magnetic field on the liquid—solid transformation in materials and on the microstructure of the solid. Mater Sci Eng A 287:205–212

Nakada M, Shiohara Y, Flemings MC (1990) Modification of solidification structures by pulse electric discharging. ISIJ Int 30:27–33

Spencer DB, Mehrabian R, Flemings MC (1972) Rheological behavior of Sn-15 Pct Pb in the crystallization range. Metall Trans 3:1925–1932

Appendino P, Crivellone G, Mus C, Spriano S (2002) Dynamic solidification of sand-cast aluminium alloys. Metall Sci Technol 20:27–32

Deshpande J (2006), The Effect of Mechanical Mold Vibration on the Characteristics of Aluminium Alloys. Worcester Polytechnic Institute.

StJohn DH, Dahle AK, Abbott T, Nave MD, Qian M (2003) Solidification of cast magnesium alloys. TMS (The Minerals, Metals & Materials Society) 2003:95–100

Pillai RM, Biju Kumar KS, Pai BC (2004) A simple inexpensive technique for enhancing density and mechanical properties of Al–Si alloys. J Mater Process Technol 146(3):338–348. https://doi.org/10.1016/j.jmatprotec.2003.11.022

Gittus JH (1959) The inoculation of solidifying iron and steel castings by means of vibration. J Iron Steel Inst 192:118–131

Nofal A et al (2010) Structural refinement of 15%Cr-2%Mo white irons. Key Eng Mater 457:231–236. https://doi.org/10.4028/www.scientific.net/KEM.457.231

Reda R, Nofal A, Ibrahim K, Hussien A (2010) Investigation of improving wear performance of hypereutectic 15%Cr-2%Mo white irons. China Foundry 7(4):438–446

Kantenik SN, Karpenko MI, Svyatkin BK, Spasskii KV (1974) Influence of ultra-sound and inoculation on the graphitization process of malleable iron. Izvestiya VUZ Chernaya Metall 7:143–147

S.K. Kantenik, M.I.K., B.K. Svyatkin, Ultrasonic degassing of iron melts. Russian Castings Production, (7): p. 284–285.

Huang ZF, Xing JD, Gao YM, Cheng XL (2011) Microstructure and properties of hypereutectic high chromium white cast iron prepared under pressure. Ironmak Steelmaking 38(5):359–362. https://doi.org/10.1179/030192310x12706364542821

Huang ZF, Xing JD, Guo C (2013) Microstructure and properties of semisolid hypereutectic high chromium cast iron prepared by slope cooling body method. Ironmak Steelmaking 37(8):607–611. https://doi.org/10.1179/030192309x12549935902266

Kim CK, Lee S, Jung J-Y (2006) Effects of heat treatment on wear resistance and fracture toughness of duo-cast materials composed of high-chromium white cast iron and low-chromium steel. Metall Mater Trans A 37A:633–643

Hinckley B, Dolman KF, Wuhrer R, Yeung W, Ray A (2008) SEM investigation of heat treated high-chromium cast irons. Mater Forum 32:55–71

Dupin P, Saverna J, Schissler JM (1982) A structural study of chromium white cast irons. Trans Am Foundrymen’s Soc 90:711–718

Skoblo TS, Vishnyakova EN, Mozharova NM, Dubrov VA, Bondin RD (1990) Increasing the quality of rolling rolls of high-chromium cast iron by high-temperature heat treatment. Metal Sci Heat Treat 32(10):734–736

Pearce JTH (1983) Examination of M7C3 carbides in high chromium cast irons using thin foil transmission electron microscopy. J Mater Sci Lett 2:428–432

Zhang MX, Kelly P, Gates JD (2001) The effect of heat treatment on the toughness, hardness and microstructure of low carbon white cast irons. J Mater Sci 36:3865–3875. https://doi.org/10.1023/A:1017949600733

Zhi X et al (2008) Effect of heat treatment on microstructure and mechanical properties of a Ti-bearing hypereutectic high chromium white cast iron. Mater Sci Eng A 487(1–2):171–179. https://doi.org/10.1016/j.msea.2007.10.009

