Abstract

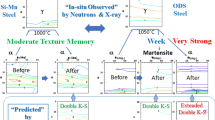

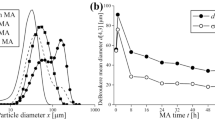

Texture and microstructure evolution in a ferritic/martensitic 9wt%Cr oxide dispersion strengthened (ODS) steels during heat treatment after cold tube forming are studied via in situ synchrotron X-ray diffraction analysis. The initial textures of cold-formed ODS steel tubes present a well-known α-fiber (< 110 >//RD). During high-temperature heat treatment, this initial sharp fiber texture, inherited from cold forming, is transformed by the phase transition to austenite into a weak < 111 > fiber. During cooling, a texture memory effect is observed with a strong dependency of the fiber intensity on the cooling rate. After quenching into martensite, the < 110 > fiber becomes weaker than in the initial ferrite. By contrast, after slow cooling into ferrite, the < 110 > fiber develops and becomes stronger than initially. For many materials, texture memory effect can be explained by a variant selection phenomenon. Accordingly, experimental results are compared to the double Kurdjumov–Sachs (DKS) model. During heating, a limited texture heritage is exhibited with essentially a Kurdjumov–Sachs (K–S) relation between the two phases. During cooling the DKS relation correctly predicts the texture fiber components. However, the strong enhancement of texture during slow cooling remains not completely explained. A Williamson–Hall analysis of the size and strain evolutions during the heating cycle showed a remarkable stability of the crystallites size which is the same in ferrite, austenite and martensite.

Similar content being viewed by others

References

Yvon P, Carre F (2009) Structural materials challenges for advanced reactor systems. J Nucl Mater 385:217–222

Toualbi L, Cayron C, Olier P, Malaplate J, Praud M, Mathon MH, Bossu D (2012) Assessment of a new fabrication route for Fe–9Cr–1W ODS cladding tubes. J Nucl Mater 428:47–53

Vakhitova E, Sornin D, Barcelo F, François M (2017) Texture evolution in oxide dispersion strengthened (ODS) steel tubes during pilgering process. J Nucl Mater 494:20–28

Wenk H-R, Bortolotti M, Barton N, Oliver E, Brown D (2007) Dauphiné twinning and texture memory in polycrystalline quartz. Phys Chem Miner 34:599–607

Bhattacharyya D, Viswanathan GB, Vogel SC, Williams DJ, Venkatesh V, Fraser HL (2006) A study of the mechanism of α to β phase transformation by tracking texture evolution with temperature in Ti–6Al–4V using neutron diffraction. Scr Mater 54:231–236

Romero J, Preuss M, Quinta da Fonseca J (2009) Texture memory and variant selection during phase transformation of a zirconium alloy. Acta Mater 57:5501–5511

Tomida T, Wakita M, Yasuyama M, Sugaya S, Tomota Y, Vogel SC (2013) Memory effects of transformation textures in steel and its prediction by the double Kurdjumov–Sachs relation. Acta Mater 61:2828–2839

Tomida T, Wakita M, Vogel S, Sandim HRZ (2015) Quantitative prediction of transformation texture in steel by Double Kurdjumov-Sachs relation. In: IOP conference series: materials science and engineering, vol 82, p 012060

Tanaka Y, Tomida T, Mohles V (2015) Quantitative prediction of deformed austenite and transformed ferrite texture in hot-rolled steel sheet. In: IOP Conference series: materials science and engineering, vol 82, p 012057

Wenk H-R, Huensche I, Kestens L (2007) In-situ observation of texture changes during phase transformations in ultra-low-carbon steel. Metall Mater Trans A 38:261–267

Lischewski I, Gottstein G (2011) Nucleation and variant selection during the α–γ–α phase transformation in microalloyed steel. Acta Mater 59:1530–1541

Tomida T, Wakita M, Yoshida N, Imai N (2008) Quantitative prediction of transformation texture in hot-rolled steel sheets by multiple KS relation. In: Rollett AD (ed) Materials processing and texture. Ceramic transactions series, Chap. 36, pp 325–332. https://doi.org/10.1002/9780470444191

Vakhitova E (2018) Microstructural and micromechanical study of ODS steel tubes transformed by cold pilgering process, PhD thesis. University of Technology of Troyes, France

Ashiotis G, Deschildre A, Nawaz Z, Wright JP, Karkoulis D, Picca FE, Kieffer J (2015) The fast azimuthal integration Python library: pyFAI. J Appl Crystallogr 48:510–519

