Abstract

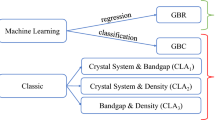

Superalloys are high-temperature materials with outstanding strength and resistance to corrosion. A prior knowledge about its hardness is essential for development of new superalloys for its applications in aeronautics and power industries. Determining the hardness of a material with experiments is usually a destructive process. In this study, using structural, compositional and processing condition parameters as descriptors, machine learning (ML) models are developed to predict Vickers hardness. We employed image processing tools, which extract structural descriptors such as volume fraction, area, perimeter and aspect ratio of the phases in the microstructures. Using the structural features in combination with elemental and processing information as features, a Gaussian process regression model for the prediction of Vickers hardness of superalloys is developed. The model gives an unprecedented accuracy with a minimum root mean square error of 0.15. The descriptors provide insights into structure–property relationships, which are important for designing superalloys with improved Vickers hardness. The proposed method for extracting features from microstructures and combining them with elemental and processing information can be extended to develop ML model for prediction of other mechanical properties of superalloys.

Similar content being viewed by others

Data availability

The data and models will be made available to the readers upon request.

References

Reed RC (2008) The superalloys: fundamentals and applications. Cambridge University Press, Cambridge

Sims CT, Stoloff NS, Hagel WC (1987) Superalloys II. Wiley, New York

Caron P, Khan T (1999) Evolution of Ni-based superalloys for single crystal gas turbine blade applications. Aerosp Sci Technol 3(8):513–523

Sato J, Omori T, Oikawa K, Ohnuma I, Kainuma R, Ishida K (2006) Cobalt-base high-temperature alloys. Science 312(5770):90–91

Zhao S, Xie X, Smith GD, Patel SJ (2003) Microstructural stability and mechanical properties of a new nickel-based superalloy. Mater Sci Eng A 355(1–2):96–105

Leitner A, Maier-Kiener V, Kiener D (2017) Extraction of flow behavior and Hall–Petch parameters using a nanoindentation multiple sharp tip approach. Adv Eng Mater 19(4):1600669

Jiang X, Yin HQ, Zhang C, Zhang RJ, Zhang KQ, Deng ZH, Liu Gq QuXh (2018) An materials informatics approach to Ni-based single crystal superalloys lattice misfit prediction. Comput Mater Sci 143:295–300

Lookman T, Alexander FJ, Rajan K (2016) Information science for materials discovery and design. Springer, Berlin

Zhang Y, Ling C (2018) A strategy to apply machine learning to small datasets in materials science. NPJ Comput Mater 4(1):25

Kalidindi SR, De Graef M (2015) Materials data science: current status and future outlook. Annu Rev Mater Res 45:171–193

Ramprasad R, Batra R, Pilania G, Mannodi-Kanakkithodi A, Kim C (2017) Machine learning in materials informatics: recent applications and prospects. NPJ Comput Mater 3(1):54

Seko A, Hayashi H, Nakayama K, Takahashi A, Tanaka I (2017) Representation of compounds for machine-learning prediction of physical properties. Phys Rev B 95(14):144110

Schütt K, Glawe H, Brockherde F, Sanna A, Müller K, Gross E (2014) How to represent crystal structures for machine learning: towards fast prediction of electronic properties. Phys Rev B 89(20):205118

Rajan AC, Mishra A, Satsangi S, Vaish R, Mizuseki H, Lee KR, Singh AK (2018) Machine-learning-assisted accurate band gap predictions of functionalized mxene. Chem Mater 30(12):4031–4038

Mishra A, Satsangi S, Rajan AC, Mizuseki H, Lee KR, Singh AK (2019) Accelerated data-driven accurate positioning of the band edges of mxenes. J Phys Chem Lett 10(4):780–785

Juneja R, Yumnam G, Satsangi S, Singh AK (2019) Coupling high-throughput property map to machine learning for predicting lattice thermal conductivity. Chem Mater 31(14):5145–5151

Hansen K, Biegler F, Ramakrishnan R, Pronobis W, Lilienfeld A, Muller KR, Tkatchenko A (2015) Machine learning predictions of molecular properties: accurate many-body potentials and nonlocality in chemical space. J Phys Chem Lett 6(12):2326–2331

Li Z, Kermode JR, De Vita A (2015) Molecular dynamics with on-the-fly machine learning of quantum-mechanical forces. Phys Rev Lett 114(9):096405

Ma X, Li Z, Achenie LE, Xin H (2015) Machine-learning-augmented chemisorption model for CO2 electroreduction catalyst screening. J Phys Chem Lett 6(18):3528–3533

Xue D, Balachandran PV, Hogden J, Theiler J, Xue D, Lookman T (2016) Accelerated search for materials with targeted properties by adaptive design. Nat Commun 7:11241