Yilmaz SO, Teker T (2016) Effect of TiBAl inoculation and heat treatment on microstructure and mechanical properties of hypereutectic high chromium white cast iron. J Alloy Compd 672:324–331. https://doi.org/10.1016/j.jallcom.2016.02.125

Liu Q et al (2012) Effect of heat treatment on microstructure and mechanical properties of Ti-alloyed hypereutectic high chromium cast iron. ISIJ Int 52(12):2288–2294. https://doi.org/10.2355/isijinternational.52.2288

Arnold BK, Sare IR (1995) The influence of heat treatment on the high-stress abrasion resistance and fracture toughness of alloy white cast irons. Metall Mater Trans A 26A:1785–1793

Gasan H, Erturk F (2013) Effects of a destabilization heat treatment on the microstructure and abrasive wear behavior of high-chromium white cast iron investigated using different characterization techniques. Metall Mater Trans A 44(11):4993–5005. https://doi.org/10.1007/s11661-013-1851-3

Abdel-Aziz K, El-Shennawy M, Omar AA (2017) Microstructural characteristics and mechanical properties of heat treated high-Cr white cast iron alloys. Int J Appl Eng 12:4675–4686

Hinckley B, Dolman KF, Wuhrer R, Ray A, Yeung W (2008) SEM and EBSD investigations of high-chromium cast irons. Microsc Microanal 14(S2):550–551. https://doi.org/10.1017/s1431927608084067

Powell GLF (1980) Morphology of eutectic M3C and M7C3 in white iron castings. Metals Forum 3(1):37–46

Inthidech S, Sricharoenchai P, Matsubara Y (2006) Effect of alloying elements on heat treatment behavior of hypoeutectic high chromium cast iron. Mater Trans 47:72–81

Inthidech S et al (2010) Effect of repeated tempering on hardness and retained austenite of high chromium cast iron containing molybdenum. Mater Trans 51(7):1264–1271. https://doi.org/10.2320/matertrans.M2010018

Bedolla-Jacuinde A, Arias L, Hernández B (2003) Kinetics of secondary carbides precipitation in a high-chromium white iron. J Mater Eng Perform 12(4):371–382

Tabrett CP, Sare IR (1998) Effect of high temperature and sub-ambient treatments on the matrix structure and abrasion resistance of a high-chromium white iron. Scripta Mater 38:1747–1753

Laird G, Powell GLF (1993) Solidification and solid-state transformation mechanisms in si alloyed high-chromium white cast irons. Metall Trans A 24A:981–988

Bunin KP, Taran YN (1967) Metallography of cast iron. Metal Sci Heat Treat 9(5):397–402

Easton M, StJohn D (1999) Grain refinement of aluminum alloys-part I. the nucleant and solute paradigms—a review of the literature. Metall Mater Trans A 30A:1613–1623

Easton M, StJohn D (1999) Grain refinement of aluminum alloys- Part II. confirmation of, and a mechanism for, the solute paradigm. Metall Mater Trans A 30A:1625–1633

Lekakh SN, Neroslavskii OM, Rozum VA (1989) Reaction of complex modifiers with liquid cast iron. Izvestiya Akademii Nauk SSSR Metally 5:12–18

Fu H-G, Wu XJ, Li XY, Xing JD, Lei YP, Zhi XH (2009) Effect of TiC particle additions on structure and properties of hypereutectic high chromium cast iron. J Mater Eng Perform 18(8):1109–1115. https://doi.org/10.1007/s11665-008-9330-5

Roman Radon RR (2016) Hypereutectic white iron alloys comprising chromium and nitrogen and articles made therefrom

Zhi X, Liu J, Xing J, Ma S (2014) Effect of cerium modification on microstructure and properties of hypereutectic high chromium cast iron. Mater Sci Eng A 603:98–103. https://doi.org/10.1016/j.msea.2014.02.080

Chao Chang W, Tsun HH, Qian M (2013) Formation of spheroidal carbide in vanadium white cast iron by rare earth modification. Mater Sci Technol 6(9):905–910. https://doi.org/10.1179/mst.1990.6.9.905

Kopyciński D, Piasny S (2016) Influence of inoculation on structure of chromium cast iron. Characterization of Minerals, Metals and Materials, TMS, 2016

Kopyciński D (2009) Inoculation of chromium white cast iron. Arch Foundry Eng 9(1):191–194

