Abstract

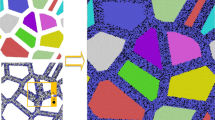

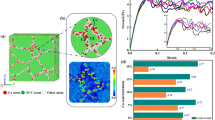

Grain boundary (GB) migration and grain growth in nanocrystalline metals are major obstructions to exploit these materials to their fullest potential, thus limiting their utility as advanced structural materials. Here, we investigate the effect of Zr segregation to a Ni GB on migration and subsequent strengthening during shear deformation and high-temperature bending creep. Specifically, using molecular dynamics simulation, we simulate deformation of a Ni bicrystal specimen having a symmetric ∑5 grain boundary with and without segregated Zr. It is found that GB segregation up to 0.4 at.% pins the CSL boundary resulting in increased shear strength. Similar behavior is also observed in the case of bending creep deformation where the creep resistance increases only up to 0.4 at.%. This study indicates that larger amounts of GB segregation cause destabilization of the local atomic structure and consequently affect the GB stiffness. Moreover, we investigate the effect of Zr segregation on the interaction between the GB and a dislocation. We find that the preexisting dislocation is absorbed in the GB region for both clean and segregated specimens; however, the absorption path of the dislocation is different due to the change in GB stiffness caused by the Zr segregation.

Similar content being viewed by others

References

Gleiter H (1991) Nanocrystalline materials. Advanced Structural and Functional Materials. Springer, Berlin, pp 1–37

Valiev R (2002) Materials science: nanomaterial advantage. Nature 419(6910):887–889

Sasaki TT, Mukai T, Hono K (2007) A high-strength bulk nanocrystalline Al–Fe alloy processed by mechanical alloying and spark plasma sintering. Scr Mater 57(3):189–192

Cai XC, Song J, Yang TT, Peng QM, Huang JY, Shen TD (2018) A bulk nanocrystalline Mg–Ti alloy with high thermal stability and strength. Mater Lett 210:121–123

Krasnowski M, Kulik T (2010) Nanocrystalline Al–Fe intermetallics–light weight alloys with high hardness. Intermetallics 18(1):47–50

Esquivel J, Murdoch HA, Darling KA, Gupta RK (2018) Excellent corrosion resistance and hardness in Al alloys by extended solid solubility and nanocrystalline structure. Mater Res Lett 6(1):79–83

Driver JH (2004) Stability of nanostructured metals and alloys. Scr Mater 51(8):819–823

Ma E (2003) Nanocrystalline materials: controlling plastic instability. Nat Mater 2(1):7–8

Koch CC (2007) Structural nanocrystalline materials: an overview. J Mater Sci 42(5):1403–1414. https://doi.org/10.1007/s10853-006-0609-3

Donaldson OK, Hattar K, Kaub T, Thompson GB, Trelewicz JR (2018) Solute stabilization of nanocrystalline tungsten against abnormal grain growth. J Mater Res 33(1):68–80

Jiao ZB, Schuh CA (2018) Nanocrystalline Ag-W alloys lose stability upon solute desegregation from grain boundaries. Acta Mater 161:194–206

Buban JP, Matsunaga K, Chen J, Shibata N, Ching WY, Yamamoto T, Ikuhara Y (2006) Grain boundary strengthening in alumina by rare earth impurities. Science 311(5758):212–215

Nie JF, Zhu YM, Liu JZ, Fang XY (2013) Periodic segregation of solute atoms in fully coherent twin boundaries. Science 340(6135):957–960

Zhang Y, Tucker GJ, Trelewicz JR (2017) Stress-assisted grain growth in nanocrystalline metals: grain boundary mediated mechanisms and stabilization through alloying. Acta Mater 131:39–47

Kalidindi AR, Schuh CA (2017) Stability criteria for nanocrystalline alloys. Acta Mater 132:128–137

Borovikov V, Mendelev MI, King AH (2017) Effects of solutes on dislocation nucleation from grain boundaries. Int J Plast 90:146–155

