Abstract

The influence of microstructure on slip irreversibility and crack initiation during high-cycle fatigue of a titanium alloy has been explored. The results indicate that the fatigue strength of lamellar microstructure is higher than the bimodal microstructure. The underlying microstructure and strain partition below the fatigue crack origins have been revealed through electron backscattered diffraction (EBSD). Furthermore, the slip irreversibility and the corresponding accumulative strain to fracture were calculated and compared for these two microstructures. Finally, a critical parameter about (8.1 ± 2) × 10–4·μm−2 for fatigue crack initiation was achieved with the present titanium alloy, which was found to be independent of microstructural types.

Similar content being viewed by others

References

Leyens C, Peters M (2003) Titanium and titanium alloys: fundamentals and applications. John Wiley & Sons, New Jersey

Banerjee D, Williams JC (2013) Perspectives on titanium science and technology. Acta Mater 61(3):844–879

Williams JC (2007) Titanium, 2nd edn. Springer, New York

Jha SK, Szczepanski CJ, John R, Larsen JM (2015) Deformation heterogeneities and their role in life-limiting fatigue failures in a two-phase titanium alloy. Acta Mater 82:378–395

Cowles BA (1996) High cycle fatigue in aircraft gas turbines-an industry perspective. Int J Fracture 80:147–163

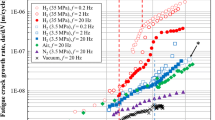

Huang CW, Zhao YQ, Xin SW, Tan CS, Zhou W, Li Q, Zeng WD (2017) Effect of microstructure on high cycle fatigue behavior of Ti–5Al–5Mo–5V–3Cr–1Zr titanium alloy. Int J Fatigue 94:30–40

Pineau A, McDowell DL, Busso EP, Antolovich SD (2016) Failure of metals II: Fatigue. Acta Mater 107:484–507

Suresh S (1998) Fatigue of materials. Cambridge University Press, Cambridge

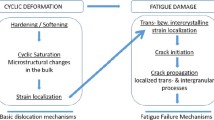

Mughrabi H (2015) Microstructural mechanisms of cyclic deformation, fatigue crack initiation and early crack growth philosophical transactions of the royal society of London a: mathematical. Phys Eng Sci 373(2038):20140132

Sangid MD (2013) The physics of fatigue crack initiation. Int J fatigue 57:58–72

Mughrabi H (2013) Cyclic slip irreversibility and fatigue life: a microstructure-based analysis. Acta Mater 61(4):1197–1203

Mughrabi H (2009) Cyclic slip irreversibilities and the evolution of fatigue damage. Metall Mater Trans B 40(4):431–453

Li L, Zhang ZJ, Zhang P, Li CH, Zhang ZF (2018) Dislocation arrangements within slip bands during fatigue cracking. Mater Charact 145:96–100

Mughrabi H (2013) Microstructural fatigue mechanisms: cyclic slip irreversibility, crack initiation, non-linear elastic damage analysis. Int J Fatigue 57:2–8

Weidner A, Amberger D, Pyczak F, Schöonbauer B, Tschegg SS, Mughrabi H (2010) Fatigue damage in copper polycrystals subjected to ultrahigh-cycle fatigue below the PSB threshold. Int J Fatigue 32(6):872–878

Agius D, Kourousis K, Wallbrink C (2018) A review of the as-built SLM Ti–6Al–4V mechanical properties towards achieving fatigue resistant designs. Metals 8(1):75

Chan KS (2010) Roles of microstructure in fatigue crack initiation. Int J Fatigue 32(9):1428–1447

Tan CS, Li XL, Sun QY, Xiao L, Zhao YQ, Sun J (2015) Effect of a-phase morphology on low-cycle fatigue behavior of TC21 alloy. Int J Fatigue 75(2015):1–9

Tan CS, Sun QY, Xiao L, Zhao YQ, Sun J (2018) Cyclic deformation and microcrack initiation during stress controlled high cycle fatigue of a titanium alloy. Mater Sci Eng A 711C:212–222

Wang ZR (2004) Cyclic deformation response of planar-slip materials and a new criterion for the wavy-to-planar-slip transition. Philos Mag 84(3–5):351–379

Panin AV, Kazachenok MS, Kozelskaya AI, Balokhonov RR, Romanova VA, Perevalova OB, Pochivalov YI (2017) The effect of ultrasonic impact treatment on the deformation behavior of commercially pure titanium under uniaxial tension. Mater Design 117:371–381

Kar SK, Suman S, Shivaprasad S, Chaudhuri A, Bhattachariee A (2014) Processing microstructure-yield strength correlation in a near b Ti alloy Ti–5Al–5Mo–5V–3Cr. Mater Sci Eng A 610:171–180