Chung RJ et al (2009) Effects of titanium addition on microstructure and wear resistance of hypereutectic high chromium cast iron Fe–25wt.%Cr–4wt.%C. Wear 267(1–4):356–361. https://doi.org/10.1016/j.wear.2008.12.061

Ali Y et al (2015) Current research progress in grain refinement of cast magnesium alloys: A review article. J Alloy Compd 619:639–651. https://doi.org/10.1016/j.jallcom.2014.09.061

StJohn DH, Qian M, Easton MA, Cao P, Hildebrand Z (2005) Grain refinement of magnesium alloys. Metall Mater Trans 36(7):1669–1679

McCartney DG (1989) Grain refining of aluminium and its alloys using inoculants. Int Mater Rev 34(1):247–260.

Murty BS, Kori SA, Chakraborty M (2013) Grain refinement of aluminium and its alloys by heterogeneous nucleation and alloying. Int Mater Rev 47(1):3–29. https://doi.org/10.1179/095066001225001049

Liu Z (2017) Review of grain refinement of cast metals through inoculation: theories and developments. Metall Mater Trans A 48(10):4755–4776. https://doi.org/10.1007/s11661-017-4275-7

Wu X et al (2007) Effect of titanium on the morphology of primary M7C3 carbides in hypereutectic high chromium white iron. Mater Sci Eng A 457(1–2):180–185. https://doi.org/10.1016/j.msea.2006.12.006

Huang ZF et al (2014) Effect of Ti addition on morphology and size of primary M7C3 type carbide in hypereutectic high chromium cast iron. Mater Sci Technol 27(1):426–430. https://doi.org/10.1179/026708309x12601952777666

Huang Z, Xing J, Gao Y, Zhi X (2012) Effect of titanium on the as-cast microstructure and impact toughness of hypereutectic high-chromium cast iron. Int J Mater Res 103(5):609–612

Zhang Y et al (2020) The formation of TiC–NbC core-shell structure in hypereutectic high chromium cast iron leads to significant refinement of primary M7C3. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.153806

Ding H et al (2016) Improving impact toughness of a high chromium cast iron regarding joint additive of nitrogen and titanium. Mater Des 90:958–968. https://doi.org/10.1016/j.matdes.2015.11.055

Wang Y, Zeng X, Ding W (2006) Effect of Al–4Ti–5B master alloy on the grain refinement of AZ31 magnesium alloy. Scripta Mater 54(2):269–273. https://doi.org/10.1016/j.scriptamat.2005.09.022

Davies IG, Dennis JM, Hellawell A (1970) The nucleation of aluminum grains in alloys of aluminum with titanium and boron. Metall Trans 1:275–280

Kopyciński D (2013) The inoculation of white cast iron. In: TMS2013 Annual Meeting Supplemental Proceedings, pp. 601–608.

Studnicki A, Jezierski J (2012) Stereological parameters of carbides in modified wear resistant Fe-C-Cr alloys. In: METAL 2012 - Conference Proceedings, 21st International Conference on Metallurgy and Materials 201, pp. 795–802.

Hao F et al (2011) Effect of rare earth oxides on the morphology of carbides in hardfacing metal of high chromium cast iron. J Rare Earths 29(2):168–172. https://doi.org/10.1016/s1002-0721(10)60425-5

Hao F et al (2011) Effects of rare earth oxide on hardfacing metal microstructure of medium carbon steel and its refinement mechanism. J Rare Earths 29(6):609–613. https://doi.org/10.1016/s1002-0721(10)60507-8

Yang J et al (2014) Microstructure and wear resistance of the hypereutectic Fe–Cr–C alloy hardfacing metals with different La2O3 additives. Appl Surf Sci 289:437–444. https://doi.org/10.1016/j.apsusc.2013.10.186

Zhou Y et al (2012) Influence of La2O3 addition on microstructure and wear resistance of Fe–Cr–C cladding formed by arc surface welding. J Rare Earths 30(10):1069–1074. https://doi.org/10.1016/s1002-0721(12)60180-x

Tuttle R (2013) Effect of rare earth oxides in plain carbon steels. In: AISTECH: iron and steel technology conference proceedings, vol. 1, pp. 1085–1093.