Darling KA, Tschopp MA, VanLeeuwen BK, Atwater MA, Liu ZK (2014) Mitigating grain growth in binary nanocrystalline alloys through solute selection based on thermodynamic stability maps. Comput Mater Sci 84:255–266

Yamaguchi M, Shiga M, Kaburaki H (2005) Grain boundary decohesion by impurity segregation in a nickel-sulfur system. Science 307(5708):393–397

Luo J, Cheng H, Asl KM, Kiely CJ, Harmer MP (2011) The role of a bilayer interfacial phase on liquid metal embrittlement. Science 333(6050):1730–1733

Dillon SJ, Harmer MP, Luo J (2009) Grain boundary complexions in ceramics and metals: an overview. JOM 61(12):38–44

Luo J (2009) Grain boundary complexions: the interplay of premelting, prewetting, and multilayer adsorption. Appl Phys Lett 95(7):071911

Dillon SJ, Tang M, Carter WC, Harmer MP (2007) Complexion: a new concept for kinetic engineering in materials science. Acta Mater 55(18):6208–6218

Feng B, Yokoi T, Kumamoto A, Yoshiya M, Ikuhara Y, Shibata N (2016) Atomically ordered solute segregation behavior in an oxide grain boundary. Nat Commun 7:11079

Rupert TJ, Gianola DS, Gan Y, Hemker KJ (2009) Experimental observations of stress-driven grain boundary migration. Science 326(5960):1686–1690

Gorkaya T, Molodov DA, Gottstein G (2009) Stress-driven migration of symmetrical 〈1 0 0〉 tilt grain boundaries in Al bicrystals. Acta Mater 57(18):5396–5405

Farkas D, Frøseth A, Van Swygenhoven H (2006) Grain boundary migration during room temperature deformation of nanocrystalline Ni. Scr Mater 55(8):695–698

Ovid’Ko IA, Sheinerman AG, Aifantis EC (2008) Stress-driven migration of grain boundaries and fracture processes in nanocrystalline ceramics and metals. Acta Mater 56(12):2718–2727

Pal S, Meraj M, Deng C (2017) Effect of Zr addition on creep properties of ultra-fine grained nanocrystalline Ni studied by molecular dynamics simulations. Comput Mater Sci 126:382–392

Zhao YS, Zhang J, Luo YS, Zhang B, Sha G, Li LF, Tang DZ, Feng Q (2019) Improvement of grain boundary tolerance by minor additions of Hf and B in a second generation single crystal superalloy. Acta Mater 176:109–122

Reddy KV, Pal S (2018) Effect of grain boundary complexions on the deformation behavior of Ni bicrystal during bending creep. J Mol Model 24(4):87

Reddy KV, Pal S (2018) Influence of Grain Boundary Complexion on Deformation Mechanism of High Temperature Bending Creep Process of Cu Bicrystal. Trans Indian Inst Met 71(7):1721–1734

Reddy KV, Pal S (2018) Influence of dislocations, twins, and stacking faults on the fracture behavior of nanocrystalline Ni nanowire under constant bending load: a molecular dynamics study. J Mol Model 24(10):277

Kirchheim R (2002) Grain coarsening inhibited by solute segregation. Acta Mater 50(2):413–419

Liu F, Kirchheim R (2004) Nano-scale grain growth inhibited by reducing grain boundary energy through solute segregation. J Cryst Growth 264(1–3):385–391

Mathaudhu SN, Boyce BL (2015) Thermal stability: the next frontier for nanocrystalline materials. JOM 67(12):2785–2787

Abdeljawad F, Foiles SM (2016) Interface-driven phenomena in solids: thermodynamics, kinetics and chemistry. JOM 68(6):1594–1595

Kapoor M, Kaub T, Darling KA, Boyce BL, Thompson GB (2017) An atom probe study on Nb solute partitioning and nanocrystalline grain stabilization in mechanically alloyed Cu-Nb. Acta Mater 126:564–575