Raccuglia P, Elbert KC, Adler PD, Falk C, Wenny MB, Mollo A, Zeller M, Friedler SA, Schrier J, Norquist AJ (2016) Machine-learning-assisted materials discovery using failed experiments. Nature 533(7601):73

Islam N, Huang W, Zhuang HL (2018) Machine learning for phase selection in multi-principal element alloys. Comput Mater Sci 150:230–235

Kelleher JD, Mac Namee B, D’arcy A (2015) Fundamentals of machine learning for predictive data analytics: algorithms, worked examples, and case studies. MIT Press, Cambridge

Arisoy YM, Özel T (2015) Machine learning based predictive modeling of machining induced microhardness and grain size in Ti–6Al–4V alloy. Mater Manuf Process 30(4):425–433

Donachie MJ, Donachie SJ (2002) Superalloys: a technical guide. ASM International, Cleveland

Acharya T, Ray AK (2005) Image processing: principles and applications. Wiley, New York

Nathal M, Ebert L (1985) The influence of cobalt, tantalum, and tungsten on the microstructure of single crystal nickel-base superalloys. Metall Trans A 16(10):1849–1862

Prokoshkin S, Khmelevskaya IY, Dobatkin S, Trubitsyna I, Tatyanin E, Stolyarov V, Prokofiev E (2005) Alloy composition, deformation temperature, pressure and post-deformation annealing effects in severely deformed Ti-Ni based shape memory alloys. Acta Mater 53(9):2703–2714

Jensen JR, Lulla K (1987) Introductory digital image processing: a remote sensing perspective. Prentice Hall, Upper Saddle River

Müller H, Michoux N, Bandon D, Geissbuhler A (2004) A review of content-based image retrieval systems in medical applicationsclinical benefits and future directions. Int J Med Inform 73(1):1–23

Wejrzanowski T, Spychalski W, Roniatowski K, Kurzydlowski K (2008) Image based analysis of complex microstructures of engineering materials. Int J Appl Math Comput Sci 18(1):33–39

Russ JC (2016) The image processing handbook. CRC Press, Boca Raton

Yue ZQ, Bekking W, Morin I (1995) Application of digital image processing to quantitative study of asphalt concrete microstructure. Transp Res Rec 1492:53–60

Niezgoda SR, Yabansu YC, Kalidindi SR (2011) Understanding and visualizing microstructure and microstructure variance as a stochastic process. Acta Mater 59(16):6387–6400

Steinmetz P, Yabansu YC, Hötzer J, Jainta M, Nestler B, Kalidindi SR (2016) Analytics for microstructure datasets produced by phase-field simulations. Acta Mater 103:192–203

Bradski G, Kaehler A (2008) Learning OpenCV: computer vision with the OpenCV library. O’Reilly Media, Inc., Newton

Buades A, Coll B, Morel JM (2005) A non-local algorithm for image denoising. In: 2005 IEEE computer society conference on computer vision and pattern recognition (CVPR’05), vol 2. IEEE, pp 60–65

Sezgin M, Sankur B (2004) Survey over image thresholding techniques and quantitative performance evaluation. J Electron Imaging 13(1):146–166

Sauvola J, Pietikäinen M (2000) Adaptive document image binarization. Pattern Recognit 33(2):225–236

Canny J (1987) A computational approach to edge detection. In: Fischler MA, Firschein O (eds) Readings in computer vision. Elsevier, Amsterdam, pp 184–203

Cheng K, Cheng X, Hao Q (2018) A review of feature extraction technologies for plankton images. In: Proceedings of the 2018 international conference on information hiding and image processing. ACM, pp 48–56

Quiñonero-Candela J, Rasmussen CE (2005) A unifying view of sparse approximate Gaussian process regression. J Mach Learn Res 6:1939–1959

Rasmussen CE (2003) Gaussian processes in machine learning. In: Bousquet O, von Luxburg U, Rätsch G (eds) Summer school on machine learning. Springer, Berlin, pp 63–71

Friedman J, Hastie T, Tibshirani R (2008) Sparse inverse covariance estimation with the graphical lasso. Biostatistics 9(3):432–441

Pedregosa F, Varoquaux G, Gramfort A, Michel V, Thirion B, Grisel O, Blondel M, Prettenhofer P, Weiss R, Dubourg V et al (2011) Scikit-learn: machine learning in python. J Mach Learn Res 12:2825–2830

Zhang Y, Fu H, Zhou X, Zhang Y, Xie J (2018) Effects of aluminum and molybdenum content on the microstructure and properties of multi-component \(\gamma\)-strengthened cobalt-base superalloys. Mater Sci Eng A 737:265–273

Haralick RM, Shanmugam K et al (1973) Textural features for image classification. IEEE Trans Syst Man Cybern 6:610–621

Mohanaiah P, Sathyanarayana P, GuruKumar L (2013) Image texture feature extraction using glcm approach. Int J Sci Res 3(5):1