Zhi X et al (2008) Effect of titanium on the as-cast microstructure of hypereutectic high chromium cast iron. Mater Charact 59(9):1221–1226. https://doi.org/10.1016/j.matchar.2007.10.010

Bedolla-Jacuinde A et al (2005) Effect of titanium on the as-cast microstructure of a 16%chromium white iron. Mater Sci Eng A 398(1–2):297–308. https://doi.org/10.1016/j.msea.2005.03.072

Kopyciński D et al (2017) The effect of Fe-Ti inoculation on solidification, structure and mechanical properties of high chromium cast iron. Arch Metall Mater 62(4):2183–2187. https://doi.org/10.1515/amm-2017-0321

Kopyciński D, Piasny S (2012) Influence of tungsten and titanium on the structure of chromium cast iron. Arch Foundry Eng 12(1):57–60. https://doi.org/10.2478/v10266-012-0011-3

Filipovic M et al (2013) Microstructure and mechanical properties of Fe–Cr–C–Nb white cast irons. Mater Des 47:41–48. https://doi.org/10.1016/j.matdes.2012.12.034

Wang YP et al (2011) Improving the wear resistance of white cast iron using a new concept—high-entropy microstructure. Wear 271(9–10):1623–1628. https://doi.org/10.1016/j.wear.2010.12.029

Zhi X et al (2008) Effect of niobium on the as-cast microstructure of hypereutectic high chromium cast iron. Mater Lett 62(6–7):857–860. https://doi.org/10.1016/j.matlet.2007.06.084

Maja ME, Maruma MG, Mampuru LA, Moema SJ (2016) Effect of niobium on the solidification structure and properties of hypoeutectic high-chromium white cast irons. J South Afr Inst Min Metall 116(10):981–986. https://doi.org/10.17159/2411-9717/2016/v116n10a14

Liu S et al (2017) Experiments and calculations on refining mechanism of NbC on primary M7C3 carbide in hypereutectic Fe–Cr–C alloy. J Alloy Compd 713:108–118. https://doi.org/10.1016/j.jallcom.2017.04.167

Chen H-X, Chang Z-C, Lu J-C, Lin H-T (1993) Effect of niobium on wear resistance of 15%Cr white cast iron. Wear 166:197–201

Chung RJ et al (2013) Microstructure refinement of hypereutectic high Cr cast irons using hard carbide-forming elements for improved wear resistance. Wear 301(1–2):695–706. https://doi.org/10.1016/j.wear.2013.01.079

Ma Y, Li X, Liu Y, Zhou S, Dang X (2013) Microstructure and properties of Ti–Nb–V–Mo-alloyed high chromium cast iron. Bull Mater Sci 36(5):839–844

Filipovic M, Kamberovic Z, Korac M (2011) Solidification of high chromium white cast iron alloyed with vanadium. Mater Trans 52(3):386–390. https://doi.org/10.2320/matertrans.M2010059

Filipovic M et al (2013) Correlation of microstructure with the wear resistance and fracture toughness of white cast iron alloys. Met Mater Int 19(3):473–481. https://doi.org/10.1007/s12540-013-3013-y

Radulovic M, Fiset M, Peev K, Tomovic M (1994) The influence of vanadium on fracture toughness and abrasion resistance in high chromium white cast irons. J Mater Sci 29:5085–5094. https://doi.org/10.1007/BF01151101

Mampuru LA, Maruma MG, Moema JS (2016) Grain refinement of 25 wt.% high-chromium white cast iron by addition of vanadium. J South Afr Ins Min Metall 116(10):969–972. https://doi.org/10.17159/2411-9717/2016/v116n10a12

M.R. Nikolaenko, G.A.K., N.A. Grinberg, Influence of boron, vanadium and nickel on the structure and properties of high chromium cast irons deposited with powder-filled strip. Welding Production, 1973. 20(4):56–60.