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117(1):1–19

Xie X, Mishin Y (2002) Monte Carlo simulation of grain boundary segregation and decohesion in NiAl. Acta Mater 50(17):4303–4313

Hirel P (2015) Atomsk: a tool for manipulating and converting atomic data files. Comput Phys Commun 197:212–219

Evans DJ, Holian BL (1985) The nose–hoover thermostat. J Chem Phys 83(8):4069–4074

Timoshenko SP, Gere JM (1972) Mechanics of Materials. VanNordstrand Reinhold Company, New York

Wilson SR, Mendelev MI (2015) Anisotropy of the solid–liquid interface properties of the Ni–Zr B33 phase from molecular dynamics simulation. Philos Mag 95(2):224–241

Stukowski A (2009) Visualization and analysis of atomistic simulation data with OVITO–the open visualization tool. Modell Simul Mater Sci Eng 18(1):015012

Kelchner CL, Plimpton SJ, Hamilton JC (1998) Dislocation nucleation and defect structure during surface indentation. Phys Rev B 58(17):11085

Honeycutt JD, Andersen HC (1987) Molecular dynamics study of melting and freezing of small Lennard–Jones clusters. J Phys Chem 91(19):4950–4963

Stukowski A (2012) Structure identification methods for atomistic simulations of crystalline materials. Modell Simul Mater Sci Eng 20(4):045021

Stukowski A (2016) Visualization and analysis strategies for atomistic simulations. In: Multiscale materials modeling for nanomechanics. Springer, Cham, pp 317–336

Stukowski A, Bulatov VV, Arsenlis A (2012) Automated identification and indexing of dislocations in crystal interfaces. Modell Simul Mater Sci Eng 20(8):085007

Schäfer J, Albe K (2012) Influence of solutes on the competition between mesoscopic grain boundary sliding and coupled grain boundary motion. Scr Mater 66(5):315–317

Xiao C, Mirshams RA, Whang SH, Yin WM (2001) Tensile behavior and fracture in nickel and carbon doped nanocrystalline nickel. Mater Sci Eng A 301(1):35–43

Rajabzadeh A, Mompiou F, Legros M, Combe N (2013) Elementary mechanisms of shear-coupled grain boundary migration. Phys Rev Lett 110(26):265507

Cahn JW, Mishin Y, Suzuki A (2006) Coupling grain boundary motion to shear deformation. Acta Mater 54(19):4953–4975

Khater HA, Serra A, Pond RC, Hirth JP (2012) The disconnection mechanism of coupled migration and shear at grain boundaries. Acta Mater 60(5):2007–2020

Zhu Q, Cao G, Wang J, Deng C, Li J, Zhang Z, Mao SX (2019) In situ atomistic observation of disconnection-mediated grain boundary migration. Nat Commun 10(1):156

Huber L, Hadian R, Grabowski B, Neugebauer J (2018) A machine learning approach to model solute grain boundary segregation. NPJ Comput Mater 4(1):1–8

O’Brien CJ, Foiles SM (2016) Exploration of the mechanisms of temperature-dependent grain boundary mobility: search for the common origin of ultrafast grain boundary motion. J Mater Sci 51(14):6607–6623. https://doi.org/10.1007/s10853-016-9944-1

Reddy KV, Meraj M, Pal S (2017) Mechanistic study of bending creep behavior of bicrystal nanobeam. Comput Mater Sci 136:36–43

Bobylev SV, Gutkin MY, Ovid’ko IA (2004) Transformations of grain boundaries in deformed nanocrystalline materials. Acta Mater 52(13):3793–3805

Acknowledgement

The authors would like to acknowledge the Computer Centre of National Institute of Technology, Rourkela, for giving access to the high-performance computing facility (HPCF), which has been necessary for performing this molecular dynamics research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pal, S., Vijay Reddy, K. & Spearot, D.E. Zr segregation in Ni–Zr alloy: implication on deformation mechanism during shear loading and bending creep. J Mater Sci 55, 6172–6186 (2020). https://doi.org/10.1007/s10853-020-04411-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04411-1