Abstract

Cubic-phase garnet-type Li7La3Z2O12 is a promising candidate for an electrolyte of all-solid-state lithium-ion batteries; however, its poor sinterability due to Li sublimation during firing has impeded large scale development. This study demonstrates a solid-state reactive sintering (SSRS) process with added CuO as a sintering aid to enable enhanced materials processing at lower temperatures. Applying the SSRS process with the addition of 1 wt% CuO decreased the sintering temperature for 0.5 mol%Ta-doped LLZTO pellets having over 90% relative density from 1250 to 1100 °C to reduce Li loss. The 1 wt% CuO addition did not lead to secondary phase formation as detected by XRD, nor to appreciable electronic conduction below 100 °C as measured by four-point probe method. The 1 wt% CuO-mixed LLZTO pellet exhibited high conductivity of approximately 3.0 × 10−4 S·cm−1 (bulk) and 5.45x10−5 S·cm−1 (grain boundary). The mechanism of CuO function as a sintering aid is presumed to be enabling liquid-phase sintering along with enhancing the decomposition of LiOH. The combined SSRS process along with optimized CuO sintering aid addition is a one-step process that is a practical technique to enhance the preparation of LLZO-based electrolyte for all-solid-state lithium-ion batteries.

Similar content being viewed by others

References

Murugan R, Thangadurai V, Weppner W (2007) Fast lithium ion conduction in garnet-type Li7La 3Zr2O12. Angew Chem Int Ed 46:7778–7781. https://doi.org/10.1002/anie.200701144

Liu M, Li X, Wang X et al (2018) Facile synthesis and electrochemical properties of high lithium ionic conductivity Li1.7Al0.3Ti1.7Si0.4P2.6O12 ceramic solid electrolyte. J Alloys Comp 756:103–110. https://doi.org/10.1016/j.jallcom.2018.04.333

Thompson T, Yu S, Williams L et al (2017) Electrochemical window of the Li-Ion Solid Electrolyte Li7La3Zr2O12. ACS Energy Lett 2:462–468. https://doi.org/10.1021/acsenergylett.6b00593

Han F, Zhu Y, He X et al (2016) Electrochemical stability of Li10GeP2S12 and Li7La3Zr2O12 solid electrolytes. Adv Energy Mater 6:1–9. https://doi.org/10.1002/aenm.201501590

Rettenwander D, Blaha P, Laskowski R et al (2014) DFT study of the role of Al 3 + in the fast ion-conductor Li 7–3 x Al 3 + x La 3 Zr 2 O 12 garnet. Chem Mater 26:2617–2623. https://doi.org/10.1021/cm5000999

Wagner R, Redhammer GJ, Rettenwander D et al (2016) Crystal structure of garnet-related Li-Ion conductor Li7-3xGaxLa3Zr2O12: fast Li-Ion conduction caused by a different cubic modification? Chem Mater 28:1861–1871. https://doi.org/10.1021/acs.chemmater.6b00038

Robben L, Merzlyakova E, Heitjans P, Gesing TM (2016) Symmetry reduction due to gallium substitution in the garnet Li6.43(2)Ga0.52(3)La2.67(4)Zr2O12. Acta Cryst Sect E Cryst Commun 72:287–289. https://doi.org/10.1107/S2056989016001924

Rettenwander D, Langer J, Schmidt W et al (2015) Site Occupation of Ga and Al in Stabilized Cubic Li 7–3(x + y) Ga x Al y La 3 Zr 2 O 12 Garnets As Deduced from 27 Al and 71 Ga MAS NMR at Ultrahigh Magnetic Fields. Chem Mater 27:3135–3142. https://doi.org/10.1021/acs.chemmater.5b00684

Gu W, Ezbiri M, Prasada Rao R et al (2015) Effects of penta-and trivalent dopants on structure and conductivity of Li7La3Zr2O12. Solid State Ion 274:100–105. https://doi.org/10.1016/j.ssi.2015.03.019

Thompson T, Wolfenstine J, Allen JL et al (2014) Tetragonal vs. cubic phase stability in Al-free Ta doped Li 7La3Zr2O12 (LLZO). J Mater Chem A 2:13431–13436. https://doi.org/10.1039/c4ta02099e

Rettenwander D, Redhammer G, Preishuber-Pflügl F et al (2016) Structural and electrochemical consequences of Al and Ga Cosubstitution in Li7La3Zr2O12 solid electrolytes. Chem Mater 28:2384–2392. https://doi.org/10.1021/acs.chemmater.6b00579

Hubaud AA, Schroeder DJ, Ingram BJ et al (2015) Thermal expansion in the garnet-type solid electrolyte (Li7 − Al/3)La3Zr2O12 as a function of Al content. J Alloys Comp 644:804–807. https://doi.org/10.1016/j.jallcom.2015.05.067