W Zhao, Z Liu, Z Ju, B Liao, X Chen (2008) Effects of vanadium and rare-earth on carbides and properties of high chromium cast iron. Mater Sci Forum 575–578:1414–1419. https://doi.org/10.4028/www.scientific.net/MSF.575-578.1414

Efremenko VG et al (2013) Abrasive wear resistance of spheroidal vanadium carbide cast irons. J Friction Wear 34(6):466–474. https://doi.org/10.3103/s1068366613060068

Bedolla-Jacuinde A et al (2015) Abrasive wear of V-Nb–Ti alloyed high-chromium white irons. Wear 332–333:1006–1011. https://doi.org/10.1016/j.wear.2015.01.049

Zhi X et al (2008) Effect of fluctuation and modification on microstructure and impact toughness of 20 wt.% Cr hypereutectic white cast iron. Materialwiss Werkstofftech 39(6):391–393. https://doi.org/10.1002/mawe.200700219

Shen J, Zhou QD (1988) Solidification behaviour of boron-bearing high-chromium cast iron and the modification mechanism of silicon. Cast Metals 1(2):79–85. https://doi.org/10.1080/09534962.1988.11818951

Jacuinde AB, Rainforth WM (2001) The wear behaviour of high-chromium white cast irons as a function of silicon and Mischmetal content. Wear 250:449–461

Bedolla-Jacuinde A, Rainforth MW, Mejía I (2012) The role of silicon in the solidification of high-Cr cast irons. Metall Mater Trans A 44(2):856–872. https://doi.org/10.1007/s11661-012-1434-8

Powell G, Randle V (1997) The effect of Si on the relationship between orientation and carbide morphology in high chromium white irons. J Mater Sci 32:561–565. https://doi.org/10.1023/A:1018558928916

Jinhai L, Gensheng L, Guolu L, Wang K (1998) Research and application of as-cast wear resistance high chromium cast iron. Chin J Mech Eng 11(2):130–135

Lai J-P et al (2018) Effect of Si content on the microstructure and wear resistance of high chromium cast iron. ISIJ Int 58(8):1532–1537. https://doi.org/10.2355/isijinternational.ISIJINT-2018-099

Inthidech S, Sricharoenchai P, Matsubara Y (2013) Effect of molybdenum content on subcritical heat treatment behaviour of hypoeutectic 16 and 26 wt-% chromium cast irons. Int J Cast Met Res 25(5):257–263. https://doi.org/10.1179/1743133612y.0000000009

Scandian C et al (2009) Effect of molybdenum and chromium contents in sliding wear of high-chromium white cast iron: the relationship between microstructure and wear. Wear 267(1–4):401–408. https://doi.org/10.1016/j.wear.2008.12.095

Kusumoto K et al (2017) Abrasive wear characteristics of Fe-2C-5Cr-5Mo-5W-5Nb multi-component white cast iron. Wear 376–377:22–29. https://doi.org/10.1016/j.wear.2017.01.096

Bereza JM, D.I.T. (1981) Wear and impact resistant white cast irons. The British Foundryman 74(10):205–211.

Yamamoto K, Inthidech S, Sasaguri N, Matsubara Y (2014) Influence of Mo and W on high temperature hardness of M7C3 carbide in high chromium white cast iron. Mater Trans 55(4):684–689. https://doi.org/10.2320/matertrans.F-M2014801

Maldonado-Ruíz SI et al (2016) Wear resistance of high chromium—high carbon cast irons. Int J Cast Met Res 15(6):589–594. https://doi.org/10.1080/13640461.2003.11819545

Mousavi Anijdan SH et al (2007) Effects of tungsten on erosion–corrosion behavior of high chromium white cast iron. Mater Sci Eng A 454–455:623–628. https://doi.org/10.1016/j.msea.2006.11.128

Heydari D, Skandani AA, Al Haik M (2012) Effect of carbon content on carbide morphology and mechanical properties of A.R. white cast iron with 10–12% tungsten. Mater Sci Eng A 542:113–126. https://doi.org/10.1016/j.msea.2012.02.040

Lv Y et al (2012) Effect of tungsten on microstructure and properties of high chromium cast iron. Mater Des 39:303–308. https://doi.org/10.1016/j.matdes.2012.02.048

Inoue A, Masumoto T (1994) Light-metal base amorphous alloys containing lanthanide metal. J Alloys Compd 207/208:340–348

Xiao DH et al (2003) Effect of rare earth Ce addition on the microstructure and mechanical properties of an Al–Cu–Mg–Ag alloy. J Alloy Compd 352(1–2):84–88. https://doi.org/10.1016/s0925-8388(02)01162-3