Vincent OR, Folorunso O et al (2009) A descriptive algorithm for Sobel image edge detection. In: Proceedings of informing science and IT education conference (InSITE), vol 40, Informing Science Institute California, pp 97–107

Xu H, Liu R, Choudhary A, Chen W (2015) A machine learning-based design representation method for designing heterogeneous microstructures. J Mech Des 137(5):051403

DeCost BL, Holm EA (2015) A computer vision approach for automated analysis and classification of microstructural image data. Comput Mater Sci 110:126–133

Chowdhury A, Kautz E, Yener B, Lewis D (2016) Image driven machine learning methods for microstructure recognition. Comput Mater Sci 123:176–187

Campbell A, Murray P, Yakushina E, Marshall S, Ion W (2018) New methods for automatic quantification of microstructural features using digital image processing. Mater Des 141:395–406

Cui C, Ping D, Gu Y, Harada H (2006) A new co-base superalloy strengthened by \(\gamma\) phase. Mater Trans 47(8):2099–2102

Xu H, Li Y, Brinson C, Chen W (2014) A descriptor-based design methodology for developing heterogeneous microstructural materials system. J Mech Des 136(5):051007

Denton AR, Ashcroft NW (1991) Vegards law. Phys Rev A 43(6):3161

Weast RC, Astle MJ, Beyer WH et al (1988) CRC handbook of chemistry and physics, vol 69. CRC Press, Boca Raton

Tian Y, Gontcharov A, Gauvin R, Lowden P, Brochu M (2016) Effect of heat treatments on microstructure evolution and mechanical properties of blended nickel-based superalloys powders fabricated by laser powder deposition. Mater Sci Eng A 674:646–657

Baler N, Pandey P, Palanisamy D, Makineni SK, Phanikumar G, Chattopadhyay K (2020) On the effect of W addition on microstructural evolution and \(\gamma\) precipitate coarsening in a Co–30Ni–10Al–5Mo–2Ta–2Ti alloy. Materialia 100632

Sudbrack CK, Ziebell TD, Noebe RD, Seidman DN (2008) Effects of a tungsten addition on the morphological evolution, spatial correlations and temporal evolution of a model Ni-Al-Cr superalloy. Acta Mater 56(3):448–463

Mignanelli P, Jones N, Hardy M, Stone H (2014) The influence of Al:Nb ratio on the microstructure and mechanical response of quaternary Ni–Cr–Al–Nb alloys. Mater Sci Eng A 612:179–186

Liu R, Yao MX, Wu X (2004) Influence of carbon content in cobalt-based superalloys on mechanical and wear properties. J Eng Mater Technol 126(2):204–212

Povstugar I, Choi PP, Neumeier S, Bauer A, Zenk CH, Göken M, Raabe D (2014) Elemental partitioning and mechanical properties of Ti-and Ta-containing Co–Al–W-base superalloys studied by atom probe tomography and nanoindentation. Acta Mater 78:78–85

Wangyao P, Jariyasakuntham P, Polsilapa S, Promboobpa A, Pongsugitwat S (2014) Effects of al additions and reheat treatments on microstructures of modified nickel-based superalloy, grade inconel 738, by vacuum arc melting process. In: Advanced Materials Research, vol 1025.Trans Tech Publ, pp 395–402

Milman YV, Luyckx S, Northrop I (1999) Influence of temperature, grain size and cobalt content on the hardness of WC–Co alloys. Int J Refract Met Hard Mater 17(1–3):39–44

Kim H, Chun S, Yao X, Fang Y, Choi J (1997) Gamma prime (\(\gamma\)) precipitating and ageing behaviours in two newly developed nickel-base superalloys. J Mater Sci 32(18):4917–4923

Kawahara K, Kaneno Y, Kakitsuji A, Takasugi T (2009) Microstructural factors affecting hardness property of dual two-phase intermetallic alloys based on Ni3Al–Ni3V pseudo-binary alloy system. Intermetallics 17(11):938–944

Mangen W, Nembach E (1989) The effect of grain size on the yield strength of the \(\gamma\)-hardened superalloy nimonic pe16. Acta Metall 37(5):1451–1463

Yan HY, Vorontsov V, Dye D (2014) Alloying effects in polycrystalline \(\gamma\) strengthened Co–Al–W base alloys. Intermetallics 48:44–53

Acknowledgements

The authors thank Materials Research Centre, Materials Informatics Initiative of IISc (MI3), TUE and Supercomputer Education and Research Centre, Indian Institute of Science, for providing computing facilities. The authors thank DST India-Korea Joint Programme of Cooperation in Science and Technology for support. Sucheta Swetlana acknowledges support from DST through INSPIRE Fellowship (IF180007).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Avinash Dongare.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Swetlana, S., Khatavkar, N. & Singh, A.K. Development of Vickers hardness prediction models via microstructural analysis and machine learning. J Mater Sci 55, 15845–15856 (2020). https://doi.org/10.1007/s10853-020-05153-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05153-w