Jonson RA, McGinn PJ (2018) Tape casting and sintering of Li7La3Zr1.75Nb0.25Al0.1O12with Li3BO3additions. Solid State Ion 323:49–55. https://doi.org/10.1016/j.ssi.2018.05.015

Shin RH, Son SI, Lee SM et al (2016) Effect of Li3BO3 additive on densification and ion conductivity of garnet-type Li7La3Zr2O12 solid electrolytes of all-solid-state lithium-ion batteries. J Korean Ceram Soc 53:712–718. https://doi.org/10.4191/kcers.2016.53.6.712

Ohta S, Komagata S, Seki J et al (2013) All-solid-state lithium ion battery using garnet-type oxide and Li3BO3 solid electrolytes fabricated by screen-printing. J Power Sources 238:53–56. https://doi.org/10.1016/j.jpowsour.2013.02.073

Tadanaga K, Takano R, Ichinose T et al (2013) Low temperature synthesis of highly ion conductive Li 7 La 3 Zr 2 O 12 -Li 3 BO 3 composites. Electrochem Commun 33:51–54. https://doi.org/10.1016/j.elecom.2013.04.004

Takano R, Tadanaga K, Hayashi A, Tatsumisago M (2014) Low temperature synthesis of Al-doped Li7La3Zr 2O12 solid electrolyte by a sol-gel process. Solid State Ion 255:104–107. https://doi.org/10.1016/j.ssi.2013.12.006

Janani N, Deviannapoorani C, Dhivya L, Murugan R (2014) Influence of sintering additives on densification and Li + conductivity of Al doped Li7La3Zr2O12 lithium garnet. RSC Adv 4:51228–51238. https://doi.org/10.1039/c4ra08674k

Wakudkar P, Deshpande AV (2019) Effect of Li4SiO4 addition in Li6.22Al0.16La3Zr1.7Ta0.3O12 garnet type solid electrolyte for lithium ion battery application. Ceram Int 45:20113–20120. https://doi.org/10.1016/j.ceramint.2019.06.276

Janani N, Ramakumar S, Kannan S, Murugan R (2015) Optimization of lithium content and sintering aid for maximized Li + conductivity and density in Ta-Doped Li7La3Zr2O12. J Am Ceram Soc 98:2039–2046. https://doi.org/10.1111/jace.13578

Deng Y, Eames C, Fleutot B et al (2017) Enhancing the Lithium Ion Conductivity in Lithium Superionic Conductor (LISICON) solid electrolytes through a mixed polyanion effect. ACS Appl Mater Interfaces 9:7050–7058. https://doi.org/10.1021/acsami.6b14402

Liu K, Ma JT, Wang CA (2014) Excess lithium salt functions more than compensating for lithium loss when synthesizing Li6.5La3Ta0.5Zr 1.5O12 in alumina crucible. J Power Sources 260:109–114. https://doi.org/10.1016/j.jpowsour.2014.02.065

Huang Z, Liu K, Chen L et al (2017) Sintering behavior of garnet-type Li6.4La3Zr1.4Ta0.6O12 in Li2CO3 atmosphere and its electrochemical property. Int J Appl Ceram Technol 14:921–927. https://doi.org/10.1111/ijac.12735

Huang X, Xiu T, Badding ME, Wen Z (2018) Two-step sintering strategy to prepare dense Li-Garnet electrolyte ceramics with high Li + conductivity. Ceram Int 44:5660–5667. https://doi.org/10.1016/j.ceramint.2017.12.217

Huang X, Lu Y, Song Z et al (2019) Preparation of dense Ta-LLZO/MgO composite Li-ion solid electrolyte: sintering, microstructure, performance and the role of MgO. J Energy Chem 39:8–16. https://doi.org/10.1016/j.jechem.2019.01.013

Zhang W, Sun C (2019) Effects of CuO on the microstructure and electrochemical properties of garnet-type solid electrolyte. J Phys Chem Solids 135:109080. https://doi.org/10.1016/j.jpcs.2019.109080

Ueno K, Hatada N, Han D, Uda T (2019) Thermodynamic maximum of y doping level in barium zirconate in co-sintering with NiO. J Mater Chem A 7:7232–7241. https://doi.org/10.1039/c8ta12245h

Wang B, Bi L, Zhao XS (2018) Exploring the role of NiO as a sintering aid in BaZr0.1Ce0.7Y0.2O3-δ electrolyte for proton-conducting solid oxide fuel cells. J Power Sources 399:207–214. https://doi.org/10.1016/J.JPOWSOUR.2018.07.087

Tong J, Clark D, Bernau L et al (2010) Solid-state reactive sintering mechanism for large-grained yttrium-doped barium zirconate proton conducting ceramics. J Mater Chem 20:6333–6341. https://doi.org/10.1039/c0jm00381f