Tan CS, Sun QY, Zhang GJ, Zhao YQ (2020) Remarkable increase in high-cycle fatigue resistance in a titanium alloy with a fully lamellar microstructure, Int J Fatigue (accepted)

Bosh N, Müller C, Mozaffari-Jovein H (2019) Deformation twinning in cp–Ti and its effect on fatigue cracking. Mater Charact 155:109810

Balasundar I, Raghu T (2017) Experimental and numerical investigation on the tensile properties of a titanium alloy disc with dual microstructure. Mater Sci Eng A 706:104–114

Jones IP, Hutchinson WB (1981) Stress-state dependence of slip in titanium-6Al-4V and other HCP metals. Acta Metall 29(6):951–968

Tan CS, Sun QY, Xiao L, Zhao YQ, Sun J (2017) Slip transmission behavior across α/β interface and strength prediction with a modified rule of mixtures in TC21 titanium alloy. J Alloys Compd 724:112–120

Ankem S, Margolin H (1986) A rationalization of stress-strain behavior of two-ductile phase alloys. Metall Mater Trans A 17:2209–2226

Chan KS, Lee YD (2008) Effects of deformation-induced constraint on high-cycle fatigue in Ti alloys with a duplex microstructure. Metall Mater Trans A 39(7):1665–1675

Li LL, Zhang ZJ, Zhang P, Yang JB, Zhang ZF (2016) Distinct fatigue cracking modes of grain boundaries with coplanar slip systems. Acta Mater 120:120–129

Pan QS, Zhou HF, Lu QH, Gao HJ, Lu L (2017) History-independent cyclic response of nanotwinned metals. Nature 551:214–217

Cao F, Chandran KSR (2017) The role of crack origin size and early stage crack growth on high cycle fatigue of powder metallurgy Ti–6Al–4V alloy. Int J Fatigue 102:48–58

Yang K, Huang Q, Wang Q, Chen Q (2020) Competing crack initiation behaviors of a laser additively manufactured nickel-based superalloy in high and very high cycle fatigue regimes. Int J Fatigue 136:105580

Echlin MLP, Stinville JC, Miller VM, Lenthe WC, Pollock TM (2016) Incipient slip and long range plastic strain localization in microtextured Ti–6Al–4V titanium. Acta Mater 114:164–175

Lukáš P, Klesnil M (1973) Cyclic stress-strain response and fatigue life of metals in low amplitude region. Mater Sci Eng A 11:345–356

Joseph S, Bantanous I, Lindley TC, Dye D (2017) Slip transfer and deformation structures resulting from the low cycle fatigue of near-alpha titanium alloy Ti-6242Si. Int J Plasticity 100:90–103

Ankem S, Margolin H, Greene CA, Neuberger BW, Oberson PG (2006) Mechanical properties of alloys consisting of two ductile phases. Prog Mater Sci 51(5):632–709

Bai YY, Xi YT, Gao KW, Yang HS, Pang XL, Yang XS, Volinsky AA (2019) Brittle coating effects on fatigue cracks behavior in Ti alloys. Int J Fatigue 125:432–439

Guo T, Pang XL, He JY, Zhang ZL, Qiao LJ (2019) Substrate slip steps promote cracking and buckling of thin brittle film. Scripta Mater 163:82–85

Chan KS (2003) A microstructure-based fatigue-crack-initiation model. Metall Mater Trans A 34(1):43–58

Chan KS (2010) Changes in fatigue life mechanism due to soft grains and hard particles. Int J Fatigue 32(3):526–534

Abuzaid W, Sangid MD, Carroll JD, Sehitoglu H, Lambros J (2012) Slip transfer and plastic strain accumulation across grain boundaries in Hastelloy X. J Mech Phy Solids 60(6):1201–1220

Guo Y, Britton TB, Wilkinson AJ (2014) Slip band-grain boundary interactions in commercial-purity titanium. Acta Mater 76:1–12

Acknowledgements

This project was financially supported by the Natural Science Basic Research Program of Shaanxi (Program No. 2020JQ-618), the National Natural Science Foundation of China (51671158, 51621063), 973 Program of China (2014CB644003) and Xi’an University of Technology (101-256081814).

Author information

Authors and Affiliations

Contributions

QY. Sun designed and supervised the project. CS. Tan performed the experiments and data analysis and wrote the paper. GJ. Zhang provided valuable comments and suggestions for this paper. YQ. Zhao provided the original materials and valuable comments as well as suggestions for the work. All authors contributed to discussions of the results.

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare no conflicts of interest.

Data availability statement

All data generated or analyzed during this study are included in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tan, C., Sun, Q., Zhang, G. et al. High-cycle fatigue of a titanium alloy: the role of microstructure in slip irreversibility and crack initiation. J Mater Sci 55, 12476–12487 (2020). https://doi.org/10.1007/s10853-020-04845-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04845-7