Radulovic M, Fiset M, Peev K (1994) Effect of rare earth elements on microstructure and properties of high chromium white iron. Mater Sci Technol 10(12):1057–1062. https://doi.org/10.1179/mst.1994.10.12.1057

Qu Y et al (2008) Effect of cerium on the as-cast microstructure of a hypereutectic high chromium cast iron. Mater Lett 62(17–18):3024–3027. https://doi.org/10.1016/j.matlet.2008.01.129

Bramfitt BL (1970) The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron. Metall Trans 1:1987–1995

Zhou YF et al (2012) Fe–24wt.%Cr–4.1wt.%C hardfacing alloy: microstructure and carbide refinement mechanisms with ceria additive. Mater Charact 72:77–86. https://doi.org/10.1016/j.matchar.2012.07.004

Hou Y et al (2012) Influence of rare earth nanoparticles and inoculants on performance and microstructure of high chromium cast iron. J Rare Earths 30(3):283–288. https://doi.org/10.1016/s1002-0721(12)60038-6

Aso S et al (2016) The effect of solidification conditions on phase transformation of iron matrix of Fe-25mass%Cr–C–B alloys. Int J Cast Met Res 11(5):285–290. https://doi.org/10.1080/13640461.1999.11819287

Li M et al (2016) Crystallographic study of grain refinement in low and medium carbon steels. Philos Mag 96(15):1556–1578. https://doi.org/10.1080/14786435.2016.1171413

Li M et al (2017) A new grain refiner for ferritic steels. Metall Mater Trans B 48(6):2902–2912. https://doi.org/10.1007/s11663-017-1101-y

Zhang M et al (2005) Crystallographic study of grain refinement in aluminum alloys using the edge-to-edge matching model. Acta Mater 53(5):1427–1438. https://doi.org/10.1016/j.actamat.2004.11.037

Wang F et al (2013) The grain refinement mechanism of cast aluminium by zirconium. Acta Mater 61(15):5636–5645. https://doi.org/10.1016/j.actamat.2013.05.044

StJohn DH et al (2011) The interdependence theory: the relationship between grain formation and nucleant selection. Acta Mater 59(12):4907–4921. https://doi.org/10.1016/j.actamat.2011.04.035

Crossley FA, Mondolfo LF (1951) Mechanism of grain refinement in aluminum alloys. J Metals 3:1143–1148

Lu L, Dahle AK, StJohn DH (2005) Grain refinement efficiency and mechanism of aluminium carbide in Mg–Al alloys. Scripta Mater 53(5):517–522. https://doi.org/10.1016/j.scriptamat.2005.05.008

Zhang MX et al (2005) Crystallography of grain refinement in Mg–Al based alloys. Acta Mater 53(11):3261–3270. https://doi.org/10.1016/j.actamat.2005.03.030

Men H, Jiang B, Fan Z (2010) Mechanisms of grain refinement by intensive shearing of AZ91 alloy melt. Acta Mater 58(19):6526–6534. https://doi.org/10.1016/j.actamat.2010.08.016

Bermingham MJ et al (2008) The mechanism of grain refinement of titanium by silicon. Scripta Mater 58(12):1050–1053. https://doi.org/10.1016/j.scriptamat.2008.01.041

Tamirisakandala S et al (2005) Grain refinement of cast titanium alloys via trace boron addition. Scripta Mater 53(12):1421–1426. https://doi.org/10.1016/j.scriptamat.2005.08.020

Bermingham MJ et al (2011) Grain-refinement mechanisms in titanium alloys. J Mater Res 23(1):97–104. https://doi.org/10.1557/jmr.2008.0002

Bermingham MJ et al (2011) Segregation and grain refinement in cast titanium alloys. J Mater Res 24(4):1529–1535. https://doi.org/10.1557/jmr.2009.0173

Li M et al (2018) Effect of solutes on grain refinement of As-Cast Fe-4Si Alloy. Metall Mater Trans A 49(6):2235–2247. https://doi.org/10.1007/s11661-018-4571-x