Knudsen EB, Sorensen HO, Wright JP, Goret G, Kieffer J (2013) FabIO: easy access to two-dimensional X-ray detector images in Python. J Appl Crystallogr 46:537–539

He BB, Preckwinkel U, Smith KL (2000) Fundamentals of two-dimensional X-ray diffraction. Adv X-Ray Anal 43:273–280

Ischia G, Wenk H-R, Lutterotti L, Berberich F (2005) Quantitative Rietveld texture analysis of zirconium from single synchrotron diffraction images. J Appl Crystallogr 38:377–380

Bachmann F, Hielscher R, Schaeben H (2010) Texture analysis with MTEX—free and open source software toolbox. Solid State Phenom 160:63–68

Bunge HJ (1982) Texture analysis in materials science. Butterworth-Heinemann, London, 614 p

Dahms M, Bunge HJ (1989) The iterative series-expansion method for quantitative texture analysis. I. General outline. J Appl Crystallogr 22:439–447

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall 1:22–31

Ribis J, Bordas E, Trocellier P, Serruys Y, de Carlan Y, Legris A (2015) Comparison of the neutron and ion irradiation response of nano-oxides in oxide dispersion strengthened materials. J Mater Res 30:2210–2221

Loyer-Prost M, Merot JS, Ribis J, Le Bouar Y, Chaffron L, Legendre F (2016) High resolution Transmission Electron Microscopy characterization of a milled oxide dispersion strengthened steel powder. J Nucl Mater 479:76–84

Hatzoglou C, Radiguet B, Vurpillot F, Pareige P (2018) A chemical composition correction model for nanoclusters observed by APT—application to ODS steel nanoparticles. J Nucl Mater 505:240–248

Béchade JL, Menut D, Lescoat ML, Sitaud B, Schlutig S, Solari PL, Llorens I, Hermange H, de Carlan Y, Ribis J, Toualbi L (2012) Application of synchrotron radiation to analyze the precipitation in ODS materials before irradiation in Fe–9%Cr single grain of powder and consolidated Fe–18%Cr. J Nucl Mater 428:183–191

Tomida T (2018) Variant selection mechanism by elastic anisotropy and double K–S relation for transformation texture in steel; difference between martensite and ferrite. Acta Mater 146:25–41

Brachet J-C (1994) Décomposition isotherme et anisotherme de l’austenite en ferrite dans des aciers de base 9Cr1Mo: aspects cinétiques et microstructuraux. Journal de Physique IV Colloque 4(C3):83–91

Fournier B (2007) Fatigue-fluage des aciers martensitiques à 9-12%Cr : comportement et endommagement. Mécanique [physics.medph]. École Nationale Supérieure des Mines de Paris, Paris. https://tel.archives-ouvertes.fr/tel-00203753/

Dadé M, Malaplate J, Garnier J, De Geuser F, Barcelo F, Wident P, Deschamps A (2017) Influence of microstructural parameters on the mechanical properties of oxide dispersion strengthened Fe–14Cr steels. Acta Mater 127:165–177

Hutchinson B, Kestens LAI (2008) Origins of texture memory in steels. In: Rollett AD (ed) Applications of texture analysis. Ceramic transactions series, Chap. 30. The American Ceramic Society, pp 281–290. https://doi.org/10.1002/9780470444214

Yamamoto M, Ukai S, Hayashi S, Kaito T, Ohtsuka S (2011) Reverse phase transformation from α to γ in 9Cr-ODS ferritic steels. J Nucl Mater 417:237–240

Yamamoto M, Ukai S, Hayashi S, Kaito T, Ohtsuka S (2010) Formation of residual ferrite in 9Cr-ODS ferritic steels. Mater Sci Eng A 527:4418–4423

Hutchinson WB, Ryde L, Bate PS (2005) Transformation textures in steels. Mater Sci Forum 495–497:1141–1150

Acknowledgements

The authors warmly thank ESRF team for the technical help in the development of the furnace and scientific support in data post-treatment (IN1018).

Funding

This work has been supported by CEA, EDF and AREVA in the framework of the MACNA project agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vakhitova, E., Sornin, D., Wright, J. et al. In situ synchrotron analysis of phase transformation at high temperatures in ODS ferritic steel. J Mater Sci 55, 5600–5612 (2020). https://doi.org/10.1007/s10853-020-04360-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04360-9