Nikodemski S, Tong J, O’Hayre R (2013) Solid-state reactive sintering mechanism for proton conducting ceramics. Solid State Ion 253:201–210. https://doi.org/10.1016/j.ssi.2013.09.025

Chen F, Li J, Huang Z et al (2018) Origin of the Phase Transition in Lithium Garnets. J Phys Chem C 122:1963–1972. https://doi.org/10.1021/acs.jpcc.7b10911

Krevit L (1988) Database Management Systems. Med Ref Serv Q 6:65–68. https://doi.org/10.1300/J115v06n04_07

Wu J-F, Chen E-Y, Yu Y et al (2017) Gallium-Doped Li 7 La 3 Zr 2 O 12 garnet-type electrolytes with high lithium-ion conductivity. ACS Appl Mater Interfaces 9:1542–1552. https://doi.org/10.1021/acsami.6b13902

Zhu Y, Connell JG, Tepavcevic S et al (2019) Dopant-Dependent Stability of Garnet Solid Electrolyte Interfaces with Lithium Metal. Adv Energy Mater. 9:1803440–1803451. https://doi.org/10.1002/aenm.201803440

Chen X, Wang T, Lu W et al (2018) Synthesis of Ta and Ca doped Li7La3Zr2O12 solid-state electrolyte via simple solution method and its application in suppressing shuttle effect of Li-S battery. J Alloys Comp 744:386–394. https://doi.org/10.1016/j.jallcom.2018.02.134

Li C, Liu Y, He J, Brinkman KS (2017) Ga-substituted Li7La3Zr2O12: an investigation based on grain coarsening in garnet-type lithium ion conductors. J Alloys Comp 695:3744–3752. https://doi.org/10.1016/j.jallcom.2016.11.277

Kumar PJ, Nishimura K, Senna M et al (2016) A novel low-temperature solid-state route for nanostructured cubic garnet Li7La3Zr2O12 and its application to Li-ion battery. RSC Adv 6:62656–62667. https://doi.org/10.1039/c6ra09695f

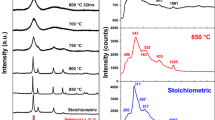

Elisabeth M, Reyer A, Rettenwander D, et al A Raman spectroscopic study on fast ionic conducting variants of Li7La3Zr2O12. In Conference XXV ICORS2016

Pfenninger R, Struzik M, Garbayo I et al (2019) A low ride on processing temperature for fast lithium conduction in garnet solid-state battery films. Nat Energy. 4:475–483. https://doi.org/10.1038/s41560-019-0384-4

Zhang Y, Deng J, Hu D et al (2019) Synergistic regulation of garnet-type Ta-doped Li7La3Zr2O12 solid electrolyte by Li + concentration and Li + transport channel size. Electrochim Acta. 296:823–829. https://doi.org/10.1016/j.electacta.2018.11.136

Beyer H, Meini S, Tsiouvaras N et al (2013) Thermal and electrochemical decomposition of lithium peroxide in non-catalyzed carbon cathodes for Li-air batteries. Phys Chem Chem Phys 15:11025–11037. https://doi.org/10.1039/c3cp51056e

Geng H, Chen K, Yi D et al (2016) Formation mechanism of garnet-like Li7La3Zr2O12 powder prepared by solid state reaction. Rare Metal Mater Eng 45:612–616. https://doi.org/10.1016/s1875-5372(16)30081-9

Abdullaev GK, Mamedov KhS, Buludov NT (1982) Sodium oxide-cadmium oxide-boron oxide system. Zh Neorg Khim 27(11):2948

Zhao M, Russell P, Amoroso J et al (2020) Exploring the links between crystal chemistry, cesium retention, thermochemistry and chemical durability in single-phase andite. J Mater Sci. 55:6401–6416. https://doi.org/10.1007/s10853-020-04447-3

Grote R, Zhao M, Shuller-Nickles L et al (2019) Compositional control of tunnel features in hollandite-based ceramics: structure and stability of (Ba,Cs)1.33(Zn,Ti)8O16. J Mater Sci. 54:1112–1125. https://doi.org/10.1007/s10853-018-2904-1

Acknowledgement

KSB acknowledges support of SRNL LDRD through SRNS TASK ORDER AGREEMENT (TOA) 0000453661 “Solid State Ionics: Advanced Manufacturing.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Co-authors: Changlong Li, Akihiro Ishii.

Rights and permissions

About this article

Cite this article

Li, C., Ishii, A., Roy, L. et al. Solid-state reactive sintering of dense and highly conductive Ta-doped Li7La3Z2O12 using CuO as a sintering aid. J Mater Sci 55, 16470–16481 (2020). https://doi.org/10.1007/s10853-020-05221-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05221-1