Ji Y, Zhang M-X, Ren H (2018) Roles of lanthanum and cerium in grain refinement of steels during solidification. Metals. https://doi.org/10.3390/met8110884

Winegard WC, Chalmers B (1954) Supercooling and dendritic freezing in alloys. Trans Am Soc Metals 46:1214–1224

Hutt J, Stjohn D (1998) The origins of the equiaxed zone—review of theoretical and experimental work. Int J Cast Met Res 11(1):13–22. https://doi.org/10.1080/13640461.1998.11819254

Cao P, Qian M, StJohn DH (2005) Native grain refinement of magnesium alloys. Scripta Mater 53(7):841–844. https://doi.org/10.1016/j.scriptamat.2005.06.010

Easton MA et al (2006) Grain refinement of Mg–Al(–Mn) alloys by SiC additions. Scripta Mater 55(4):379–382. https://doi.org/10.1016/j.scriptamat.2006.04.014

Liu Y, Liu X, Xiufang B (2004) Grain refinement of Mg–Al alloys with Al4C3–SiC/Al master alloy. Mater Lett 58(7–8):1282–1287. https://doi.org/10.1016/j.matlet.2003.09.022

Genders R (1926) The interpretation of the macrostructure of cast metals. J Inst Metal 35

Chalmers BB (1963) The structure of ingots. J Aust Inst Metals 8(3):255–263

Ohno A, Motegi T (1977) Formation mechanism of equiaxed zones in cast metals. AFS Int Cast Metals J 2(1):28–36

Ohno A (1987) Solidification: the separation theory and its practical applications. Springer, New York

Motoyasu G et al (2015) Some perspectives on innovative processing and materials development. J Mater Eng Perform 24(6):2240–2249. https://doi.org/10.1007/s11665-015-1513-2

Ohno A (1996) Grain growth control by solidification technology. Mater Sci Forum 204–206:169–178. https://doi.org/10.4028/www.scientific.net/MSF.204-206.169

Gruzleski JE, Mohantya PS (1995) Mechanism of grain refinement in aluminum. Acta Metall Mater 43:2001–2012

Johnsson M, Bäckerud L (1992) Nucleants in grain refined aluminum after addition of Ti- and B- containing master alloys. Z Metallkd 83(11):774–780

Johnsson M, Bäckerud L, Sigworth GK (1993) Study of the mechanism of grain refinement of aluminum after additions of Ti- and B- containing master alloys. Metall Trans A 24A:481–491

Arnberg L, Backerud L, Klang H (1982) Production and properties of master alloys of AI–Ti–B type and their ability to grain refine aluminium. Metals Technol 9:1–6

Jones GP, Pearson J (1976) Factors affecting the grain-refinement of aluminum using titanium and boron additives. Metall Trans B 7B:223–234

Sigworth GK (1996) Communication on mechanism of grain refinement in aluminum. Scripta Mater 34:919–922

Schumacher P et al (2013) New studies of nucleation mechanisms in aluminium alloys: implications for grain refinement practice. Mater Sci Technol 14(5):394–404. https://doi.org/10.1179/mst.1998.14.5.394

Fan Z (2012) An epitaxial model for heterogeneous nucleation on potent substrates. Metall Mater Trans A 44(3):1409–1418. https://doi.org/10.1007/s11661-012-1495-8

Fan Z et al (2015) Grain refining mechanism in the Al/Al–Ti–B system. Acta Mater 84:292–304. https://doi.org/10.1016/j.actamat.2014.10.055

Lee YC, Dahle AK, StJohn DH (2000) The role of solute in grain refinement of magnesium. Metall Mater Trans A 31A:2895–2906

Men H, Fan Z (2011) Effects of solute content on grain refinement in an isothermal melt. Acta Mater 59(7):2704–2712. https://doi.org/10.1016/j.actamat.2011.01.008

Quested T, Dinsdale A, Greer A (2005) Thermodynamic modelling of growth-restriction effects in aluminium alloys. Acta Mater 53(5):1323–1334. https://doi.org/10.1016/j.actamat.2004.11.024

Schmid-Fetzer R, Kozlov A (2011) Thermodynamic aspects of grain growth restriction in multicomponent alloy solidification. Acta Mater 59(15):6133–6144. https://doi.org/10.1016/j.actamat.2011.06.026

Easton MA, StJohn DH (2001) A model of grain refinement incorporating alloy constitution and potency of heterogenous nucleant particles. Acta Mater 49:1867–1878

Fan Z, Gao F, Zhou L, Lu SZ (2018) A new concept for growth restriction during solidification. Acta Mater 152:248–257. https://doi.org/10.1016/j.actamat.2018.04.045

StJohn DH, Cao P, Qian M, Easton MA (2007) A new analytical approach to reveal the mechanisms of grain refinement. Adv Eng Mater 9(9):739–746. https://doi.org/10.1002/adem.200700157

Easton M, StJohn D (2005) An analysis of the relationship between grain size, solute content and the potency and number density of nucleant particles. Metall Mater Trans 36A:1911–1920

Greer AL, Bunn AM, Tronche A, Evans PV, Bristow DJ (2000) Modelling of inoculation of metallic melts: application to grain refinement of aluminium by Al–Ti–B. Acta Materialia 48(11):2823–2835. https://doi.org/10.1016/S1359-6454(00)00094-X

Günther R, Hartig C, Bormann R (2006) Grain refinement of AZ31 by (SiC)P: theoretical calculation and experiment. Acta Mater 54(20):5591–5597. https://doi.org/10.1016/j.actamat.2006.07.035

Qian M (2007) Heterogeneous nucleation on potent spherical substrates during solidification. Acta Mater 55(3):943–953. https://doi.org/10.1016/j.actamat.2006.09.016

Qian M et al (2010) An analytical model for constitutional supercooling-driven grain formation and grain size prediction. Acta Mater 58(9):3262–3270. https://doi.org/10.1016/j.actamat.2010.01.052

Turnbull D, Vonnegut B (1952) Nucleation Catalysis. Ind Eng Chem 44(6):1292–1298. https://doi.org/10.1021/ie50510a031

Liu S et al (2009) Effect of Mg–TiB2 master alloy on the grain refinement of AZ91D magnesium alloy. J Alloy Compd 487(1–2):202–205. https://doi.org/10.1016/j.jallcom.2009.08.065

Wang Y et al (2011) Characterisation of magnesium oxide and its interface with α-Mg in Mg–Al-based alloys. Philos Mag Lett 91(8):516–529. https://doi.org/10.1080/09500839.2011.591744

Zhang MX, Kelly PM (1999) Edge to edge matching—a new approach to the morphology and crystallography of precipitates. Mater Forum 23:22

Zhang MX, Kelly PM (2005) Edge-to-edge matching and its applications. Acta Mater 53(4):1085–1096. https://doi.org/10.1016/j.actamat.2004.11.005

Zhang MX, Kelly PM (2005) Edge-to-edge matching and its applications. Acta Mater 53(4):1073–1084. https://doi.org/10.1016/j.actamat.2004.11.007

Qiu D et al (2009) A new approach to designing a grain refiner for Mg casting alloys and its use in Mg–Y-based alloys. Acta Mater 57(10):3052–3059. https://doi.org/10.1016/j.actamat.2009.03.011

Wang F et al (2016) A refining mechanism of primary Al3Ti intermetallic particles by ultrasonic treatment in the liquid state. Acta Mater 116:354–363. https://doi.org/10.1016/j.actamat.2016.06.056

Liu Z et al (2014) The grain refining mechanism of cast zinc through silver inoculation. Acta Mater 79:315–326. https://doi.org/10.1016/j.actamat.2014.07.026

Kelly PM, Zhang MZ (2006) Edge to edge matching—the fundamentals. Metall Mater Trans A 37A:833–839

Zhang MX, Kelly PM (2005) Edge-to-edge matching model for predicting orientation relationships and habit planes—the improvements. Scripta Mater 52(10):963–968. https://doi.org/10.1016/j.scriptamat.2005.01.040

Acknowledgements

The authors would like to thank Australia Research Council (ARC) Industrial Transformation Training Centre program (IC160100036) for funding support.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jain, AS., Chang, H., Tang, X. et al. Refinement of primary carbides in hypereutectic high-chromium cast irons: a review. J Mater Sci 56, 999–1038 (2021). https://doi.org/10.1007/s10853-020-05260-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05260-8